This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Scuba fabric offers structure with moderate stretch, making it perfect for dresses, skirts and jackets that hold their shape.

When sewing, use a ballpoint needle and polyester thread. Keep stitch length at 2.5-3mm and avoid high heat which can damage the fabric.

Pre-wash cold and air dry to prevent shrinkage. Cut with sharp scissors or a rotary cutter for clean edges.

The fabric’s thickness lets you leave edges raw for many projects, saving time on finishing. The right techniques will transform this modern textile into professional-looking garments that turn heads.

Table Of Contents

Key Takeaways

- You’ll need a ballpoint needle and polyester thread when sewing scuba fabric, keeping stitch length at 2.5-3mm and avoiding high heat which can damage the material.

- You don’t need to finish raw edges with scuba fabric as it won’t fray, saving you significant time while still achieving professional-looking results.

- You’ll find scuba fabric perfect for structured garments like fit-and-flare dresses, peplum tops, and blazers due to its unique combination of structure and stretch.

- You should always pre-wash scuba fabric in cold water and air dry it to prevent shrinkage, using sharp scissors or a rotary cutter for clean edges.

What is Scuba Fabric

You’ll find scuba fabric is a double-knit material made from polyester and spandex, giving it exceptional stretch with impressive recovery.

This medium to heavyweight textile offers both structure and flexibility, making it perfect for creating garments that maintain their shape while providing comfort.

Scuba Fabric Properties

When you work with scuba fabric, you’re handling a textile powerhouse with remarkable properties.

This medium to heavyweight fabric combines polyester (90-95%) with spandex to create a material that stands out in the textile world.

- Fabric Thickness varies from medium to heavyweight, providing structure without unnecessary bulk

- Material Blend of polyester and spandex delivers exceptional durability and flexibility

- Textile Strength guarantees your garments keep their shape wear after wear

- Stretch Recovery allows the fabric to bounce back perfectly after being stretched

The fiber content creates a smooth, springy surface that resists wrinkles, making it perfect for structured garments that need to maintain their shape.

You’ll appreciate how this double-knit fabric offers comfortable movement while still holding its form.

With impressive durability and easy maintenance, scuba fabric projects will withstand countless wears and washes without losing their appeal.

Scuba Fabric Characteristics

Your hands will immediately recognize scuba fabric by its distinctive characteristics. This double knit fabric boasts impressive fabric thickness—medium to heavyweight—providing excellent structure without unnecessary bulk.

The material blend primarily features polyester with spandex, creating a smooth surface with remarkable textile strength that maintains shape through countless wears. What sets scuba fabric apart is its exceptional stretch recovery; garments snap back to their original form after being stretched.

The fiber content creates a springy texture that resists wrinkling while offering impressive flexibility. Though weight varies between styles, all scuba fabrics deliver superior shape retention compared to standard knits.

Performance-wise, scuba fabric characteristics include moisture-wicking properties and water resistance while remaining breathable. These scuba fabric properties make it versatile for numerous scuba fabric uses where structure and comfort are equally important.

Scuba Fabric Composition

Scuba fabric derives its remarkable performance from a precise composition of typically 95% polyester and 5% spandex.

This polyester-spandex blend creates the ideal balance between structure and flexibility. The double knit construction contributes to its distinctive thickness and density, setting it apart from regular knits.

When examining scuba fabric properties, you’ll notice the two-way stretch with excellent recovery – a direct result of its fiber blends. The weave density provides that smooth surface perfect for contemporary garments.

Unlike other textiles, scuba fabric characteristics include fine gauge threads in a structured weave, created through synthetic polymerization for unique performance.

Sewing Scuba Fabric

You’ll need a few specific techniques to transform scuba fabric into beautiful garments that maintain their structure and stretch.

Using ballpoint needles and walking feet while sewing at a moderate pace will help you create professional-looking items with this versatile material.

Pre-Wash The Material

Now that you understand what scuba fabric is, let’s tackle your first preparation step. Pre-washing isn’t optional—it’s your fabric’s first line of defense against shrinkage.

For proper pre-wash:

- Use cold water only to prevent shrinkage

- Choose mild detergent to protect fibers

- Skip fabric softeners which damage stretch properties

- Avoid hot temperature settings completely

I’ve seen countless projects ruined by dye bleeding and unexpected shrinking. This simple care routine preserves your fabric’s dimensional stability and saves your finished garment from unwelcome surprises.

