This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ve got three main types: straight grain (lengthwise threads running parallel to selvages), cross grain (widthwise threads perpendicular to selvages), and bias grain (diagonal cut at 45 degrees).

Understanding what is sewing grain matters because it affects how your fabric behaves—straight grain provides stability, cross grain offers slight stretch, and bias grain gives maximum stretch and drape.

When you cut pattern pieces, you’ll follow grainline arrows to guarantee proper fit and hang.

Ignoring grain direction can lead to twisted seams, poor drape, and garments that won’t hold their shape.

The selvage edges help you identify straight grain easily.

Mastering grain alignment transforms your sewing from amateur to professional-looking results.

Table Of Contents

- Key Takeaways

- Understanding Fabric Grain

- How Fabric Grain Affects Sewing

- Getting Fabric on Grain

- Importance of Aligning Fabric on Grain Before Sewing

- Techniques for Getting Fabric on Grain: Steam Pressing, Stretching, and Straightening

- Tools That Can Help With Aligning Fabric on Grain

- Tips for Checking and Adjusting Grainline During The Cutting Process

- Benefits of Working With Fabric on Grain for Better Sewing Results

- Workshop and Preparation

- Additional Information

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- You’ll identify grain direction using selvage edges as your guide—straight grain runs parallel to selvages, cross grain runs perpendicular, and bias grain cuts diagonally at 45 degrees between them.

- You must align pattern pieces with grainline arrows to prevent twisted seams, poor drape, and garments that won’t hold their shape over time.

- You’ll achieve professional results by straightening fabric before cutting using steam pressing, gentle stretching, and pulling crosswise threads to ensure proper alignment.

- You can’t mix different grain directions at seams without causing puckering and distortion—always match grainlines where pieces connect for stability and a polished finish.

Understanding Fabric Grain

When you’re sewing, fabric grain acts as your invisible guide that determines how your finished garment will look, fit, and behave.

Understanding fabric grain direction prevents common issues like twisted seams, poor drape, and garments that lose their shape over time, which is crucial for achieving a professional finish and ensuring the garment behaves as intended.

Importance of Fabric Grain in Sewing

Fabric grain acts as your garment’s foundation, determining how clothes hang and move on your body.

Proper grain alignment prevents common sewing disasters while ensuring professional results.

- Grain and fit work together to create garments that flatter your shape

- Seam distortion occurs when you ignore grain direction during cutting

- Fabric drape depends entirely on respecting the fabric’s natural grain structure

Following sewing grain principles transforms amateur projects into polished pieces with enhanced garment longevity.

Impact of Fabric Grain on Garment Outcome

Proper grain direction dramatically impacts your garment’s success.

When you align fabric grain correctly, you’ll achieve professional drape and fit while preventing grain distortion.

Incorrect sewing grain causes twisted seams, poor garment longevity, and compromised visual appeal.

Master grain direction in garment construction for fabric drape that moves naturally with your body.

Types of Fabric Grain: Straight, Cross, Bias

Understanding grain types is like reading a fabric’s blueprint. Straight grain runs parallel to selvages, offering maximum stability for structured garments.

Cross grain runs perpendicular, providing slight stretch for comfort. Bias grain cuts diagonally at 45 degrees, creating flowing drape and maximum stretch.

Each grain direction serves specific sewing purposes, affecting how your fabric behaves and drapes.

Garments requiring curved edges often utilize flexible bias grain to prevent distortion.

Identifying Fabric Grain Through Selvages and Thread Direction

When you’re ready to identify fabric grain, start with selvage identification and visual inspection of thread direction.

The fabric selvage runs parallel to warp threads, which provide stability, while weft threads run crosswise.

Here’s your systematic approach:

- Locate the selvage edges for immediate grain alignment reference

- Test fabric stretch – less stretch indicates warp threads direction

- Pull individual threads to confirm grain direction accuracy

- Examine weave patterns to distinguish between warp and weft threads

This foundation guarantees proper grain alignment for professional sewing results, ensuring a clear understanding of fabric grain through systematic approach.

Pattern Markings for Grainline

Pattern markings serve as your roadmap to successful sewing projects.

The grainline arrow shows exactly how to position pattern pieces on fabric for desirable results. When you align this arrow parallel to the selvage, you’re ensuring proper grain direction throughout your garment.

