This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ll commonly find 40, 50, and 60 weight threads, where higher numbers mean thinner threads.

Cotton embroidery thread typically comes in 30 and 50 weights.

Choose 40 weight for bold designs on heavy fabrics, 50 weight for general embroidery work, and 60 weight for delicate details on lightweight materials.

Your needle size should match your thread weight – thicker threads need larger needles to prevent fabric damage.

The right thread weight transforms ordinary stitching into professional-looking embroidery that won’t pucker or break mid-project.

Table Of Contents

Key Takeaways

- You’ll find that higher thread weight numbers mean thinner threads – so 60wt is much finer than 40wt, which is the opposite of what you’d expect

- Match your thread weight to your project: use 40wt for bold designs on heavy fabrics, 50wt for general embroidery work, and 60wt for delicate details on lightweight materials

- Your needle size must match your thread thickness – heavier threads need larger needles to prevent fabric damage and thread breakage during stitching

- Quality thread matters more than you think – premium threads reduce lint, maintain color fastness, break less often, and keep your embroidery machine running smoothly

Thread Weight Basics

You’ll encounter three main thread weight categories when choosing embroidery threads: standard weights (40-50wt), fine weights (60-100wt), and heavy weights (3-30wt).

Understanding these categories helps you select the right thread thickness for your specific embroidery project and fabric type, which is crucial for the overall success of your embroidery project.

Standard Thread Weights

When you’re starting your embroidery journey, common weights like 40wt and 50wt serve as your reliable foundation.

These medium-weight threads offer versatility for general sewing and home décor projects.

Made from cotton, polyester, rayon, or metallic materials, they provide excellent blending options.

Machine embroidery thread in these weights delivers consistent results, while hand embroidery thread creates beautiful texture and coverage for most designs, making them a great choice for general sewing.

Fine Thread Weights

Fine weight threads ranging from 60wt to 100wt are your go-to choice for delicate fabrics and intricate details.

These fine embroidery thread options excel at reducing bulk while creating precise fine seams and stunning lace work.

Here’s when fine weight threads shine:

- Detailed embroidery – Perfect for intricate patterns without overwhelming fabric

- Delicate materials – Won’t damage lightweight fabrics during stitching

- Professional finishing – Creates smooth, refined results in fine embroidery thread applications

As embroidery thread weight increases numerically, thickness decreases, making these threads ideal for sophisticated projects.

Heavy Thread Weights

Heavy weight threads range from 12wt to 3wt, with lower numbers meaning thicker threads.

These cotton threads create bold effects and textural embroidery on heavy fabrics.

You’ll use thick embroidery thread for decorative stitching, couching techniques, and dimensional work.

Heavy weight threads add substance to your designs, making stitches pop off the fabric, and they’re perfect when you want your embroidery to make a statement.

Understanding thread weight basics is essential for achieving professional embroidery results.

Embroidery Thread Selection

You’ll discover that choosing the right embroidery thread isn’t just about color—weight and material dramatically affect your finished project’s appearance and durability.

The key lies in matching thread characteristics to your specific fabric type and desired embroidery effect, which is crucial for achieving the desired outcome with embroidery thread.

Material Types

Cotton threads offer the strongest foundation for embroidery projects, providing excellent stitch definition and durability.

Polyester threads resist fading and maintain vibrant colors longer than other materials. Rayon threads create beautiful shine and luster for decorative work.

Metallic threads add sparkle but require careful handling. Blended threads combine multiple materials for balanced performance in machine embroidery applications.

Choosing the correct thread weight is essential for achieving ideal results, as discussed in this complete thread guide, which provides a comprehensive overview of embroidery projects and the importance of thread weight for optimal performance, ensuring vibrant colors.

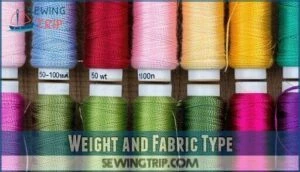

Weight and Fabric Type

Matching embroidery thread weight to fabric type guarantees professional results.

Light fabrics like silk need 60-100 wt threads for delicate fabric threads compatibility.

Medium-weight cotton works best with standard 40 wt thread.

Heavy fabrics require 12-30 wt heavy fabric threads for durability.

For general embroidery, a 40wt thread is ideal due to its shine and durability.

You can find a variety of options online for this thread.

This fabric weight pairing prevents puckering and breakage while ensuring the best thread choice for your embroidery project’s success.

Application-Based Recommendations

Choose your embroidery thread weight based on project demands and fabric compatibility.

