This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your fabric scissors felt razor-sharp last month. Now they barely glide through cotton without snagging. This isn’t bad luck—it’s materials science in action.

Fabric itself dulls blades faster than most sewers realize, especially when synthetic fibers, dense weaves, and invisible residue gang up on those precision edges. The microscopic damage happens with every cut, accelerated by friction heat and fiber hardness you can’t see.

Understanding what’s attacking your blades—and why dedicated fabric scissors still surrender to dullness—gives you the power to dramatically extend their cutting life and recognize when prevention shifts to repair.

Table Of Contents

- Key Takeaways

- Why Do Fabric Scissors Get Dull Quickly?

- Impact of Fabric Types on Scissor Sharpness

- Consequences of Using Scissors on Non-Fabric Materials

- How Improper Storage Leads to Dull Blades

- Role of Residue and Buildup in Dulling

- Misuse and Mishandling: Key Causes of Dulling

- Effects of Poor Maintenance on Scissor Longevity

- Frequency of Use and Natural Wear Factors

- Preventative Care to Prolong Scissor Sharpness

- When to Sharpen or Replace Your Fabric Scissors

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Fabric itself—especially synthetic fibers like polyester and dense weaves like denim—dulls scissors faster than paper through microscopic friction, heat, and abrasive wear that damages blade edges with every cut.

- Using fabric scissors on non-fabric materials (paper, plastic, cardboard) and cutting over pins or zippers accelerates dulling through micro-chipping, burrs, and edge contamination that no amount of cleaning can reverse.

- Invisible enemies like adhesive residue, lint buildup, moisture exposure, and improper storage (loose in drawers, damp rooms) silently degrade blade sharpness between uses through rust, corrosion, and misalignment from accidental drops.

- Dedicating scissors to fabric only, cleaning blades after each use, storing them in protective cases, and recognizing when sharpening won’t help anymore are the non-negotiable habits that extend scissor life from months to years.

Why Do Fabric Scissors Get Dull Quickly?

You might think fabric scissors dull because you use them too much, but that’s not the whole story. The real culprits hide in how scissor blades interact with different materials at a microscopic level.

When damage goes beyond surface wear, learning how to sharpen fabric scissors at home can restore dulled edges before investing in replacements.

Let’s clear up some common myths and look at what actually happens when metal meets fabric.

Common Misconceptions About Dullness

Why do your favorite shears lose their edge so fast? Scissor mythbusting starts here. Many sewers believe paper instantly ruins fabric scissors, but that’s exaggerated—quality blades tolerate occasional paper cuts. Another myth: dullness always means cheap tools. Even premium shears wear down with normal use.

If you’re wondering how hard sewing really is when your tools fight you, proper scissor care makes a measurable difference.

The truth? Fabric itself, especially synthetics like polyester, can dull blades faster than you’d expect. Understanding real dullness causes transforms your scissor care and maintenance routine. Proper scissor care techniques can also help extend the life of your scissors.

The Science Behind Blade Wear

Now let’s explore what actually happens inside the blade. When you cut fabric, the blade material undergoes microstructure degradation—tiny carbides and metal phases shift under stress. Textile fibers create micro-scratches that become visible edge roll.

Over time, this wear pattern forces home sewers to replace their tools—choosing fabric scissors designed for precision and durability helps delay that cycle.

Why does this matter for sharp blades and scissor maintenance?

- Harder fibers accelerate edge rounding

- Friction generates heat that softens edge alloys

- Wear mechanisms reduce cutting precision

- Proper blade care prevents early degradation

Edge geometry changes with every cut.

Regular cleaning and maintenance of fabric scissors helps preserve that edge precision between sharpenings.

Impact of Fabric Types on Scissor Sharpness

Not all fabrics treat your scissors the same way. Some materials are basically sandpaper for your blades, wearing down that sharp edge faster than you’d think.

Let’s look at which fabric types accelerate dullness and why they’re so tough on your scissors.

Cutting Thick and Heavy Fabrics

Cutting thick fabrics accelerates edge wear on your fabric scissors faster than you’d think. Heavy materials like denim and canvas create intense cutting resistance, forcing the blade angle to work harder with each pass.

