This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Understanding thread weights for sewing means grasping a counterintuitive numbering system—higher numbers indicate thinner threads, not thicker ones.

Understanding thread weights for sewing means grasping a counterintuitive numbering system—higher numbers indicate thinner threads, not thicker ones.

You’ll find 30-weight thread creates bold, visible stitches, while 80-weight thread produces nearly invisible seams.

This weight system measures thread length per kilogram, so more thread fits into that kilogram when it’s thinner.

For delicate fabrics like silk, you’ll want 60-100 weight threads to prevent puckering.

General sewing projects work best with 40-50 weight threads for versatility and durability.

Heavy-duty projects demand 12-30 weight threads for maximum strength.

The secret lies in matching thread weight to your fabric’s personality.

Table Of Contents

Key Takeaways

- You’ll master thread selection by remembering that higher numbers mean thinner threads—80-weight creates invisible seams while 30-weight makes bold, visible stitches.

- You should match thread weight to your fabric’s thickness and project needs: use 60-100 weight for delicate fabrics like silk, 40-50 weight for general sewing, and 12-30 weight for heavy-duty projects.

- You can’t judge thread quality by weight alone—invest in reputable brands that offer consistent performance, better color retention, and reduced lint production to avoid frustrating machine jams and project failures.

- You’ll get professional results by testing different thread weights on fabric scraps first, adjusting your machine’s thread tension accordingly, and pairing the right needle size with your chosen thread weight.

Thread Weights Explained

Thread weight numbers tell you how thick or thin your thread actually is.

You’ll discover that higher numbers mean finer threads, while lower numbers indicate thicker, stronger options for your projects, with thicker being a key characteristic of lower numbered threads.

Thread Weight Measurement

Most sewers encounter confusing thread weight measurement systems that can make selecting the right thread feel like cracking a code.

Understanding these measurement standards transforms your thread selection from guesswork into precision. Thread labels use different systems, making direct comparisons tricky without knowing the basics.

Key thread weight measurement systems include:

- Weight System: Measures thread length per kilogram – higher numbers mean thinner threads

- Tex Measurement: Calculates grams per 1,000 meters of thread length for precise classification

- Denier Scale: Measures grams per 9,000 meters, commonly used in industrial applications

- Thread Classification: Numbers like 50/2 indicate weight and ply count together

- Thread Gauge: Consistent labeling standards prevent project mishaps and guarantee proper selection

Mastering the thread weight basics is essential for choosing the right thread. Master these systems to confidently choose threads that match your fabric perfectly every time.

Thread Weight and Thickness

Why does thread weight matter for thickness? Higher numbers mean thinner threads, while lower numbers indicate thicker diameters.

A 30-weight thread creates bold, visible stitches, whereas 80-weight thread practically disappears. Thread diameter directly affects your project’s appearance and bulk.

Ply count adds strength without changing the weight number. Understanding label variations like tex system and denier measurement helps you choose correctly.

To further clarify, thread weight numbers standardize measurements across different brands.

Thread Weight and Strength

Understanding thickness alone won’t guarantee project success—you need to evaluate how well your thread will hold up under stress.

While thread weight indicates thickness, thread strength determines whether your seams survive washing, wearing, and everyday use.

Thread density plays a major role here.

Multiple plies twisted together create stronger threads even at lighter weights, giving you better breakage resistance than single-ply options.

This is why a 40/2 thread (two plies) outperforms a 40/1 thread in demanding applications.

Material selection dramatically affects sewing performance.

Polyester threads offer superior fabric durability compared to cotton or rayon, handling higher thread tension without snapping.

When your machine’s running at full speed, you’ll appreciate threads that won’t break mid-seam.

- Ply construction: Multiple twisted strands prevent thread breakage under stress

- Fiber composition: Polyester resists breaking better than natural fiber alternatives

- Tension tolerance: Stronger threads handle aggressive machine settings without failure

- Seam integrity: Proper thread strength prevents stitch failure in high-wear areas

- Project longevity: Matching thread strength to fabric weight guarantees lasting results

Choosing The Right Thread Weight

Selecting the right thread weight transforms your sewing from amateur to professional, matching fabric thickness with thread diameter for perfect results.

You’ll discover that pairing delicate silks with fine threads and heavy denim with robust weights creates stronger seams and cleaner finishes every time.

Thread Weight for Delicate Fabrics

Delicate fabrics require your most thoughtful approach to thread selection. When working with fine weaves like silk, chiffon, or voile, you’ll want lightweight thread in the 60-100 weight range to prevent puckering and maintain the fabric’s natural drape.

