This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Industrial sewing machines built for thick materials don’t flinch at this challenge. They deliver the motor torque, throat clearance, and feed precision needed to stitch through densities that would break a household needle in seconds. The difference isn’t just power—it’s engineering designed for relentless performance under load.

Whether you’re quilting upholstery-weight projects or layering multiple battings for heirloom pieces, choosing the right industrial setup transforms frustration into control. Here’s what separates machines that muscle through heavy quilts from those that merely claim they can.

Table Of Contents

- Key Takeaways

- Best Industrial Machines for Quilting Thick Materials

- 1. Brother High Speed Sewing Machine

- 2. Juki Heavy Duty Sewing Machine

- 3. Sewing Machine Seam Guide Gauge

- 4. Magnetic Sewing Guide for Machines

- 5. Industrial Upholstery Sewing Machine Set

- 6. Industrial Leather Sewing Machine Head

- 7. Meander Quilting Templates for Sewing

- 8. Juki Platinum Sewing Machine Edition

- 9. Industrial Heavy Duty Sewing Machine

- 10. Industrial Sewing Machine Needles Set

- Essential Features for Heavy Fabric Quilting

- Optimizing Machine Setup for Thick Quilts

- Quilting Techniques for Industrial Machines

- Industrial Vs. Domestic Machines: Pros and Cons

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Industrial machines outmuscle domestic models with 550-750 watt motors that deliver ten times the power, pushing through thick materials at speeds up to 5,500 stitches per minute without the needle deflection or skipped stitches that plague home machines.

- Walking foot and compound feed systems eliminate the layer shifting that ruins heavyweight quilts by gripping fabric from both top and bottom simultaneously, maintaining precise alignment through twelve-layer sandwiches that would choke standard presser feet.

- Proper needle and thread pairing determines success more than raw power—matching 18-21 gauge needles with 20-30 weight thread for heavy canvas prevents the breakage and tension failures that stop projects cold, while mismatched combinations shred fibers regardless of machine strength.

- The $465-$7,110 investment in industrial equipment pays back within 2-4 years through 60% faster completion times and 15-25 year lifespans that double domestic machine longevity, but only if you commit the dedicated floor space and regular maintenance these workhorses demand.

Best Industrial Machines for Quilting Thick Materials

Finding the right industrial machine for quilting thick materials isn’t just about power—it’s about precision, control, and the right feature set working in harmony. You need equipment that won’t blink when faced with multiple layers of batting, denim, or canvas, and that can maintain consistent stitch quality from start to finish.

Below, you’ll find a curated selection of machines and accessories that quilters trust when tackling heavyweight projects.

1. Brother High Speed Sewing Machine

The Brother PQ1600S stands out as a powerhouse for thick material quilting, delivering industrial sewing machine reliability with quilting precision. You’ll hit speeds of 1,500 stitches per minute—that’s high performance that transforms your sewing efficiency when tackling heavy fabrics.

The 11.1 x 23.3-inch workspace gives you room to maneuver weighted blankets and multi-layered quilts without fighting the machine. Brother’s heavy-duty sewing design includes a pin feed mechanism and knee lifter, making this industrial machine manage thick materials like a dream.

At $1,499.99 with a 25-year warranty, you’re investing in Brother Speed that won’t quit when quilting machines need to power through heavy-duty sewing projects.

Best For: Quilters and sewists who regularly work with thick, multi-layered fabrics and need industrial-grade speed and reliability for large projects like weighted blankets and home decor.

- Blazing fast 1,500 stitches per minute with an extra-large 11.1 x 23.3-inch workspace makes short work of heavy-duty quilting projects

- Pin feed mechanism and built-in knee lifter give you hands-free control when managing thick, bulky materials without feed dog marks

- 25-year warranty and heavy-duty metal construction mean this machine will handle years of professional or high-volume home use

- Side-loading bobbin doesn’t alert you when thread runs out, which can interrupt your workflow on long seams

- Top thread tension dial is hard to see and adjust, especially mid-project when you’re switching between fabric weights

- Not beginner-friendly—the industrial features and lack of stitch variety make this overkill if you’re just learning to sew

2. Juki Heavy Duty Sewing Machine

If speed alone impressed you, the Juki Heavy Duty Sewing Machine sets a new standard with industrial-grade materials built for relentless performance. The Juki DLN1541S and DNU1541 models deliver sewing speed control up to 5,500 stitches per minute—nearly four times faster than the Brother—while maintaining rock-solid precision through heavy fabrics like denim and canvas.