Dense weaves generate friction that grinds down sharp blades through micro-abrasion. Layering multiple folds magnifies the problem, bending tips and creating nicks that ruin precision fast.

Effects of Synthetic Fibers Like Polyester

Polyester fibers pose a hidden threat to your fabric scissors. These synthetic strands are harder and more abrasive than cotton, accelerating Polyester Fiber Damage through constant microfiber edge wear.

Each pass creates friction in blade micro-grooves, grinding down the cutting edge. Abrasive cutting risks multiply with polyester blends, forcing you to sharpen more often than silk or wool projects demand. That’s the Synthetic Material Impact on your fabric shear care routine.

Challenges With Dense or Fibrous Textiles

Textile Resistance turns every cut through canvas or denim into a marathon for your blade. Dense weaves force higher cutting pressure, creating Edge Wear that chips away at sharpness.

- Fibrous textures shed strands that clog blade serrations and increase drag

- Thick pile introduces uneven contact, causing micro-damage with each slice

- Heavy resistance raises Cutting Fatigue, demanding more force per inch

- Variable thickness in quilted materials stresses the pivot point

- Interlocking fibers multiply Blade Strain compared to smooth silk

Consequences of Using Scissors on Non-Fabric Materials

You might think it’s no big deal to grab your fabric scissors for a quick job cutting paper or plastic. But here’s the truth: those harder materials wreck your blades faster than you’d imagine.

Let’s look at exactly what happens when you use fabric scissors on the wrong stuff.

Risks of Cutting Paper, Plastic, or Cardboard

You might think paper is harmless, but paper damage sneaks up fast. Each paper cut deposits fibrous particles and glue residues that abrade your fabric scissors. Plastic dulling happens even faster—hard plastics create micro-burrs and sticky residues that hinder edge contact.

Over time, you’ll notice nicks, uneven cuts, or fabric crushing—telltale signs that it’s time to sharpen your scissors properly before the damage becomes permanent.

Cardboard wear accelerates everything: corrugation increases drag, moisture promotes rust, and hidden staples chip blades. Mixed materials spread edge contamination between cuts, forcing you to sharpen more often.

How Hard Materials Damage Blade Edges

Contact with hard substrates triggers blade microchipping you can’t see. Material hardness on the Rockwell scale predicts edge wear patterns—metals, ceramics, and stones transfer localized stress that rounds your edge and destroys the acute angle. Abrasive contact creates burrs that multiply friction, demanding frequent sharpening.

That’s why scissor care and cutting tool maintenance start with proper material selection, not just blade care and maintenance afterward.

How Improper Storage Leads to Dull Blades

You might think storing scissors is no big deal, but where and how you keep them matters more than you’d expect. A drawer full of loose tools or a damp workroom can turn sharp blades dull surprisingly fast.

Let’s look at three storage mistakes that wreck your scissors—and how to avoid them.

Effects of Moisture and Rust

Water is your scissors’ worst enemy. When humidity climbs above 60%, rust can bloom on your blades within just 24 to 72 hours—sometimes faster. That orange-brown creep isn’t just ugly; it’s steel degradation in action.

Blade corrosion creates rough spots that kill your edge and make every cut harder.

Moisture control and rust prevention through proper storage, regular oiling, and immediate drying after use keep your scissors sharp longer.

Damage From Dropping or Misplacement

One drop can wreck your sharp scissors faster than months of normal use. When scissors hit the floor, blade pivots shift out of alignment, tips bend or chip, and screw tension loosens—all invisible damage that shows up as dull performance. Edge chipping from impact creates tiny fractures that spread with each cut.

Check your scissors after every handling error and tighten pivots immediately. Proper scissor care means treating them like precision instruments, not kitchen utensils.

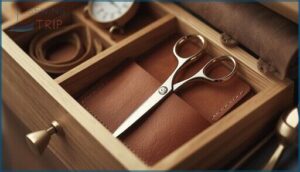

Importance of Protective Storage Cases

Protective storage cases aren’t optional—they’re your first defense against accelerated dulling. A good case or blade guard isolates your fabric shears from humidity, dust, and accidental impacts that degrade edges between uses.

