This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

But what exactly happens, and how could it be averted? Solving your troubles lies in finding out the root causes of thread breaks.

This article will reveal five common culprits that cause threads to break in sewing machines—from issues with the needle to tension imbalances—and devise practical ways out for each factor.

In learning to identify these problems, you will be better equipped to maintain your sewing machine and keep up with projects

Table Of Contents

Key Takeaways

- Needle know-how is your secret weapon. Like Goldilocks, you need the just-right size and sharpness for your fabric and thread. A dull or bent needle? That’s a recipe for thread-snapping disaster!

- threading your machine isn’t rocket science, but it’s close. Miss a disc or lever, and you’ll be playing a frustrating game of thread tug-of-war. Take your time, follow the path, and you’ll be smooth sailing.

- Tension troubles got you in knots? It’s all about finding that sweet spot. Too tight, and your thread’s walking a tightrope. Too loose, and it’s a sloppy mess. Adjust with care, and you’ll be stitching like a pro in no time.

- Keep your sewing machine spick and span. Lint is the silent thread assassin, lurking in nooks and crannies. Give your machine some TLC with regular cleaning, and it’ll reward you with snag-free sewing sessions

Why Does My Sewing Machine Cut the Thread?

If your sewing machine keeps cutting the thread, you’re not alone. This frustrating issue often stems from one of five culprits: needle problems, improper threading, bobbin issues, tension imbalance, or maintenance needs.

Your thread might be snapping due to a dull or bent needle, incorrect threading path, or lint buildup in the bobbin case. Tension imbalances between the top and bottom threads can also cause breakage.

Regular maintenance, including cleaning and oiling, is crucial to prevent thread-cutting woes.

Needle Issues

Much of the thread breakage with your sewing machine can be attributed to the sewing machine needle. A wrong-size needle for thread weight, a bent or blunt needle, or one that’s too small compared to the thickness of the fabric can mean maddening cuts in the thread while sewing.

Incorrect Needle Size for Thread Weight

If your sewing machine is cutting the thread, it may be because of an incorrect needle size for the weight of the thread. Matching your sewing needle size about your thread weight is good practice. Consider this:

- Thicker threads need larger needle eyes

• Fine threads will require thin needles

Universal needles work on most fabrics.

Specialty needles suit particular materials.

Applying the wrong size can lead to tension problems, which could cause the thread to snap. Remember, the perfect combination of needle and thread is where you’re able to sew smoothly without those maddening cuts in your thread.

Bent, Damaged, or Dull Needle

The condition of your needle is critical to the integrity of the thread. A bent, damaged, or dull needle can ruin a sewing project.

Search for signs of wear: chipped-off point, needle burr, or rough eye. These all include problems that could mean the end of the thread or cause machine vibration.

Even if you can’t notice damage, regular use of a needle will eventually dull it and reduce its performance.

Replace your needle every 8 hours or whenever you’re switching to a different type of fabric for smooth stitches

Using a Needle That’s Too Fine for the Fabric

When you’re using a needle that’s too fine for your fabric, you’re asking for trouble. Your thread’s likely to break, and your machine might throw a fit.

Think of it like trying to cut a steak with a butter knife – it’s just not up to the task.

Match your needle size to your fabric weight and thread thickness. A beefier needle can handle heavier fabrics without breaking a sweat, ensuring smooth stitches and happy sewing sessions

Improper Threading

One of the biggest contributors to this problem of the sewing machine constantly cutting the thread could be improper threading. You’ll then want to make sure that you have threaded your machine in the correct path, that your thread is seated properly in the tension disks, and that it’s correctly seated within the take-up lever.

Incorrect Threading Path

Now, while addressing the issues of the needles, let’s get to the wrong threading paths. How your thread passes into the machine becomes very crucial. When it doesn’t take the right way, it will cause breaks over and over again.

Check for burrs or sharp edges along the thread path that might catch your thread. Refer to your machine’s threading diagram to ensure you’re taking the right path.

Proper threading is undoubtedly essential to avoid frustrating breaks and give smooth stitches

Tension Discs Not Threaded Properly

Once your thread is on the right track, it’s equally essential to thread your tension discs** properly. These guys control the flow of your thread and, if not threaded correctly, can cut your thread with your machine. See how that thread flows through the tension. Here are a couple of things to keep in mind:

- Ensure the thread is firmly between the tension discs

- Check for thread compatibility with your machine

- Use a thread guard for slippery threads

Clean tension discs regularly to ward off buildup.

Thread Not Seated in Take-up Lever

While threading your sewing machine, don’t forget to pass it through the take-up lever. If you don’t have your thread seated properly in that most critical part, then you’re just begging for problems.

The function of the take-up lever is to adjust tension in the thread and allow it to flow without serious hitches through the system, hence promoting smooth stitching. If this isn’t done, common problems that could result include excessive tension, breaking threads, and irregular stitches.

