This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You wouldn’t use a butter knife to slice through leather, right? The same logic applies when you’re cutting fabric. A dull pair of scissors will fray your edges, snag delicate fibers, and leave you wrestling with material instead of creating.

The difference between a clean cut and a frustrating mess comes down to knowing what to look for when choosing fabric scissors. Blade material, handle comfort, and weight distribution aren’t just fancy specs—they’re the features that separate tools that work with you from ones that fight you every step.

Whether you’re hemming curtains or piecing together a quilt, the right scissors transform cutting from a chore into a breeze.

Table Of Contents

Key Takeaways

- Sharp, high-quality blades made from high carbon steel or titanium-coated materials maintain their edge longer and cut cleanly through fabric without fraying, making blade material the most critical feature when choosing scissors.

- Match your scissors to your project—long blades (9-12 inches) power through wide fabric in fewer strokes, while shorter blades (4-6 inches) give you precision control for detailed work like embroidery or quilting.

- Ergonomic handles with soft-touch grips and proper weight distribution prevent hand fatigue during extended cutting sessions, transforming marathon projects from exhausting to manageable.

- Regular maintenance including cleaning after each use, proper dry storage, and sharpening every 6-12 months protects your investment and keeps your scissors performing like new for years.

Key Features to Look for in Fabric Scissors

You can’t just grab any scissors and expect perfect cuts through layers of cotton or silk. The right fabric scissors make the difference between clean edges and frustrating snags that ruin your project.

If you’re starting out or upgrading your tools, check out this guide to the best sewing scissors for sharper, more reliable results.

The right fabric scissors make the difference between clean edges and frustrating snags that ruin your project

Let’s break down the five features that separate professional-grade scissors from the ones that’ll sit unused in your drawer.

Whether you’re upgrading your toolkit or buying your first pair, choosing the right fabric scissors for professional seamstresses starts with understanding what actually makes them worth the investment.

Blade Material and Sharpness

Your blade’s the boss—nothing else matters if it can’t cut clean. High carbon steel maintains sharpness longer than standard alloys, while titanium-coated blades deliver three times the edge retention. Stainless steel blades resist rust in humid spaces.

Professional stitchers often pair these durable blades with precision couture sewing construction methods to ensure every cut supports clean, lasting seams.

Factory edges sit between 15° and 20° for that sweet spot of cutting efficiency and blade durability. Sharp blades slice through fabric without snags, making every project a breeze.

For home maintenance, sharpening fabric scissors at the correct angle keeps them performing like new between professional services.

Blade Length and Cutting Capacity

Long blades—think 10 inches or more—let you power through wide fabric in one smooth stroke. That’s precision cutting without constant repositioning!

Standard dressmaker scissors sit at 8 to 10 inches, balancing scissor efficiency with maneuverability.

Heavy-duty projects need 9 to 12 inches to handle fabric thickness without wearing you out.

Your blade length directly impacts cutting capacity, so match it to your material before you commit.

Handle Design and Ergonomic Comfort

Your grip controls every cut, so grip design matters more than you think. Look for ergonomic grips with soft-touch overlays and contoured finger grooves—they’ll mold to your hand and reduce fatigue during marathon sessions.

Textured surfaces prevent slips when your palms get sweaty. Ambidextrous designs work for lefties and righties alike.

That pronounced palm support distributes pressure across your whole hand, not just your fingertips!

If you’re looking for the right pair to match your cutting style, check out these top fabric scissors for home sewers.

Weight and Balance Considerations

A well-balanced pair feels lighter than its actual weight—that’s the magic of smart weight distribution. When the pivot aligns with your grip, you get smooth cutting action without wrestling the fabric.

Ergonomic design with balanced blades means your hand won’t cramp after twenty minutes. Heavy-duty scissors with proper balance let you slice through layers like a breeze, reducing fatigue so you stay in control.

Pivot Quality and Cutting Smoothness

The secret to impeccable cuts? A pivot that rotates freely without wobble. Smooth action keeps blade alignment tight, so your cutting precision stays sharp through every layer.

Over time, pivot wear can throw off your cuts and cause snags. Look for welded or adjustable pivots—they let you make micro adjustments to maintain scissor sharpness and cutting efficiency for years.

Types of Fabric Scissors and Their Uses

Not all fabric scissors are created equal—each type has a specific job to do. You wouldn’t use a sledgehammer to hang a picture frame, right?

The same goes for scissors: choosing the right tool makes your cutting precise, smooth, and frustration-free.

Dressmaker Shears for Garment Cutting

When garment cutting demands absolute control, dressmakers shears deliver the sewing precision you need. These specialized fabric scissors feature 8–12 inch blades with razor-sharp edges that slice through fabric layers without fraying.

