This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Concretely speaking, in its functioning process, the sewing machine coordinates the movement of the needle with the feeding of cloth and the adjustment in thread tension to produce a variety of stitches, all uniformly done.

This guide will explain in detail essential components such as the needle, bobbin, and feed dogs and their functions. Knowing these mechanics will give you appreciation and confidence while operating your sewing machine effectively

Table Of Contents

- Key Takeaways

- How Does a Sewing Machine Work?

- The Sewing Machine Mechanism

- The Power Source and Drive Mechanism

- The Stitching Cycle and Power

- The Main Parts of a Sewing Machine

- The Basic Working Principle

- The Needle Mechanism

- The Bobbin and Shuttle Mechanism

- The Feed Dog Mechanism

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- A sewing machine’s needle and hook dance together to form loops of thread, creating stitches that hold your fabric together like a cozy hug.

- The feed dogs are the tiny teeth that gently guide your fabric through the machine, like a shepherd herding sheep.

- The tension dial is the master of thread control, ensuring your stitches are neither too loose nor too tight, like Goldilocks finding her perfect porridge.

- The stitch adjustment dial lets you customize the length of your stitches, from tiny baby steps to giant leaps, depending on the fabric and the look you want

How Does a Sewing Machine Work?

A sewing machine works by coordinating the up-and-down movements between the needle, thread, and fabric to form stitches. You control it with a pedal that powers an electric motor, which drives a belt connected to the hand wheel. This rotation moves the needle up and down. The needle mechanism includes a take-up lever and wheels connected to a crankshaft, through which the needle is efficiently pushed through fabric.

Underneath, the bobbin and shuttle mechanism works to loop the thread on the lower side with the upper thread. The feed dogs pull the fabric through, and the tension regulator achieves smooth stitching.

Well, stick around if you would like more details just like this!

The Sewing Machine Mechanism

You’re about to learn how a sewing machine’s mechanism creates stitches using two threads. The machine’s electromechanical design synchronizes the stitching process with fabric movement, resulting in a uniform line of stitches

Double-Threaded Stitching

Be amazed at how the sewing machine does its magic with double-threaded stitching. It’s an intricate dance of upper thread and bobbin thread working in harmony. As the needle plunges through the fabric, carrying the upper thread with it, a loop is created that will be caught by the bobbin hook below.

• The tension regulator will ensure that both threads engage each other perfectly.

- A well-placed hook catches the upper thread loop

- The upward motion of the needle tightens the stitch.

Synchronized Stitching and Fabric Motion

You’ve seen how a double-threaded stitch forms, but there’s more to it. In a sewing machine, everything works in order.

With the needle dancing up and down, it’s matched with the perfect harmony of the feed dogs, moving the fabric forward, which enables each stitch to fall into place.

Timing on the take-up lever is critical: It works with the stitching mechanism to maintain tension while adjusting for thickness in the fabric

Electromechanical Design

Your sewing machine’s electromechanical design is a marvel of engineering. It combines an electric motor with mechanical parts and a circuit board for precise control.

The motor powers the threading mechanisms, while the circuit board manages stitch adjustments and the reverse stitch button. This clever design allows you to work with various fabric types and tackle creative projects with ease.

Regular machine maintenance keeps this intricate system running smoothly

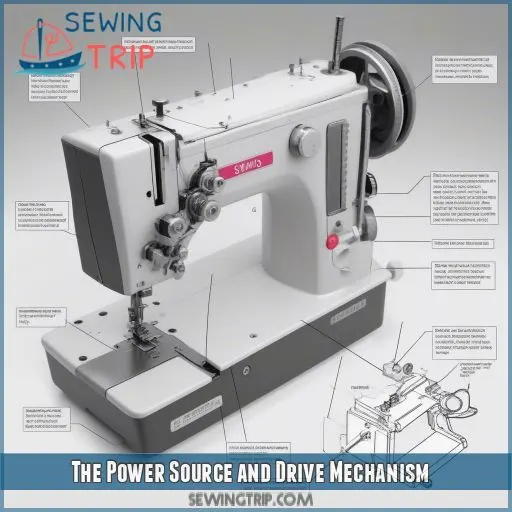

The Power Source and Drive Mechanism

You’ll find that a sewing machine’s power source is an electric motor controlled by a foot pedal. This motor’s rotational energy is transferred through a belt to the hand wheel, which then drives the various mechanisms responsible for stitching and fabric movement