Pattern layout becomes straightforward when you understand these grainline symbols. Notches and grain work together, helping you match seams while maintaining correct fabric orientation.

Even bias direction pieces have specific markings to guide placement and prevent costly cutting mistakes, which is crucial for successful sewing projects.

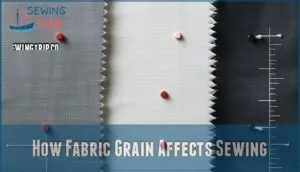

How Fabric Grain Affects Sewing

When you cut and sew fabric, the grain direction determines how your finished garment will hang, stretch, and move with your body.

Understanding grainline becomes essential because it affects everything from seam stability to the overall drape of your project.

Influence of Grainline on Fabric Behavior, Drape, and Stretch

Fabric behavior changes dramatically when you cut along different grain directions.

Understanding grain direction is the secret to transforming amateur projects into professional masterpieces.

The lengthwise grain provides stability and minimal stretch, while crosswise grain offers slight flexibility.

Bias drape creates flowing movement with maximum stretch.

Grain and fit work together—proper grain direction prevents fabric distortion and guarantees seam stability, while incorrect grainline causes unwanted pulling and poor drape, which affects the overall fabric distortion and drape.

Considerations for Sewing With Woven and Knit Fabrics

Woven fabrics behave differently than knits due to their stable grain structure, while knit fabrics offer natural stretch that requires special handling techniques.

When working with these fabric types, you’ll need specific approaches to maintain proper grain alignment and achieve professional results.

Knit fabrics require special attention to stretch and recovery.

- Ballpoint needles prevent snagging knit fibers during stitching

- Pattern weights keep slippery knits flat while cutting

- Elastic tape reinforces knit shoulder seams against stretching

- Short stitch lengths strengthen woven fabric seams

- Leader fabric prevents loose woven fabrics from slipping

Cutting on The Straight Grain for Optimal Results

When you cut fabric on the straight grain, you’re setting yourself up for sewing success.

This cutting method aligns your pattern pieces with the lengthwise grain, ensuring maximum seam stability and preventing distortion during construction.

Professional results depend on proper pattern alignment with grain direction.

Your garments will maintain their shape better, resist stretching, and display improved garment longevity when you follow this fundamental cutting fabric technique consistently.

Understanding selvage edge identification can further improve accuracy, and help achieve professional results with maximum seam stability.

Potential Issues When Different Grainlines Meet at Seams

When different grainlines meet at seams, you’ll face serious construction challenges.

When grainlines fight, your seams surrender – creating pulls, puckers, and twisted chaos that destroys professional finish.

Seam puckering occurs as fabrics with varying stretch properties pull against each other.

This grain mismatch creates uneven drape, compromises structural integrity, and causes twisting garments.

Poor grain matching leads to fabric distortion and warping, making professional results nearly impossible to achieve.

Importance of Aligning Grainline With Garment Design and Prints

Aligning your fabric’s grain line with garment design and prints creates visual harmony and design integrity.

When you match the grain direction properly, patterned fabrics maintain their intended appearance and fabric texture enhances the overall look.

Pattern matching becomes easier when you respect the sewing grain, preventing distorted prints that can ruin your project’s professional finish, and thus ensuring that the fabric’s natural look is preserved with design integrity.

Getting Fabric on Grain

You’ll need to straighten your fabric before cutting to guarantee professional results. Steam pressing, gentle stretching, and pulling crosswise threads help align the grain properly for accurate pattern placement.

Importance of Aligning Fabric on Grain Before Sewing

Proper fabric alignment forms the foundation of professional sewing results.

When you align sewing grain correctly before cutting, you guarantee superior fit and drape while preventing seam distortion.

This vital step maintains structural integrity, enhances visual appeal, and promotes garment longevity.

Smart sewists know that taking time to check grain direction and fabric alignment prevents costly mistakes later.

Techniques for Getting Fabric on Grain: Steam Pressing, Stretching, and Straightening

Steam pressing relaxes fabric fibers, allowing proper fabric grain alignment.

Gentle stretching along diagonal corners corrects grain distortion when steam alone isn’t enough. Straightening methods like pulling crosswise threads create accurate cutting lines.

Proper technique often involves using a specialized pressing cloth for best results.

