This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You reach for your phone, keys, or wallet dozens of times a day without giving it a second thought. That pocket you depend on stays functional because of a hidden layer most people never notice—the pocket lining.

This inner fabric forms the actual bag where your items sit, protecting both your belongings and the garment’s outer material from constant friction and wear. Without proper lining, pockets stretch out, tear open, and fail within weeks of regular use.

The right pocket lining fabric makes the difference between a garment that lasts years and one that falls apart after a few months. Understanding what pocket lining is and how it works gives you control over your clothing’s durability.

Table Of Contents

Key Takeaways

- Pocket lining is the hidden inner fabric that forms the actual bag where your items sit, protecting both your belongings and the garment’s outer material from friction and wear that would otherwise cause stretching, tearing, and failure within weeks.

- Cotton offers natural breathability and comfort but shrinks 2-5% after washing, while polyester and blends deliver superior durability with less than 1% shrinkage and better abrasion resistance for daily use.

- Match your pocket lining weight and type to your garment—dress pants need smooth 40-70 denier poly-cotton, outerwear requires moisture-resistant ripstop nylon, and knits demand lightweight fabrics that stretch without snagging.

- You can repair small tears with iron-on patches and zigzag stitching or replace entire worn linings by cutting new fabric with proper seam allowances and reattaching with whipstitch or machine stitch.

What is Pocket Lining?

Pocket lining is the hidden fabric inside your pockets that does more heavy lifting than you’d think. It’s what stands between your keys and the outer fabric of your pants, and it’s built to handle daily wear without falling apart.

It works similarly to how lining protects and structures the entire garment, just focused on that one high-use area.

Let’s break down what it is, why garment makers use it, and how it became a staple in clothing construction.

Definition of Pocket Lining

Pocket lining is the inner fabric layer that forms the pocket bag on the inside of your garment. In garment engineering, this lining material creates the closed volume where you place your belongings. Unlike the outer fashion fabric, pocket lining uses specialized pocketing fabrics designed for durability and comfort.

You’ll find it tucked behind pocket openings in trousers, jackets, and skirts—essential for proper pocket construction and textile science. The choice of fabric is vital, considering factors like pocket fabric options to ensure the right balance of durability and comfort.

Purpose in Garment Construction

Beyond concealing what’s inside, pocket lining plays a critical structural role in your garments. Smart fabric selection protects outer material from friction and keeps pocket openings stable during use. Here’s what it does for garment construction:

Pre-washing your pocket lining helps you stabilize fabric before construction and prevents uneven shrinkage that could distort the finished pocket shape.

- Stabilizes seam lines around pocket reinforcement zones

- Balances weight distribution when you carry items

- Prevents outer fabric abrasion at entry points

- Maintains pocket shape through repeated sewing and use

- Delivers smooth access without snagging or chafing

Historical Use in Fashion

Fashion evolution tells a story that’s centuries old. Since the 1600s, your ancestors relied on pocket lining to protect expensive outer fabrics from daily wear. Early cotton and linen textiles shielded fashionable silks and wools in vintage garments.

Since the 1600s, pocket lining has protected expensive outer fabrics from the wear of daily life

By the 1800s, custom-fitted suits demanded structured linings for shape retention. The 20th century brought synthetic options—rayon, then polyester—revolutionizing garment construction through stronger, easier-to-work textile choices in antique fabrics and modern sewing techniques.

Modern sewers often encounter challenges working with delicate synthetic linings, especially when precise seam allowances determine the garment’s final drape and structure.

Common Pocket Lining Fabrics

You won’t find one-size-fits-all fabric for pocket linings. Different materials work better for different jobs, and knowing your options helps you pick the right one for your project.

For durability in high-stress projects, polyester blends resist fraying better than cotton, especially at hand-sewn corners where precision matters most.

Let’s look at the most common fabrics you’ll encounter when working with pocket linings.

Cotton Pocketing

You’ll find cotton weaves offer the most natural choice for pocket lining. This breathable fabric keeps you comfortable without trapping heat or moisture. Cotton twill pocketing weighs between 40 and 100 grams per square meter, providing solid fabric durability for everyday use.

- Natural fibers feel softer against your skin than synthetic alternatives

- Breathability tests show cotton wicks moisture away efficiently

- Pre-washing prevents shrinkage issues during pocket construction

- Cotton blends combine natural comfort with added strength

- Proper sewing techniques extend the life of cotton pocketing

Polyester and Blends

Synthetic materials deliver superior fabric durability when your pockets face daily abuse. Polyester blends combine high strength with abrasion resistance, keeping linings intact through countless wash cycles. You’ll notice polyester mixed with cotton creates a softer feel while maintaining dimensional stability.

Textile innovation now includes recycled polyester options, giving you eco-friendly fabrics that perform just as well. These synthetic materials resist shrinkage better than pure cotton during sewing and garment construction.

Specialty and Technical Linings

Technical pocket linings bring serious performance upgrades to specialized garments. Moisture management fabrics wick sweat away from your skin with hydrophilic finishes that boost spreading speed over 200 percent. Thermal regulation materials use phase change technology to buffer temperature swings during activity.