Electric Motor Powered by Pedal

Now that you understand how a sewing machine works, let’s discuss the power source. I’ll discuss your sewing machine being equipped with an electric motor that’s controlled using a foot pedal.

• Foot controller controls speed

*Motor converts electrical energy to mechanical motion.

*The drive shaft rotates, powered by the motor.

Belt transfer system initiates movement.

- Power transmission activates all mechanisms

You’re in control with the stitching speed adjusted by the simple press of a foot. It’s just like driving a car, but on fabric!

Belt Connects Motor to Hand Wheel

Now that you have your motor purring let’s couple it to the handwheel. These two are connected with a sturdy, usually rubber or leather, belt.

How long this belt lasts smoothly depends on its tension and proper alignment. You’ll be asked to maintain it occasionally by checking the wear and tear.

When finally worn enough to replace, ensure that you get the appropriate one for your machine’s pulley system

Transmission of Movement to Stitching and Fabric Motion

Once the hand wheel’s spinning, it’s time for the real magic to begin. The gear system kicks into action, transferring power through a network of belts, drive shafts, and cranks.

This intricate dance of motion propels the needle up and down, while simultaneously moving the presser foot and fabric forward.

The cam mechanism orchestrates the lock stitch formation, all happening just above the throat plate

The Stitching Cycle and Power

You’ll find that a sewing machine’s stitching cycle speed depends on its power, with low-end models running at about 600 rounds per minute. Higher-end machines can stitch twice as fast, and more powerful motors allow for stronger needles that can handle thicker fabrics

Complete Stitching Cycle Depends on Machine Power

The power of your sewing machine directly impacts its stitching cycle. You’ll notice that different machines can handle varying workloads. Here’s what affects your machine’s performance:

- Motor efficiency: More powerful motors can drive faster stitching

- Stitch speed: Higher-end machines can create up to 1200 stitches per minute

- Power requirements: Heavier fabrics and multiple layers need more juice to stitch through

Needle Strength and Thick Fabric Stitching

Knowing how a sewing machine works, one can see that there’s much needed in terms of needle strength. These are necessary and more so while dealing with thick fabrics.

High-power motors make it possible to use stronger needles that can pierce heavyweight materials, making solid seams. This reaches as far as industrial applications, where double-threaded stitching plows through multiple layers of heavyweight material.

With electronic strides, today’s machines glide through anything from the most delicate silks to sturdy denim, all to make your sewing projects much more accessible to execute

The Main Parts of a Sewing Machine

Knowing how a sewing machine works requires you to understand the major parts. This comprises a bobbin, a bobbin case, a presser foot, a needle clamp, and a throat plate. These are combined to form perfect stitches in most cases.

Bobbin

You have probably heard of a bobbin, but did you learn about the significant function it furthers in your sewing machine? This is one small spool that holds the lower thread, which cooperates with the upper thread to form stitches. Here is what you should know about bobbins:

• They come in different sizes to suit different machines

- Proper winding for smooth operation

• Contribute towards quality of stitches by correct tension

- Need regular inspection for optimal performance

Mastering how to use the bobbin is truly a prerequisite to unlocking your sewing potential.

Bobbin Case

The bobbin case of your sewing machine is its unsung hero since it holds the bobbin, and there’s always tension for your bobbin thread.

You’ll also notice varied bobbin sizes to ensure you’re using the correct ones for your sewing machine.

Wind your bobbin tightly, but don’t forget about the tension within the bobbin case since this plays a critical role in creating perfect stitches.

