This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Mastering the essential parts of a sewing machine empowers creative potential.

Mastering the essential parts of a sewing machine empowers creative potential.

The bobbin and bobbin case handle the bottom thread.

Tension regulators, take-up levers, and thread guides manage the top thread.

Fabric handling components like the presser foot, feed dogs, and throat plate keep material moving smoothly.

Customize stitches with length/width selectors, menu screens, reverse buttons, and foot controllers.

Terminology defines key elements like the arm housing mechanisms, the bed supporting fabric, and the needle eye threading point.

Familiarize yourself with these components to achieve precise, professional-grade results in your projects—and to explore more advanced techniques.

Table Of Contents

Key Takeaways

- The bobbin and bobbin case handle the bottom thread, while tension regulators, take-up levers, and thread guides manage the top thread for precise stitch quality.

- Fabric handling components like the presser foot, feed dogs, and throat plate keep the material moving smoothly for professional-grade results.

- Customizing stitches is easy with length/width selectors, menu screens, reverse buttons, and foot controllers.

- Familiarizing yourself with key terminology like the arm, bed, and needle eye empowers you to explore more advanced sewing techniques.

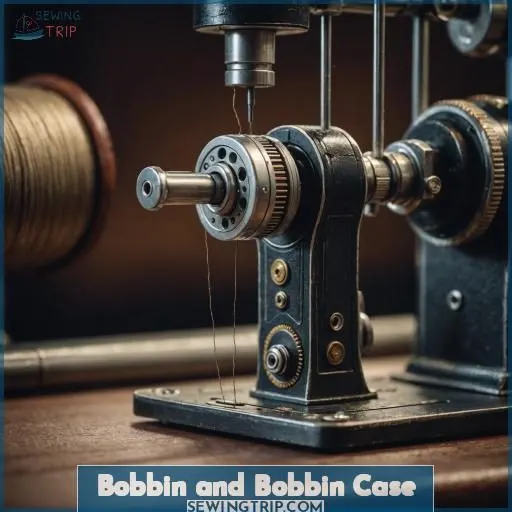

Bobbin and Bobbin Case

The bobbin and bobbin case are the heart of your sewing machine, providing the bottom thread for your stitches.

Proper bobbin placement is key – gently drop it into the bobbin case, ensuring it spins counterclockwise.

Winding the bobbin is a breeze with your machine’s built-in bobbin winder.

Just pop on a spool of thread, follow the guides, and let it run!

Adjust the bobbin thread tension by turning the tiny screw on the bobbin case.

Too tight and your fabric will pucker; too loose and you’ll get loops on the underside.

Keep that bobbin case well-oiled and free of lint for smooth sailing.

With a little tender loving care, your bobbin and case will keep your projects stitched up tight!

Threading and Tension

To guarantee proper thread tension and seamless stitching, you’ll need to focus on components like:

The tension regulator, which governs the tightness of the top thread.

The take-up lever, which moves up and down with the needle, guiding the thread.

Moreover, parts such as:

The bobbin winder tension disk.

The bobbin winder.

The thread guides play critical roles in regulating thread tension throughout the sewing process.

Tension Regulator

The tension regulator is the dial that governs the tension on your top thread. Appropriate tension guarantees that your top and bobbin threads meet in consistent stitches. To regulate tension:

- Turn the dial in a clockwise direction to intensify tension for thicker threads or more substantial fabrics.

- Turn counterclockwise to diminish tension for finer threads or delicate fabrics.

- Always make minor adjustments and test on scrap fabric.

Take-Up Lever

The take-up lever is a vital component of your sewing machine.

It moves up and down in rhythm with the needle to preserve appropriate thread tension.

Modify it if required, but replacement is seldom necessary.

Its role is to tighten the thread after each stitch, ensuring uniform stitch length.

Combine it with the stitch length selector and foot pedal for ideal sewing control.

Bobbin Winder Tension Disk

The bobbin winder tension disk is a critical component that regulates thread tension during bobbin winding. It guarantees the thread winds evenly onto the bobbin, preventing tangles and ensuring consistent stitch quality. The disk applies pressure to the thread, controlling its tension as it passes through the thread guides and onto the bobbin. Proper tension is essential for smooth bobbin winding and efficient sewing performance.