Here’s what makes them essential for your projects:

- Offset blade design reduces wrist strain during extended cutting sessions

- Stout construction manages heavy denim and lightweight wool equally well

- Blade sharpness maintains cutting efficiency through repeated seam lines

- Long blade length allows straight cuts up to 3–4 inches from fabric edges

- Precision cutting capability perfect for woven fabrics and garment construction

Embroidery Scissors for Detailed Work

When intricate needlework demands pinpoint accuracy, embroidery scissors become your secret weapon. These petite fabric scissors feature 3–4 inch sharp blades with pointed tips that navigate tight corners without fabric snag.

You’ll breeze through thread cutting on delicate linen and silk while ergonomic grips reduce fatigue during extended sewing and embroidery sessions. Their lightweight design keeps your hand steady for precise snips.

Pinking Shears for Preventing Fraying

Stop fabric edges from unraveling with pinking shears—those distinctive zigzag cuts aren’t just decorative. These fabric scissors feature serrated blades that slice a unique pattern, delivering instant fray prevention on woven fabrics and apparel seams.

You’ll find their 8–12 inch length manages multiple layers with ease. Just remember: consistent scissor maintenance keeps that zigzag edge sharp for reliable fray reduction on every fabric cutting project.

Quilting Scissors for Precision Projects

Precision cutting transforms quilting techniques from guesswork into mastery. You need quilting scissors with 4–6 inch blades that balance control and reach—perfect for patches, templates, and tight seam allowances. Ergonomic grips prevent fatigue during marathon sessions, while razor-sharp edges slice through cottons and flannels without hesitation.

Your fabric selection deserves tools that match your skill, and brands like Gingher deliver the precision cutting power serious quilters demand.

Heavy-Duty Tailor Scissors

When thick fabrics meet ordinary scissors, you’re fighting a losing battle. Heavy-duty tailor scissors pack 9–10 inch stainless steel blades built for canvas, denim, and leather—materials that laugh at weaker tools.

Their sturdy pivot grips torque without flexing, delivering precision cutting through multiple layers.

Professional tailors rely on this tailoring equipment for alterations and layout work because blade durability matters when fabric thickness tests your limits daily.

Top 5 Fabric Scissors Worth Considering

You’ve got the theory down—now let’s talk real tools. These five fabric scissors stand out for their cutting power, comfort, and durability across different budgets and project needs.

Each one brings something different to your sewing table, so you can find the right match for how you work.

1. LIVINGO Titanium Scissors

You’ll love how LIVINGO titanium-coated blades slice through denim and canvas without hesitation. These 9.5-inch fabric scissors pack stainless steel construction with a multi-color titanium coating that fights rust and keeps sharp blades working longer.

The comfort grip handles give you precision control, so your hand won’t cramp during marathon cutting sessions. At 5.4 ounces, they balance nicely for both intricate snips and heavy-duty fabric work.

The ergonomic grips deliver cutting efficiency whether you’re tailoring jeans or piecing quilts—and blade durability that outlasts your standard craft scissors.

| Best For | Sewers, quilters, and crafters who need sharp, rust-resistant scissors that can handle thick fabrics like denim and canvas without losing their edge. |

|---|---|

| Blade Material | Stainless Steel |

| Length | 9.5 inches |

| Handle Design | Comfort Grip |

| Primary Use | Sewing & Tailoring |

| Weight | 5.4 ounces |

| Color | Black/Red |

| Additional Features |

|

- Titanium-coated stainless steel blades stay sharp longer and resist rust and adhesive buildup

- Comfortable ergonomic grip reduces hand fatigue during extended cutting sessions

- Cuts cleanly through multiple layers and heavy materials like jeans at a good price point

- Some users find the 5.4-ounce weight a bit heavy for detailed maneuvering

- May not suit people with weak hands or limited grip strength

- Not as smooth-cutting as premium Japanese scissors according to some reviewers

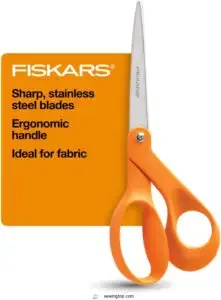

2. Fiskars Orange Handled Scissors

Fiskars orange-handled scissors bring ergonomic design to your sewing table without breaking the bank. The bent-handle construction keeps fabric flat while you cut, and those precision-ground stainless steel blades deliver sharpness that slices clean to the tip.

At 8.41 inches, they’re light enough for detail work yet powerful for cutting efficiency through multiple fabric layers. The ergonomic handle fits comfortably during long quilting sessions, and blade sharpness holds up through hundreds of cuts.

