This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your sewing machine just choked on that third layer of canvas, leaving you with a bird’s nest of broken thread and a deadline that won’t wait. Regular thread snaps under pressure because it wasn’t built for the job—heavy-duty projects demand thread that can handle strain, friction, and movement without failing.

The difference between amateur work and professional results often comes down to matching the right thread to your fabric’s demands. Whether you’re stitching leather upholstery, reinforcing camping gear, or tackling industrial applications, understanding thread strength, weight, and compatibility with your needle size transforms frustrating failures into seams that last for years.

Table Of Contents

Key Takeaways

- Match your thread weight to needle size using the 80/40 rule—40-weight thread needs an 80/12 needle, and heavy-duty threads (Tex 70-135) require needles between 100/16 and 125/20 to prevent breakage and skipped stitches.

- Bonded polyester thread retains over 67% of its strength after a year in direct sunlight and resists moisture, making it your best choice for outdoor gear, marine projects, and awnings that face UV exposure and weather.

- Loosen your upper tension to 2.0-3.5 when sewing with heavy-duty thread, and pair it with regular thread in the bobbin to reduce bulk while maintaining strong seams and smoother machine performance.

- Kevlar thread delivers five times the strength-to-weight ratio of steel and maintains 90% of its power at 600°F, making it the go-to choice for industrial applications, fire gear, and projects where thread failure isn’t an option.

Heavy Duty Thread Types

Not all heavy duty threads are created equal, and picking the right one makes the difference between a project that holds strong and one that fails under pressure.

Choosing the right heavy duty thread is the difference between a project that endures and one that falls apart under pressure

Each thread type brings its own strengths to the table, whether you’re working with outdoor gear, leather, or industrial fabrics.

Let’s break down the main players so you can match the thread to your project’s demands.

Heavy-duty Thread Properties and Uses

Heavy-duty thread is the backbone of projects that demand outstanding strength and durability. When you’re working with thick fabrics or load-bearing applications, you need thread that won’t snap under pressure. Thread tensile strength ranges from 2,500 to 6,000 centinewtons for polyester, giving you the confidence to tackle upholstery, leatherwork, and outdoor gear without worrying about seam failure. A key factor is understanding thread strength properties to assure longevity.

Here’s what makes these threads work so hard for you:

- Breaking elongation between 10-30% lets your seams flex without failing

- Abrasion resistance stands up to friction and repeated movement

- Thread diameter (Tex 70 or higher) creates visible topstitching while boosting seam longevity

- Continuous filament construction delivers consistent strength throughout your entire project

You’ll find these heavy-duty thread properties essential for automotive upholstery, camping equipment, and industrial applications where regular thread simply can’t handle the job.

PTFE and EPTFE Threads for Chemical Resistance

For extreme chemical environments, PTFE and ePTFE threads are your go-to choice. These specialized threads resist nearly all acids, bases, and solvents across the entire pH range from 1 to 14, making them perfect for chemical processing and industrial filtration work.

You’ll get thermal stability from −260°C to 260°C, plus mechanical performance that outshines standard polyester. GORE ePTFE threads deliver tensile strengths exceeding 6 grams per denier while maintaining zero water absorption.

They’re pricier, but their peerless durability and chemical inertness justify the investment for demanding applications. The global market expands due to high-performance needs.

Polyester Thread for UV Resistance and Water Repellency

When you’re sewing gear that’ll face sun and rain, polyester thread delivers the durability you need. It keeps over 67% of its tensile strength after 12 months of sunlight exposure, far outperforming nylon’s UV degradation resistance. For marine sewing and outdoor projects, this means your seams won’t fail when it matters most.

Here’s what makes polyester thread your best choice:

- UV resistance maintains strength for 3–5 years in direct sun

- Water repellency prevents moisture absorption and mildew growth

- Strength retention stays above 85% after extended weathering

- Marine applications handle saltwater and humidity without breaking down

- Environmental impact lessens with recycled options reducing carbon footprint by 30%

You’ll find #138 bonded polyester keeps boat covers and awnings secure, even under harsh conditions.

