This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

That presser foot you barely notice holds more power over your seams than the thread you pick or the stitch length you set. It’s the difference between fabric that glides smoothly and layers that bunch, between professional-looking hems and amateur puckering.

Most sewers stick with the standard foot that came on their machine, unaware they’re working twice as hard for half the results. Each presser foot functions as a specialized tool—zipper feet slide along teeth without catching, walking feet tame slippery knits, and rolled hem feet turn raw edges into crisp finishes in a single pass.

Understanding presser foot functions and uses transforms frustrating projects into predictable successes, giving you control over fabrics that once fought back.

Table Of Contents

Key Takeaways

- The presser foot controls fabric stability and stitch quality more than thread choice or stitch length, with proper pressure preventing puckering, slippage, and seam distortion across different fabric weights.

- Each specialized foot—zipper, walking, rolled hem, buttonhole—functions as a precision tool designed for specific tasks, transforming difficult projects into predictable results when matched correctly to fabric type and technique.

- Shank compatibility and attachment systems (snap-on versus screw-on) determine which presser feet work with your machine, making pre-purchase verification essential to avoid wasted money on incompatible accessories.

- Regular maintenance including lint removal after eight hours of use, proper storage in compartmentalized boxes, and wear inspection for scratches or misalignment doubles presser foot lifespan and prevents mid-project failures.

What is a Presser Foot?

You can’t master your machine without knowing the tool doing most of the work. The presser foot sits right under your needle, holding fabric steady while the feed dogs pull material through each stitch.

Getting the right pressure settings for your presser foot prevents fabric from puckering or sliding around as you sew.

Let’s break down what it’s, how it actually works, and why it matters more than you might think.

From industrial sewing fabric handling to everyday garment construction, understanding the mechanics behind it helps you work smarter and get better results.

Definition and Core Function

Your presser foot is the metal or plastic attachment that holds fabric flat against the throat plate as your sewing machine forms each stitch. Fixed to the presser bar above the needle, it clamps down during stitch formation, enabling feed control and fabric stabilization. Without proper pressure adjustment, you’ll see uneven seams. Standard presser feet handle everyday tasks—zigzag and straight stitches both. To choose the right accessory, be aware that such as shank height play a vital role.

Understanding how to identify your sewing machine foot type helps you match shank compatibility and avoid costly mistakes when upgrading accessories.

How Presser Feet Work on Sewing Machines

When you lower the presser foot lever, you engage a mechanical dance. The foot presses fabric flat while feed dogs grip from below, pulling material forward in sync with each needle stroke. As the needle rises, feed dogs advance; as it drops, they pause. This coordination prevents slippage and wandering seams. Understanding the variety and purposes of can further improve your sewing precision and versatility.

Mastering how to thread an embroidery machine properly ensures your needle and feed dogs work in perfect harmony, preventing thread breaks and tension issues before they ruin your project.

- Fabric feed relies on steady downward pressure from the foot against upward motion of feed dogs

- Presser foot height determines clearance—roughly 5/16 inch when raised—controlling how many fabric layers fit underneath

- Foot pressure adjustments let you fine-tune compression for different weights, preventing puckering on delicate material

- Stitch regulation depends on proper timing between needle penetration and feed dog movement underneath the throat plate

Importance in Stitch Quality and Fabric Control

You’ve set up the mechanics—now let’s see what hangs in the balance. Stitch consistency starts at the presser foot. When pressure is off, fabric slides; too much, and you stretch the top ply, locking in feed pucker. Research shows ply-shift ranges from 1 mm to 12 mm as pressure changes. Proper fabric tension and feed control prevent seam distortion, keeping lines straight and lengths uniform.