You’ll appreciate the 11-inch arm space and 5mm stitch length that manage thick quilts without hesitation.

This Juki machine overview reveals why seasoned quilters trust its heavy-duty features: sturdy construction, outstanding quilting foot options, and the muscle to power through multiple layers where lesser industrial sewing machines falter.

Best For: Quilters and sewists who work with thick, heavy materials and need industrial-level speed and durability for large-scale projects.

- Blazing fast sewing speed up to 5,500 stitches per minute with excellent precision through multiple layers of heavy fabrics like leather, canvas, and denim

- Generous 11-inch arm space and 5mm stitch length accommodate large quilts and bulky projects with ease

- Built with industrial-grade aluminum die-cast frame for durability and reduced vibration, plus convenient features like automatic needle threader and thread trimmer

- Assembly required and can be challenging without proper instructions—some users report needing professional help to set it up

- No printed manual or instructions included, and some customers have received machines with missing parts or damaged components

- Walking foot mechanism sold separately, adding to the overall cost for those who need it for quilting

3. Sewing Machine Seam Guide Gauge

Precision separates professional results from amateur work, and a seam guide gauge gives you the control you need. This measurement tool attaches to your industrial sewing machine—usually by screw-on bracket or magnetic mount—and ensures consistent seam allowances between 1/8 inch and 1 1/2 inches.

When quilting and embroidery projects demand uniform stitching through heavy fabrics, the rigid guide eliminates the guesswork that comes with rulers or tape measures. Gauge accuracy reaches within 1/32 inch in controlled settings, and you’ll see why manufacturers report 15–25% time savings in high-volume work.

Whether you’re managing fabric thickness exceeding 0.25 inches or fine-tuning sewing precision on denim and canvas, this simple addition transforms your sewing machine selection into a powerhouse for consistent, straight-line quilting.

Best For: Quilters and sewers who need precise, repeatable seam allowances on both industrial and home machines without constantly measuring or marking fabric.

- Cuts measuring time by 15–25% and reduces seam placement errors by up to 40% compared to rulers or tape measures

- Works with most machines through screw-on or magnetic attachment, handling fabric thicknesses over 0.25 inches

- Durable stainless steel construction lasts 5,000 hours with accuracy within 1/32 inch, priced affordably at $2–$6

- Doesn’t fit every machine model—some users report compatibility issues with certain Brother and other brands

- Magnetic versions can cause skin irritation in people with nickel sensitivity and may interfere with computerized machines

- Limited adjustability once installed, and some users find the attachment process tricky or the stick length restrictive

4. Magnetic Sewing Guide for Machines

A magnetic guide locks onto your machine’s metal throat plate without screws or clamps, delivering sewing precision that screw-on gauges can’t match. Top models offer 20 times the holding power of basic magnets and stay put even at 1,500 stitches per minute—zero drift, zero hassle.

You’ll cut prep time by half since you won’t mark seams manually, and quilting accuracy jumps when you hold ±0.5 mm deviation across multiple heavy fabrics layers.

Position it anywhere for seam allowances from 1/8 inch to over 1 inch, making machine optimization fast for straight-line or curved freemotion quilting. Just keep it away from computerized controls—strong magnets and electronics don’t play nice.

Best For: Sewers and quilters who need rock-solid seam accuracy on mechanical machines with metal throat plates, especially when working with heavy fabrics or high-speed stitching.

- Stays locked in place with zero drift even at 1,500 stitches per minute, eliminating the shifting problems of weaker magnetic guides

- Cuts prep time in half by removing the need for manual seam marking while maintaining ±0.5 mm precision across thick fabric layers

- Adjusts instantly to any seam allowance from 1/8 inch to over 1 inch without tools or screws, making it fast to switch between projects

- Won’t work on computerized machines due to magnetic interference with electronics, limiting compatibility with newer models

- Requires a solid metal throat plate behind the presser foot—machines with drop-in horizontal bobbins or limited metal coverage can’t use it

- Strong magnets pose safety risks for people with pacemakers or medical devices and must be kept away from other electronics

5. Industrial Upholstery Sewing Machine Set

An Upholstery Machine set transforms thick-fabric quilting into precision work you’d expect from sewing automation. These industrial sewing rigs combine heavy-duty motors with sophisticated stitching mechanisms—walking foot and compound feed systems grip multiple layers of industrial fabric without slippage, even when you’re pushing canvas or vinyl through at speed.

You’ll manage heavy fabrics that choke domestic models, and the servo motor gives you stitch-by-stitch control for industrial quilting machine setup. Sewing machine maintenance stays straightforward since these upholstery sewing workhorses use standard lubricating oil and simple tension adjustments.