Nylon Thread for Flexibility and Strength

While polyester handles UV exposure well, nylon thread wins when you need flexibility paired with raw power. Bonded nylon stretches around 26% before breaking—that’s nearly ten times more than polyester—making seam recovery a breeze in projects that bend and flex. You’ll get 15 lbs of tensile strength with size 92 thread, perfect for upholstery and leather work where movement matters.

Here’s why nylon elasticity makes it your go-to choice:

- Withstands temperatures up to 285°F before softening begins

- Resists mildew and organic solvents in damp conditions

- Accommodates heavy duty sewing thread needs in automotive seats

- Maintains strength through repeated stress cycles

- Market trends show 6.5% annual growth in industrial applications

Temperature resistance stays solid below 300°F, keeping your seams secure.

Cotton Thread for Natural Strength and Grip

When you’re stitching natural fabrics like linen or denim, cotton thread delivers a superior grip that synthetic options can’t replicate. Its fiber structure locks onto cotton and natural textiles, reducing seam slippage and keeping your heavy-duty sewing secure. You’ll find cotton thread possesses around 100 MPa tensile strength—solid for quilting, upholstery, and workwear where natural fabric grip matters most.

| Performance Factor | Cotton Thread Capability |

|---|---|

| Cotton Tensile Strength | 100 MPa at 4.5% strain |

| Abrasion Resistance | 2,500 Martindale cycles |

| Environmental Impact | 1.15-6.07 kg CO2eq/kg |

| Heavy Applications | Quilting, upholstery, denim |

Cotton’s moderate abrasion resistance works well indoors, though it produces more lint than polyester under friction.

Choosing Right Needle Size

Choosing the right needle size is like matching your tool to the job—get it wrong, and you’ll end up with broken threads, skipped stitches, or damaged fabric. The needle has to handle the thickness of your thread while still piercing cleanly through heavy materials.

Let’s break down what you need to know about pairing needles with heavy-duty threads so your projects hold up under real-world stress.

Needle Size Requirements for Heavy-duty Threads

Think of needle diameter as the doorway your thread needs to pass through—too narrow, and you’ll get jams and breaks. For heavy-duty threads ranging from Tex 70 to Tex 210, you’ll need needle sizes between 100/16 and 180/24. Here’s what works best:

- Tex 70 threads pair with 100/16 to 110/18 needles for canvas and denim

- Tex 90 threads need 110/18 to 125/20 for outdoor fabrics

- Tex 135 threads require 125/20 to 160/23 for leather projects

- Home machines max out at 110/18, limiting thread thickness

- Industrial machines handle sizes up to 230/26 for multi-layer work

Match fabric type with thread weight for best stitch quality.

Thread Weight and Needle Size Relationship

Here’s the thing about thread weight and needle size—they work like partners. The 80/40 rule breaks it down: pair 40-weight thread with an 80/12 needle. Your thread diameter should fill about 40% of the needle’s groove, creating that sweet spot for stitch quality.

When you mismatch these, you’ll face shredding, tension problems, and skipped stitches. Heavy duty sewing demands precision—using a smaller needle with thick thread increases breakage rates by 37%. Match your thread thickness to needle size for machine compatibility and reliable results.

Selecting Needles for Heavy-duty Sewing Machines

Your heavy-duty machine performs best when you match industrial-grade needles to your thread specs. Size standards matter—for Tex 70–135 threads, stick with 100/16 to 125/20 needles. Choosing the right needle size prevents skipped stitches and guarantees consistent results.

Here’s your needle size guide for serious projects:

- Needle point geometry: Use wedge points for leather, sharp points for canvas

- Material coatings: Titanium reduces breakage by 30%

- Fabric compatibility: 110/18 needles handle denim and upholstery

- Durability metrics: Chromium coatings cut friction by 25%

- Thread weight and needle size: Pair size 69 thread with 110/18 needles

Heavy Duty Thread Applications

Heavy duty thread isn’t just for show—it’s built to handle the toughest jobs you can throw at it. When you’re working on gear that needs to stand up to weather, wear, and real-world abuse, the right thread makes all the difference.

Let’s look at where these workhorse threads shine brightest.

Using Heavy-duty Thread for Outdoor Equipment

Your outdoor equipment faces relentless sun, rain, and mechanical stress—so your thread choice can make or break its durability.