This scissor durability makes them a workhorse for sewing and crafting projects.

| Best For | Sewers, quilters, and crafters who need reliable, comfortable scissors for cutting fabric and other materials during extended work sessions. |

|---|---|

| Blade Material | Stainless Steel |

| Length | 8.41 inches |

| Handle Design | Ergonomic Sculpted |

| Primary Use | Fabric & Crafts |

| Weight | 3.04 ounces |

| Color | Orange |

| Additional Features |

|

- Precision-ground stainless steel blades stay sharp through hundreds of cuts and slice cleanly all the way to the tip

- Bent-handle design keeps fabric flat on your work surface for accurate cutting, plus the ergonomic grip reduces hand fatigue

- Lightweight at just over 3 ounces but durable enough to handle multiple fabric layers without losing cutting performance

- Priced higher than basic scissors, though still mid-range for fabric-specific tools

- Designed primarily for right-handed users, so left-handed crafters may find them awkward

- Needs regular maintenance like occasional sharpening and pivot cleaning to keep performance consistent

3. Professional Heavy Duty Fabric Scissors

Professional Heavy Duty Fabric Scissors deliver cutting power for sewists who refuse to compromise. Built with high carbon steel blades and titanium-coated surfaces, these heavy-duty scissors slice through thick denim and upholstery like butter. The stainless steel blades maintain sharp edge retention even after hundreds of cuts—no more sawing through fabric.

Professional cutting demands professional tools, and the reinforced pivot keeps blades aligned under pressure. Your hand won’t cramp during marathon sewing sessions thanks to ergonomic, non-slip grips. That’s fabric precision you can feel with every snip.

| Best For | Sewists, tailors, and crafters who work with heavy fabrics like denim, canvas, or upholstery and need scissors that stay sharp through extended cutting sessions. |

|---|---|

| Blade Material | High Carbon Steel |

| Length | 5.51 inches |

| Handle Design | Ergonomic Rounded |

| Primary Use | Sewing & Tailoring |

| Weight | Not specified |

| Color | Black |

| Additional Features |

|

- High carbon steel blades with titanium coating maintain sharp edges through hundreds of cuts without dulling

- Reinforced pivot joint keeps blades perfectly aligned even when cutting thick, tough materials

- Ergonomic non-slip handles reduce hand fatigue during long sewing or crafting projects

- Heavier weight may cause fatigue for users with weaker grip strength

- Screw mechanism can rust over time and requires occasional maintenance

- Blade alignment may loosen with heavy use and need periodic adjustment

4. Wteehn Heavy Duty Fabric Scissors

When your project demands industrial-grade steel blades that won’t bend under pressure, Wteehn Heavy Duty Fabric Scissors deliver. These scissors pack an 8-inch blade made from zinc manganese—perfect for cutting through multiple layers of denim or canvas without flinching. The 45° blade angle creates smooth, accurate cuts every time.

You’ll appreciate the aluminum alloy handle with its non-slip grip during extended cutting sessions. The adjustable bolt lock lets you fine-tune tension for your cutting style. At 8.1 ounces, they balance power with control beautifully.

| Best For | Sewers, quilters, and crafters who regularly cut through thick fabrics like denim, canvas, or multiple layers and need scissors that won’t bend or dull quickly. |

|---|---|

| Blade Material | Zinc Manganese |

| Length | 8 inches |

| Handle Design | Ergonomic Non-slip |

| Primary Use | Sewing & Tailoring |

| Weight | 8.1 ounces |

| Color | Black |

| Additional Features |

|

- Industrial-grade zinc manganese blades with a 45° angle cut smoothly through heavy materials without bending

- Ergonomic aluminum handle with non-slip grip reduces hand fatigue during long cutting sessions

- Adjustable bolt lock lets you customize cutting tension for different fabric types

- Prone to rusting when exposed to water, requiring extra care and maintenance

- Finger holes lack padding, which may cause discomfort during extended use

- Zinc manganese material isn’t as corrosion-resistant as stainless steel options

5. Fiskars RazorEdge Fabric Scissors

You need precision without the premium price tag? Fiskars RazorEdge Scissors deliver exactly that. Their premium stainless steel blades feature RazorEdge Technology for superior sharpness and fabric cutting performance. The refined pivot design creates smooth, seamless cuts through cotton, silk, or layered quilting materials.

What makes these sharp blades stand out is the ergonomic design—SoftGrip touchpoints reduce hand fatigue during marathon sewing sessions. At 4 ounces with a protective sheath included, they balance scissor durability with comfortable handling. The ergonomic grips fit naturally, giving you control project after project.

| Best For | Sewers and quilters who need reliable, comfortable scissors for cutting fabric without spending top dollar. |

|---|---|

| Blade Material | Stainless Steel |

| Length | 9.45 inches |

| Handle Design | SoftGrip Ergonomic |

| Primary Use | Sewing & Quilting |

| Weight | 4 ounces |

| Color | White/Orange |

| Additional Features |

|

- Ultra-sharp stainless steel blades with RazorEdge Technology cut cleanly through multiple fabric layers

- SoftGrip touchpoints and ergonomic design reduce hand fatigue during long projects

- Lightweight at 4 ounces with included protective sheath for safe storage

- Handle size might not fit comfortably for all hand sizes

- Actual blade length around 5 inches, shorter than the 8-inch expectation some buyers have

- Manufactured in China, which may be a consideration for some users

How to Maintain Your Fabric Scissors

You’ve invested in quality fabric scissors—now it’s time to keep them performing like new. Good maintenance isn’t complicated, but it makes the difference between blades that stay sharp for years and ones that lose their edge after a few projects.