Built-in tables support large quilt weight, letting you focus on the pattern instead of wrestling bulk.

Best For: Tailors, upholstery shops, fashion designers, and small manufacturers who need to handle heavy fabrics like leather, canvas, and vinyl with professional precision and speed.

- Premium 550W motor with servo control lets you adjust speeds up to 3500 stitches per minute while staying whisper-quiet at 30db, giving you precise control for detailed work or high-speed production runs.

- Automatic threading system and adjustable stitch length up to 5mm make setup quick and versatile enough to handle everything from light synthetics to thick upholstery materials without constant adjustments.

- Complete ready-to-use set includes the motor, table stand, and machine with walking foot mechanism that feeds multiple fabric layers evenly, eliminating the skipped stitches you’d get with domestic models.

- Limited to medium-thickness materials, so extremely heavy leather or multi-layer industrial applications might exceed the machine’s capacity compared to higher-end upholstery models.

- Requires specific 110V/60Hz power and regular maintenance with 10 White Oil, adding ongoing costs and limiting portability if you work in different locations or countries.

- Initial assembly and learning curve can slow down beginners, and the 1-year warranty means you’ll need to factor in potential repair costs for long-term heavy use.

6. Industrial Leather Sewing Machine Head

A leather sewing machine head powers through thick materials that stop conventional industrial sewing equipment cold—you’ll process stacked leather up to 7/8 inch, canvas, and heavy upholstery with motors delivering 550 watts of pure torque. Triple-feed walking foot mechanisms grip your work from top and bottom, eliminating slippage during leather stitching and leather crafting projects.

Machine customization lets you pair the head with your choice of servo motor and table setup, while presser foot lifts reaching 13 mm accommodate multiple heavy fabrics without strain.

These cast-iron workhorses deliver leather sewing precision across 20-30 year service lives, making them the backbone of serious heavy duty motors operations in industrial machine shops focused on upholstery sewing and professional leatherwork.

Best For: Professional leatherworkers, upholsterers, and industrial shops who need to sew heavy materials with power, flexibility, and long-term reliability.

- Handles thick and tough materials like stacked leather, canvas, and heavy-duty upholstery with ease.

- Customizable setup allows pairing with your choice of motor and table for specific workshop needs.

- Built for long-term, high-volume use with durable cast-iron construction and triple-feed mechanisms for precise stitching.

- Requires separate purchase and setup of motor and table, which adds to the initial investment and complexity.

- Heavy and bulky design limits portability and requires significant workspace.

- Maintenance is more frequent compared to domestic machines, with lubrication and care needed every 8 hours of use.

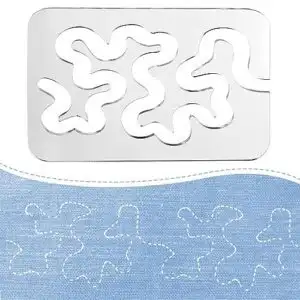

7. Meander Quilting Templates for Sewing

Meander quilting templates offer a fast track to professional free-motion results. These 3mm acrylic guides significantly reduce your learning curve by 60% as you master consistent patterns across thick quilt layers.

Templates range from 2″ to 5″ designs, compatible with your ruler foot, allowing you to handle everything from tight stipple work to flowing border fills. The transparent material ensures your quilt design remains visible during stitching, while marked start-stop points guide your path through loops, spirals, and classic meandering patterns without pre-marking fabric.

Priced between $20-40, these templates deliver serious sewing accuracy improvements. 87% of quilters report better consistency when using these guides with their free-motion quilting techniques.

Best For: Quilters looking to speed up their free-motion quilting learning curve and achieve consistent meander patterns without extensive hand-marking.

- Cuts learning time by 60% with guided paths that help beginners build muscle memory and confidence quickly

- Transparent 3mm acrylic lets you see your fabric design while stitching, with marked start-stop points eliminating guesswork

- Versatile sizing (2″-5″) works for everything from tight stippling to flowing borders on both domestic and longarm machines

- May not fit smaller sewing machines with limited throat space or clearance around the needle area

- Can slip on thick batting or large quilts without grip tape, requiring extra accessories for stability

- Some units arrive damaged in shipping due to the brittle nature of acrylic material

8. Juki Platinum Sewing Machine Edition

The Juki TL-2020 PE Platinum Edition isn’t just another industrial machine—it’s a limited collector’s piece with only 2,000 units produced for the U.S. market.

