This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

This synchronized control eliminates the slippage that ruins heavy leather goods, thick upholstery, and multi-layer quilts. Manufacturers rely on walking foot technology to maintain consistent stitch quality through materials that would jam or pucker on conventional machines.

Whether you’re scaling up production or tackling projects that demand precision through bulk, understanding how these machines work gives you the control to deliver results that endure under real-world use.

Table Of Contents

- Key Takeaways

- What is Industrial Walking Foot Sewing?

- Types of Industrial Walking Foot Machines

- Leading Brands and Popular Models

- Key Features and Specifications

- Materials and Projects Suited for Walking Foot Machines

- Essential Accessories and Attachments

- Maintenance and Longevity Tips

- Market Trends and Buying Considerations

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Industrial walking foot machines use synchronized top and bottom feed systems that grip fabric from both sides simultaneously, eliminating the slippage and puckering that standard single-feed machines create when handling heavy materials like leather, vinyl, or multiple fabric layers.

- The dual-feed mechanism delivers consistent stitch quality across difficult materials by maintaining even pressure and synchronized movement throughout each stitch cycle, making these machines essential for professional results in upholstery, quilting, and heavy-duty manufacturing.

- Machine selection depends on matching specific capabilities to your workload—factors like fabric thickness capacity (up to 14mm), production speed (up to 3,300 stitches per minute), flatbed versus cylinder bed configuration, and whether you need single or double needle models directly impact project outcomes.

- Regular maintenance including oiling every 7-8 hours, needle replacement on the same schedule, daily lint removal, and proper tension adjustments prevents costly breakdowns and maintains the precision these machines are built to deliver across years of heavy use.

What is Industrial Walking Foot Sewing?

Industrial walking foot sewing machines work differently than standard machines because they feed fabric from both the top and bottom simultaneously. This dual-feed system keeps your material stable and prevents shifting, which is especially important when you’re working with tricky fabrics or stacking multiple layers.

Here’s what sets them apart and why they’re built the way they’re.

Walking Foot Mechanism Explained

Ever wonder how a walking foot machine feeds fabric so smoothly that it almost seems to pull itself through? The walking foot mechanism uses synchronized top and bottom feed dogs that grip fabric from both sides.

As your needle moves down, the top feed dog lowers and grips the material. When the needle rises, feeding synchronization kicks in—both the needle movement and pressure regulation work together. The bottom feed dog advances fabric forward while the top foot lifts slightly, then grips again for the next stitch.

This differential feed guarantees even, controlled fabric gripping throughout each cycle, preventing slippage on difficult materials.

Differences From Standard Sewing Machines

While the walking foot does the heavy lifting on fabric control, a standard sewing machine leaves you wrestling with the material on your own. Here’s what sets them apart:

- Dual feeding mechanism: Walking foot machines grip fabric from top and bottom simultaneously, while standard lockstitch machines only feed from below

- Pressure regulation: The synchronized top and bottom feed dogs maintain consistent material control across all fabric types

- Stitch consistency: Even feed produces uniform stitches on difficult materials; standard machines often cause puckering or slippage

- Motor power: Industrial walking foot sewing machines deliver higher torque for needle feed through multiple layers without bogging down

Standard machines work fine for lightweight cotton, but they can’t meet the demands of leather, vinyl, or layered quilting the way a walking foot machine can.

Benefits for Heavy and Layered Fabrics

When you’re working with thick fabrics or stacking multiple layers, a walking foot machine becomes your best ally because it feeds material evenly from both top and bottom, preventing the slippage and puckering that standard machines struggle with. This dual fabric feed control manages heavy fabrics like denim and canvas without bogging down.

You get consistent stitching on every pass, reduced slippage on multiple fabric layers, and a professional finish that holds up. The enhanced durability comes from that synchronized feeding—your seams stay tight and even, turn after turn.

That’s why quilting, upholstery, and heavyweight materials demand a walking foot machine.

Types of Industrial Walking Foot Machines

Industrial walking foot machines come in different configurations to manage various projects and production needs. The machine type you choose depends on what you’re sewing, how much space you have, and whether you’re working solo or running production lines.

Let’s explore the main categories that can help you find the right fit.

