This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You pick up two spools that look identical, but one thread snaps under tension while the other holds firm through a hundred washes. The difference? Thread weight—a number printed on every spool that most sewers ignore until a project fails.

Thread weight determines whether your stitches disappear into silk or sit proudly on denim, whether your seams pucker or lie flat, whether your needle jams or glides. This measurement system controls thickness, strength, and compatibility with fabric, yet it uses backward numbering that confuses even experienced stitchers.

Master thread weight, and you’ll stop guessing why some projects work while others unravel.

Table Of Contents

Key Takeaways

- Thread weight uses backward numbering where higher numbers mean thinner thread—40 wt is thicker than 60 wt, which trips up most sewers until they understand the length-per-mass calculation system.

- Matching thread weight to your fabric type prevents puckering, broken seams, and machine strain—delicate silks need 60-100 wt, everyday cottons work with 40-50 wt, and heavy denim demands 12-30 wt for durability.

- Thread weight locks you into specific needle sizes because fine threads shred in large needles while thick threads jam in small ones—get this pairing wrong and your stitches skip, break, or look sloppy.

- Higher quality thread cuts machine lint by 30 percent and delivers consistent color across dye lots, but it fails if you store it in humid conditions or near UV light that degrades the fibers before you even load your machine.

What is Thread Weight in Sewing?

Thread weight determines how thick or thin your sewing thread is, and it directly affects how your finished project looks and performs.

Getting your bobbin tension and thread weight matched correctly prevents puckering, skipped stitches, and thread breakage during sewing.

The numbering system runs backward from what you’d expect, which trips up most sewers at first. Here’s what you need to know to decode thread weight and use it to your advantage.

Definition of Thread Weight

Thread weight is your roadmap to thread thickness. It’s a thread classification system based on fiber density—the ratio of length to mass. In standard weight systems, higher numbers mean finer threads, while lower numbers signal thicker strands. Thread weight measurement controls every stitch you make.

Here’s what thread weight tells you:

- Visibility – Lower weight numbers create bold, prominent stitches that stand out on fabric

- Strength – Thread thickness directly affects seam durability and stitch integrity

- Compatibility – Weight determines which needles, fabrics, and techniques work together

- Texture – Heavier threads add dimension; finer threads blend seamlessly into your work

- Systems – Tex, Denier, and standard weight all measure the same core property differently

For a deeper understanding of the differences between thread weight and tex systems, it’s helpful to consult conversion charts and guidelines.

How Thread Weight is Calculated

You calculate thread weight using length-per-mass or mass-per-length systems.

In the common wt system, thread measurement works backward: 40 wt means 40 kilometers weigh one kilogram. Tex calculation flips it—Tex measures grams per 1,000 meters, so higher numbers mean heavier threads.

The Denier system uses grams per 9,000 meters. Decitex refines Tex using 10,000-meter intervals. Metric counting divides meters by grams for precise weight conversion.

For a deeper understanding of the different sewing thread numbering systems, explore the factors that influence thread sizing and selection.

Thread Weight Numbering Explained

Now that you understand the calculation, let’s break down what those numbers on your spool actually mean. When you see 30wt, 40wt, or 50wt on thread labeling, the lower number indicates thicker fiber thickness. A 30wt thread is heavier than 50wt.

Thread sizing often includes ply counting—like 40/2—where the second number shows twisted strands. Weight conversion between systems like Tex, Denier, and Decitex helps compare thread measurement across brands.

How Thread Weight is Measured

You can’t pick the right thread until you know how manufacturers measure it. The sewing industry uses several different systems, and each one calculates thread weight in its own way.

Here’s what you need to understand about the main measurement systems.

Weight System (US Standard)

In US standards, you’ll find thread weight numbers that flip common logic: higher numbers mean thinner thread. A 40 wt thread gives you exactly 40 kilometers per kilogram, while 30 wt delivers just 30 kilometers at the same mass—proving it’s thicker. This thread classification system simplifies sewing metrics across brands.