For marine upholstery and boat covers, UV bonded polyester maintains seam strength while resisting fading. PTFE threads offer outstanding weatherproof thread tech, staying strong from -268°C to 327°C without rotting or losing color.

Tent seam strength benefits from nylon’s 26% stretch and 15-pound tensile capacity, though UV-treated varieties work best for prolonged sun exposure.

When you’re working on awnings or tarps, awning thread types like treated polyester help your outdoor projects withstand nature’s toughest tests.

Thread Uses for Camping Gear, Luggage, and Sports Equipment

Luggage seams failing mid-trip? Your camping gear, luggage, and sports equipment demand thread that won’t quit when things get rough.

Heavy duty sewing thread keeps your gear battle-ready through demanding conditions:

- Camping gear like tents and backpacks need UV-resistant polyester thread (V-69 weight) to handle moisture and sunlight

- Luggage threads such as ballistic nylon withstand 1,000+ zipper cycles and 25kg suspension loads

- Sports equipment benefits from flexible nylon thread that resists repetitive stress

- Waterproofing threads with bonded polyester construction prevent seam failure in outdoor equipment exposed to rain

Proper seam strength starts with matching thread type to your project’s real-world abuse.

Sewing With Heavy Duty Thread

Working with heavy duty thread isn’t quite the same as sewing with your standard all-purpose thread. Your machine needs a few adjustments to handle the extra thickness and strength without causing frustration or broken stitches.

Let’s walk through the key changes you’ll need to make for smooth, professional results.

Adjusting Tension for Heavy-duty Thread

When should you adjust thread tension for heavy duty sewing? Start by loosening your upper tension to around 2.0–3.5, especially when working with thicker thread diameter. Test stitch balance on scrap fabric layers, watching for loops underneath. If puckering happens, drop your machine tension even more.

For multiple fabric layers, you’ll need tension between 4–6. Bobbin tension stays around 18–22 grams for most heavy duty sewing machines. Proper tension troubleshooting prevents breakage and ensures professional-looking seams.

Using Regular Thread in The Bobbin for Simplicity

You’ll find that pairing regular thread in your bobbin with heavy-duty top thread actually makes your life easier. This setup delivers seam bulk reduction while improving machine performance and stitch quality.

You’ll get economic benefits too—regular thread costs less and winds more on each bobbin.

Just remember the application limits: reversible projects need matching thread on both sides for consistent strength and appearance.

Changing Stitch Length and Width for Heavy-duty Thread

Set your stitch length between 3.5 and 4.0 mm when working with heavy-duty thread—this reduces seam perforation by roughly 25% compared to standard settings. For zigzag work, you’ll want widths around 5 to 6 mm to improve tension distribution across thick layers.

These sewing machine adjustments help fabric feed stay smooth and prevent puckering. Always test your seam calibration on scraps first, adjusting thread tension as needed.

These sewing techniques make heavy-duty sewing far more reliable and give you professional-grade results.

Top 6 Heavy Duty Threads

You’ve got the techniques down, now it’s time to pick the right thread for your project. The market offers dozens of options, but not all threads can handle what you’re throwing at them.

Here are six proven performers that won’t let you down when the stitching gets tough.

1. Gutermann Black Sew All Thread

You deserve thread that won’t quit halfway through a project, and Gutermann Black Sew All Thread delivers. Built with Micro Core Tech, this 100% polyester thread boasts tensile strength that tackles everything from denim repairs to upholstery work without breaking.

It’s passed rigorous colorfastness tests, so your black stitches stay dark through countless washes and UV exposure. The sewing performance is smooth—no lint jamming your machine, no frustrating snags.

You’ll find spool sizes ranging from 100 meters for quick fixes to 1,000 meters for larger jobs. Gutermann threads have earned their reputation in both home studios and industrial settings. When you need quality thread for heavy-duty sewing, this workhorse won’t let you down.

Best For: Sewers who need reliable, strong thread for both everyday repairs and heavy-duty projects like quilting, upholstery, or denim work.

- Micro Core Technology gives you 20-25% stronger thread than regular polyester, so seams hold up under stress without breaking.