Effective storage solutions include:

- Hard-shell cases with foam inserts that cushion blades

- Magnetic blade guards that snap securely over cutting edges

- Scissor holsters mounted near your workspace for quick access

- Protective wraps made from moisture-resistant materials

Case materials matter: choose options that block moisture while allowing air circulation to prevent rust formation.

Role of Residue and Buildup in Dulling

You mightn’t realize it, but invisible enemies are working against your blades every time you cut. Sticky residues and tiny fibers cling to the cutting edge, creating a barrier that prevents clean slicing.

Let’s look at the two biggest culprits that quietly steal your scissors’ sharpness.

Fabric Glue and Tape Residue

Every time you cut fabric with glue or tape residue, you’re coating your blades with a sticky film. This adhesive buildup doesn’t just slow your cuts—it attracts lint and creates micro-abrasions that accelerate edge wear. Tape buildup hardens under friction, while solvent-based glues can actually etch the blade surface, causing permanent damage to your textile scissors.

Adhesive removal isn’t optional—it’s essential maintenance for your fabric cutting tools.

| Residue Type | How It Transfers | Impact on Blades |

|---|---|---|

| Fabric Glue | Cuts through treated seams | Creates sticky film reducing blade travel |

| Tape Adhesive | Direct contact during cutting | Attracts fibers, forms tacky buildup |

| Solvent-Based Glue | Cutting coated materials | Hardens and micro-etches blade surface |

| Mixed Residue | Accumulated use over time | Uneven blade contact, inconsistent cutting |

Accumulation of Lint and Fibers

While adhesive gunk is obvious, lint and fibers are sneakier culprits. High-pile fabrics shed microfibers that create a film on your blade surfaces, triggering microscopic abrasions that dull your fabric scissors faster than you’d think.

This fiber adhesion clogs blade gaps and increases friction during fabric cutting. Blade clogging varies with textile type—fuzzy materials produce more fabric residue than smooth weaves.

Regular lint removal after each sewing experience keeps your cutting tools performing precisely.

Misuse and Mishandling: Key Causes of Dulling

You can baby your scissors with perfect storage and cleaning, but one wrong move with your hands undoes it all. Misuse is the silent saboteur—the accidental blade bump, the lazy cutting habit, the “just this once” decision that chips away at sharpness.

Let’s break down the three most common ways your own actions are working against you.

Cutting Over Pins or Zippers

Cutting fabric over pins or zippers invites disaster for your blades. Those metal obstacles aren’t just inconvenient—they’re edge destroyers. Here’s what happens when you ignore them:

- Pin Damage scores microscopic grooves into blade edges from rare metal impurities

- Zipper Safety violations create edge burrs when metal teeth meet sharp cutting edges

- Blade Chipping accelerates with each obstruction you slice through

- Scissor Protection demands using seam rippers near zippers instead

- Pin-free cutting techniques preserve sharpness far longer than careless passes

Remove those pins first.

Incorrect Cutting Techniques

Beyond pins and zippers, how you actually move your scissors matters enormously. Slashing through fabric while it’s stretched too tight compresses fibers against the blade, accelerating edge wear. Gripping scissors wrong throws off blade alignment during every cut. Rapid, forceful opening and closing creates tiny corrugations along the edge—micro-damage that accumulates fast.

Your cutting speed and fabric tension control how long sharpness lasts.

| Error | What Happens | Prevention |

|---|---|---|

| Cutting on the bias without stabilizing | Zigzag edges and fraying | Pin fabric flat first |

| Slipping fabric under blade | Uneven, jagged cuts | Mark guidelines clearly |

| Wrong-hand grip | Inconsistent blade alignment | Match scissor to dominant hand |

| Taut fabric tension | Compressed dulling | Let fabric rest naturally |

| Forceful, rapid motions | Edge micro-corrugations | Use smooth, controlled strokes |

Blade Misalignment From Accidents

One careless drop can ruin your scissors forever. When fabric shears hit the floor, blades bend and lose their parallel alignment, creating uneven contact that dulls edges fast. You’ll notice snagging instead of clean cuts.

Fixing this requires pivot adjustment and careful blade realignment—sometimes even professional sharpening methods.