This powerhouse manages heavy fabric sewing with ease, pushing 1,500 stitches per minute through multiple denim layers or thick leather while maintaining quilting accuracy that rivals dedicated longarm setups.

Its aluminum die-cast frame delivers industrial durability in a portable 25.4-lb package, and the 12mm presser foot lift manages bulky quilt sandwiches without hesitation.

You’ll appreciate how this industrial machine bridges professional quilting techniques with home workshop convenience, especially when free-motion work demands precision control through heavy fabrics.

Best For: Professional quilters and serious sewists who need industrial-grade performance for heavy fabrics, free-motion quilting, and multi-layer projects while valuing a limited-edition collector’s piece.

- Industrial aluminum die-cast build delivers 1,500 stitches per minute through thick materials like multiple denim layers and leather while maintaining precise tension control

- 12mm presser foot lift with knee lifter handles bulky quilt sandwiches effortlessly, plus automatic thread trimmer and needle threader speed up workflow considerably

- Limited edition status with only 2,000 units produced and serialized Certificate of Authenticity makes it a valuable collector’s item alongside its professional functionality

- Straight-stitch only design means no zigzag or decorative stitches, limiting versatility for general sewing projects

- $1,899 price point puts it out of reach for casual sewists or those just starting their quilting journey

- Limited availability as a discontinued model means finding replacement parts or support may become challenging over time

9. Industrial Heavy Duty Sewing Machine

When thick quilts or heavy fabric meet your production floor, you need industrial sewing machines built for relentless durability—think 550-watt to 750-watt powerful motors that punch through multiple denim layers without hesitation.

These heavy duty components include cast-iron frames, reinforced needlefeed systems, and stitch speeds reaching 5,000 stitches per minute, transforming industrial quilting challenges into optimized workflow.

You’re looking at machine durability that spans decades in commercial environments, with presser foot clearance up to 1 inch and adjustable stitch lengths to 11mm managing materials up to 7/8 inch thick.

Best For: Commercial quilters and upholstery shops handling thick materials like leather, canvas, and multi-layer fabrics who need reliable, high-speed production capacity.

- Powerful 550W-750W servo motors handle materials up to 7/8 inch thick with stitch speeds reaching 5,000 stitches per minute for fast commercial output

- Heavy-duty metal frames and cast-iron construction deliver decade-plus longevity in demanding production environments with minimal downtime

- Large workspace (up to 25 inches) and 1-inch presser foot clearance accommodate bulky quilts and multiple fabric layers with ease

- Assembly can be complicated with unclear instructions, often requiring professional setup or technical knowledge

- Heavy weight (38-43 pounds) and large footprint demand dedicated floor space and may complicate relocation

- More frequent maintenance needed compared to domestic machines, including regular lubrication and lint removal to prevent performance issues

10. Industrial Sewing Machine Needles Set

You won’t master thick-quilt stitching without matching your needle to the job—Needle Size and Needle Material determine whether you pierce twelve denim layers or snap mid-seam.

For heavy Quilting Techniques, reach for 140/22 (size 23/160) needles in hardened steel with titanium-nitride plating, supporting Thread Compatibility up to 207-weight thread while your Sewing Speed climbs past 3,000 stitches per minute.

Selecting proper needles and threads means checking your machine’s system code—DBx1, 135×17—then stocking a 30-piece set spanning denim points for canvas and reinforced shafts for batting.

Monitor thread tension and swap needles every eight hours of run-time; Needle Maintenance isn’t optional when quilting thread and thick materials wear cutting edges faster than lightweight cotton ever could.

Best For: Sewers tackling heavy-duty projects like thick quilts, denim, leather, and canvas on industrial lockstitch or compatible domestic machines.

- Sharp iron alloy construction handles multiple layers of thick fabric without bending or breaking mid-project

- Size 140/22 works with heavier threads (up to 207-weight) for secure stitching on demanding materials

- 30-needle pack gives you plenty of replacements for long quilting sessions or commercial workloads

- No warranty or durability information provided, so longevity is uncertain compared to premium brands

- DBx1 system may not fit all machines—you’ll need to verify compatibility with your model before ordering

- Basic plating (appears to be standard iron alloy) wears faster than titanium-coated needles during extended high-speed use

Essential Features for Heavy Fabric Quilting

When you’re working with thick materials like denim, canvas, or multiple quilt layers, your machine needs the right muscle and mechanics to manage the job.

The features that separate industrial workhorses from home machines aren’t just nice to have—they’re what keep your stitches clean and your projects moving forward.

Let’s break down the core capabilities you should look for when choosing a machine that won’t back down from heavy fabric.