You’ll find antimicrobial properties in active wear linings that inhibit bacteria, while breathable materials with electric conductivity can route power to devices.

Modern fabrics blend function with form, and understanding technical sewing terminology helps you work with these advanced textiles more effectively.

These textile materials transform pocket lining fabric selection into strategic sewing decisions. The integration of smart textiles, such as those using conductive fabrics, is becoming increasingly important in the development of high-tech clothing.

Key Properties of Pocket Lining

Not all pocket lining fabric works the same way. The right material needs to handle daily wear without falling apart, feel comfortable against your skin, and stay stable through countless washes.

Let’s look at the three properties that separate good pocket lining from cheap fabric that won’t last.

Durability and Strength

You need a pocket lining fabric that can take a beating. Look for materials with high tear resistance and low shrinkage—nylon and polyester blends outperform cotton in abrasion testing.

Fabric finish matters, too. Resin coatings boost durability without stiffness.

Seam reinforcement at pocket openings and stress distribution through double-layer construction prevent fabric failure. Choose wisely, and your pockets won’t quit on you.

Comfort and Smoothness

A rough pocket lining feels like sandpaper against your hand every time you reach in. Fabric softness and surface finish make all the difference—satin weaves and combed yarns reduce friction better than plain cotton.

Smooth texture matters for comfort, especially in dress pants where you’re constantly moving. Polyester blends and modal fibers deliver that silk-like glide without the premium price tag.

Breathability and Shrinkage

Cotton pocket lining fabric breathes better than polyester. Plain weaves deliver 5 to 20 CFM air permeability, while dense synthetics stay below 10. Fabric porosity affects moisture management directly.

Shrinkage control matters too: cotton pocketing shrinks 2–5% after washing, polyester under 1%. Breathability testing and low shrinkage together define fabric properties and selection for durability you can trust.

Choosing Pocket Lining for Different Garments

Your garment type determines the right pocket lining. Different clothes need different fabric weights, textures, and performance features to hold up under use.

Here’s how to match your pocket lining to what you’re making.

Dress Pants and Trousers

Dress pants demand smooth, low-friction pocket fabric that won’t bunch or add bulk. Polyester or poly-cotton blends are ideal—they resist wrinkles and won’t shrink during garment care. Cotton pocketing works too, especially in casual trouser design, but watch for dimensional changes after washing. Your fabric selection matters: aim for 40 to 70 denier weights.

Proper pant construction means reinforcing pocket corners with bar-tacks, keeping seam allowances tight for clean sewing and repairing pockets later.

Jackets and Blazers

Jackets and blazers call for linings that won’t fight your fabric selection or weigh down garment structure. Cupro, lightweight polyester, or satin blends slide smoothly and keep jacket pockets clean inside.

Look for 45 to 100 g/m² weights—they support sewing techniques without bulk. Lining patterns should mirror your shell panels, ensuring proper pocket placement and durability where hands dig in daily.

Outerwear and Sportswear

When you’re building outerwear or sportswear, pocket lining has to handle more than just keys. Choose polyester or nylon blends—they resist moisture, control odor, and outlast cotton in harsh conditions. Look for ripstop weaves or DWR treatments if you need durability in cold, wet environments.

Thermal regulation matters too: breathable linings let sweat escape while keeping hands warm without adding bulk.

Knit Garments and Sweaters

Sweaters and knit garments need pocket lining that moves with the fabric. Use lightweight cotton muslin or rayon blends—they won’t snag on yarn loops or restrict garment stretch. Match lining weight to your knit’s drape so pockets hold their shape without pulling.

Consider these tactics:

- Choose low-friction fabrics to prevent snagging

- Test stretch compatibility before sewing

- Use overlock seams for flexibility

- Skip interfacing on lightweight knits

- Check breathability to avoid trapped moisture

How Pocket Lining is Constructed

Building a pocket lining isn’t complicated, but you need to follow the right steps to make it strong and smooth. The process starts with cutting your fabric and ends with securing it inside the garment.

Here’s how you construct a pocket lining from start to finish.

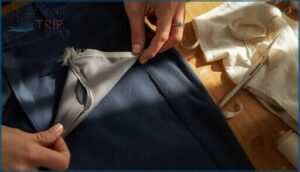

Cutting and Shaping The Lining

You’ll create lining patterns as mirror images of your garment’s front pieces. Cut each piece with 3/8 inch seam allowances, paying attention to fabric grain to maintain proper drape.

Add notches to align with your outer fabric during assembly. You won’t need interfacing on every component—only where your garment design demands extra structure and stability.

Stitching and Assembly Techniques

You’ll secure your pocket lining with a straight stitch along seam allowances, then finish edges with serging or zigzag stitching to prevent fraying. A whipstitch works for hand-sewing delicate areas.

Match your thread to the lining fabric, not the shell. For added durability, reinforce stress points with backstitching.