Accident prevention beats repair every time: store scissors flat, handle them deliberately, and never leave them near table edges.

Effects of Poor Maintenance on Scissor Longevity

You wouldn’t skip oil changes for your car and expect it to run forever. Fabric scissors work the same way.

Here are three maintenance mistakes that cut your scissors’ lifespan short.

Neglecting Cleaning Routines

Your blades don’t dull from cutting alone—they dull from what you leave behind. Lint accumulation and fabric fiber buildup create drag that wears edges faster than heavy use. Skipping cleaning routines accelerates this damage:

- Residue buildup from adhesives masks sharp edges and reduces cutting efficiency

- Rust prevention requires removing moisture after each use—pitting destroys blade geometry permanently

- Debris between blades causes micro-scratches that degrade precision

Regular fabric scissor maintenance preserves sharpness measurably. Make sewing tool care a habit, not an afterthought.

Lack of Oiling and Lubrication

Often overlooked, blade lubrication is your secret weapon against premature dulling. Regular oiling creates friction reduction between metal surfaces, preventing the micro-tearing that kills sharp edges. Without proper corrosion prevention through oil types suited for steel, moisture triggers rust—and rust means permanent damage.

Smart maintenance schedules for sewing tool care include pivot-point lubrication after every major project. Your fabric scissor maintenance routine isn’t complete without it.

Ignoring Regular Inspections

Skipping inspection schedules is like driving without checking your gauges—you won’t spot trouble until it’s too late. Regular edge monitoring catches micro-chips and rust before they wreck your blades.

Pair sharpness tests with routine tool maintenance to extend scissor longevity considerably. Visual checks reveal alignment issues that accelerate blade wear, so make inspections part of your scissor maintenance and care routine. Your shears will thank you.

Frequency of Use and Natural Wear Factors

Even the best fabric scissors won’t stay sharp forever. The more you cut, the faster your blades lose their edge—it’s simple physics at work.

Let’s look at how your sewing habits and the passage of time both play a role in wearing down those blades.

High-volume Sewing and Crafting

If you’re churning through batch production or marathon sewing sessions, your fabric scissors face relentless blade engagement. Frequent cutting of multiple fabric layers accelerates edge wear dramatically—sometimes within hours of continuous crafting tools use.

That’s why sewing efficiency suffers when you skip regular sharpening scissors routines. Proper scissor ergonomics and mindful fabric handling extend blade life, but high-volume work demands consistent sewing tool maintenance to sustain cutting performance.

Time-based Edge Degradation

Even with perfect care, your scissors won’t stay razor-sharp forever. Edge Wear Patterns emerge from micro-abrasion during each cut—usually 5,000 to 10,000 cycles before noticeable Metal Fatigue and dullness appear.

Even perfect care can’t prevent edge wear—scissors naturally dull after 5,000 to 10,000 cuts through fabric

Blade Geometry and steel hardness affect Sharpness Retention, while humidity accelerates Corrosion Effects on high-carbon blades.

Regular Edge Sharpening and proper Scissor Sharpening Techniques restore Cutting Performance, but time-based degradation is inevitable.

Preventative Care to Prolong Scissor Sharpness

You’ve learned what dulls your scissors—now let’s talk about keeping them sharp in the first place.

A few simple habits can add years to your blades and save you from constant resharpening. These three strategies form the foundation of scissor care that actually works.

Dedicating Scissors to Fabric Only

Your fabric scissors deserve one job: cutting fabric. Mixing tasks with paper or plastic invites dulling from adhesives and coatings that cling to blades. Keep your cutting techniques sharp with these Sewing Scissor Care Tips:

- Label your fabric scissors clearly with colored tape

- Store them separately from general-purpose shears

- Pair them with a fabric-only cutting mat

- Audit your tool organization monthly to maintain discipline

Proper Cleaning After Each Use

Wipe your blades clean with a soft cloth right after cutting—lint and fabric residue cling fast. Use mild soap or a fabric-safe solvent to dissolve stubborn adhesive, then dry thoroughly to prevent rust.

Inspect for nicks while you’re at it. A light oil on the pivot keeps things gliding smooth.

These blade maintenance habits beat any scissor sharpening methods you’ll find later.