Flatbed Vs. Cylinder Bed Machines

Your choice between flatbed and cylinder bed machines comes down to the shape and size of what you’re sewing. Flatbed walking foot machines work best for quilting and flat projects where you need plenty of workspace. Cylinder bed models are suitable for round or bulky items like sleeves and saddles. Consider these key differences:

- Flatbed advantages include easier fabric manipulation and ideal space for large quilting projects

- Cylinder applications excel with tubular garments and irregularly shaped work

- Space considerations matter—flatbed machines need more table room than cylinder models

- Project suitability determines your best choice: flat work versus curved pieces

- Cost comparison shows flatbed walking foot machines often cost less than specialized cylinder bed units

Your workspace and project types should guide your decision between these industrial walking foot sewing machine options.

Single Needle Vs. Double Needle Models

Picking between single and double needle machines comes down to how much work you need to push through in a day. Single needle models give you flexibility for varied fabric types and application variety, while double needle machines increase your production speed greatly. Here’s how they stack up:

| Feature | Single Needle | Double Needle | Best For |

|---|---|---|---|

| Stitch Aesthetics | Clean, uniform lockstitch | Dual parallel lockstitch seams | Detail work vs. speed |

| Production Speed | Moderate throughput | Double output per pass | High-volume orders |

| Fabric Types | All materials treated equally | Heavier fabrics benefit most | Adaptability vs. efficiency |

| Seam Strength | Standard reinforcement | Enhanced strength with dual seams | Durability demands |

| Application Variety | Broad range of projects | Specialized heavy-duty work | General work vs. specific tasks |

Double needle walking foot sewing machines excel when you’re running production schedules. You’ll complete two seams simultaneously, cutting your time in half. Single needle units offer better control for detailed work and adapt to different fabric weights without adjustment hassles.

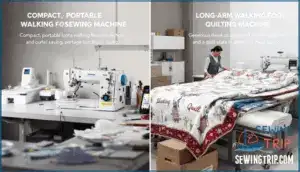

Portable and Long Arm Options

Sometimes the best tool for a job isn’t the one that fits your whole workshop—it’s the one that fits your hand and gets the work done wherever you are.

Portable and long-arm walking foot sewing machines give you exactly that kind of control. Here’s what sets them apart:

- Portable models weigh less and move easily between workspaces, perfect for small shops or shared facilities.

- Long arm machines provide 18-24 inches of throat space for larger quilting and upholstery projects.

- Arm lengths range from standard flatbed to extended reach, matching your project size needs.

- Storage options in portable units fold down compactly, solving workspace constraints.

Choose portability when your workspace needs flexibility. Pick long-arm machines when project size demands extra room. Either way, you’re getting industrial walking foot sewing power adapted to where you actually work.

Leading Brands and Popular Models

You’ve got plenty of solid brands to choose from when shopping for an industrial walking foot machine. Each one brings something different to the table, whether you’re running a small operation or managing big production runs.

Let’s break down the leading manufacturers and their most popular models so you can figure out what matches your needs.

Consew, Reliable, Highlead, Juki, Techsew

Regarding walking foot sewing machines, five brands dominate the market. Consew leads with rugged portability—their CP206RL weighs just 23 lbs and accommodates materials up to 14mm thick. Reliable innovates through direct-drive servomotors and programmable needle positioning on models like the 4020SW.

Highlead specializes in heavy-duty leather work, with the GC0618-1SC reaching 2,000 stitches per minute. Highlead machines are designed for sewing thick materials, including leather and vinyl.

Juki ranks among the top six global industrial brands, offering adaptable models like the TL2010Q for quilting. Techsew focuses on affordability for small shops with accessible machines like the 0302. Each brand fills a specific market niche.

Standout Models and Their Features

Each flagship model delivers precision for specific workflows. The Consew CP206RL excels with portable setup and 14mm capacity—ideal for field work. Reliable’s 5600SW pairs servo motors with programmable positioning for consistent results. Highlead’s GC0618-1SC dominates leather applications at 2,000 stitches per minute. Juki’s TL2010Q offers quilting adaptability. Techsew’s 0302 provides budget-friendly entry without sacrificing walking foot performance.