For detailed work like monograms, 60wt thread delivers crisp lines without overwhelming delicate materials.

Standard 40wt works perfectly for most machine embroidery projects, while 30wt creates bold decorative effects on heavy fabrics.

Match your thread weight guide recommendations to design complexity and adjust machine settings accordingly for superior results.

For projects requiring durability, consider using polyester embroidery thread for superior results.

Thread Weight Applications

Understanding thread weight applications helps you select the perfect thread for each embroidery project you tackle.

Each weight category serves specific purposes, from creating fine details to adding bold decorative elements that transform your work.

General Sewing Uses

Medium weight threads (30-40 wt) serve as your go-to choice for garment construction and home decor projects.

These threads offer excellent fabric compatibility across various materials while providing reliable seam strength.

You’ll find polyester and cotton options work well for everyday sewing tasks, and their versatile applications make them perfect for hemming, topstitching, and basic embroidery work where thread thickness needs balance.

Detailed Embroidery Work

Fine threads ranging from 60wt to 100wt excel at intricate designs where precision matters most.

Fine threads transform complex designs into precise masterpieces without overwhelming delicate fabrics.

These delicate threads create clean lines without overwhelming your fabric choice, making them perfect for detailed work.

Here’s when fine threads shine brightest:

- Text embroidery – Sharp letters that won’t blur together

- Lace effects – Delicate patterns that look professionally finished

- Miniature motifs – Small designs that need crisp definition

- Lightweight fabrics – Won’t pucker or distort delicate materials

- Multi-layered designs – Reduces bulk when stitching overlapping elements

Your needle selection becomes vital with fine threads – use smaller needles to prevent fabric damage and guarantee smooth thread flow.

Many suppliers offer specialized thread options for these projects.

Bold Decorative Effects

Bold decorative effects in embroidery come alive when you embrace heavyweight thread types like 12wt to 30wt cotton.

These thick threads create stunning textural thread effects and dimensional stitching that practically leap off your fabric.

For creative applications, heavy embroidery thread weight delivers the visual punch you’re after.

The bold embroidery results speak volumes, transforming simple designs into eye-catching masterpieces through superior thread thickness embroidery techniques.

For general sewing projects, consider using 40-50 weight threads.

Measuring Thread Weight

You’ll need to understand three different measurement systems to select the right thread for your embroidery projects.

The weight system uses numbers like 40wt or 60wt, while tex and denier systems provide alternative ways to measure the same thread thickness.

Weight System Explanation

Understanding the thread weight system is like learning a new language for embroidery.

The weight measurement works backwards from what you’d expect – higher numbers mean thinner threads, this system measures kilometers of thread per kilogram, so 40wt means 40 kilometers weighs one kilogram.

The thread weight chart shows this inverse relationship clearly, and when comparing thread weight conversion between systems, remember that embroidery thread weight follows this counterintuitive pattern throughout all measurement methods, which is crucial for understanding the thread weight system.

Tex and Denier Measurements

Professional embroidery requires precise thread weight measurements beyond the basic weight system.

Tex measures thread weight in grams per 1,000 meters, while Denier calculates grams per 9,000 meters.

Both systems use higher numbers for thicker threads, providing measurement accuracy essential for industry usage.

Standard equivalents help you match thread specifications across different measurement systems for consistent embroidery results, ensuring consistent embroidery and precise thread weight measurements.

Conversion Formulas

Converting between embroidery thread weight systems becomes straightforward with simple formulas.

For Weight to Denier conversion, divide 9,000 by the weight number (40wt = 225 denier).

Weight to Tex conversion requires dividing 1,000 by the weight (40wt = 25 tex).

These formulas help you compare different thread specifications accurately across manufacturers and systems, using simple formulas.

Choosing Right Thread Weight

You’ll need to match your thread weight with the right needle size and adjust your machine settings for professional results.

Choosing the correct thread weight makes the difference between embroidery that looks homemade and work that rivals commercial quality.

Needle Size Considerations

Matching your embroidery thread weight with the right needle size prevents thread damage and guarantees smooth stitching.

The needle eye should be about 40% larger than your thread’s diameter for perfect tension balance.

Follow these needle compatibility guidelines:

- Fine threads (60-100wt): Use 60/8 to 80/12 needles to avoid fabric punctures

- Medium threads (40-50wt): Choose 80/12 to 90/14 needle sizes for balanced performance

- Heavy threads (12-30wt): Select 90/14 to 100/16 needles for superior stitch quality

Selecting the correct size can be aided by understanding available needle options.