- Maintains even thread tension during bobbin winding

- Prevents thread tangles and ensures consistent stitch quality

- Applies pressure to thread as it passes through thread guides

- Ensures smooth bobbin winding and efficient sewing performance

Bobbin Winder

The bobbin winder fills your bobbin with thread.

It’s powered by the flywheel and has a tension disk that controls the winding tension.

Winding the bobbin is easy – just place it on the winder, thread through the tension disk, and press the bobbin winder stopper.

Refer to your sewing machine parts diagram if needed.

Proper bobbin tension is key for stitch quality.

Thread Guides

Thread guides are indispensable components that control thread tension and guarantee a seamless, consistent thread route from the spool to the needle. Optimal thread tension is vital for stitch perfection. Alter thread guides as required for various fabrics and threads. Purify thread guides routinely to avert lint aggregation that could cause tension difficulties.

- Sustain appropriate thread tension for immaculate stitches

- Abide by the correct thread path for frictionless sewing

- Modify thread guides as necessary for disparate projects

- Cleanse thread guides frequently to preclude tension tribulations

Fabric Handling

Fabric handling components enable your sewing machine to grasp, move, and position the fabric smoothly as you work. The presser foot holds the material flat against the throat plate, while the feed dogs grip and pull the fabric through as the flywheel rotates the stitch selector to create your desired stitch pattern.

Presser Foot

The presser foot is a key element that holds your fabric in place while sewing. It’s available in different types, including the zipper foot for installing zippers, the nonstick foot for handling sticky fabrics, and the roller foot for sewing slippery materials. Adjust the presser foot pressure to suit various fabric weights and specialized stitches for best results.

Throat Plate

The throat plate is a metal plate beneath your sewing machine’s needle and presser foot. It has holes or slots for the needle to pass through, accommodating different needle positions and fancy stitches. The throat plate provides a smooth surface for fabric as it passes through and is marked with guidelines for seam allowances of varying widths.

Spool Pin

The spool pin is where your thread spool sits, providing thread for the top of your sewing machine.

Proper spool pin positioning is crucial for smooth thread delivery and even tension.

Adjust the spool pin height to accommodate different thread types and weights.

Use a spool pin adapter for narrow thread spools.

Make sure your spool pin is compatible with your specific sewing machine model for the best possible performance.

Flywheel

The flywheel, also known as the handwheel, is an essential part of your sewing machine. It manually lifts and lowers the needle, allowing you to control the stitching process. To guarantee the best performance, keep the flywheel properly lubricated and aligned. If you notice excessive shaking or difficulty turning, refer to your sewing machine manual for troubleshooting advice or think about replacing the flywheel.

| Flywheel Function | Description |

|---|---|

| Needle Control | Manually lifts and lowers the needle |

| Lubrication | Keep well-oiled for smooth operation |

| Alignment | Ensure proper positioning for even stitches |

| Vibration | Excessive vibration may indicate a problem |

| Replacement | Replace if damaged or worn for proper function |

Stitch Selector

The stitch selector allows you to choose from a variety of decorative stitches, stitch types, and patterns. It’s like having a whole library of stitches at your fingertips! With a simple turn of the dial, you can create stunning zigzag stitches, intricate designs, or even combine stitches for unique effects. The stitch selector puts the power of specialty stitches right at your fingertips.

- Easily select from a wide range of decorative stitches

- Combine stitches for custom looks

- Quickly switch between stitch types with the turn of a dial

Stitch Customization

You have extensive control over stitch customization on your sewing machine.

The stitch-length selector allows you to adjust the tightness or looseness of stitches.

The stitch width-selector enables you to vary the width for decorative stitches.

In addition, many modern machines have menu screens to fine-tune functions and stitch options.

They have reverse-stitch buttons to secure seam ends.

They also have foot controllers that regulate stitch speed.

Stitch-Length Selector

The stitch-length selector allows you to adjust the length of each stitch, from very short to quite long.

Choosing the right stitch length depends on your needle size, thread type, fabric choice, and tension adjustment.

A longer stitch is ideal for basting or gathering fabric, while a shorter stitch produces a stronger seam.

Experiment to find the perfect stitch length for your sewing machine and project.

Stitch Width-Selector

The stitch width selector allows you to adjust the width of decorative stitches.