To improve productivity, consider models with automatic thread trimming. Feature prioritization guides your selection: speed, material thickness, automation level, and budget constraints determine which industrial walking foot sewing machine matches your production demands.

Choosing The Right Brand for Your Needs

Your brand choice boils down to matching machine capabilities with what you actually need to produce. When you’re picking between Consew, Reliable, Highlead, Juki, Techsew, and Family Sew, think about three core things: the materials you’ll sew most often, your production speed requirements, and your budget.

If you’re working primarily with leather and vinyl, Highlead machines like the GC20698 series are built for that job. They run at consistent speeds and manage the material thickness without slipping. For quilting and lighter layered work, Juki’s reputation for precision makes it worth considering—you’re paying for reliability across different fabric types. Consew fits well if portability matters or you need flexibility across multiple workspace setups.

Budget isn’t just about the upfront cost. Brands like Techsew offer solid walking foot performance at lower price points, which works fine if you’re starting out or running smaller jobs. Reliable and Juki tend to sit higher on the investment scale, but they generally retain their value and need fewer repairs over time. See what the manufacturer recommends for maintenance too—some brands have better parts availability in your area, which saves you money when you need service.

The real question is this: which brand’s machines can take on your toughest job without strain? That’s your answer.

Key Features and Specifications

Every industrial walking foot machine has its own set of built-in features and technical specs that shape how it performs on different projects. Understanding these features helps you pick the right machine for your work and get the most out of it once you have it running.

Here’s what you need to know about the key specs that matter most.

Stitch Length and Width Adjustments

Getting your stitch length and width just right can make the difference between a seam that holds and one that falls apart under stress. Most walking foot machines feature a dial-operated stitch length regulator that lets you adjust from fine to heavy stitching.

You’ll want to match your stitch length to fabric thickness and needle size—heavier fabrics demand longer stitches for proper stitch density and seam quality. Smaller needles fare better with tighter stitches on delicate materials, while larger needles accommodate thicker layers.

Adjusting tension alongside stitch length guarantees consistent results across different projects.

Feed Mechanisms and Speed Ratings

The walking foot and feed dogs work together as a team to move fabric through the machine at a steady pace, and understanding how they interact is key to getting clean, professional seams every time. Feed synchronization between top and bottom mechanisms makes certain even fabric advancement without slipping or bunching.

Your machine’s maximum speed—usually up to 3300 stitches per minute—depends on motor type and power consumption. Proper feed mechanism adjustment optimizes stitch regulation and fabric feeding for consistent results across different materials and weights.

Safety Clutch and Lubrication Systems

A safety clutch prevents your machine from jamming when you encounter resistance, while the lubrication system keeps everything running smooth without constant maintenance headaches. Here’s what you need to know:

- Safety clutch mechanism protects your motor by disengaging when fabric gets stuck, preventing costly damage and needle breakage.

- Automatic lubrication systems reduce failure risks by distributing oil to critical points during operation, greatly cutting manual maintenance time.

- Lubrication types vary—some machines use semi-automatic oiling while others require manual application, depending on your model and budget.

- Clutch maintenance involves regular inspection and adjustment to guarantee reliable safety benefits and consistent performance across all sewing tasks.

Optional Pneumatic Presser Foot Lifters

Once you’ve got your safety systems dialed in, a pneumatic presser foot lifter takes the strain out of manipulating fabric by doing the heavy lifting for you. This optional feature uses an air compressor to raise and lower the presser foot automatically, which saves your hands from repetitive motions when working with heavy fabrics.

Installation costs vary, but the benefits pay off quickly on high-volume projects. You’ll adjust foot height with simple controls, making pneumatic presser foot lifter systems ideal for production work where speed and consistency matter.

Materials and Projects Suited for Walking Foot Machines

Walking foot machines are built to tackle the toughest fabrics and most demanding projects out there. Whether you’re working with tough materials like leather and vinyl, layering multiple pieces of fabric, or tackling large-scale production runs, these machines are up for the job.

Let’s explore the specific materials and projects where a walking foot machine really shines.