Work Slowly

Slowing down creates the foundation for successful scuba fabric projects. Take your time with each stitch to minimize errors and avoid unpicking later. Set your machine to a moderate pace, especially when working through curves and handling bulk.

| Sewing Speed | Result | Technique |

|---|---|---|

| Fast | Distorted seams | Avoid completely |

| Moderate | Precise stitching | Use for straight sections |

| Slow | Perfect control | Essential for curves |

Patient stitching prevents distortion while reducing mistakes—a vital technique when sewing scuba fabric that professionals swear by. This approach ensures perfect control and helps achieve precise stitching, which are crucial for a successful project.

Trim by Hand

Now that you’ve mastered working at a steady pace, it’s time to focus on trimming. Hand trimming your scuba fabric delivers precision that machine cutting simply can’t match.

When working with this unique material, follow these steps for best results:

- Use sharp scissors dedicated only to fabric—never paper—to prevent dulling that could damage your scuba fabric

- Trim seam allowances in small increments to reduce bulk while maintaining shape

- Cut curves and corners with precise snips to guarantee professional finishing

Hand trimming prevents distortion in stretchy scuba fabric, preserving your garment’s intended silhouette. This careful approach minimizes seam bulk and creates cleaner lines in your finished pieces—worth every minute of extra effort to achieve cleaner lines and a more professional look!

Raw Edges Are Welcome

After trimming your pieces, you’ll discover one of scuba fabric’s greatest advantages – those raw edges require no finishing.

Unlike traditional textiles that fray constantly, scuba fabric maintains clean, durable edges without hemming or serging.

This design freedom saves you significant time while creating minimalist designs with a professional look.

You can confidently leave seam allowances and hems unfinished – they won’t unravel or deteriorate with wear and washing.

This edge durability makes scuba fabric sewing particularly beginner-friendly.

Many sewing tutorials don’t mention this valuable shortcut: skipping edge finishing lets you concentrate on perfecting other sewing tips and techniques while still achieving polished results.

This ability to skip finishing also highlights the edge durability of scuba fabric, making it a preferred choice for many sewing projects.

It allows sewers to focus on other aspects of their craft, ensuring that their final products look professional and well-made, with a focus on perfecting other sewing tips.

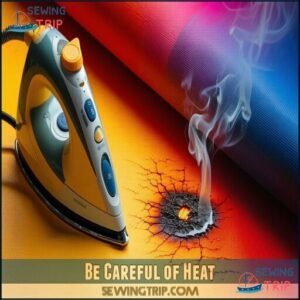

Be Careful of Heat

While raw edges save you time, heat can destroy your scuba fabric in seconds. This synthetic material demands caution when applying heat.

- Set your iron to low heat (usually synthetic setting) and always use a pressing cloth to prevent melting temperatures from damaging the fabric.

- Consider steaming alternatives when possible, holding the steamer an inch away from the fabric surface.

- Never use high dryer settings; air-drying is your safest option.

Test your ironing techniques on a scrap piece first. Remember, heat sensitivity is real—once you’ve melted or scorched scuba fabric, there’s no going back.

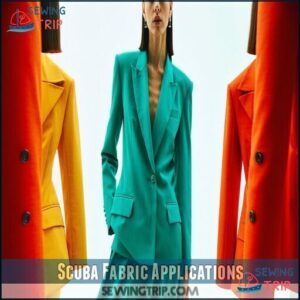

Scuba Fabric Applications

You’ll find scuba fabric can transform your sewing projects into structured yet comfortable garments ranging from fashion-forward dresses to modern activewear.

This versatile material’s exceptional stretch and stability makes it perfect for creating everything from statement skirts that hold their shape to bold blazers with crisp lines without excessive bulk or complicated construction techniques, making it ideal for fashion-forward designs.

Fashion-forward Dresses

Now that you’ve learned the basics of handling scuba fabric, let’s explore creating stunning fashion-forward dresses.

Scuba fabric’s unique structure creates defined silhouettes that highlight your best features while remaining comfortable to wear.

You’ll achieve professional results using stretch stitches that maintain elasticity.

The fabric naturally smooths imperfections without extra underlining.

Today’s dress trends favor scuba’s ability to hold bold prints and architectural details beautifully.

Contemporary Activewear

While dresses showcase scuba fabric’s elegance, it’s equally impressive in the activewear arena. This performance fabric excels in creating functional yet stylish workout gear.