Stitch consistency hinges on presser foot pressure—too little and fabric slides, too much and you’re stretching plies into puckered seams

| Pressure Setting | Effect on Fabric | Seam Quality Result |

|---|---|---|

| Too Low | Fabric slips, uneven feeding | Crooked seams, stitch gaps |

| Ideal | Controlled movement, balanced tension | Clean, uniform stitching |

| Too High | Top ply stretches, friction drag | Puckering, fabric damage |

Types of Presser Feet and Their Uses

Your sewing machine probably came with more than one presser foot for a reason. Each foot handles a specific task, from installing zippers to creating invisible hems.

Let’s walk through the essential types you’ll actually use and what makes each one worth keeping in your toolkit.

Standard Presser Foot (Straight and Zigzag Stitches)

Your standard presser foot is the workhorse that stays on your sewing machine most of the time. It manages both straight stitch and zig zag through one wide needle opening, giving you sewing precision across everyday projects.

If you’re just starting out, pairing it with a few specialty presser feet for beginners will expand what you can tackle without overwhelming your setup.

Presser foot height matters—set it right and you’ll see proper fabric guidance and consistent stitch formation. Adjust zigzag settings up to 5 mm for decorative work.

Zipper Foot (Regular and Invisible Zippers)

A narrow zipper foot slips past bulky teeth where your standard presser foot can’t go. You’ll stitch closer to regular zippers using the offset toe for zipper alignment, while an invisible zipper foot guides coils through underside grooves for concealed seams.

Both improve zipper installation by enhancing fabric guidance and stitch quality—just position the foot adjustment properly for your sewing machine and watch your sewing techniques transform.

Buttonhole and Button Sewing Feet

Precision matters when you’re using a buttonhole foot or sewing buttons—one misstep in foot alignment and you’ll risk a crooked finish. Rely on fabric stabilizers for crisp results, and always test stitch density on scraps.

Modern sewing machine presser feet automate buttonhole tips, while button sewing feet clamp buttons securely, streamlining your sewing techniques for professional-looking closures.

Overcast and Blind Hem Feet

Two specialty feet tackle edge finishing with distinct approaches. An overcasting foot wraps thread around raw fabric edges, reducing fraying through overcast stitch patterns. Meanwhile, a blind hem foot uses fabric guidance and foot adjustment to create nearly invisible hems. Both demand stitch consistency and proper setup:

- Test blind stitch width on scrap fabric first

- Adjust thread tension for edge joining

- Position fabric folds precisely along guide blades

- Monitor hem visibility throughout your seam

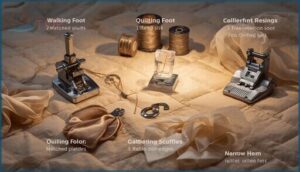

Specialty Feet: Walking, Quilting, Embroidery, Gathering, and Rolled Hem

Specialized feet expand your machine’s reach beyond basic seams. A walking foot adds upper feed dogs that move all layers together—think quilting thick sandwiches or matching plaids without shift. Quilting feet hop between stitches, letting you guide fabric freely for intricate patterns. Embroidery feet glide over stabilizers during dense designs, while gathering feet ruffle lightweight fabric automatically. Rolled hem feet curl edges through a scroll for narrow, professional hems.

| Foot Type | Primary Function | Best For |

|---|---|---|

| Walking foot | Even layer feeding with upper feed dogs | Quilting techniques, thick fabrics, matching patterns |

| Quilting foot | Free motion control with hopping action | Embroidery designs, curved motifs, darning repairs |

| Embroidery foot | Low-profile glide over stabilizers | Dense stitch work, monogramming, appliqué |

| Gathering foot | Automatic ruffling with walking stitch | Gathering methods on lightweight wovens, skirt details |

| Rolled hem foot | Edge curling through spiral guide | Rolled hems on chiffon, sheer fabrics, delicate finishes |

How to Select The Right Presser Foot

Picking the wrong presser foot wastes time and ruins seams. You need to match the foot to your fabric weight, your machine’s attachment system, and the specific task at hand.

Here’s how to choose the right one every time.