- Steam pressing: Use appropriate heat settings with pressing cloth to prevent fabric damage while achieving fabric relaxation

- Stretching limits: Apply gentle diagonal pressure from corner to corner, avoiding excessive force that distorts printed designs

- Straightening methods: Pull single crosswise threads from selvage to selvage for precise grain line reference during cutting

Tools That Can Help With Aligning Fabric on Grain

Having the right tools makes fabric alignment simpler and more accurate.

Grid rulers provide transparent guidance for measuring grainlines directly on fabric. Clear acrylic surfaces let you see through to verify alignment without guesswork.

- Grid Rulers – Transparent measuring guides for precise grainline placement

- Rotary Cutters – Sharp wheels that slice clean, straight edges along grain

- Pattern Weights – Heavy objects that hold fabric steady during alignment

- Straight Edges – Long rulers that help establish perfect cutting lines

Consider using grid rulers for sewing to guarantee accurate measurements.

Tips for Checking and Adjusting Grainline During The Cutting Process

Frequently check selvages during cutting to verify they remain parallel and aligned.

Pull a crosswise thread to verify your fabric grain stays straight as you work.

Test fabric stretching periodically—lengthwise grain should feel firmer than crosswise.

Use grainline tools like quilting rulers to maintain pattern alignment throughout the cutting process, preventing costly mistakes, and ensure your fabric stays on the correct grain, with the lengthwise grain feeling firmer than crosswise.

Benefits of Working With Fabric on Grain for Better Sewing Results

Working with fabric on grain prevents common problems like twisted seams and uneven hems.

You’ll achieve seam stability and enhanced drape when your fabric maintains proper alignment.

On-grain cutting guarantees garment longevity by preventing fabric stretching over time.

This attention to fabric stability creates a professional finish with superior comfort fit that moves naturally with your body, ensuring a natural look and feel.

Workshop and Preparation

You’ll get hands-on practice with fabric grain principles at our upcoming workshop on April 13, where you’ll make cloth napkins from start to finish.

This project teaches proper cutting and pinning techniques while reinforcing the importance of careful preparation for professional sewing results.

Mention of Upcoming Hands-on Workshop on April 13

Looking ahead, you’ll gain hands-on fabric grain experience at our upcoming sewing workshop on April 13th.

This practical session offers invaluable skill development through direct experience with lengthwise grain, crosswise grain, and bias grain concepts.

You’ll join our welcoming sewing community while mastering grainline techniques that transform your sewing results.

Workshop Project: Making Cloth Napkins

Your cloth napkin project teaches grain fundamentals through hands-on practice.

You’ll cut fabric squares following the grainline, ensuring lengthwise grain runs straight along napkin edges.

Focus on fabric selection, size variations, and proper corner mitering techniques.

Practice napkin hemming while maintaining grain alignment, then explore design embellishments that complement your crosswise grain choices.

Benefits of Attending a Sewing Workshop for Learning About Fabric Grain

Hands-on experience at a sewing workshop transforms your fabric understanding from theory to practice.

Expert instruction guides you through practical application while you develop skills alongside fellow sewers in a community learning environment. Structured lesson plans guarantee clear learning objectives.

- Expert instruction – Professional guidance on identifying grain direction and proper alignment techniques

- Practical application – Cut actual fabric pieces while learning grain principles through direct manipulation

- Skill development – Practice matching grainlines at seams and troubleshooting common grain-related issues

- Community learning – Share experiences with other sewers and learn from their fabric grain challenges

- Fabric knowledge – Build intuition for how different fabrics behave when cut on various grainlines

Emphasis on The Importance of Cutting and Pinning in Sewing

Accurate cutting and pinning techniques form the foundation of professional-looking garments.

You’ll prevent distortion and achieve perfect seam alignment when you take time with fabric preparation.

Pin pattern pieces following the grainline arrows, guaranteeing grain matching at every seam.

Your careful cutting fabric approach, respecting the fabric grain direction, eliminates puckering and stretching issues that plague rushed projects.

Selecting the right tools guarantees clean cuts, so consider specialized cutting implements.

Reminder to Take Time and Focus on Preparation for Better Sewing Outcomes

Slow sewing starts with mindful preparation—your foundation for success.

Quality materials deserve careful handling to avoid mistakes later.

Follow these preparation steps:

- Press fabric smooth to reveal true grainline direction

- Mark lengthwise grain using selvage as your guide

- Check crosswise grain alignment before cutting

Accurate cutting on proper fabric grain prevents costly errors.