Matching thread weight to fabric density prevents tension issues—this embroidery machine thread guide walks through pairing decisions for stable, professional stitching.

Later, we’ll explore how Tex and Denier measurements compare for thread conversion.

Tex and Denier Systems

Global sewing metrics rely on Tex and Denier for thread density. Tex measures grams per 1,000 meters—Tex 25 weighs exactly 25 grams—while Denier uses 9,000 meters, so a 225 Denier thread matches that same Tex 25.

Higher numbers always mean thicker yarn in both systems. For Tex conversion, multiply Tex by 9 to get Denier; divide Denier by 9 for Tex.

This matters for fabric thickness and needle size pairing.

English Count (Ne) and Metric Count (Nm)

Cotton and yarn suppliers use Ne and Nm count systems to measure thread fineness. English Count Ne tracks how many 840-yard hanks weigh one pound—Ne 40 means finer yarn thickness than Ne 20.

Metric Count Nm uses kilometers per kilogram, so Nm 60 outranks Nm 30 in thread weight precision. Both systems flip the script: higher numbers equal thinner thread, opposite of Tex and Denier.

Using Conversion Charts

Thread comparison becomes straightforward when you use conversion formulas to jump between weight, Tex, Denier, English Count, and Metric Count. Chart limitations exist because twist and finish vary, so always test first.

Here’s what most charts include:

- Weight to Tex and Denier conversions

- Needle selection guides per thread size

- Tension settings recommendations

- Brand-to-brand equivalents

- Project-specific size ranges

Why Thread Weight Matters

Thread weight isn’t just a technical detail—it’s the difference between a seam that lasts and one that falls apart. Choose the wrong weight, and you’ll fight tension issues, broken threads, and stitches that look sloppy or unprofessional.

Thread weight separates seams that endure from those that fail under tension, broken stitches, and sloppy appearance

Here’s exactly how thread weight affects your work and what happens when you get it wrong.

Impact on Stitch Durability

You want stitches that hold, not ones that fail when you need them most. Thread weight directly influences seam durability because thicker threads—say, 30-weight versus 50-weight—pack more fibers into each stitch, boosting thread strength and fabric resistance.

Heavier threads create better seam integrity under stress, while finer threads suit delicate work where stitch longevity depends on reduced abrasion rather than raw tensile force.

Effect on Seam Appearance

A heavy thread creates bold lines that command attention, while fine thread practically disappears into your fabric. Your seam visibility becomes part of the design language when you match thread weight to your vision, affecting fabric drape and visual balance across every inch of stitching.

- Contrast on denim: 12-weight topstitching threads deliver graphic seam lines that define edges

- Blended piecing: 50-weight thread lets fabric patterns stay front and center, not the stitches

- Smooth couture: 80-weight thread gives invisible seams where stitch texture vanishes completely

Control thread weight, and you control whether seams shout or whisper.

Consequences of Incorrect Thread Weight

Get the weight wrong, and your project pays the price. Weakened seams from too-fine thread snap under stress, while frequent breaks and thread shredding slow you to a crawl.

Fabric distortion appears when heavy thread puckers delicate material, and machine strain shows up as skipped stitches.

Thread breaking ruins stitch quality and tanks seam durability—mistakes that turn finished work into waste.

Choosing The Right Thread Weight

Getting the thread weight right isn’t about following rigid rules. It’s about understanding what your fabric needs, what your project demands, and how your needle fits into the equation.

Here’s how to match everything up so your stitches hold strong and look clean.

Matching Thread to Fabric Type

Fabric thread compatibility starts with one rule: match your thread weight to fabric type, not just color.

Fine 60 to 100 weight thread prevents puckering on chiffon and silk, while 40 to 50 weight manages quilting cotton and linen.

Heavy denim and canvas demand thicker 12 to 30 weight thread for fabric seam integrity under stress.

Selecting Thread for Different Projects

Your sewing thread selection depends on project type and stress level. Everyday garments run smoothly with medium 40 to 50 weight threads, balancing strength and flexibility.