Your activewear projects benefit from scuba fabric’s remarkable properties:

- Sweat-wicking moisture management keeps you dry during intense training sessions

- Superior shape retention prevents sagging even after countless squats and stretches

- Four-way stretch technology allows unrestricted movement for any activity

- Smooth texture prevents chafing during high-intensity workouts

- Durability withstands frequent washing without losing elasticity

Perfect for leggings, sports bras, dancewear, and swimwear, scuba fabric combines athleisure trends with practical performance. Its structure maintains clean lines while its stretch accommodates your body’s full range of motion, providing superior shape retention and durability.

Structured Jackets and Blazers

Scuba fabric transforms ordinary outerwear into architectural statement pieces with crisp lapels and defined shoulders.

You’ll find this doubleknit material perfect for structured jackets and blazers due to its natural body and shape retention.

When choosing lining options and closure options, the fabric’s stability simplifies fitting while providing comfortable stretch.

For professional shoulder shaping, utilize stretch stitches at stress points.

The smooth surface elevates pocket styles with a polished finish, making your handmade structured garments indistinguishable from high-end fashion pieces with crisp lapels and defined shoulders.

Statement Skirts

While jackets showcase scuba fabric’s structured potential, statement skirts truly highlight its unique bounce and flexibility. When creating skirts with this versatile material, you’ll appreciate how it maintains shape throughout wear without sacrificing comfort.

The fabric’s exceptional structure makes it perfect for various skirt silhouettes – from playful skater styles to elegant maxis. You’ll find pattern selection surprisingly forgiving, as scuba holds crisp pleats and clean waistlines beautifully.

Want to elevate your scuba fabric projects? Try embellishment techniques like decorative topstitching or adding simple appliqués – the smooth surface serves as an ideal canvas. Its water-resistant nature also makes it ideal for skirts worn in unpredictable weather.

For styling tips, pair your statement skirts with contrasting fabric combinations like soft cotton tops to balance the structured bottom. When following any scuba fabric tutorial, remember to use stretch stitches that preserve both structure and movement – essential for creating head-turning skirts that maintain their shape all day.

Bold Tops and Peplum Blouses

Many sewists turn to scuba fabric for creating bold tops and peplum blouses that maintain their shape throughout wear.

The fabric’s structure and stretch make it perfect for silhouette shaping while ensuring comfort.

- Peplum variations from subtle curves to dramatic flares hold their form beautifully

- Bold colors appear vibrant and saturated on scuba’s smooth surface

- Neckline options like boat necks or cowls remain crisp without sagging

- Sleeve styles from cap to bell maintain their architectural details

Choose fitted patterns that showcase scuba fabric’s body-contouring properties for truly stunning results.

Scuba Fabric Care

You’ll need to maintain your scuba fabric properly to preserve its distinctive structure and elasticity for years to come.

Washing in cold water with mild detergent and avoiding high heat during drying will protect your garments’ shape and prevent damage to the synthetic fibers.

Washing and Drying Scuba Fabric

Your fabric creations deserve proper care to maintain their vibrant appearance and structure.

Correct washing and drying techniques extend your scuba garments’ lifespan substantially.

Follow these washing instructions for pristine scuba fabric:

- Use cold water temperature with mild detergent choice to preserve elasticity

- Skip fabric softeners that break down elastic fibers over time

- Avoid bleach completely as it damages polyester components

- Select gentle cycles to prevent excessive stretching during agitation

- Turn garments inside out before washing to protect the fabric’s surface

For drying methods, air dry flat on a towel to maintain shape and prevent shrinkage.

You can trace the outline on paper beforehand to guarantee correct dimensions during drying.

Though tumble drying seems convenient, even low heat settings can compromise your fabric’s integrity, affecting its performance and appearance.

Ironing Scuba Fabric

Now that you’ve mastered washing your scuba fabric, let’s tackle proper ironing techniques.

When pressing scuba fabric, always set your iron to the lowest heat setting and use a pressing cloth to prevent shine and damage. The fabric’s heat sensitivity requires careful handling: A steam iron can be helpful, but adjustable heat settings are essential to prevent damage.

Remember, temperature control protects your fabric’s elasticity and texture, which is crucial for maintaining its quality and ensuring it looks its best, and this is achieved through careful handling and using the right techniques as outlined in the provided table.

Preventing Shrinkage

After careful ironing, let’s address a common issue: shrinkage. To prevent your scuba fabric from shrinking, always prewash your material in cold water before cutting.