Fine threads dance with delicate fabrics—choose wisely for flawless results

Silk threads excel on luxury fabrics, providing both strength and invisibility. For delicate stitches, match your fabric choice with appropriate weights:

Fabric Type Recommended Thread Weight

Understanding the thread weight systems is vital for achieving professional results. Fine weight threads demand careful thread tension adjustments—reduce tension by 10-15% from standard settings. Pair these threads with smaller needles (70/10-80/12) to avoid fabric damage.

This thread weight guide guarantees your thread weights for sewing delicate projects create professional, nearly invisible seams that preserve the fabric’s elegant character.

Thread Weight for General Sewing

Most general sewing projects benefit from 40-50 weight threads that deliver reliable performance without creating bulky seams. These medium weight threads represent the sweet spot for everyday sewing thread weights, handling everything from garment construction to home décor with consistent stitch quality.

Here’s your essential thread weight guide for general sewing:

- 40 weight thread provides durability for structured garments and decorative topstitching

- 50 weight thread offers finer seams while maintaining adequate strength for most applications

Your fabric choice determines which weight works best. Thread tension adjustments become essential when switching between weights on sewing machines. Smart thread selection means keeping both weights stocked—they’ll cover 90% of your projects. Think of these weights as your sewing toolkit’s workhorses, ready to tackle whatever creative challenge comes next.

Thread Weight for Heavy-Duty Projects

When tackling heavy fabric projects, you’ll need thick threads that won’t snap under pressure. Heavy duty thread ranges from 12wt to 30wt, delivering the strength your demanding projects require.

For industrial stitching and canvas work, these thread weight sizes make all the difference:

- 12wt polyester – Perfect for denim sewing and reinforced seams

- 20wt bonded nylon – Canvas work and outdoor gear that lasts

- 28wt heavy weight threads – Upholstery and furniture covers

- Tex 70-350 industrial thread – Professional leather and heavy canvas

- 30wt cotton – Bold topstitching that stands out beautifully

To guarantee the best results, consider the polyester thread size for your specific sewing needs. Match your thread weights for sewing to your fabric’s demands for professional results.

Thread Weight for Specific Techniques

Different sewing techniques demand specific thread weights to achieve professional results. You’ll need heavier threads for quilting topstitching and lighter weights for delicate embroidery work.

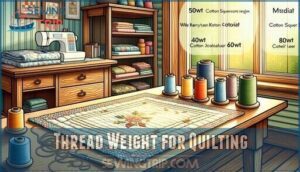

Thread Weight for Quilting

Quilting threads transform your project’s appearance and performance. Your fabric choice determines the ideal thread weight for quilting success.

Here’s your essential guide:

Cotton thread weights blend naturally with most fabrics.

Adjust thread tension when switching weights to prevent stitch issues and maximize quilt durability.

Understanding the thread weight basics is essential for selecting the right threads for your quilting projects.

Thread Weight for Embroidery

Machine embroidery thrives with 40 wt. embroidery threads – they create clean, professional stitches without overwhelming your fabric choice.

For intricate details, switch to 60 wt. thread weights that won’t compete with delicate designs.

Needle selection matters: match your needle size to thread weight for embroidery thickness.

Adjust thread tension and stitch density based on your embroidery thread weights for flawless results on embroidery projects.

Understanding thread weight options is essential for achieving the desired embroidery effect.

Thread Weight for Upholstery

Heavy-duty upholstery requires Tex 70 or Tex 90 threads that handle serious stress.

Fabric thickness guides your thread weight selection for professional results.

Your upholstery thread arsenal needs:

- Tex 70 threads for medium-weight fabrics like cotton duck, delivering 11lb breaking strength

- Tex 90 bonded nylon for heavy materials, providing 15lb durability with flexibility

- Proper thread tension adjustments preventing seam puckering while maintaining stitch integrity

Thread Weight for Decorative Stitching

Decorative stitching creates stunning visual impact with strategic thread weight choices. Use bold 30 weight threads for dramatic topstitching and texture that commands attention.

Medium 40 weight threads balance stitch visibility with refined coverage, perfect for subtle decorative elements. Experiment with metallics and variegated colors to add sparkle and depth.

Adjust thread tension carefully—heavier decorative threads need looser settings to prevent bunching and achieve smooth, professional-looking fabric contrast effects.