Learn to master this component and unleash your sewing skills as you learn

Presser Foot

The presser foot is designed to keep the fabric in place for you while sewing. It uses light pressure that keeps the feeding along through the machine smoothly.

Several types of presser feet allow for fabrics of varying kinds and tasks, from zippers to buttonholes.

Adjust the pressure of the presser foot for even stitching, but first, accessories like the quilting foot can increase those capabilities enormously

Needle/Needle Clamp

The needle and needle clamp are pivotal to sewing precision. The needle clamp secures the needle firmly, ensuring accurate needle movement. As the needle penetrates fabric, it interacts with the thread to form stitches. Choosing the right needle size and material, such as stainless steel or titanium, is essential for successful sewing and fabric compatibility

Throat Plate/Needle Plate

Next in line behind the needle/needle clamp is the throat plate. This is located under the needle and is important for stitch quality and safety. The throat plate includes an opening for a needle; the shaft travels through this and is kept on a specific path. Let’s break it down:

- Fabric supports: Reduces gathering.

- Guides thread: Holds for a straight stitching.

- Feed dogs protection: Prevents damage.

- Needle selection: Allows for different size needles

The Basic Working Principle

The most basic working principle of a sewing machine includes the following:

- The mechanism of the needle

- The mechanism of the bobbin and shuttle

- The feed-dog mechanism

- The stitching mechanism

This is all combined:

- The rising and falling of the needle

- Rotation of the bobbin and shuttle

- Pulling of fabric through the feed dogs

- Tension regulator to have the top thread tight enough for a clean stitch

Needle Mechanism: Raises and Lowers Needle

The mechanism of the needle raises the needle up and down. A particular type of rotary action reaches the needle bar through connected wheels, with a crankshaft, which converts such rotary motion into reciprocal action. Take-up levers control the upward and downward movement of the needle to allow smooth running. The speed, its placement, and lubrication are essential for the efficiency of the needle in work. Various types of needles are used for multiple fabrics and works.

| Aspect | Description |

|---|---|

| Movement | Raises and lowers |

| Speed | Adjustable on different fabrics |

| Positioning | Precise for accurate stitching |

| Types | Vary for specific materials |

| Lubrication | Needs smooth operation |

Bobbin and Shuttle Mechanism: Rotates Faster Than Needle

This bobbin and shuttle mechanism is what makes stitch formation possible.

The shuttle hook rotates at a much higher speed than that of the needle, quickly catching the upper thread loop.

The velocity is such that it allows perfect looping of the threads to balance tension in stitches.

Here, your machine’s bobbin speed could make all the difference to ensure smooth and consistent stitches in every cycle, all contributing to flawless sewing results

Feed-Dog Mechanism: Pulls Fabric Through

It is the feed-dog mechanism, the shape of which is of small-sized teeth, that’s responsible for the pull of fabric through the machine.

Proper tension of the fabric and the shape of the feed-dog set facilitate its smooth running. This requires regular maintenance concerning its lubricating frequency and cleaning techniques so that jamming doesn’t occur. The timings followed for its maintenance ensure that the feed dogs work briskly, back and forth, moving the fabric, thereby dispensing it at a perfect stitch

Stitch Mechanism: Creates Stitches

The stitch mechanism is the heart of your sewing machine, creating those perfect stitches one by one. As the needle rises and falls, the shuttle hook catches the thread loop, locking the top and bottom threads together. This synchronized dance of needle, thread, and fabric is what brings your sewing projects to life

Tension Regulator: Controls Top Thread Tension

The tension regulator is your overall control for the top thread tension. It has within it a tension dial for options in tension settings. You can also fine-tune this slightly to set the thread control so that your stitches lock together and create a strong, even seam every time.

The Needle Mechanism

The needle mechanism of your sewing machine is based on a system of wheels connected to a crankshaft, ending with the needle clamp and the needle itself. There’s also the take-up lever, which plays a vital role in the up-and-down motion of the needle, hence ensuring smooth, bunched, and accurate stitch formation.

Wheels Connected to Crankshaft

Now, let’s move the crankshaft to bring the needle mechanism alive.