This simple step guarantees your finished garment maintains its intended dimensions. For ongoing care, stick to cold water temperatures when washing and avoid high heat settings in your dryer.

Lay items flat to dry or hang them carefully. Proper storage solutions, away from direct sunlight, will further protect your scuba fabric’s integrity and shape for years to come, ensuring proper storage and cold water temperatures are maintained.

Choosing Right Tools

You’ll need the right tools to successfully work with scuba fabric and achieve professional results.

Selecting appropriate needles, sewing feet, and thread specifically designed for stretch fabrics will prevent damage and guarantee your project maintains its structural integrity.

Which Needles to Use

Now that you’ve mastered proper scuba fabric care, choosing the right needle will make all the difference in your sewing success.

Your needle selection directly impacts stitch quality and prevents unwanted fabric damage. For best results with scuba fabric, consider these options:

- Ballpoint needles (sizes 70/10-80/12) – Push between fibers instead of piercing them

- Jersey needles – Prevent skipped stitches on scuba’s unique texture

- Stretch needles – Perfect for high-stretch scuba variations

- Microtex needles (80/12) – Ideal for precise work on structured garments

Sewing machine needles with rounded tips navigate smoothly through scuba’s knit structure without creating permanent holes. You can find a variety of specialized needle products online.

Regular universal needles can snag your fabric, leading to runs and tears. Switch your needle regularly—a dull one can damage even the sturdiest scuba fabric.

Which Sewing Feet to Use

Why do the right sewing feet matter so much when working with scuba fabric? Choosing the proper presser foot can transform your sewing experience.

| Foot Type | Best For | Key Benefit |

|---|---|---|

| Walking Foot | Thick layers | Prevents shifting |

| Roller Foot | Slippery fabric | Feeds bulky layers evenly |

| Regular Foot | Decorative seams | Keeps seams flat |

| Teflon Foot | Sticky surfaces | Reduces drag |

| Wide Hem Foot | Finishing edges | Creates professional hems |

For best results, use a walking foot when sewing long seams to guarantee layers feed evenly. A roller foot helps manage scuba’s springiness when working with horizontal seams around the body.

Consider using a specialized presser foot for best results. Consider reducing presser foot pressure for multiple layers, and don’t hesitate to switch feet during your project as needed.

For decorative finishes, your standard zigzag foot with a twin needle setup works perfectly. This setup allows for a professional finish and is ideal for scuba fabric projects.

Selecting Ideal Thread

Now that you’ve got the right foot on your machine, let’s talk thread selection—the unsung hero of scuba fabric projects.

Choosing the right thread can make or break your scuba creations:

- Polyester thread is your best friend—it offers strength and recovery that perfectly complements scuba’s stretch

- Thread weight between 40-50 provides ideal durability without being too visible on seams

- Thread color should be matched in natural light, as darker threads can show through lighter scuba fabrics

- Stretch matching is critical—ensure your thread has enough give for the fabric’s movement

- Seam durability improves when you slightly reduce thread tension on your sewing machine

Remember to pair your thread selection with appropriate stretch stitches.

You’ll want to adjust your sewing machine settings for the perfect balance—too tight and seams pucker, too loose and they’ll break during wear.

To prevent snags, using ball point needles is a good idea.

Scuba Fabric Projects

You’ll find endless creative possibilities with scuba fabric’s unique structure and versatility for your next sewing project.

From bold fit-and-flare dresses to structured blazers, this material holds shape exceptionally well while providing the stretch you need for comfortable, professional-looking garments.

Creating Bold Fit-and-Flare Dresses

Now that you’ve gathered your sewing tools, let’s transform that scuba fabric into stunning fit-and-flare dresses.

This fabric’s natural body creates architectural silhouettes without extra underlinings or interfacing.

For perfect scuba fabric patterns that showcase dramatic silhouettes, consider:

- Fabric weight – Medium-weight scuba provides balance between structure and movement, while heavier varieties create more pronounced flares

- Stretch direction – Cross-grain stretch allows comfortable wear while maintaining the dress’s defined shape

- Print scale – Bold, geometric patterns complement the clean lines of fit-and-flare dresses

The fabric’s bounce and stability work like magic for hem finishes, creating crisp edges that hold their shape all day.

Many retailers offer a variety of scuba dress options.

Your scuba dresses will maintain their showstopping silhouette shaping wear after wear.