Thread Weight Purpose Recommended Use

Heavy (30 wt)

Medium (40 wt)

Specialty

Importance of High-Quality Threads

You’ll quickly discover that high-quality thread makes the difference between frustrating sewing sessions and smooth, professional results.

When you invest in superior threads, you’re not just buying string – you’re purchasing consistent performance that transforms your entire sewing experience.

Thread Quality and Lint Production

Quality thread separates smooth sewing from lint nightmares that clog your machine and ruin projects.

Quality

Quality thread is the difference between professional results and frustrating machine jams that destroy your creative flow.

Thread Quality and Lint Production directly affects your sewing experience. Poor thread composition creates excessive lint, while superior Fiber Quality maintains clean performance throughout your project.

Quality threads deliver measurable benefits:

- Enhanced Yarn Strength prevents mid-seam breakage

- Superior Color Fastness preserves vibrant hues wash after wash

- Effective Lint Reduction keeps tension discs and bobbin case clean

- Consistent Thread Weight guarantees predictable stitching results

- Improved Thread Durability withstands repeated needle penetration

Investing in quality thread saves money on machine maintenance while delivering professional results every time you sew.

Thread Quality and Durability

Beyond lint reduction, thread durability separates professional results from amateur attempts.

Thread strength varies dramatically between manufacturers, affecting your project’s lifespan.

Fiber quality determines resistance to breaking under stress.

Durability testing reveals how threads perform after washing and wear.

Thread composition impacts flexibility and resilience.

| Thread Material | Durability Rating |

|---|---|

| Polyester | Excellent – resists UV/abrasion |

| Cotton blend | Good – balanced performance |

| Pure cotton | Fair – softens over time |

| Rayon | Poor – weakens when wet |

| Silk | Variable – depends on quality |

Thread Quality and Color Retention

Premium thread quality directly impacts color retention through superior dye consistency and fading resistance.

You’ll see color fastness differences immediately when comparing budget versus quality options.

High-grade fiber strength locks dyes deeper, preventing washout and UV damage.

Smart thread weight selection paired with colorfast properties keeps your projects vibrant longer.

Thread Quality and Brand Reputation

Reputable thread manufacturers like Gutermann, Aurifil, and Mettler earn trust through consistent quality control and proven fiber durability.

Brand reputation reflects manufacturing excellence, ensuring your projects won’t suffer from poor thread quality or color retention issues.

When evaluating thread brands, consider these manufacturer reputation factors:

- Thread Materials Testing – Quality brands conduct rigorous colorfastness and strength assessments

- Brand Comparison Reviews – User feedback reveals real-world performance across different thread weights

- Quality Control Standards – Established manufacturers maintain consistent fiber durability specifications

Selecting The Best Thread for Your Project

Choosing the right thread for your project involves matching thread weight to fabric thickness and your specific sewing goals.

You’ll also need to take into account thread color, finish, brand quality, and be willing to test different options to achieve professional results.

Considering Thread Weight and Type

Successfully combining Thread Selection and Fabric Compatibility determines your project’s success.

Match thread weight to fabric thickness—60-80wt threads suit delicate materials, while 40-50wt handles general sewing tasks.

Understanding thread weight options is essential for achieving the desired sewing results.

| Thread Weight | Best Fabrics | Sewing Performance |

|---|---|---|

| 60-80wt | Silk, chiffon, organza | Minimal bulk, fine seams |

| 40-50wt | Cotton, linen, medium-weight knits | Versatile, strong stitches |

| 20-30wt | Denim, canvas, upholstery | Bold topstitching, durability |

Consider Thread Texture and Sewing Thread Thickness compatibility with your machine’s capabilities for ideal results.

Considering Thread Color and Finish

Color matching sets the foundation for professional sewing results.

Test thread against fabric in natural daylight, not store lighting, since fluorescent bulbs distort true colors. Dye lots vary between thread spools, so buy enough matching thread upfront to complete your project.

Consider these finish factors for ideal fabric blending:

- Thread sheen levels – Matte finishes blend invisibly while high-sheen threads create decorative texture effects

- Color fastness testing – Pre-wash test scraps to prevent bleeding disasters on finished garments

- Finish types compatibility – Match cotton threads with natural fabrics, polyester with synthetics for best results

- Texture effects planning – Combine different thread weights for dimensional topstitching and decorative stitching accents

Considering Thread Brand and Quality

Choosing thread brands isn’t just about pretty packaging—it’s about Quality Control that keeps your projects running smoothly.