High Presser Foot Lift and Throat Space

When you’re wrestling multiple layers of canvas, denim, or batting into place, the distance between your presser foot and needle plate becomes the difference between a smooth start and a frustrating wrestling match. High Presser Foot Adjustment on machines like the Juki DU1181 gives you the clearance to slide thick quilts under without forcing them.

Here’s what Throat Space Optimization and proper Fabric Layer Management reveal for you:

- Command over bulk – Walking foot systems grip Heavy Fabrics from both sides, eliminating shifty layers that sabotage your seams

- Freedom to pivot – Adequate throat space lets you maneuver large quilts without cramping your creativity or straining Sewing Machine Ergonomics

- Zero frustration starts – Compound Feed Machines manage Quilt Thickness Management with authority, so every stitch begins confidently

- Professional finish – Consistent pressure across layers means no puckering, no skipped stitches, just durable results that reflect your vision

Your Industrial Machine becomes an extension of your craft when these features work in harmony.

Powerful Motors and Speed Capabilities

Raw motor strength separates machines that power through from those that choke on density. A 550-watt brushless servo motor delivers the torque output you need for consistent penetration, while motor efficiency above 80% keeps power consumption reasonable during long sessions. Speed control lets you dial from 1,000 to 5,000 stitches per minute—high-speed sewing when you’re racing deadlines, controlled precision when detail matters.

Understanding the differences in industrial sewing machines is vital for selecting the right equipment for your projects.

| Feature | Industrial | Domestic |

|---|---|---|

| Motor strength | 550–750W | ~60W |

| Stitch Rate | 1,000–5,000 SPM | ~800 SPM |

| Torque at low speed | Constant high | Drops markedly |

Controlling machine speed with a responsive foot pedal transforms your industrial machine components into extensions of your intent, maintaining penetrative force whether you’re creeping through twenty layers or flying across open fabric.

Walking Foot and Compound Feed Systems

Speed means nothing if layers shift mid-stitch—that’s where walking foot and compound feed systems lock down fabric control. The feed dog mechanism grips from below while the presser foot lift engages from above, creating synchronized fabric grip that prevents bunching when you’re quilting heavy fabrics.

This dual-action compound feed eliminates the puckering and drag you’d battle with standard industrial machine setups, keeping even twelve-layer sandwiches tracking straight.

Adjustable Stitch Length and Tension

Fabric control doesn’t mean much if your stitch length can’t match the material density—adjustable stitch length and tension turn your machine into a precision tool that handles whatever weight you’re quilting. Dial in longer stitches for thick batting, tighten thread tension to prevent loops, and customize every pass through dense layers:

- Stitch regulation lets you match fabric thickness without fighting the feed

- Tension control eliminates thread breaks on heavy canvas sandwiches

- Adjusting tension for thick layers prevents puckering that ruins hours of work

- Stitch customization transforms one industrial machine into a multi-weight workhorse

- Thread tension balance keeps top and bobbin threads locked perfectly through twelve layers

Selecting Proper Needles and Threads

Three elements—needle gauge, thread weight, and point geometry—determine whether you punch clean holes through thick batting or shred fibers into a maintenance nightmare. Fabric compatibility hinges on pairing the right needle with stitch demands—get it wrong and you’ll chase thread breaks all day.

Match needle size to material thickness: 18–21 gauge penetrates multiple denim layers without deflection. Thread tension rises with thicker thread, so use heavier polyester or nylon that won’t snap mid-stitch.

| Material Thickness | Needle Gauge | Thread Weight | Point Type | Stitch Quality |

|---|---|---|---|---|

| Light batting | 14–16 | 40–50 wt | Sharp | Clean penetration |

| Medium layers | 16–18 | 30–40 wt | Ball point | Smooth feeding |

| Heavy canvas | 18–21 | 20–30 wt | Cutting point | No deflection |

| Denim stacks | 20–23 | 15–20 wt | Wedge | Strong lockstitch |

| Leather/vinyl | 21–25 | 12–18 wt | Triangle | Precision holes |

Optimizing Machine Setup for Thick Quilts

Setting up your industrial machine properly makes all the difference when you’re tackling thick quilts—it’s the foundation that separates smooth, professional results from frustrating jams and uneven stitches.

Your workspace layout, tension adjustments, and choice of presser feet all work together like gears in a well-oiled mechanism. Here’s how to dial in each element for maximum control and consistent performance.