The up-and-down motion of the crankshaft is driven through crankshaft wheels that function as the engine. As these wheels rotate, the crankshaft converts their action from one of rotary motion into reciprocal action. This is very useful as the other end of the crankshaft is coupled to the take-up lever to precisely control the needle

Crankshaft Attaches to Needle Clamp and Needle

The crankshaft is attached to the needle clamp and the needle, which converts rotary motion into reciprocal motion. This link with the crankshaft is important in the movement of a needle that provides accurate stitching. Key points:

- Needle clamp function: This holds the needle firm.

- Crankshaft connection: Provides uniform motion to the needle.

- Rotary to Reciprocal Motion: Smooth and efficient in its operation.

We then examine the crucial take-up lever role in controlling the movement of the needle.

Take-up Lever Controls Needle Movement

The take-up lever moves the needle; it changes the rotary motion made by the crankshaft into reciprocal motion.

This lever, hooked up to the crankshaft, will glide your needle smoothly up and down so your thread will pass through the fabric without a fiddle.

As it goes up and down, it participates in that complicated, coordinated dance that results in your perfect stitch

The Bobbin and Shuttle Mechanism

The bobbin holds the thread for the underside of the stitch and is secured in the bobbin case. The shuttle rotates rapidly, with its hook catching the top thread loop, assisting in forming each stitch

Bobbin: Spool of Thread for Underside of Stitch

This holds the bobbin thread used on the underside of your stitch. The machine ties a knot with the bobbin thread to the top thread as it stitches. To run this machine problem-free, you must:

- Wind the thread correctly on the bobbin.

- Check the tension of your bobbin first.

- Always use a bobbin case of correct size

Bobbin Case: Holds Bobbin

This case keeps the bobbin snug to provide a smooth thread supply.

It’s designed according to the shape of a particular bobbin and is usually made of metal or plastic.

As such, this case offers a place for storing the bobbin but also serves an essential purpose during replacement.

Proper bobbin winding is crucial to prevent thread jams and ensure consistent stitches

Shuttle: Rotates and Has Hook on End

The shuttle rotates at high speed, providing smooth interaction of threads with a hook at its end. Rotation of the hook is significant in holding thread loops formed by the needle. Its perfect performance requires frequent tension adjustments and regular service maintenance for lubrication purposes. This will keep it sewing smoothly without jamming threads and clean stitches.

Hook Passes Through Loop Made by Top Thread

The hook of the sewing machine passes through the top thread loop, following a similar path as that of the hook thread. This hook catches the thread by forming a lock stitch due to its exact shape at the end of the hook tip.

Proper lubrication inside the hook allows for smooth movement, and durable material, like stainless steel, improves the practicality in performance further. This synchronization forms secure stitches every time

The Feed Dog Mechanism

The feed dogs are small teeth that pull fabric through the sewing machine. An egg-shaped wheel rocks back and forth, while a crank mechanism moves the feed dog up and down, ensuring smooth fabric motion during stitching

Feed Dogs: Small Teeth That Pull Fabric Through

The feed dog teeth hold the material under the needle and advance it with great accuracy. These minute teeth act in a reciprocating fashion for smooth control of the movement of fabric, well coordinated with the action of the needle.

The pressure of the feed dogs can be adjusted for different materials. Proper timing of feeding dogs is equally essential for uniform stitch formation. There are different kinds of feed dogs available for various types of fabrics and sewing applications to enhance their versatility

Egg-shaped Wheel Rocks Back and Forth

This feed dog mechanism has an oval wheel in the center that rocks from side to side. In doing so, it produces a reciprocating action that draws the fabric through the machine. At the same time, the rocking action drives the small, serrated feed dogs that grip the fabric and move it incrementally with each stitch. The result is smooth, controlled feeding of the material through for sewing.

- The oval-shaped wheel provides the shuttle with the oscillating motion to drive the feed dogs.

- The feed dogs hold on to the fabric and pull it through the machine with every stitch

This synchronized movement provides for even, continuous feeding of the material.