Heavy-duty bags and upholstery demand 12 to 30 weight threads that resist friction without snapping. Decorative topstitching uses those same bold threads.

Heirloom work requires fine 60 to 100 weight threads for invisible seams.

Thread Weight and Needle Compatibility

Your thread weight choice locks you into a specific needle size range—skip this step and watch your stitches unravel. Fine 100 weight threads need 60/8 or 70/10 needles to prevent shredding.

Standard 50 weight pairs with 80/12 needles for stitch balance.

Heavy 30 weight and Tex 70 threads demand 100/16 needles for fabric compatibility and thread tension control, ensuring reliable sewing performance.

Thread Types and Their Applications

Thread weight isn’t the only variable you control. The fiber type, intended use, and specific construction of your thread determine how it performs in real-world conditions.

Here’s what you need to know about matching thread types to their best applications.

Cotton, Polyester, and Specialty Threads

Your choice of thread fiber determines whether your seam holds or fails under stress. Cotton thread uses spun staple fibers twisted together, while polyester thread is engineered from continuous synthetic filaments. Cotton mercerization boosts strength and thread colorfastness, but polyester stretch makes it ideal for knits. Here’s your thread fiber comparison:

- Cotton: rigid, absorbent, perfect for stable wovens and quilting cotton

- Polyester: flexible, UV-resistant, manages synthetic blends and high-speed sewing

- Metallic: decorative film-wrapped core for embroidery sparkle

- Rayon: high sheen finish for decorative stitching only

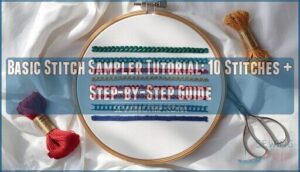

Thread Weight for Quilting, Embroidery, and Serging

Different machines require specific thread weights to achieve clean stitches without tension issues. Most machine quilting works best with 40 to 50 weight thread, providing strength and a polished look on cotton quilt fabrics. Embroidery designs are typically digitized for 40 weight thread as the standard, so switching to 30 weight results in wider, more textured satin stitches. Serger cones usually use 40 weight thread for durable seams at high speeds.

| Technique | Recommended Weight | Common Purpose |

|---|---|---|

| Quilting | 40–50 wt | General piecing and quilting |

| Quilting (decorative) | 30 wt | Bold topstitching lines |

| Embroidery | 40 wt | Standard machine designs |

| Embroidery (fine detail) | 60 wt | Intricate text and filigree |

| Serging | 40 wt | Strong overlocked seams |

When transitioning from 40 to 60 weight embroidery thread, increase design density to ensure the finer thread fully covers the fabric. Heavier quilting thread, like 30 weight, creates visible grooves that emphasize each quilting line. Fine 60 to 80 weight thread adds texture without obvious thread lines in dense background fills. Serger tensions need loosening when using thicker thread in the loopers to prevent tight, rope-like edges. Stitch quality improves when thread weight matches the project’s fabric and design complexity.

Bobbin and Serger Thread Weights

Fine specialty threads keep bulk under control in multi-thread applications. Bobbin Thread usually runs 60 to 90 weight, letting dense embroidery pack closely without puckering or showing on the right side. Serger Thread usually lands around Tex 25 to Tex 27, so three or four cones won’t stiffen edges. Lighter weights improve Stitch Formation and Thread Tension while fitting more Thread Yardage onto smaller Bobbin Sizes, reducing stops mid-seam and keeping Serger Settings balanced.

- Choose 90 weight bobbin thread for intricate designs without underside bulk.

- Use Tex 25 serger cones for flexible, professional overlocked seams.

- Match finer thread weight to smaller needles for smooth stitching.

- Check Denier ratings when comparing brands across different measurement systems.

Thread Quality, Storage, and Maintenance

The best thread in the world won’t perform if you don’t treat it right. Quality matters from the moment you buy it, and how you store and handle your thread directly affects your results at the machine.

Let’s break down what separates premium thread from bargain spools and how to keep every spool working like new.