Matching Presser Feet to Fabric Types and Projects

Fabric selection drives every presser foot decision you’ll make. Match your foot to what you’re sewing, not what’s already on your sewing machine. Here’s how fabric handling and project planning work together:

- Woven cottons: Use your standard zigzag presser foot with 2-3mm straight stitches for balanced seam finishing and stitch quality

- Knits and stretch fabrics: Grab a tricot foot to prevent distortion during garment construction

- Lightweight voile or chiffon: Rolled hem feet deliver clean edge control on delicate materials

- Thick quilts or multiple layers: A quilting foot (walking foot) synchronizes layers and stops shifting cold

Weight, stretch, and seam type determine which foot wins.

Understanding Shank Types and Machine Compatibility

Your sewing machine’s shank height determines which presser feet will actually mount. Measure from the center of the attachment screw to the needle plate—around 0.5 inches signals low shank, about 1 inch means high shank.

Most domestic machines use low shank geometry, but brands like Bernina require presser foot adapters for standard sewing machine accessories. Check your machine’s anatomy before buying new sewing machine presser feet.

Snap-on Vs. Screw-on Presser Feet

Snap-on presser feet clip onto a horizontal bar without tools—press a lever, and the foot drops free. Screw-on feet require you to loosen a thumbscrew each time you swap attachments.

Most domestic machines built after 1980 use snap-on systems for sewing efficiency, though heavy-duty tasks like walking feet still demand screw-on presser foot durability and shank compatibility for machine adaptability.

Proper Installation and Maintenance Tips

Your presser foot won’t last long if you’re jamming it on wrong or skipping cleanings. Proper installation takes ten seconds when you know the trick, and regular maintenance can double its working life.

Here’s how to handle your presser feet like a pro—from attachment to storage to spotting problems before they ruin a project.

Attaching and Removing Presser Feet Correctly

You’ll save yourself hours of frustration once you nail down the simple rhythm of swapping presser feet—raise the needle, lift the lever, and snap or screw that foot into place with zero drama. Master lever control and shank systems now. Proper attachment methods guarantee foot security every time.

Key Foot Alignment Tips:

- Position the presser foot holder directly above the foot’s mounting bar before releasing the lever

- Listen for the distinct click with snap-on sewing machine accessories—that’s your confirmation

- Check alignment from multiple angles before lowering the needle into fabric

Cleaning and Storing Presser Feet

Once you’ve mastered snapping feet on, keep them working longer with regular cleaning—lint builds up fast. Brush each presser foot after every eight hours of stitching, then dry them completely. Store sewing machine accessories in compartmentalized boxes away from humidity for rust prevention. Your maintenance schedules matter: clean tools perform better and last years longer than neglected ones.

| Cleaning Methods | Storage Solutions | Maintenance Schedules |

|---|---|---|

| Soft brush removes lint | Dry compartmentalized boxes | Clean after 8 hours of use |

| Mild detergent + water | Climate-controlled space | Monthly for light sewers |

| Thorough air-drying | Closed containers with lids | Inspect during each cleaning |

| Avoid harsh chemicals | Away from heavy objects | Service before oiling machine |

Inspecting for Wear and Preventing Damage

Regular wear inspection catches problems before they wreck your stitch quality. Check each presser foot for surface scratches, burrs around the needle hole, and side-to-side play—any of these kills precision fast.

Follow these damage prevention steps:

- Confirm the needle clears the foot opening without touching metal

- Verify foot alignment sits flat against the throat plate

- Store sewing machine accessories in protective cases, never loose in drawers

Proper sewing machine maintenance doubles presser foot lifespan.

Troubleshooting Common Presser Foot Issues

Even the best presser foot won’t perform if something’s off with attachment, alignment, or wear. You’ll face fabric slippage, skipped stitches, or complete malfunction when issues develop.

Here’s how to diagnose problems fast and get your machine back to reliable stitching.