Safe Handling and Storage Tips

Beyond cleaning, your storage habits determine blade longevity. Drop your scissors once and the pivot can misalign, causing uneven edge wear that no sharpening stone will fix.

Protect your investment with these cutting safety and blade protection practices:

- Store scissors in a dry case or sheath, never loose in humid drawers

- Keep blades closed to prevent nicks from other metal objects

- Hang on a dedicated cutting tool maintenance rack, away from children

- Inspect storage spots monthly for rust or moisture damage

- Use silicone sleeves for handle maintenance and grip preservation

Proper tool organization beats frequent scissor sharpening methods.

When to Sharpen or Replace Your Fabric Scissors

Even sharp scissors won’t last forever, and knowing when to act saves you from frustration mid-project. You need to catch the warning signs early, understand your sharpening options, and recognize when a blade has reached the end of its life.

Let’s break down how to make smart decisions about maintenance and replacement.

Recognizing Signs of Dullness

Your scissors whisper warnings before they quit on you completely. Watch for increased cutting resistance—when fabric fibers drag instead of slicing clean. Check for fraying or micro-tears along cut edges. Run your thumb gently across the blade during edge inspection to feel nicks.

When blade performance drops and dull scissors require real muscle to cut, you’ve ignored the dullness indicators too long.

Effective Sharpening Methods

Restore your blades with the right sharpening tools, not guesswork. Use a dedicated fabric scissor sharpener or whetstone to rebuild edge integrity without stripping metal. Hold the blade at a consistent 25–30 degree angle during blade sharpening—this precision matters for clean cuts.

- Run the blade along a fine ceramic rod in smooth, controlled strokes

- Apply light pressure to avoid micro-chipping the edge

- Sharpen both sides evenly to maintain balance

- Test on scrap fabric after sharpening techniques restore the edge

- Consider professional services for curved or severely damaged blades

Avoid generic knife sharpeners—they’ll wreck your scissor maintenance efforts.

Knowing When Replacement is Necessary

Sometimes even the best scissor sharpeners can’t save your blades. When dullness indicators persist after multiple sharpening techniques, replacement is smarter than endless maintenance. Watch for these blade failure signals:

| Replacement Signs | What Happens | Your Next Step |

|---|---|---|

| Chipped or bent edges | Cuts fray fabric badly | Replace immediately |

| Chronic misalignment | Blades catch mid-cut | Check pivot; likely replace |

| Rust or corrosion spots | Sewing tool maintenance fails | Assess damage severity |

| Poor sharpness tests results | Fabric scissor sharpening yields temporary fix only | Budget for new scissors |

Track your scissor lifespan with performance logs. When dull scissors refuse improvement despite proper care, you’ve reached the endpoint.

Frequently Asked Questions (FAQs)

Can using fabric softener dull fabric scissors?

Yes, fabric softener residue can gradually coat your blades, attracting lint and creating drag that dulls scissors over time. Regular cleaning and avoiding treated fabrics help maintain scissor blade sharpness.

Should scissors be sharpened before first use?

Most high-quality fabric scissors arrive with a factory edge optimized for cutting, so initial sharpening isn’t necessary.

Pre-use blade inspection helps confirm readiness, but avoid early sharpening—it may void your scissor warranty.

Does cutting wet fabric damage scissor blades?

Cutting wet fabric promotes rust on blade materials when moisture lingers.

Water accelerates corrosion control challenges, so dry your fabric scissors immediately and apply light oil for blade care and peak cutting performance.

Are expensive scissors immune to dulling problems?

Even professional-grade fabric scissors with premium steel quality and optimized blade geometry experience dulling. Enhanced edge retention extends sharpening frequency, but no scissor material eliminates wear.

All scissors eventually need sharpening.

Conclusion

Your fabric scissors are like high-performance athletes—they need the right conditions to stay sharp. Fiber friction, residue buildup, and those sneaky non-fabric cutting detours all take their toll.

Dedicate your blades to fabric alone. Clean them after every project. Store them properly. These simple habits transform scissor care from guesswork into a predictable system.

Sharp tools don’t happen by accident—they’re the result of intentional choices you make every single day.