Making Modern Peplum Tops

Peplum tops showcase scuba fabric’s natural structure, creating defined silhouettes without additional interfacing. The fabric’s unique drape holds the characteristic flare perfectly at the waistline.

When sewing, use stretch stitches for professional results. Consider design variations like asymmetrical hems or color blocking. For embellishment options, try decorative topstitching or statement buttons.

Make fit adjustments by allowing the hemline to fall naturally—scuba’s bounce creates the perfect flare without forcing it. Remember, garment fitting is simpler with scuba fabric’s forgiving yet structured nature.

Consider exploring trendy sewing ideas for additional inspiration, and utilize scuba fabric to create unique designs with a natural flare.

Designing Structured Blazers

While scuba fabric mightn’t seem like a traditional choice, it’s perfect for designing structured blazers that hold their shape beautifully.

- Select patterns with princess seams to maximize scuba’s natural structure while ensuring proper shoulder shaping

- Choose medium-weight scuba (12-14oz) for ideal lapel construction without excessive bulk

- Apply stretch stitches at stress points and consider simple closure options that complement the fabric

- Allow 1/2" extra ease during fitting to accommodate the fabric’s unique properties while planning strategic pocket styles

The key to working with scuba fabric is to understand its unique properties and plan accordingly, ensuring a well-structured and comfortable garment.

Crafting Fashionable Skater Skirts

After mastering structured blazers, you’ll find skater skirts equally rewarding with scuba fabric.

The material’s natural body creates perfect skirt volume without added interfacing.

Select sewing patterns specifically designed for stretch knit fabric, experimenting with different waistband options and hem finishes.

Use a ballpoint needle and stretch stitch for clean seams.

Pattern alterations are simple—scuba fabric‘s stability holds flared silhouettes beautifully while maintaining crisp edges that won’t droop or collapse.

Working With Scuba Fabric

You’ll need to match scuba fabric weight to your project type for best results.

Consider factors like stretch percentage, texture feel, and durability requirements when selecting the right scuba fabric for your specific garment needs, ensuring you choose a fabric that meets your durability requirements.

Identifying Suitable Weights for Garments

After creating exciting projects with scuba fabric, you’ll need to match fabric weight to your garment design for best results.

Selecting the right scuba knit weight influences how your creation hangs and performs. Lightweight scuba (220-250 gsm) offers fluid drape for relaxed tops and dresses, while heavyweight varieties (270-300 gsm) provide structure for blazers and fitted skirts.

- Your fabric thickness should align with both garment type and activity level—a summer dress needs lighter weight than a structured jacket for cooler seasons.

Considering Factors Like Stretch and Texture

When selecting scuba fabric, stretch and texture substantially influence your project’s outcome. You’ll want to analyze both before cutting your first piece.

A fabric’s stretch recovery determines how well it returns to its original shape, while texture impacts both appearance and function.

| Feature | Lightweight Scuba | Thicker Scuba |

|---|---|---|

| Stretch | 20-30% elasticity | 30-40% elasticity |

| Texture | Silky, soft drape | Dense, structured feel |

| Weight | 220-280 GSM | 300-380 GSM |

| Best For | Tops, summer dresses | Blazers, structured skirts |

Evaluating Durability and Maintenance Needs

Evaluating a fabric’s staying power helps determine if your scuba creations will stand the test of time. When properly cared for, scuba fabric offers exceptional longevity expectations and maintenance simplicity.

To assess your fabric’s durability:

- Test washing temperature tolerance on small swatches

- Check stain resistance with common substances

- Examine pilling prevention by rubbing surfaces together

- Verify colorfastness testing with damp cloth rubs

- Learn basic repair techniques for minor damages

These practical evaluations guarantee your scuba garments maintain their structure through countless wears while minimizing fabric care challenges.

Managing Fraying and Raveling Edges

With scuba fabric, you’ll enjoy a significant benefit – it doesn’t fray or ravel. Due to its dense double-knit structure, raw edges remain intact without special treatment.

While edge finishing isn’t necessary for fray prevention, techniques like twin-needle stitching provide professional seam finishes when desired. For clean cuts, simply use sharp scissors – no edge stabilizers required.

Scuba fabric’s structure includes spun polyester with lycra, giving it a unique drape. This built-in raveling resistance makes scuba fabric perfect for beginners avoiding complex binding techniques and experts seeking efficiency, eliminating the need for serger alternatives or traditional overlocking.