- Stays colorfast through 50 washes and resists UV fading, keeping your black stitches looking sharp over time.

- Works smoothly in high-speed machines up to 9,000 rpm with minimal lint, reducing thread breaks and machine jams.

- Costs more than budget thread options, which adds up if you’re buying multiple spools.

- Some users report occasional breakage, so it might not work perfectly with every machine or tension setting.

- The 1,000-meter spool may be overkill for casual sewers who only tackle small projects occasionally.

2. Dual Duty General Purpose Thread

Corespun construction gives Dual Duty General Purpose Thread its backbone—a high-tenacity polyester core wrapped in a cotton wrap that protects against needle heat during fast sewing. This medium-weight thread (Tex 30) works across your fabric collection, from knits to wovens, without skipping stitches.

You’ll get excellent seam appearance and durability that lasts through repeated washings. Needle compatibility is straightforward—size 12 suits most jobs.

EcoVerde options use recycled polyester and Better Cotton Initiative cotton, meeting Global Recycled Standard certification if sustainability matters to your heavy-duty sewing projects.

Best For: Sewers who need a reliable all-purpose thread that handles everything from delicate fabrics to heavy denim without constant adjustments or breakage.

- Corespun construction with polyester core and cotton wrap prevents needle heat damage during high-speed sewing while maintaining strong, smooth seams across all fabric types.

- Medium weight (Tex 30) works on both vintage and modern machines with consistent tension and minimal thread breaks, skipped stitches, or jams.

- EcoVerde options offer recycled polyester with Global Recycled Standard certification for environmentally conscious sewers without sacrificing durability or performance.

- Some users find standard spool sizes (250-400 yards) run out too quickly for large projects, especially in popular colors like black and white.

- Thread weight may feel thin for sewers accustomed to heavier threads, though the polyester core compensates with strength.

- Made in Mexico, which may not appeal to those specifically seeking American-made sewing supplies.

3. Coats Outdoor Living 200yd Buff Thread

You need strength that won’t quit when sewing outdoor projects, and Coats Outdoor Living 200yd Buff thread delivers. This bonded polyester thread (Tex 90) withstands UV rays and weather without fading, making it perfect for awnings, patio cushions, and marine canvas.

It works smoothly with size 16-18 needles on your machine and pairs well with Sunbrella fabric. Outdoor durability tests show it withstands 500+ hours of sun exposure while maintaining color matching across your project.

At around $6 per spool, you’re getting solid value for money on heavy-duty sewing that lasts.

Best For: Anyone sewing outdoor furniture covers, marine canvas, awnings, or patio cushions who needs UV-resistant thread that won’t fade or break down in the elements.

- Withstands 500 hours of sun exposure without fading, plus resists moisture and mildew for true outdoor durability

- Works smoothly with standard heavy-duty needles (size 16-18) and pairs well with tough fabrics like Sunbrella and canvas

- Strong tensile strength (6.5 pounds-force) handles thick seams and high-stress outdoor projects without snapping

- Limited to one color per spool, so you’ll need to buy multiple if your project requires different shades

- Some users find the $6 price point a bit high compared to indoor thread options

- Thread strength gets mixed reviews from a few customers, though most report it holds up well

4. Coats Clark Dual Duty Plus Denim Thread

You’ll want Coats Clark Dual Duty Plus for your denim repairs and heavy-duty sewing projects. This cotton-covered polyester thread (35wt) combines strength with flexibility, handling everything from mending jeans to topstitching workwear.

It resists abrasion through hundreds of wash cycles while maintaining color matching denim in classic blue jean shades. The 125-yard spool works with standard needles and rates 4.7 out of 5 stars for durability and abrasion performance.

At $1.65-$3.08, it’s affordable thread for stitching denim repairs that hold up under stress.

Best For: Home sewers and DIY enthusiasts who need reliable thread for mending jeans, topstitching denim jackets, or repairing heavy workwear that can withstand repeated washing and wear.

- Cotton-wrapped polyester construction gives you the strength of synthetic thread with the smooth stitching feel of natural fiber, reducing breakage during sewing.