Take time now, save frustration later.

Additional Information

Now you’ll understand the precise roles that lengthwise and crosswise grain play in creating well-constructed garments.

You’ll also learn that selvage can be spelled as "selvedge" — both terms refer to the same finished edge of fabric, which is also known as the selvage.

Definition and Role of Lengthwise and Crosswise Grain in Garment Construction

Understanding lengthwise and crosswise grain transforms your garment construction.

Lengthwise grain (warp) runs parallel to selvage, providing maximum fabric stability and garment durability through stronger thread direction.

Crosswise grain (weft) runs perpendicular, offering flexibility.

When you align grainline correctly, you harness each grain’s strength for professional results.

Visual inspection helps confirm accurate grain identification and is crucial for understanding the importance of garment construction and fabric stability.

Note About Alternate Spelling of Selvage as Selvedge

You’ll encounter both "selvage" and "selvedge" when reading about fabric grain, and both spellings are correct.

The spelling variations stem from regional usage and historical context, with each term referring to the same tightly woven fabric edges that help identify grain direction.

- Spelling Origin: "Selvedge" derives from "self-edge," describing how fabric edges finish themselves

- Regional Usage: American sources typically prefer "selvage" while British texts often use "selvedge"

- Preferred Spelling: Most contemporary sewing patterns and fabric terminology use "selvage"

- Historical Context: Both spellings have coexisted in fabric terms since the textile industry’s early days

Regardless of which spelling you see, these edges remain your best reference point for finding fabric grain.

Frequently Asked Questions (FAQs)

What is grain in sewing?

Grain refers to the direction of threads in woven fabric.

You’ll find lengthwise grain (warp) running parallel to the selvage, crosswise grain (weft) perpendicular to it, and bias at 45 degrees between them.

What does sewing against the grain mean?

Cutting against the grain creates puckering, stretching, and distortion in your fabric. You’ll notice seams that twist, garments that hang poorly, and fabric that loses its intended drape and structure.

What is grain in fabric?

Fabric grain refers to the direction of threads in woven material. You’ll find lengthwise grain running parallel to the selvage and crosswise grain running perpendicular to it.

What are the different types of fabric grain?

Think of fabric as a woven roadmap – you’ve got three main paths to follow.

Lengthwise grain runs parallel to selvage edges, crosswise grain goes perpendicular, and bias grain cuts diagonally at forty-five degrees between them, forming a key concept of fabric structure based on bias grain.

What is a grainline on a sewing pattern?

A grainline is the straight arrow printed on pattern pieces that shows you exactly where to align the pattern with your fabric’s lengthwise grain for proper fit and drape.

What is the difference between fabric grain and lengthwise grain?

Here’s the mystery most sewers don’t realize: "fabric grain" is the umbrella term covering all thread directions,

while "lengthwise grain" specifically refers to the warp threads running parallel to your fabric’s selvage edge.

What is the grain in sewing?

In sewing, grain refers to the direction of woven threads in fabric.

You’ll find lengthwise grain running parallel to selvage edges, crosswise grain perpendicular to it, and bias grain at forty-five degrees between them.

What are the three types of grain in fabric?

You’ll encounter three grain types when working with fabric: straight grain (lengthwise warp threads parallel to selvage), cross grain (crosswise weft threads perpendicular to selvage), and bias grain (diagonal 45-degree angle between them).

Can you sew different fabric grains together?

Sure, you can mix fabric grains like a rebel chef throwing random ingredients together—though your garment might twist like a pretzel.

Match grainlines at seams for stability and prevent puckering.

How does fabric grain affect pattern matching?

Proper grain alignment guarantees pattern elements match seamlessly at seams. When you cut pieces off-grain, patterns shift, creating mismatched stripes, plaids, or prints that appear unprofessional and disrupt visual flow.

Conclusion

Mastering fabric grain is like building a house with a solid foundation—it’s the backbone of every successful sewing project.

Now you understand what’s sewing grain and how it transforms your work from amateur to professional.

You’ve learned to identify straight, cross, and bias grains, use pattern markings correctly, and align fabric properly before cutting.

These techniques guarantee your garments hang beautifully, maintain their shape, and look polished.

Take time with preparation—it’s the secret ingredient that separates good sewers from great ones.