- The reciprocating action of the feed mechanism is one of the primary conditions for correct stitching.

Crank Mechanism Moves Feed Dog Up and Down

The feed dog mechanism can be considered the unsung hero of your sewing machine. In an egg-shaped wheel, it rocks back and forth, moving the feed dog teeth in a choreographed dance that gently guides your fabric through the stitching. This crank-driven motion ensures that your material, with every stitch, moves a little ahead to create a seamless finish.

| Feed Dog Motion | Feed Dog Teeth | Rocking Motion |

|---|---|---|

| Synchronized | Gentle Guidance | Egg-Shaped Wheel |

| Fabric Progressive | Stitching Process | Crank-Driven |

Frequently Asked Questions (FAQs)

How does a sewing machine work step by step?

A sewing machine works by the motor driving the needle mechanism and feed dogs. The needle pushes the thread through fabric, the shuttle hook catches the thread loop, and they form a stitch that’s pulled tight

How did the sewing machine work?

A sewing machine works by using an electric motor to drive a needle that pushes thread through fabric, while a shuttle and feed dogs synchronize to create stitches, locking upper and lower threads together efficiently

How does a mechanical sewing machine work?

It has mechanisms that pump the heart of a sewing machine into the rhythm of a symphony between a needle thread, and fabric. Unleash its power at your fingertips, and let the machine do its magic.

How does a sewing machine sew clothes explain?

You use a sewing machine to sew by feeding fabric under the needle, which threads through the material. The machine’s motor, shuttle, and feed dogs work together, creating tight stitches and moving the fabric forward

What is a good sewing machine for a beginner?

The Brother CS7000X is the best sewing machine for beginners, offering 70 built-in stitches, a wide table extension, and an automatic needle threader. It’s compact, intuitive, and versatile for various projects (Source)

How to operate a basic sewing machine?

To operate a basic sewing machine, thread the needle and bobbin, place your fabric under the presser foot, lower the needle into the fabric, then press the pedal to start stitching, guiding the fabric gently

What are some tips for using a sewing machine?

First of all, make sure that you thread your machine correctly. Adjust the tension and then practice on scrap fabric. Keep the machine clean, change needles regularly, and use a proper foot according to the type of fabric used for smooth running.

How do you thread a sewing machine?

Thread your sewing machine by placing the spool on the spindle, guiding the thread through the thread guide, tension discs, and take-up lever, finally threading it through the needle. Don’t forget to wind and insert the bobbin

What is the purpose of the presser foot?

The presser foot is the unsung hero of your sewing machine. It holds the fabric in place as the feed dogs whisk it along, ensuring your stitches are neat and tidy. Don’t forget to lower it before you start sewing!

How does the sewing machine create a chain stitch?

To create a chain stitch, your sewing machine’s needle forms a loop with the upper thread. The looper then passes through this loop, creating interlocking loops that form a continuous chain stitch on the fabric

What is the role of the thread take-up lever?

The thread take-up lever draws the thread and tightens it after the shuttle hook forms a stitch. It controls the flow of thread from spool to needle for smooth and regular stitching.

How does the sewing machine handle different fabric thicknesses?

Oh, your delicate linen and rugged denim? A sewing machine relies on adjustable tension and pressure, letting the needle pierce anything from silk to leather with ease. Just tweak the settings, and you’re golden!

What is the function of the stitch adjustment dial?

The stitch adjustment dial on your sewing machine lets you change the stitch length by modifying how much fabric is fed through with each stitch, ensuring the best results for various fabrics and sewing types (Source)

Conclusion

Did you know that a sewing machine can make up to 1,500 stitches per minute? Now that you understand how a sewing machine works, you can appreciate the inner workings and precise coordination required to create smooth, uniform stitches.

By mastering the essential components and their functions—from the needle mechanism to the feed dogs—you’ll operate your sewing machine with confidence and efficiency.

Embrace this knowledge, and your sewing projects will be more rewarding than ever