Increase the width for bolder stitch patterns or decrease it for more delicate designs.

Experiment with different stitch widths to add visual interest to your sewing projects.

The stitch width impacts the overall look and application of the stitch, so play around to find what works best for your needs.

Menu Screen

The menu screen on your sewing machine is your command center for customizing stitches and functions. Navigate through settings to adjust stitch options, select decorative stitches, and control machine functions. Explore display options to optimize your sewing experience. Consult your manual to master the menu screen and access the full capabilities of your sewing machine.

Reverse-Stitch Button

The reverse-stitch button is a handy tool for securing seams and reinforcing stitches. Simply press and hold it to sew in reverse, creating a tacking stitch for buttonholes or securing the end of a seam. Some machines even offer automatic reverse stitching for efficiency. Master this button to take your sewing to the next level!

- Secures seams and reinforces stitches

- Creates tacking stitches for buttonholes

- Sews in reverse direction

- Offers automatic reverse stitching

- Improves sewing machine efficiency

Foot Controller

The foot controller governs the pace of your sewing machine. Position it conveniently beneath your foot for accurate speed adjustment. Its user-friendly design facilitates hours of sewing without strain. Compatible with numerous machines, it effortlessly joins your system. Wireless foot controllers are also obtainable for increased ease. Command speed control and enhance your sewing machine’s efficiency with this vital accessory.

Machine Terminology

The arm is the top part of the sewing machine where the needle-driving components are located. The bed, on the other hand, is the bottom section that houses the bobbin and presser foot.

Arm

The arm is the curved top part of the sewing machine that houses the needle-driving mechanism. It’s designed for comfort and efficiency, with an ergonomic shape that allows for easy maneuvering of fabric. The arm’s material, typically metal, guarantees durability and stability during sewing. Its functionality is essential for handling various projects, from upholstery and curtains to leather and canvas.

- Ergonomic design for comfort and control

- Durable metal construction for long-lasting performance

- Versatile for sewing a wide range of fabrics

- Essential for handling large or bulky projects

- Allows for precise control of the needle and thread

Bed

The bed is the flat surface on the bottom of the sewing machine where the fabric rests.

It comes in various sizes, materials, and shapes to accommodate different projects.

A larger bed is ideal for quilting.

A smaller, more portable bed works well for travel.

The bed’s material and dimensions impact the machine’s overall size and weight.

Choose a bed that suits your sewing needs and workspace.

Needle Eye

The needle eye is the opening at the tip of the sewing needle where the thread goes through. It’s essential for proper threading and stitch formation. To get the best results:

- Use a needle threader for easy threading

- Match needle size to fabric thickness

- Choose the right needle type for your project, like sharp for woven fabrics or ball point for knits

The needle eye is the key to beautiful stitches on clothes, purses, tents, sails and more. Keep it sharp and properly threaded for sewing success!

Frequently Asked Questions (FAQs)

How do I clean my sewing machine?

Irony aside, thoroughly cleaning that dust-covered machine’s a necessity. Unplug it, gently brush away lint, use a vacuum’s hose, then sparingly apply sewing machine oil – watch it transform, purring smoothly once more.

What type of oil should I use?

For sewing machines, you’ll want to use a high-quality sewing machine oil designed for lubricating metal components. This special oil prevents friction and wear while being lint-free and non-gumming.

Where can I find replacement parts?

You’re in luck! Scoring hard-to-find replacement parts is a breeze these days. Visit a reputable sewing machine dealer or browse online retailers for an extensive selection customized to your machine’s needs.

How do I adjust the needle position?

To adjust needle position, locate the stitch width dial or lever. Turn it forward to move the needle left, away from you to shift it right. Consult your machine’s manual for precise steps and any alternate methods.

What accessories are available for my machine?

You’ve stepped into the captivating world of sewing accessories, my friend! From spools to treadles, a treasure chest awaits to amplify your machine’s abilities and your creative journey.

Conclusion

Ultimately, understanding the components of a sewing machine unleashes your creative potential. By comprehending the functions of the bobbin, threading mechanisms, fabric handlers, stitch customizers, and key terminology, you’ll achieve professional-grade results. Acquaint yourself with these essential elements to investigate advanced techniques and elevate your sewing projects to the next level.