Here’s how to protect your investment and guarantee every cut stays clean and smooth.

Regular Cleaning After Each Use

You can’t let fabric dust sabotage your blades. After each cutting session, wipe your scissors with a dry cloth to banish fibers and prevent rust. Here’s your daily upkeep routine:

- Remove all lint from the pivot area using a soft brush

- Dry blades thoroughly before storing—moisture is your enemy

- Apply light oil to the pivot point for smooth operation

This cleaning technique keeps your investment sharp.

Proper Storage to Prevent Damage

Where you stash your scissors matters more than you think. Store them in a dry spot with a protective sheath covering the blades—humidity above 60% invites rust on steel.

Use magnetic guards or soft pouches for blade protection, and keep them away from abrasive surfaces that dull edges. Smart storage solutions and rust prevention extend your tool’s lifespan dramatically.

Sharpening Techniques and Frequency

Dull blades kill precision cutting before you notice. Sharpen fabric scissors every 6 to 12 months with regular use—heavy daily cutting demands attention every 2 to 3 months.

Use a fine-grit whetstone for blade honing while preserving edge geometry. Between sharpenings, light stropping maintains cutting efficiency.

Test on scrap fabric after each maintenance session to confirm your sharpening tools delivered clean, fray-free cuts.

Lubricating The Pivot Point

A smooth pivot point transforms every cut from struggle to seamless precision. Apply one or two drops of light, non-residue lubricant directly at the pivot every few months—or after heavy projects—to slash friction and extend scissor longevity.

- Friction reduction keeps blades gliding without resistance through multiple layers

- Proper lubricant types prevent dust attraction and fabric contamination

- Routine pivot cleaning removes buildup before applying fresh lubricant

- Targeted application delivers benefits without messy excess that stains your work

- Strategic pivot maintenance protects your investment while ensuring impeccable cutting performance

Avoiding Non-Fabric Materials

Your fabric scissors deserve dedicated duty—cutting paper, cardboard, or plastic dulls those precision edges faster than you’d think. Reserve your shears exclusively for textiles to maintain blade sharpness and prevent contamination risk.

Before each project, inspect your stainless steel or titanium-coated blades for burrs or residue that could snag threads. This simple cutting precaution protects your investment and guarantees clean cuts every time.

Frequently Asked Questions (FAQs)

Can left-handed scissors really make a difference?

Like a key cut for the wrong lock, standard scissors fight your natural grip. Left-handed fabric scissors offer proper blade alignment and ergonomic grips, reducing hand fatigue while boosting cutting accuracy during sewing and crafting sessions.

How often should fabric scissors be replaced?

Your scissors need replacing every 6–12 months with regular use, or sooner if you notice jagged cuts and declining blade sharpness.

Heavy-duty projects demand faster replacement to maintain cutting efficiency and precision.

Are expensive scissors worth the investment?

Think of premium shears as a reliable car—higher cost, yes, but hardened steel blades maintain sharpness longer, precision pivots reduce hand fatigue, and lifetime warranties often justify the investment for serious sewers.

Whats the difference between scissors and shears?

The main distinction? Shears feature longer blades and offset handle ergonomics for powerful cutting action through thick materials, while sewing scissors offer shorter blades with symmetrical grips for detail work and precision trimming.

Can fabric scissors cut through multiple layers?

Yes—high-grade steel fabric scissors slice through 2–3 fabric layers with ease. Blade sharpness and titanium-coated edges boost cutting efficiency.

Heavy-duty scissors handle thicker materials, while precision cutting depends on proper layered cutting technique.

Conclusion

The wrong scissors can turn a simple project into a battle you’ll lose every time. But when you know what to look for when choosing fabric scissors—sharp blades, comfortable grips, solid construction—you’re not just buying a tool. You’re claiming control over every cut, every edge, every piece you create.

Your work deserves precision. Your time deserves efficiency. And your craft deserves scissors that won’t let you down.

- https://www.sciencedirect.com/science/article/pii/S0749208123000268

- https://github.com/vinhphunguyen/how-to-write-a-paper/blob/master/how-to-write-paper.out

- https://x.com/godofprompt/status/1990526288063324577

- https://blog.wordvice.com/formatting-research-paper-headings-and-subheadings/

- https://pmc.ncbi.nlm.nih.gov/articles/instance/9553038/bin/pone.0275964.s005.docx