Identifying Attachment and Alignment Problems

When your needle snaps mid-seam or stitches wander, foot alignment issues are usually the culprit. Start by checking these common sewing machine presser feet problems:

| Problem Sign | Likely Cause |

|---|---|

| Needle strikes presser foot | Incorrect shank compatibility or loose attachment |

| Fabric won’t feed evenly | Feed dog adjustment needed or presser foot height too low |

| Rubbing or scraping sounds | Needle clearance issue from misaligned foot opening |

| Stitches skip or pucker | Presser foot tilted or excessive pressure |

| Foot sits crooked | Mounting screw loose or incompatible sewing machine accessories |

Raise your presser foot and check the needle clearance—it should pass cleanly through the opening without touching metal.

Dealing With Fabric Slippage or Stitch Inconsistency

Precision in fabric handling starts with proper presser foot pressure and feed dog adjustment. If stitch quality falters or seams wander, review these five steps:

- Adjust presser foot pressure for fabric tension.

- Check feed dog height for stitch regulation.

- Use a walking foot for tricky layers.

- Inspect thread tensioning.

- Test sewing techniques and tips for improvement.

Solutions for Presser Foot Malfunction or Breakage

When mechanical failure strikes, start with malfunction diagnosis before replacing parts. For a non-moving presser foot, inspect the presser bar linkage—internal binding often requires disassembly.

Loosen the shank screw for foot realignment, rotating until the needle centers between the toes. Adjust pressure to prevent jamming on thick seams.

Breakage prevention means regular cleaning and proper storage of sewing machine accessories.

Frequently Asked Questions (FAQs)

What setting should a presser foot be on?

The best presser foot setting seems elusive yet simple: adjust pressure until fabric feeds smoothly without puckering.

Start at standard pressure, then fine-tune based on fabric weight—lighter materials need gentler tension control.

Can a presser foot improve my sewing?

Yes. The right presser foot transforms stitch quality, fabric guidance, and seam consistency. Proper sewing machine feet stabilize material against feed dogs, preventing skipped stitches and delivering sewing precision that manual control alone can’t match.

Can you use presser feet on vintage machines?

Most snap-on presser feet work beautifully with vintage sewing machines—provided you match the shank type. Low shank adapters enable modern foot conversion for antique restoration, while high shank or slant machines need specialized sewing machine accessories.

Do presser feet affect thread tension settings?

Thread tension and presser foot pressure work together to control stitch quality. When you lower the presser foot, it closes the tension discs—raising it opens them completely.

Fabric guidance and presser pressure both influence tension balance on your sewing machine.

Which presser foot works best for leather?

For leather stitching, a walking foot delivers the best control on thick layers. Teflon feet and roller feet reduce drag on sticky surfaces.

Match your presser foot choice to your leather types and sewing machine capabilities.

Are expensive presser feet worth the investment?

Premium features deliver real sewing efficiency gains—reducing fabric slippage on leather and vinyl while improving fabric precision.

For serious hobbyists tackling diverse projects, the cost benefit and investment value clearly justify higher-quality sewing machine accessories.

How do you adapt presser feet for thick seams?

Thick fabric clearance demands height compensation tools behind your foot. Adjust presser foot pressure on your sewing machine.

Walking feet advance dense layers evenly.

Use bulk seam techniques and hand-crank across junctions for control.

Conclusion

The smallest detail on your machine makes the biggest difference in what you can create. Mastering presser foot functions and uses doesn’t complicate your sewing—it simplifies everything that once felt impossible.

You now hold the exact knowledge needed to choose, install, and troubleshoot every foot with confidence. Stop fighting your fabric. Start letting the right tool do the work it was engineered to handle, and watch your projects transform from unpredictable struggles into controlled, professional results.

- https://singer-featherweight.com/blogs/schoolhouse/presser-foot-height-adjustment-and-alignment

- https://sewcutepatterns.com/blog/the-ultimate-guide-to-sewing-machine-feet

- https://www.sewessential.co.uk/blog/sewing-machine-presser-feet-guide/

- https://www.missouriquiltco.com/collections/sewing-machine-presser-feet

- https://reddeersewing.com/presser-foot-guide/