Edge binding protects high-wear zones on heavy-use pockets.

Attaching Lining to Garments

You’ll attach pocket lining to your garment construction using connected seam finishing along front and back edges. Stay-stitching prevents fabric distortion during handling.

Use stitch lengths between 2.0 and 3.0 mm for balanced durability. Edge stabilization with interfacing methods keeps seams flat and prevents waviness.

Trim allowances, press with a tailor’s ham, and reinforce corners. A whipstitch works for delicate hand-sewing areas.

Repairing and Replacing Pocket Linings

Pocket linings take a beating from keys, coins, and everyday wear. When tears appear or fabric wears thin, you don’t need to toss the whole garment. Here’s how to fix damage, swap out old linings, and keep your pockets working longer.

Fixing Holes and Tears

A small tear doesn’t mean you need to toss your favorite pants. You can fix holes in pocket lining with simple patch repair techniques that restore fabric strength and extend wear time.

- Use iron-on patches with heat-activated adhesives for quick hole mending

- Match thread color to the surrounding lining for invisible seam restoration

- Apply zigzag stitching along tear edges for durable fabric reinforcement

- Add bar tacks at pocket corners to prevent future damage

Replacing Worn-Out Linings

When widespread thinning or multiple tears compromise your pocket lining, full replacement becomes the smarter fix. You’ll need to select lining materials that match or exceed the original fabric’s tear strength and durability testing standards.

Strip out the damaged pocket lining completely, then cut new fabric with proper seam allowances. Use a whipstitch or machine stitch for attachment, ensuring smooth edges that won’t snag. Replacement costs stay low but restore full pocket function.

Preventative Maintenance Tips

A little care now saves you hours of mending later. Your pocket lining fabric deserves attention before tears and stains take control.

- Inspect seams regularly and reinforce pocket corners with small stitches for durability

- Treat stains immediately with mild detergent and proper laundry tips to prevent permanent damage

- Store garments folded or hung in cool, dry spaces using fabric care storage methods

- Keep a basic repair kit ready for quick fixes when repairing becomes necessary

Pocket Lining Trends and Innovations

Pocket lining isn’t just a practical afterthought anymore. Manufacturers now use it as a branding tool, a statement of quality, and even a way to meet environmental standards.

Here’s what’s changing in the pocket fabric industry.

Printed and Branded Linings

You’ll find printed fabrics and branded textiles showing up inside premium garments more often now. Designers use logo embroidery and custom designs on pocket lining to signal quality without changing the outside look.

These fashion branding touches work well in streetwear and luxury pieces. The prints need proper barrier coatings so they won’t rub off onto your skin or clothes during pocket construction and sewing.

Eco-Friendly and Antibacterial Fabrics

Organic cotton and recycled polyester are leading the charge in eco-friendly pocket lining fabric. You’ll find biodegradable fabrics treated with plant-based antimicrobial agents like chitosan that stop bacteria without harsh chemicals.

Green manufacturing processes cut water use and emissions substantially. These eco textiles meet OEKO-TEX standards, proving sustainable materials can deliver antibacterial protection while staying gentle on your skin and the planet.

Advances in Fabric Technology

Smart textiles now bring conductive materials into your pocket lining, letting you shield credit cards from unwanted RFID scans. Nano fabrics with copper-nickel fibers block up to 99.99 percent of radio waves.

High-tech weaves use sustainable dyes and closed-loop lyocell production to cut waste.

These advances in garment construction techniques prove fabric technology can protect your data while respecting the planet.

Frequently Asked Questions (FAQs)

Can you use silk as pocket lining?

Yes, you can use silk as pocket lining. Silk offers a smooth, luxurious texture that reduces friction and wear. However, silk blends with cotton or polyester provide better durability for everyday use.

How much fabric needed for one pocket?

You’ll need about 25 to 5 yards of fabric per pocket, depending on garment type and pocket depth. Dress pants use less; outerwear pockets require more due to reinforcement and sizing considerations.

Does pocket lining color affect garment appearance?

Lining color can subtly shift how you perceive your garment’s tone at seams and openings. Light fabrics show this effect more clearly.

Neutral pocket linings minimize visual disruption, while contrasting colors may alter perceived depth or finish quality.

Should pocket lining match the garment weight?

Perfectly paired pocket lining preserves proper garment drape and seam stability. Match your fabric weight within one or two ounces per yard.

Weight parity prevents puckering, reduces bulk, and ensures lining durability over time.

Where to buy pocket lining fabric locally?

Check local fabric stores in Ashburn for broadcloth and textile materials. Specialty shops and wholesale markets often stock pocket lining fabric. Community resources like sewing guilds can point you toward nearby suppliers.

Conclusion

A torn pocket lining turns a $200 pair of trousers into a liability—keys fall through, seams rip wider, and the garment becomes unwearable. You now understand what pocket lining does, which fabrics hold up longest, and how to repair damage before it spreads.

This knowledge puts durability back in your hands. Choose the right materials, maintain them properly, and your garments will serve you reliably for years instead of failing when you need them most.