Flatbed Vs. Longarm Machine Selection

Choosing between a flatbed industrial machine and a longarm quilting machine shapes your entire quilting workflow. If you’re working with king-size projects or running a production studio, here’s what drives the Machine Comparison:

- Workspace Ergonomics: Longarm quilting machines offer 18 to 26 inches of throat space and stand-up operation, while flatbed industrial machines like the Juki DDL8700 provide 6 to 11 inches but demand less floor space

- Speed Optimization: Longarms achieve 1,500–3,500 stitches per minute for Quilting Efficiency gains up to 60%, compared to flatbed models running 700–1,200 stitches per minute

- Fabric Management: Longarms cut fabric management time by 40% on thick quilts, whereas flatbeds excel at smaller projects with a quilting foot and precise control

- Investment Reality: Flatbed industrial machines cost $2,000–$6,000 versus longarms at $10,000–$25,000, but professional studios see cost-per-quilt drop 30–40% with longarm throughput

- When selecting a machine, consider the importance of heavy fabric capabilities to guarantee peak performance.

Your project size and production volume determine which path unlocks mastery.

Setting Up Workspace and Extension Tables

Your workspace geometry unlocks quilting potential—or chokes it—long before you thread the first needle. Extension tables transform cramped Sewing Stations into efficient zones where fabric layers glide instead of bunch. Here’s your Workspace Optimization blueprint:

| Table Configuration | Work Area Dimensions | Best For |

|---|---|---|

| L-shaped Extension Table | 48″ × 24″ side support | Large projects, king-size quilts |

| Flush-mount platform | Level with machine bed | Smooth fabric feeding, precision control |

| Adjustable-height station | 28″–36″ range | Ergonomic Setup, reduced fatigue |

Proper space considerations mean quilting thick materials becomes a rhythm, not a wrestling match.

Adjusting Tension for Thick Layers

Tension missteps turn dream quilts into puckered disasters—thick layers demand a calibrated dance between upper and lower thread that domestic machines rarely master.

Start by increasing upper Thread Tension incrementally—test on scrap quilt sandwich first. Your needle thread should lock precisely mid-fabric, not pulling bottom thread topside. Adjust bobbin tension cautiously; even quarter-turns impact Layer Management.

Proper Tension Control means balanced stitches through dense Thick Fabric without tunneling or skipped stitches—that’s Sewing Precision at work.

Using Quilting or Free-Motion Feet

Swapping your standard presser foot for a quilting or free-motion foot is like trading training wheels for precision steering—suddenly, you control every curve and corner instead of fighting the machine’s default path.

Free-motion feet let you drop feed dogs and guide fabric manually, unlocking limitless Quilt Maneuvering potential:

- Quilting Foot with short shank hovers above fabric, preventing drag during intricate curves

- Freemotion Foot circular design grants 360-degree visibility for precise Stitch Control

- Spring-loaded mechanism maintains consistent Fabric Grip without crushing thick layers

- Open-toe variants reveal needle entry point, essential for detailed Free Motion patterns

A walking foot feeds layers evenly—critical before graduating to freemotion work.

Managing Quilt Weight and Fabric Handling

A king-size quilt sagging off your machine table isn’t just awkward—it’s a recipe for skipped stitches, needle deflection, and enough muscle strain to make you quit mid-project. Support heavy fabric with extension tables or rolling side stands to keep tension balanced during Fabric Management Techniques.

| Challenge | Solution | Benefit |

|---|---|---|

| Quilt Weight Management drag | Roll excess fabric into cylinders | Reduces pulling on needle bar |

| Thick Material Sewing bulk | Use batting fabric sandwich clips | Maintains layer alignment through feed dogs |

| Quilting Space Optimization limits | Position chair at table center | Improves Heavy Fabric Control reach |

Your industrial machine manages the weaving motion—you control everything else.

Quilting Techniques for Industrial Machines

Mastering thick-material quilting on an industrial machine isn’t just about raw power—it’s about technique. Your machine can punch through layers like a champ, but controlling speed, managing bulk, and marking designs will separate amateur work from professional results.

Here’s what you need to know to turn that industrial workhorse into a quilting precision tool.

Free-Motion Quilting on Thick Materials

Mastering free-motion quilting on thick materials transforms your industrial machine into a precision tool that dances across layers of batting and fabric with surprising grace. Here’s how to conquer heavy fabrics with freemotion quilting techniques:

- Drop your feed dogs and attach a free-motion foot for maximum fabric control

- Practice stitch density control on scrap layers before tackling your actual quilt

- Manage material thickness limits by testing your Juki TL2000Qi’s capacity beforehand

- Maintain consistent hand movements while guiding thick fabric manipulation through quilting patterns

These free motion tips guarantee your quilt layer management stays smooth even when working with heavy fabrics.