Sewing Leather, Vinyl, and Upholstery

Materials like leather and vinyl demand machines that won’t slip or bunch as they feed through, and a walking foot machine is built exactly for that job. The dual feed system grips both top and bottom simultaneously, preventing stretching and keeping your seams perfectly aligned. Here’s what makes these materials manageable:

- Leather stitching techniques require consistent pressure to avoid punctures and puckering

- Vinyl seam durability improves dramatically with heavy-duty thread that won’t break under tension

- Upholstery fabric choices range from dense canvas to delicate microsuede, each needing precise control

- Decorative stitch options add professional finishing touches to saddles, bags, and furniture pieces

Your industrial walking foot sewing machine manages these materials because the synchronized feeding prevents the slippage that ruins standard machines. Leather stretches differently than cotton, vinyl resists compression, and upholstery demands power—this machine delivers all three requirements.

Quilting and Layered Fabrics

When you stack fabric layers and run them through a standard machine, they slip and bunch, but a walking foot manages multiple layers like they’re a single piece of material. The dual feed mechanism grips batting and fabric simultaneously, delivering fabric layer control that keeps everything aligned. Quilting stitch regulation stays consistent across thick layers because the synchronized top and bottom feeds work together—no more puckering or shifting that ruins your piecing precision. Batting thickness guides your machine choice; heavier densities need the walking foot’s gripping power. Decorative stitch options let you add finishing touches without sacrificing quality or control.

| Feature | Benefit |

|---|---|

| Dual feed system | Prevents layer slippage and bunching |

| Heavy duty construction | Handles multiple fabric layers effortlessly |

| Consistent stitch regulation | Maintains even quilting across varying thicknesses |

Large-scale and Small Business Applications

Your factory gains real momentum when walking foot machines manage heavy-duty sewing. Large-scale production facilities report 25% productivity jumps replacing standard machines for thick materials. SMEs adopt these systems for cost efficiency—refurbished models cost 20–40% less while cutting defect rates 15–25%.

Automation benefits multiply: servo motors reduce energy consumption and noise 40%, while synchronized multi-needle units slash labor time 20%.

Market growth accelerates adoption, with walking foot equipment driving 28% of industrial sewing machine revenue through 2033.

Specialty Projects Like Boat Sails and Saddles

Beyond the factory floor, these machines tackle projects that demand precision where standard equipment just won’t cut it. Boat sails and saddles require the kind of muscle only walking foot sewing machines deliver. These specialty applications push your equipment to its limits:

- Sail Construction: Canvas and heavy marine fabrics need dual feed systems to prevent slipping during long seams

- Saddle Stitching: Layered leather demands even tension across thick material without puckering

- Awnings Material: Outdoor-grade fabrics require machines that work with UV-resistant synthetics smoothly

- Marine Upholstery: Saltwater-resistant materials need consistent stitching on curved, bulky projects

- Saddle Bags: Multiple leather layers get stitched with precision only industrial walking foot sewing machines provide

You’ll find that cylinder bed models excel here. They navigate round or irregularly shaped items where flatbed machines struggle. The walking foot mechanism keeps heavy weight materials feeding evenly, preventing jams that wreck production timelines. Your investment pays off when standard machines would fail.

Essential Accessories and Attachments

Your walking foot machine works best when you’ve got the right tools and attachments for the job. The accessories you choose can make the difference between a project that runs smoothly and one that gives you headaches.

Let’s look at what’s available to help you get more from your machine.

Flatbed Table Attachments

Flatbed table attachments are the difference between struggling with fabric control and gliding through your project with precision. These extensions dramatically expand your working surface, giving you room to maneuver bulky materials smoothly.

The adjustable steel legs keep everything stable and level, while vibration dampening prevents the machine from shifting during high-speed work. Material guides keep your fabric aligned perfectly, and height adjustments let you position the table unit to match your machine.

Extension tables and table drawers provide organized storage for thread, needles, and supplies right at your station.

Servo Motors and Electronic Controls

Servo motors and electronic controls give you precision speed management and consistency that manual machines just can’t match. A digital electronic servo motor lets you adjust stitching speed on the fly without losing power or control.

Servo integration maintains steady tension automatically, eliminating needle breakage and skipped stitches.

Programmable sewing through control systems streamlines repetitive tasks and boosts accuracy. Motor calibration guarantees your machine performs at peak efficiency every time you power up.