- Holds up through hundreds of wash cycles without losing strength or fading, making repairs last as long as the original garment stitching.

- Blends naturally with classic blue denim shades for invisible repairs, while the 125-yard spool works in any standard sewing machine.

- The 125-yard spool is smaller than typical all-purpose thread spools, so you’ll run out faster on larger projects.

- Won’t match darker denim washes like black or deep indigo jeans, limiting its use to medium and light blue denim.

- Some users feel the price point isn’t justified given the smaller spool size compared to regular thread options.

5. Polyester Overlock Sewing Thread Cones

Polyester overlock sewing thread cones give you serious thread tensile strength for heavy-duty sewing projects. These industrial applications workhorses handle 150D to 300D thread weight ranges, delivering 774 to 1,410 cN of pulling power.

You’ll find cone material durability that survives 500+ hours of UV exposure, plus colorfastness testing scores of Grade 4 for washing. Each cone holds up to 5,000 meters of sewing thread, minimizing your machine downtime.

The seam performance stays solid through high-speed runs up to 5,000 RPM, making them reliable for thread for heavy-duty sewing operations.

Best For: Sewers running high-volume projects who need durable thread that won’t break during long serging sessions on industrial or home machines.

- Handles serious tension with 774 to 1,410 cN strength, making it reliable for heavy fabrics like upholstery and outdoor gear.

- Comes in massive spools (up to 5,000 meters) so you’re not constantly stopping to reload thread mid-project.

- Holds up against UV exposure, bleach, and saltwater—perfect for items that’ll face tough conditions.

- Some users report it breaks more easily than expected, especially on high-speed consumer machines.

- The spool size might look smaller in person than the specs suggest, which can be disappointing.

- Tends to create lint on regular sewing machines, requiring more frequent cleaning.

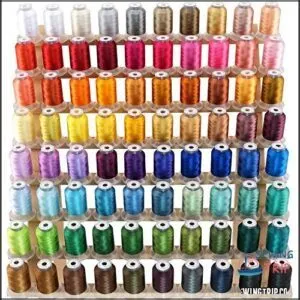

6. Polyester Embroidery Thread Kit Set

When you’re working with brighter colors on embroidery projects, these kits deliver exactly what your machine needs. The kit contents match Janome and Brother machine compatibility perfectly, with color variety spanning everything from bold primaries to subtle pastels.

You’ll get 80 spools of polyester thread at 40 weight and 500 meters each, giving you solid thread durability through thousands of stitches. Brand comparison shows New brothread offers reliable tensile strength for embroidery heavy-duty sewing, though you’ll need to store spools separately and adjust tension settings for best results.

Best For: Crafters and small businesses running Janome or Brother embroidery machines who need a wide color range for custom apparel, uniforms, or decorative projects without buying individual spools.

- 80 vibrant polyester colors at 500 meters each give you plenty of thread for multiple projects, with strong tensile strength that reduces mid-stitch breaks and fraying.

- Works smoothly with popular embroidery machines like Janome and Brother models, maintaining color brightness even after repeated washing and sun exposure.

- Offers serious value compared to buying spools individually, especially for small businesses or hobbyists who embroider workwear, linens, or custom designs regularly.

- No storage rack included, so you’ll need to buy or build your own organizer to keep 80 spools manageable and tangle-free.

- Super glossy finish looks great on many designs but might not suit every embroidery style, and you may need to tweak your machine’s tension for best results.

- Not meant for regular sewing tasks like hemming or button repairs—this thread is specifically engineered for machine embroidery, not hand or general machine stitching.

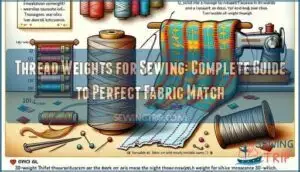

Thread Weight and Strength

Thread weight isn’t just a number on a spool—it’s the key to making sure your project holds up under pressure. You’ll need to match the right weight to your fabric and needle size, or you’ll end up with broken threads and skipped stitches.

Let’s break down what thread weight actually means and how to choose the strength your project needs.