Always check to see that your thread is through all guides, including the take-up lever, before you lower your presser foot and begin sewing.

The thread tamer can be used to help manage tricky threads

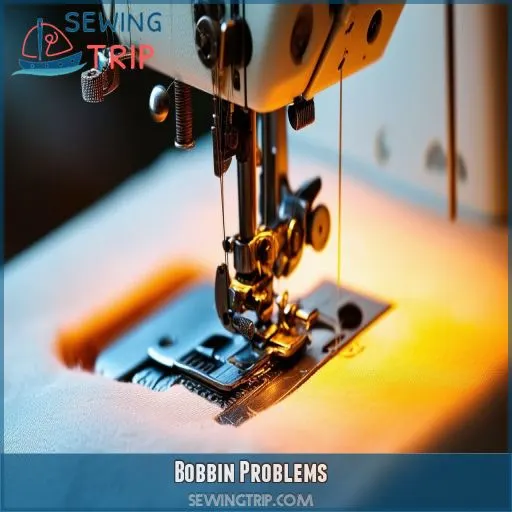

Bobbin Problems

Your bobbin can be a significant source of thread-cutting issues, often due to incorrect tension, lint buildup, or damage to the bobbin case. Check your bobbin tension, clean out any accumulated lint, and inspect the case for signs of wear or damage to prevent these common problems

Incorrect Bobbin Tension

Of all the thread-cutting woes, the miss-tensioned bobbin would likely be the sneaky culprit. If your bobbin is too loose or on the tight side, you’ll know your machine is acting up. You’ll then need to be very meticulous about calibrating your bobbin tension. Here are some essential things to consider:

- Make sure to use the right size bobbin for your machine

- Check bobbin case alignment for proper fit

• Always use good quality bobbin thread to resist breakage.

- Wind bobbins evenly and consistently

- Adjust tension gradually and check as you go

Lint Buildup in Bobbin Case

While adjusting bobbin tension can help cure this, another scoundrel causing thread breakage could be lint buildup inside your bobbin case. The tiny fibers build up while sewing and become a place of friction with your thread, which leads to snagging and eventually breaks. Another maintenance routine needing regular attention is cleaning your bobbin case. Here is a quick guide for keeping your bobbin case lint-free:

| Cleaning Step | Frequency | Tools Needed |

|---|---|---|

| Lint remove | After the project | Brush or tweezers |

| Deep clean | Monthly | Compressed air |

| Case inspection | Bi-monthly | Magnifying glass |

Damaged or Worn Bobbin Case

Your bobbin case might be the culprit behind cut threads. Check for burrs, scratches, or dents that can snag your thread. Even tiny imperfections can cause big problems.

Misalignment or lack of lubrication can also wreak havoc. Inspect the throat plate and hook mechanism for sharp edges too.

If you spot any issues, it’s time for a replacement or professional tune-up.

Regular maintenance is key to keeping your sewing smooth and snag-free

Tension Imbalance

If your sewing machine is cutting the thread, it’s likely due to tension imbalance. You’ll need to check if your top thread tension is too tight, your bobbin thread tension is too loose, or if you’re using thread that’s incompatible with your fabric

Top Thread Tension Too Tight

Does the top thread break? Maybe it’s over-tightened. Sometimes just a quick turn of the tension knob helps.

Use a Thread Tamer with slippery threads. Proper bobbin winding also helps.

Fine-tune these, and you’ll never ask again, "Why does my sewing machine cut the thread?" You’ll enjoy those free patterns

Bobbin Thread Tension Too Loose

Although adjusting the top tension indeed helps a great deal, how about the bobbin? If the thread of your bobbin is too loose, it might work to your detriment on these stitches.

There should be enough tension in the bobbin case to suspend its weight if suspended by only the thread. Be sure there’s even winding with your bobbin and it will lie flat next to its case.

Otherwise, cleaning the area with the bobbin and slightly adjusting the tension screw may help.

Let it be known that perfectly balanced tensions produce perfect stitches!

Incompatible Thread and Fabric

While loose bobbin tension can cause thread issues, incompatible thread and fabric pairings are equally troublesome. Your thread weight should match your fabric type. Using a lightweight thread on heavy denim, for instance, can lead to breakage.

Thread quality and age also play a role. Old or UV-exposed thread becomes brittle and prone to snapping.

Always choose high-quality thread appropriate for your project, and store it properly to maintain its integrity

Sewing Machine Maintenance

This means that regular servicing of the sewing machine will help to prevent thread breakage and also ensure smooth working. Cleaning away all the lint and other accumulation of debris, checking for damaged or worn-out parts, and ensuring that the timing and hook settings are correctly set to avoid cutting threads are all things you’ll want to do.

Lint and Debris Buildup

Even if the thread is at the proper tension, lint could wreak havoc on your sewing machine. Each time you sew, there’s a collection of tiny fibers in critical places inside. As this lint accumulates, it can catch your threads as they pass through and break them unexpectedly.