Testing different needle types on scrap fabric helps you find the perfect needle matching combination.

Stitch Density and Tension

Balancing embroidery thread weight with proper density adjustments prevents fabric puckering and thread breakage.

Heavier threads need wider stitch spacing to avoid overcrowding, while finer weights require closer placement for coverage.

Tension troubleshooting becomes critical with thicker threads—they create more resistance.

Poor fabric stability often stems from mismatched density settings.

Monitor stitch appearance closely, as tension problems manifest quickly when density doesn’t match your chosen embroidery thread weight.

This close monitoring is essential to prevent issues like thread breakage and fabric puckering, which can be caused by improper density adjustments.

Quality Thread Importance

High-quality embroidery thread weight matters more than you might think.

Superior threads deliver consistent stitch quality while protecting your machine from unnecessary wear. Brand reputation often reflects years of testing and refinement.

Selecting the right thread weight, such as using a 50-60 weight, is essential for delicate fabrics.

Consider these quality indicators:

- Lint Reduction – Premium machine embroidery thread produces minimal debris

- Color Fastness – Quality threads maintain vibrant hues through washing cycles

- Thread Longevity – Better construction means fewer breaks during stitching

- Machine Health – Clean-running embroidery thread types reduce maintenance needs

Frequently Asked Questions (FAQs)

What is the best thread weight for embroidery?

Why settle for guesswork when choosing embroidery thread?

You’ll want 40-weight thread for most projects—it’s the sweet spot that delivers vibrant colors and smooth stitching without overwhelming delicate fabrics or causing tension issues.

What is 60 weight embroidery thread used for?

You’ll use 60-weight thread for detailed embroidery work, fine text, delicate fabrics, and intricate designs where you don’t want the thread overwhelming your base material or design elements.

Which is heavier, 30 or 40 weight thread?

Thirty weight thread packs twice the thickness of 40 weight thread, creating bolder stitches that’ll make your embroidery pop with dimensional texture and vibrant coverage.

What thickness of thread is used for embroidery?

Embroidery typically uses 40-weight thread as the standard choice.

You’ll find this medium-weight thread perfect for most designs, providing excellent coverage without overwhelming delicate fabrics or creating excessive bulk in your finished work, with medium-weight thread being ideal for most applications, and excellent coverage being a key benefit.

Can thread weight affect embroidery hoop selection?

Thread weight doesn’t directly affect hoop selection, but heavier threads create more bulk.

You’ll need slightly larger hoops to accommodate the added thickness and prevent fabric puckering or distortion during stitching, which is a result of the heavier threads.

Does thread weight impact washing instructions?

Like a delicate fabric meeting sturdy canvas, thread weight directly influences how you’ll care for your embroidered pieces.

Heavier threads typically handle washing better, while finer weights need gentler treatment to prevent breakage and maintain stitch integrity.

How does thread weight affect color vibrancy?

Color vibrancy increases with thicker threads because they hold more dye and reflect more light.

You’ll get bolder, richer colors with 30wt threads compared to fine 60wt threads that appear more subtle.

Can different thread weights be mixed together?

Yes, you can mix different thread weights in a single embroidery project.

Combining weights creates visual depth and texture contrast.

Use heavier threads for bold outlines and finer weights for detailed fills.

Adjust needle size and tension accordingly for each weight change.

Does thread weight influence embroidery design pricing?

Ever wonder why some embroidery costs more?

Thread weight doesn’t directly affect pricing since most commercial designs use standard 40wt thread.

Pricing depends on stitch count, complexity, and design size rather than thread specifications, which is a key factor to consider when evaluating embroidery costs, particularly the impact of complexity.

Conclusion

Mastering thread weight for embroidery makes the difference between mediocre and magnificent stitching.

You’ve learned that higher numbers mean thinner threads, with 40 weight perfect for bold designs, 50 weight ideal for general work, and 60 weight excellent for delicate details.

Match your needle size to thread thickness, consider fabric weight, and remember that quality threads prevent frustrating breaks mid-project.

Your embroidery success depends on selecting the right thread weight for each specific application.

- https://www.printful.com/glossary/thread-weight

- https://blog.ricoma.com/2024/06/13/best-embroidery-thread/

- https://www.needlenthread.com/2014/02/thread-talk-sizing-up-cotton-threads.html

- https://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Category_Code=30and40weight

- https://www.youtube.com/watch?v=EqT6Q3ZRe5M