Understanding Thread Weight and Its Importance

Thread weight definition tells you whether your thread is thick or thin—think of it as the backbone of your stitch quality. Here’s why it matters for your heavy-duty sewing thread projects:

- Weight and durability work together: Thicker threads (like 30 wt) deliver up to 50% greater thread strength than finer options when you’re tackling canvas or leather.

- Machine performance depends on matching thread thickness to fabric compatibility: Heavier threads need larger needles and adjusted tension to prevent breakage during high-speed runs.

- Industry metrics guide your choices: The Tex system measures grams per 1,000 meters, helping you select threads that meet demanding standards without guesswork.

Understanding these connections gives you control over seam reliability and keeps your stitches looking professional every time.

Heavy-duty Thread Weights and Corresponding Needle Sizes

Now that you understand thread weight, let’s match it to the right needle sizes for perfect heavy-duty stitching. Thread thickness directly impacts needle compatibility and machine limitations, so follow these matching guidelines:

- 30wt to 40wt threads: Use 90/14 or 100/16 needles for smooth stitching on canvas and denim.

- Tex 70 threads: Pair with 100/16 to 110/18 needles—most home machines max out here.

Industrial standards demand larger needles for heavyweight thread selection beyond Tex 90.

Thread Strength and Durability for Heavy-duty Projects

Once you’ve matched needle sizes, focus on actual performance metrics. Tensile strength defines how much force your heavy-duty sewing thread can handle before breaking—usually 2,000 to 6,000 cN for demanding work. Material composition matters too: Kevlar hits 23 pounds breaking strength at size 69, while nylon reaches 11.31 pounds. Environmental resistance protects against UV rays and chemicals. Construction factors like twist and ply affect durability, and looped strength measures real-world wear. Test your thread under actual project conditions before committing.

| Thread Type | Breaking Strength |

|---|---|

| Kevlar (size 69) | 23 lbs |

| Nylon (size 69) | 11.31 lbs |

| Polyester | 2,000–6,000 cN |

| PTFE | Lifetime warranty rated |

Heavy Duty Thread Brands

Not all heavy duty threads are created equal, and choosing the right brand can make or break your project. The best manufacturers use specialized materials and construction methods to meet specific demands, from saltwater exposure to extreme industrial conditions.

Here are five trusted brands that deliver proven performance when you need thread that won’t let you down.

Fil-Tec Bonded Polyester Threads for Marine Use

When you’re tackling marine projects, FilTec’s bonded polyester thread delivers marine-grade strength you can count on. This powerhouse withstands saltwater, UV rays, and harsh weather without breaking a sweat. Here’s why it’s your go-to for heavy-duty sewing:

- UV resistance survives 500+ hours of colorfastness testing.

- Chemical resistance withstands salt spray and petroleum products.

- Bonded construction prevents fraying under stress.

- Longevity testing proves 94% strength retention after 1,000 hours.

Marine sewing demands reliability—this thread delivers.

GORE Multifilament EPTFE Threads for Industrial Use

When chemical exposure or extreme temperatures threaten your project, GORE’s multifilament ePTFE thread steps up, withstands the effects of acids, bases, and UV radiation without breaking down.

You’ll get 5-10 years of service life in harsh conditions—sometimes longer. It shrugs off temperatures from -180°C to 260°C, making it perfect for hot gas filtration, automotive airbags, and chemical-resistant garments.

A&E Twisted Multifilament Polyester Threads for Awnings

For awnings and marine covers, A&E’s Sunstop twisted multifilament polyester thread delivers superior UV resistance and seam strength you can count on. Its 3-ply construction holds strong through sun and storms, while non-wicking technology keeps water out.

Here’s what makes Sunstop stand out for outdoor projects:

- Sunstop UV resistance retains over 85% tensile strength after 1,000 hours of direct sun exposure

- Multifilament construction benefits include 95% seam efficiency in loading tests

- A&E sustainability options feature recycled PET for eco-conscious fabricators

You’ll find it ideal for outdoor versatility across awnings, shade sails, and boat tops.

Coats Continuous Filament Bonded Polyester Threads for Outdoor Use

When you’re stitching marine cushions or patio covers, Coats Dabond bonded polyester thread won’t let you down. This continuous filament thread resists UV rays for over 500 hours under weathering tests, keeping seams strong through sun and saltwater.