Needle and Thread Compatibility

Your needle and thread choice makes or breaks whether your walking foot machine delivers perfect seams or frustrating failures. Matching needle and thread types to your fabric prevents breakage and skipped stitches. Thread size determines tension adjustments needed for smooth stitching. Wrong needle sizing causes needle deflection and poor stitch quality.

- Needle sizing: Pick needles sized for your fabric weight and thread thickness

- Thread types: Use polyester or bonded nylon for heavy fabrics; cotton for lighter projects

- Fabric matching: Select needle type based on material—ballpoint for knits, sharp for wovens

- Tension adjustments: Fine-tune tension when switching thread sizes to prevent breakage and maintain stitch consistency

Accessories Packages for Specific Tasks

Now that you’ve got needle and thread sorted, it’s time to think about the right gear for your specific work. Manufacturers offer pre-assembled accessories packages designed around common tasks.

Quilting accessory packs bundle flatbed attachments and roller edge guides for consistent fabric movement. Leather sewing kits include specialized presser feet and tension settings. Upholstery attachments add extra table space and reinforced feed dogs. Canvas awning bundles pack heavy-duty components for industrial projects.

Custom package creation lets you mix and match based on what you’re actually building.

Maintenance and Longevity Tips

Your walking foot machine won’t last long if you skip regular care. Oil, needles, and cleaning routines make the difference between years of smooth operation and expensive breakdowns.

Here’s what you need to know to keep your machine running strong.

Oiling and Lubrication Best Practices

Every 7–8 hours of operation, your walking foot machine needs fresh oil to keep its internal components moving smoothly and prevent costly breakdowns. Always use manufacturer-recommended oil types and apply them to specified lubrication points—usually the hook assembly, needle bar, and feed mechanism.

Manual lubrication requires consistent attention, but automatic lubrication systems lessen this burden greatly.

Watch for contamination risks like lint mixing with oil, which can cause sluggish performance and require troubleshooting oiling issues immediately.

Needle and Bobbin Care

A worn needle or damaged bobbin can undo all your lubrication work in minutes, causing thread breaks and skipped stitches that halt production. Replace needles every 7–8 hours to match your oiling schedule, and choose the right needle type and size for your fabric—heavy leather demands different needles than vinyl.

Check bobbin winding tension, inspect bobbins for burrs or cracks, and verify needle and thread compatibility regularly. These routine checks maintain stitch quality and keep your machine running strong.

Daily Cleaning Routines

Lint buildup sneaks up fast, turning a smooth-running machine into a frustrating jam machine if you skip your daily cleanup.

Brush out the bobbin area, feed dogs, and needle zone after each shift to prevent thread tangles and mechanical faults.

This simple routine protects your industrial sewing machine’s precision and keeps workspace organization tight, whether you’re running manual lubrication or automatic lubrication systems.

Common Troubleshooting and Repairs

When tension goes haywire or skipped stitches pop up mid-seam, don’t panic—most walking foot hiccups trace back to a handful of fixable culprits.

Check thread tension first, then inspect needle breaks and feed issues caused by worn sewing machine components.

If motor malfunction or stitch skipping persists, your safety clutch mechanism might need adjustment—contact technical support before diving into complex sewing machine maintenance repairs.

Market Trends and Buying Considerations

The industrial sewing machine market is on the rise, and smart buyers know what to watch for before pulling the trigger on a walking foot machine. Your purchase decision hinges on several moving parts—from market growth patterns to the nitty-gritty of shipping logistics.

Let’s break down what you need to think about when buying your next industrial walking foot sewing machine.

Industrial Sewing Machine Market Growth

Industrial sewing machine sales are climbing steadily, with the market reaching $3.48 billion in 2024 and projected to hit $6.04 billion by 2034. Three forces are reshaping this landscape:

- Regional dominance — Asia Pacific leads production, with China manufacturing 77% of the region’s 7.7 million units

- Automation impact — Smart machines and IoT integration drive demand for large-scale production efficiency

- Import dependence — The U.S. imported 382,000 units in 2024, half from China

Emerging economies and expanding textile industries fuel this market CAGR of 5.9%, making sewing machines for business a solid investment.