Regular cleaning will prevent that from happening. After each project, switch off your machine and use a small brush to sweep away this debris accumulation on the bobbin case, feed dogs, and tension discs.

Also, don’t forget to clean under the throat plate, where much of the lint accumulation is hidden

Damaged or Worn Parts

While regular cleaning is essential, it won’t prevent all thread breakage due to broken or worn parts. To keep your machine running:

- Search for burrs: Inspect the plates of the needles, hooks, and bobbins for any rough edges.

- Replacing worn parts: Never hesitate to replace old components.

- Observe the maintenance schedule: Follow the suggestions of the manufacturer.

- Proper lubrication: Apply oil on moving parts as instructed.

Incorrect Timing or Hook Position

Your machine’s timing might be off if the hook isn’t catching the thread at the right moment. This can lead to skipped stitches or thread breakage. Check for these signs:

| Issue | Symptom | Solution |

|---|---|---|

| Incorrect hook timing | Skipped stitches | Adjust timing |

| Bent hook tip | Thread fraying | Replace hook |

| Misaligned needle | Inconsistent stitches | Realign needle |

A faulty timing disc or frayed hook point can also cause problems. If you’re not confident adjusting these components, consult a professional to avoid damaging your machine

Frequently Asked Questions (FAQs)

How do I stop my sewing machine from cutting thread?

Did you know that 90% of thread breaks are avoidable? Check your needle, tension, and threading. Use quality thread; clean your machine regularly, and make sure proper bobbin winding has occurred. It takes just a few steps to reduce frustrating thread cuts significantly.

Why does my needle keep cutting thread?

Your needle may be cutting thread because of its being dull or its point being damaged, its improper size, or even its improper installation. Check for burrs in the needle eye and make sure you’re using the correct type for your fabric and thread weight.

What cuts the thread on a sewing machine?

Picture a tiny blade, hidden but sharp. Your sewing machine’s thread cutter, nestled near the presser foot, snips threads with precision. It’s activated by a lever or button, making your sewing smoother and faster. You’ll love this handy feature!

What tension should my sewing machine be on?

You’ll need to adjust your machine’s tension based on your fabric and thread. Start at 4 and test on scrap material. If you see loops on top, increase tension; if loops are underneath, decrease it. Fine-tune as needed

Why is my sewing machine thread breaking?

Is your thread breaking? Check your needle, tension, and thread quality. It can be a dull needle, incorrect tension, or low-grade thread. Re-thread your machine and ensure you’re using the right needle for your fabric.

Why is my sewing machine not cutting thread?

You’re threading, you’re stitching, but your machine’s not snipping? Next, check the tension. Clean the cutter mechanism and make sure the correct threading is done. If stubborn, consult your manual or a technician for model-specific troubleshooting steps.

Why is my sewing machine snagging?

Your sewing machine’s snagging could be due to a dull needle, incorrect threading, or tension issues. Check these first. Also, inspect for burrs on the bobbin case or needle plate that might catch the thread

Why does my sewing machine skip stitches?

First, the machine could be missing stitches. Check your needle first for dullness, bending, or incorrect size. Be sure you thread right and adjust the tension. Don’t forget to inspect the bobbin; clean out the lint.

Can thread quality affect thread breakage during sewing?

Yes, thread quality can make a big difference in breakage. Usually, low-quality threads are weak and very prone to snapping. You’ll have less trouble using good-quality threads compatible with your fabric and sewing machine’s specifications. Don’t go cheap with the threads!

How do different fabric types impact thread cutting?

Different fabrics demand varying needle types and sizes. Delicate fabrics need finer needles, while heavy ones require sturdier options. You’ll want to adjust thread tension and use appropriate thread weights to prevent cutting across fabric types

Does thread storage affect its performance in sewing?

Yes, thread storage impacts sewing performance. Keep your thread away from direct sunlight and high humidity. Proper storage prevents drying, brittleness, and weakening, ensuring smoother sewing and reducing thread breakage or cutting issues during use

Can using the wrong thread type cause breakage?

Thread mismatch is like a square peg in a round hole. You risk breakage when you have the wrong type for your fabric or machine. Be sure to choose threads compatible with what your project calls for.

How does sewing speed influence thread cutting issues?

Sew too fast, and you’ll tense your thread—potentially breaking it. You want to keep up a steady pace but moderate. With fragile fabrics or threads, slow down to avoid breakage and smooth stitching.

Conclusion

Picture a smooth, uninterrupted sewing session. That’s your goal. Now you know why your sewing machine cuts the thread and how to fix it.

From needle issues to tension imbalances, you’re equipped to tackle these common culprits. Remember, regular maintenance is key. By addressing these problems promptly, you’ll keep your machine running smoothly and your projects on track.

Don’t let thread breaks frustrate you anymore. With these insights, you’re ready to sew confidently and efficiently, creating beautiful projects without interruption