Controlling Machine Speed With Foot Pedal

Once you’ve nailed the movements in free-motion quilting, the real key is learning to finesse your foot pedal like a master mechanic tuning an engine—smooth acceleration beats speed every time.

Start with feather-light pressure, letting the Juki TL2000Qi’s takeup stroke cycle steadily while your hands guide the fabric. Speed regulation isn’t about racing to 1,500 stitches per minute—it’s about maintaining stitch consistency through controlled pedal technique that matches your design complexity.

Quilt Design Marking Methods

Before your presser foot ever drops, marking your quilting design sets the roadmap that turns mechanical precision into artistic control. Choose your marking tools based on fabric weight and contrast:

- Fabric markers (water-soluble or air-erasable) for temporary lines on quilt tops

- Quilting stencils for repeating quilt patterns with precision

- Design software for digital pattern planning before marking

- Chalk wheels for quick, dust-off marking on darker materials

- Hera markers for crease-marking delicate fabrics without residue

Test markers on scrap fabric first—thick batting can obscure faint lines when using a quilting foot or free-motion foot.

Rolling and Folding Large Quilts

When you’re wrestling a king-sized quilt through an industrial machine’s throat space, smart rolling and folding techniques become the difference between smooth sailing and a frustrating tangle. Roll the quilt tightly toward the quilting line, securing it with fabric clips to control batting and prevent drag on your work surface.

For large projects on industrial sewing machines, accordion-fold sections you’ve already stitched—this keeps heavy fabrics manageable while maintaining visibility of your current quilting path.

Achieving Consistent and Durable Stitches

Consistent stitches on thick quilts demand a rhythm between needle penetration force, thread tension balance, and your steady hand guiding layers through the feed system. Test stitch quality on scrap fabric first—adjust thread tension until top and bobbin threads lock precisely between layers.

Match needle selection to thread thickness, and let the motor performance drive fabric penetration while your needle-feed mechanism manages heavy fabric feeding. That’s how you build durable stitches with rock-solid stitch formation every time.

Industrial Vs. Domestic Machines: Pros and Cons

Choosing between an industrial and domestic sewing machine isn’t just about budget—it’s about understanding what each type delivers when you’re pushing thick materials through the throat plate.

Industrial machines bring serious horsepower and durability, but they demand space and commitment that domestic models don’t.

Here’s what you need to weigh before making the call.

Advantages of Industrial Machine Design

Industrial sewing machines deliver unparalleled industrial power through 550-watt motors—nearly ten times the strength of domestic units—enabling smooth heavy fabric management through multiple thick layers. Their sturdy construction features reinforced chassis and heavy-duty components engineered for thousands of hours of reliable operation. Enhanced stitch quality comes from precise needle-feed mechanisms and extra-long take-up strokes that form durable stitches even in dense materials like canvas or leather.

| Feature | Industrial Machine | Domestic Machine |

|---|---|---|

| Motor Power | 550 watts | 60 watts |

| Stitches/Minute | Up to 3,500 | Up to 1,100 |

| Take-Up Stroke | 4 inches | 3 inches |

| Component Build | Heavy-duty, reinforced | Standard, lighter |

You’ll appreciate how industrial sewing machines maintain consistent performance on demanding quilting projects without motor strain or skipped stitches.

Limitations and Space Requirements

Despite their power and precision, industrial machines demand serious real estate. You’re looking at dedicated floor space for a sturdy table setup, room to maneuver bulky quilts, and a permanent installation that’s anything but portable. These powerhouses usually weigh 80-150 pounds and require custom tables bolted to the floor. You’ll need clearance on all sides to manage large quilts without fabric bunching at the feed dogs.

| Space Requirement | Minimum | Recommended |

|---|---|---|

| Table Dimensions | 48″ x 24″ | 60″ x 30″ |

| Work Area Clearance | 4 feet | 6-8 feet |

| Machine Weight | 80-150 lbs | N/A |

Storage solutions and room layout planning become critical when you’re committing to an industrial machine for heavy materials quilting.

Maintenance and Longevity Considerations

Your industrial machine will run like clockwork for decades—if you treat maintenance as a ritual, not an afterthought.

Regular servicing keeps heavy-duty components aligned, while oil replacement and machine cleaning protect the needle-feed mechanism from gumming up. Part replenishment—especially for worn presser feet and bobbin cases—prevents costly downtime when sewing heavy materials.

| Maintenance Task | Frequency | Impact on Longevity |

|---|---|---|

| Oil Replacement | Every 8 hours | Prevents mechanism wear |

| Machine Cleaning | Daily | Protects take-up stroke |

| Professional Servicing | Annually | Extends warranty coverage |

Industrial sewing machines reward diligence with peerless durability.