Factors Influencing Purchase Decisions

Choosing an industrial walking foot sewing machine isn’t just about the price tag—it’s about matching capabilities to your workload. Fabric compatibility is a top priority for over 83% of buyers, especially when working with thick leather or layered upholstery. Production volume also plays a crucial role, with operations producing 1,000+ units monthly favoring high-speed models rated above 3,000 stitches per minute. Stitch adaptability is another key factor, as 57% of buyers require both straight and zigzag functions. Build quality is essential for longevity, with machines featuring metal frames outlasting lighter alternatives. Trusted brands maintain strong resale value, depreciating only 20% after three years.

Here’s what shapes your decision:

| Decision Factor | Why It Matters |

|---|---|

| Fabric compatibility | Accommodates materials up to 8mm thick; reduces slippage by 70% |

| Production volume | High-speed machines boost throughput 30% for heavy materials |

| Stitch adaptability | Multiple stitch patterns suit diverse product lines |

| Build quality | Metal frames cut downtime 18% with automatic lubrication |

For sewing machine applications ranging from boat sails to small business projects, these factors determine whether your walking foot machine delivers real value or just occupies floor space.

Shipping, Assembly, and Warranty Information

Getting your machine from the warehouse to your workspace involves more than just tracking numbers—it’s a process that can either set you up for success or leave you troubleshooting before the first stitch. Shipping costs average $75–$250 depending on weight and distance.

Most manufacturers offer assembly options, with on-site setup costing $150–$400. Warranty coverage generally spans one to three years on parts, while return policies allow 30-day exchanges.

File damage claims immediately with photos—carriers require documentation within 48 hours for reimbursement.

Online Ordering and Customer Support

Before you click "purchase," remember that the machine is just one piece of the puzzle—the real test comes when you need support at 2 PM on a deadline day.

Check these before placing online orders:

- Website Structure: Confirm shipping information and return policies are visible upfront.

- Support Channels: Confirm the customer support team offers phone and email technical support during business hours.

- Order Tracking: Make sure online order processing includes real-time tracking updates.

- Online Reviews: Read feedback about response times and warranty claim processing.

Frequently Asked Questions (FAQs)

How often should I service my machine professionally?

Professional servicing every 12 to 18 months keeps your machine running smoothly, but heavy users should schedule technical support visits twice yearly. Cost factors depend on your workload and machine complexity.

Professional benefits include diagnosing hidden issues before they escalate, while finding technicians through warranty information networks guarantees qualified help.

What thread sizes work best for leather?

Thread is your silent partner—pick wrong, and leather won’t cooperate. For leather stitching, use thread sizes 69 to 138 based on leather thickness.

Thread strength and needle size must match your material. Bonded nylon or polyester addresses leather’s demands while maintaining stitch appearance and proper thread tension.

How do I prevent skipped stitches effectively?

Skipped stitches happen when needle selection, thread tension, or foot pressure aren’t right for your fabric. Match needle sizes to thread and material weight.

Check timing adjustments, stabilize fabric properly, and adjust stitch length. These steps fix most skipping issues fast.

Are used industrial walking foot machines reliable?

Used industrial sewing machines can be reliable if you inspect machine specifications carefully. Check brand reliability comparison, warranty availability, and repair cost analysis.

A thorough inspection checklist guarantees your heavy-duty sewing machine has a solid used machine lifespan ahead.

Conclusion

You’d think a machine that just moves fabric would be simpler than brain surgery, yet here we’re—walking foot mechanisms solving what standard sewing couldn’t fix for decades.

Industrial walking foot sewing turns slippage and misalignment into relics of amateur work. When your reputation rides on every stitch holding tight through years of stress, you don’t gamble on equipment that fights your material instead of controlling it.

Master this technology, and you’re not just sewing—you’re building products that outlast the competition.

- https://www.openpr.com/news/4144807/industrial-sewing-machines-industry-outlook-2025-2029-market

- https://straitsresearch.com/report/industrial-sewing-machine-market/united-states

- https://www.accio.com/business/trend-of-industrial-stitching-machines

- https://www.sewingbeefabrics.co.uk/sewing-machine-feet-guide/

- https://marinefabricatormag.com/2017/03/01/high-performance-sewing-machines/