Best Practices for Sewing Seams and Joints

Despite scuba fabric’s natural resistance to fraying, mastering proper seam techniques will elevate your projects dramatically.

When joining pieces, use a narrow zigzag or dedicated stretch stitch to maintain joint stability while accommodating movement.

Select a ballpoint needle (70/10-80/12) paired with polyester thread to prevent skipped stitches, and adjust your tension slightly looser than normal and increase stitch length to 3.0-3.5mm.

Though edge finishing isn’t required, consider a clean topstitch for a professional look, and test your seam finishes on scraps first—this small step transforms basic sewing skills into craftsmanship worth showcasing, demonstrating the importance of proper seam techniques.

Frequently Asked Questions (FAQs)

How to sew scuba fabric?

Ready to get started with sewing with scuba fabric?

Use ballpoint needles to prevent snags, set your machine to stretch stitch, and work slowly.

Don’t overstretch the fabric, and use clips instead of pins.

How to Master Scuba fabric projects?

Master scuba fabric projects by using ballpoint needles, testing on scraps first, and sewing with stretch stitches.

Don’t overstretch while working, and remember raw edges won’t fray.

Use clips instead of pins whenever possible, and consider separate lines for distinct ideas to improve workflow.

How do you make a scuba fabric dress?

Choose your pattern, cut fabric with sharp scissors, use ballpoint needles for sewing, apply stretch stitches for seams.

You’ll need clips instead of pins for best results, and finish with low heat pressing, using sharp scissors is not the only consideration for the process.

How do you tame a scuba fabric?

Scuba fabric can seem unruly at first.

Use ballpoint needles to prevent snags, clip instead of pin, employ a walking foot for even feeding, and press with low heat.

You’ll tame it in no time.

What to do with scuba fabric?

You can create structured dresses, flared skirts, fitted jackets, and contemporary activewear with scuba fabric.

Its springy texture maintains shape while offering comfort and stretch.

It’s also ideal for headbands and bags.

How do you iron scuba fabric?

Like walking on thin ice, ironing scuba fabric requires caution.

Use low heat with a pressing cloth to prevent damage.

Avoid direct contact and consider finger pressing as a safer alternative.

How to sew scuba fabric for beginners?

Use ballpoint needles and polyester thread with a walking foot attachment.

Set longer stitch lengths, practice on scraps first, and work slowly without stretching the fabric.

Don’t worry about finishing raw edges.

What to make with scuba fabric for beginners?

Try simple projects like headbands, clutches, or pencil skirts to start. You’ll enjoy working with this fabric’s structure while building confidence. A straight skirt won’t require complex pattern adjustments.

What is the difference between Ponte and scuba fabric?

While Ponte stands firm and rigid, scuba fabric dances with more stretch.

You’ll notice scuba’s smoother surface, springier texture, and greater elasticity compared to Ponte’s stable, structured feel.

Both are double-knit polyester blends.

Does scuba fabric need lining?

Scuba fabric doesn’t require lining due to its thick, structured nature.

It’s opaque, holds shape well, and won’t reveal undergarments.

You’ll save time and maintain the fabric’s natural stretch without additional layers.

Conclusion

Armed with these tutorials, scuba fabric will become your secret weapon in the sewing room.

You’ll create professional garments with structure and flexibility that traditional fabrics can’t match.

Remember to use ballpoint needles, keep temperatures low, and embrace those clean raw edges.

From statement skirts to structured blazers, your scuba fabric projects will showcase your skills while turning heads, and with these techniques, the possibilities are endless when you master these scuba fabric techniques, making you a skilled designer with a professional garment.

- https://www.sewingbeefabrics.co.uk/neoprene-and-scuba-fabric-guide

- https://www.sewdirect.com/blog/sewing-with-scuba-patterns-and-tips-for-success/?srsltid=AfmBOop4TxVoG0aIwJBNSURJrrgOhv_dFUx8D3xceI8vJRMh0h3cEkdr

- https://northshorecrafts.com/how-to-fray-fabric-edges/?srsltid=AfmBOoqv8xz4Roc36SJod1hxYgL3HXc6x7N2ETIZqM61MVXJwMFKEerC

- https://sewcutepatterns.com/blog/understanding-fraying-in-fabrics-and-types-that-resist-it

- https://www.quora.com/How-can-you-keep-fabric-edges-from-fraying-without-hemming