Importance of High-Quality Thread

You control your results the moment you pick premium sewing thread. High quality thread boosts machine performance by cutting lint buildup around 30 percent, delivers color consistency across dye lots, and ensures thread durability through repeated washing.

Strong thread weights prevent seam failure at stress points, while smooth fiber construction improves sewing efficiency and fabric safety by eliminating snags on delicate materials.

Better thread selection means fewer frustrations and professional finishes.

Proper Thread Storage Tips

Store your thread in cool, dry spaces between 15 and 25 degrees Celsius with 40 to 60 percent humidity control to protect thread quality.

- Keep spools in opaque storage containers with dust protection to block ultraviolet light and prevent color fading

- Label each container by thread weight, fiber type, and color family for quick thread selection

- Stand cones upright in divided bins to avoid tangling and thread organization chaos

- Position storage away from windows, radiators, and humid rooms to maintain thread stability

- Rotate older spools forward so you use them before newer stock

Preventing Thread Breakage and Lint Issues

Match needle size to thread weight: a fine 60 wt thread needs a size 70/10 needle, while heavier 30 wt thread requires 90/14 or larger to prevent shredding.

Check machine tension regularly—overly tight settings snap fine threads during stitch formation.

Use threads with proper lubrication to reduce friction at high speeds, and replace dull needles after 6-8 hours to stop lint buildup in your bobbin case.

Frequently Asked Questions (FAQs)

Is 40 wt thread thicker than 60 wt?

Yes, 40 wt thread is thicker than 60 wt. Think of it like reverse sizing—higher weight numbers mean thinner threads. The 40 wt delivers bolder stitch visibility, while 60 wt provides delicate detail.

What is the best weight of thread for sewing?

For everyday sewing, 40 wt or 50 wt polyester threads deliver reliable strength across most fabric types.

Your needle size and fabric thickness should guide the choice—finer fabrics need lighter threads, while denim demands heavier weights.

Can I mix different thread weights in one project?

You can break the rules and mix thread weights like a rebel with purpose. Combine 40 wt topstitching with 60 wt seams for stitch visibility control, perfect tension balance, and smart fabric compatibility.

Does thread weight affect washing and care instructions?

Absolutely. Thinner threads shred faster under hot water and heavy agitation, while heavier polyester weights handle standard cycles.

Fine embroidery demands cold washes and air drying to prevent Color Fading and thread damage.

How does humidity impact thread weight performance?

Humidity can turn your thread from reliable partner to frustrating enemy. Cotton absorbs moisture, swells in diameter, and increases friction. Polyester stays stable.

Keep your sewing space between 40 and 60 percent humidity for consistent thread performance.

Are vintage threads safe to use in modern machines?

Most vintage threads aren’t safe for modern machines. Fiber degradation makes them brittle and prone to breakage, which clogs tension discs and damages needles. Always perform thread testing with a snap test before sewing.

What thread weight works best for stretchy fabrics?

Stretch fabric demands thread that can bend the rules. You need medium weight polyester, usually 40wt to 50wt, because it balances strength with flexibility for knit seams without stiffening your fabric stretch.

Conclusion

Thread weight is the blueprint between success and frustration. You now control what separates projects that last from those that unravel—matching numbers to fabric, needles to purpose, strength to stress.

The backward logic clicks: higher numbers mean finer threads, lower numbers deliver muscle. Understanding what’s thread weight and why it matters transforms guessing into precision.

Every spool in your hands now carries readable instructions. Stop compensating for the wrong thread. Start building seams that hold.

- https://sewsimplebags.com/everything-you-need-to-know-about-thread-weight/

- https://www.qualitysewing.com/blogs/news/sewing-thread-guide-weights-uses

- https://ylithreads.com/blogs/thread-education/thread-weight-quilting-guide

- https://www.wonderfil.ca/blog/differences-between-thread-weights-where-to-use-them-amp-how-they-look/6/2/2020

- https://www.printful.com/glossary/thread-weight