Established brands like Gutermann and Coats maintain consistent Thread Materials and superior Fiber Strength through rigorous testing. Their reliable Brand Comparison standards guarantee Color Consistency across batches, while quality Thread Selection prevents mid-project headaches.

Thread quality markers you’ll love:

- Thread finish that feels smooth between your fingers

- Thread brands with consistent weight labeling accuracy

- Thread weight specifications that match actual performance

Smart sewers invest in proven quality over bargain gambles. Understanding the types of thread is vital for achieving professional results in sewing projects.

Experimenting With Different Thread Options

Branch out from your usual thread choices to discover what makes each thread weight shine.

Test thread types for sewing on fabric scraps first—pair heavy decorative threads with lightweight construction threads for stunning Thread Texture contrasts.

Mix metallic accents with cotton for Fabric Blending effects that control Stitch Visibility.

Adjust Thread Tension when experimenting with different thread options to master various Sewing Techniques and achieve professional thread selection results.

Frequently Asked Questions (FAQs)

Which is heavier, 30 or 40 weight thread?

Here’s the deal with thread weights: 30 weight thread is actually heavier than 40 weight. It’s counterintuitive, but smaller numbers mean thicker, stronger threads. Think backwards—30 packs more punch than

Which is thicker, 40 or 60 weight thread?

When comparing thread weights, 40-weight is thicker than 60-weight. Remember, higher numbers mean thinner threads. You’ll notice 40-weight creates more visible stitches, while 60-weight practically disappears into delicate fabrics.

What is a good weight for sewing thread?

Most sewers waste money on wrong thread weights—50% choose incorrectly.

For everyday projects, you’ll want 40-50 weight thread.

It’s your sweet spot for general construction, offering perfect balance between strength and versatility across most fabrics.

Is 40 wt thread thicker than 50 wt?

Yes, 40 wt thread is thicker than 50 wt thread.

Remember, higher weight numbers mean thinner threads—it’s counterintuitive but consistent across sewing.

Think of it like wire gauge: bigger numbers equal smaller diameter, and in this context, thinner threads are what you get with higher weight numbers.

What is the difference between 30 wt and 40 wt thread?

Thread weight’s like the difference between a rope and a string—30 wt is thicker and stronger than 40 wt.

You’ll use 30 wt for bold topstitching and decorative work, while 40 wt works great for general construction and everyday sewing projects.

What is 70 weight thread used for?

Fine 70-weight thread works perfectly for delicate fabrics like silk, detailed embroidery, and micro quilting.

It’s thin enough to create invisible seams without adding bulk, making your finished projects look professionally crafted.

What is the best weight for sewing thread?

Imagine this scenario: you’re staring at countless thread spools, wondering which weight won’t make your project look amateur.

For most sewing adventures, you’ll want 40-50 weight thread—it’s your reliable workhorse that handles everything from delicate blouses to sturdy home décor without breaking a sweat.

What does 50 weight thread mean?

When you see "50 weight" on thread, you’re looking at a medium-weight thread that’s perfect for everyday sewing projects.

It’s thin enough to avoid bulky seams but strong enough for most fabrics.

How does thread weight impact seam elasticity?

Heavier threads create stiffer seams with less stretch, while lighter weights maintain fabric flexibility. You’ll get better drape and elasticity with 60-80 weight threads on stretchy fabrics.

Can mismatched thread weights cause sewing issues?

Yes, mismatched thread weights absolutely cause sewing headaches.

You’ll face tension problems, uneven stitches, and fabric puckering when weights don’t match your project’s needs.

Always pair thread weight with fabric thickness.

Conclusion

Practice makes perfect, and mastering thread weights for sewing transforms your projects from amateur to professional.

You’ve learned that thread weight isn’t about thickness alone—it’s about matching your thread’s personality to your fabric’s needs.

Whether you’re creating delicate hems with 60-weight thread or reinforcing seams with 30-weight, the right choice prevents puckering, breakage, and frustration.

Remember, experimentation builds confidence, so test different weights on fabric scraps first.

Your sewing machine will thank you, and your finished projects will showcase the precision that comes from understanding these fundamental principles.

- https://www.mhthread.com/blog/products/thread-size-numbering-systems

- https://sewsimplebags.com/everything-you-need-to-know-about-thread-weight/

- https://www.qualitysewing.com/blogs/news/sewing-thread-guide-weights-uses

- https://www.sewingpartsonline.com/blogs/education/ultimate-thread-reference-guide-2

- https://madamsew.com/blogs/sewing-blog/quilter-guide-thread-weight