Specialized Stitching Vs. Versatility

Most industrial machines are built like champion racehorses—bred for one thing and absolutely unbeatable at it. Domestic machines, on the other hand, aim to be the Swiss Army knife of the sewing world. A straight-stitch industrial machine excels at precision control and fabric compatibility with heavy materials, but it lacks zigzag or decorative stitch options. Domestic machines offer customization across stitch complexity, yet they fall short in needle-feed power for true quilting dominance on thick layers.

| Feature | Industrial Machines | Domestic Machines |

|---|---|---|

| Stitch Complexity | Single-function (straight-stitch) | Multi-pattern capability |

| Machine Adaptability | Task-specific design | General-purpose versatility |

| Fabric Compatibility | Heavy materials mastery | Light to medium fabrics |

| Precision Control | Supreme consistency | Variable performance |

| Customization Options | Limited stitch types | Extensive stitch library |

Cost-Benefit Analysis for Quilters

Calculating investment returns on industrial sewing machines for quilting thick materials requires a careful analysis of upfront costs versus long-term gains. Entry-level industrial models start at around $465, while domestic machines range from $125 to $9,999. The investment can be recouped within 2–4 years through faster production output and reduced repair costs. Industrial machines significantly enhance efficiency by cutting completion time by 60%, allowing for better productivity. Annual maintenance averages just $175, and these heavy-duty components last 15–25 years, double the lifespan of home models.

The benefits of industrial machines extend beyond speed. They can handle eight layers of thick materials without skipped stitches, achieving 95%+ stitch uniformity. Cost savings compound over time, with total maintenance under $2,000 across a decade. Machine durability ensures consistent output, enabling users to focus on craftsmanship rather than equipment limitations.

| Factor | Industrial Machines | Domestic Machines |

|---|---|---|

| Initial Investment | $465–$7,110 | $125–$9,999 |

| Cost Per Quilt | $40–$60 annually | $80–$150 annually |

| Payback Period | 2–4 years | N/A (ongoing repairs) |

| Resale Value | 55% after 5 years | 20–30% after 5 years |

Frequently Asked Questions (FAQs)

What thread weight works best for thick quilts?

For quilting thick materials, opt for heavier thread weights like 40 or Thicker thread provides better fabric penetration and stitch strength, which heavy-duty components require.

Match your thread weight to your fabric thickness—heavier materials demand sturdy threads that won’t snap under tension.

How do you prevent needle breakage on heavy layers?

Nothing humbles a shiny new needle quite like a heavyweight bout with batting and denim—snap, and it’s game over.

To prevent breakage, match your needle size to the fabric weight, use heavy-duty components designed for thick layers, and don’t rush your stitch speed through dense sections.

Can industrial machines handle batting over two inches?

Batting over two inches pushes the boundaries of most industrial sewing machines.

Heavy-duty components and high presser foot lifts on walking foot models can manage extreme thickness, but you’ll need to test your specific machine’s industrial capacity and adjust tension carefully.

How do you troubleshoot uneven stitches on thick materials?

Uneven stitches often stem from incorrect stitch tension or mismatched thread selection for heavy fabrics.

Check your needle maintenance—dull or bent needles can’t penetrate thick layers consistently.

Calibrate your industrial machine’s needlefeed timing and verify straightstitch settings match your fabric preparation requirements.

Conclusion

Domestic machines surrender where industrial sewing machine quilting thick materials begins—the separation isn’t subtle, it’s mechanical fact. You’ve seen the specs, weighed the features, and now understand that throat space, feed systems, and motor torque aren’t luxuries; they’re requirements for layers that fight back.

The right machine doesn’t just survive heavyweight projects—it transforms them from endurance tests into controlled, repeatable results. Choose based on what you’ll stitch tomorrow, not what impressed you today, and your quilts will show the difference.

- https://compass-canvas.com/

- https://www.stonybrooksewandvac.com/product/brother-pq1600s-high-speed-straight-stitch-sewing-quilting-machine/

- https://topsvacuumandsewing.com/brother-pq1600s-high-speed-straight-stitch-sewing-and-quilting-machine/

- https://www.youtube.com/watch?v=nnj7Pzn0rUQ

- https://www.erinsayssew.com/brother-pq1500s-high-speed-quilting-and-sewing-machine-review/