With a break strength hitting 12.5 lbs in V92 size, it withstands thick Sunbrella and Cordura without snapping.

You’ll love that it’s mildew-proof and bleach-resistant—perfect for heavy-duty outdoor projects that face real weather, not just weekend drizzles.

Kevlar Threads for Exceptional Durability and Strength

When you need thread that refuses to quit, Kevlar thread delivers five times the strength-to-weight ratio of steel. This industrial thread maintains 90% of its power even after two hours at 600°F, making it perfect for fire gear and military equipment.

Here’s why it dominates:

- Tensile strength hits 352–365 ksi with minimal stretch

- Heat resistance sustains 316°C in continuous use

- Chemical stability resists solvents, fuels, and saltwater

The Kevlar properties shine in conveyor belts, safety gloves, and aerospace applications where thread strength matters most. With the market climbing toward $800 million by 2033, durability like this isn’t just tough—it’s where industrial uses are headed.

Frequently Asked Questions (FAQs)

What is the best thread for heavy duty sewing?

Around 30% of heavy-duty thread now uses recycled materials, proving durability doesn’t sacrifice sustainability.

For heavy-duty sewing, bonded polyester or nylon threads deliver outstanding strength and UV resistance, handling thick fabrics like canvas and leather reliably.

What is the heaviest thread you can use in a sewing machine?

Most domestic sewing machines max out at Tex 50-70 thread weight—push beyond that and you risk jamming or needle breakage.

Industrial machines handle Tex 1500 or heavier, making machine compatibility issues critical when selecting heavy duty sewing thread.

Which thread can hold the most weight?

When the going gets tough, the tough get Kevlar thread. Its tensile strength exceeds 135 pounds at Tex 400, with load-bearing capacity reaching 600+ pounds—making it peerless for extreme heavy-duty sewing applications.

Which is heavier, 40 wt or 50 wt thread?

40 wt thread is heavier and thicker than 50 wt thread. Thread weight works inversely—lower numbers mean thicker threads with greater strength. For heavy duty sewing applications requiring durability, choose 40 wt.

How do I store heavy duty thread properly?

Store your thread in sealed containers away from UV light. Keep temperature between 15–25°C and humidity around 50%. Organization methods like segmented boxes prevent tangling and preserve thread properties for years.

Can heavy duty thread be used for hand sewing?

Yes, you can hand-sew with heavy duty sewing thread, especially for denim, canvas, or outdoor gear. Choose thicker thread for knot security and material compatibility. Use the right needle selection—sizes 100/16 to 120/19 work well with proper hand sewing techniques.

What causes heavy duty thread to fray or break?

Mechanical stress from high-speed sewing, abrasion, and thread tension cause breakage.

Chemical exposure, environmental factors like UV rays and heat, material properties, and thread aging also reduce strength and durability over time.

Is bonded thread better than unbonded for upholstery?

For upholstery applications, bonded nylon delivers excellent stitch integrity and durability. The resin coating prevents fraying and reduces friction during sewing, while also withstanding heavy loads better than unbonded flexibility, making it the stronger choice.

How often should I replace industrial sewing needles?

You should replace industrial sewing needles every 6-8 hours of sewing to maintain stitch quality and prevent downtime.

Needle wear indicators include skipped stitches and thread breakage, especially when working with heavy-duty materials that accelerate material abrasiveness impact.

Conclusion

Think your sewing skills are holding you back? The real culprit is thread that can’t keep up. Selecting the right thread for heavy-duty sewing—matched to proper needle size and tension—turns weak seams into bulletproof construction.

Whether you’re reinforcing backpacks or upholstering furniture, these six threads deliver the strength and reliability your projects deserve. Stop fighting your machine. Start using thread that works as hard as you do.

- https://www.precedenceresearch.com/sewing-thread-market

- https://www.futuremarketinsights.com/reports/high-strength-polyester-thread-market

- https://www.linkedin.com/pulse/united-states-industrial-sewing-thread-market-qnsyc

- https://www.researchandmarkets.com/reports/5939445/yarn-fiber-thread-market-report

- https://www.mhthread.com/blog/products/types-of-sewing-thread