This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ll find titanium rotary blades offer superior performance over standard steel options.

You’ll find titanium rotary blades offer superior performance over standard steel options.

These blades stay sharper longer and cut through multiple fabric layers without dulling quickly.

The titanium coating creates a harder surface that resists wear and maintains clean cuts.

You’re looking at roughly three times the lifespan of regular blades, which means fewer blade changes and consistent cutting quality.

However, they cost more upfront than steel alternatives.

For heavy-duty quilting or frequent cutting projects, titanium blades prove worth the investment.

Light crafters might not notice enough difference to justify the price.

Your cutting volume and material thickness determine whether titanium delivers real value.

Table Of Contents

- Key Takeaways

- Benefits of Titanium-Coated Rotary Cutters

- Durability of Titanium-Coated Blades

- Sharpness of Titanium-Coated Rotary Cutters

- When to Use Titanium-Coated Rotary Cutters

- Where to Buy Titanium-Coated Rotary Cutters

- Common Materials for Rotary Cutter Blades

- Factors to Consider When Purchasing a Rotary Cutter

- Best 45mm Rotary Cutters

- Best 60mm Rotary Cutters

- How to Use and Maintain Rotary Cutters

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- You’ll get three times longer blade life with titanium-coated rotary blades compared to standard steel, which means fewer replacements and better long-term value despite higher upfront costs.

- You’ll experience superior cutting performance through multiple fabric layers with less pressure required, reducing hand fatigue during extended quilting or sewing sessions.

- You’ll find titanium blades maintain their razor-sharp edge longer and resist wear better, making them ideal for heavy-duty projects involving thick materials like denim or canvas.

- You’ll only see real value from titanium blades if you’re a frequent crafter or quilter – casual users won’t notice enough difference to justify the premium price over steel alternatives.

Benefits of Titanium-Coated Rotary Cutters

Beyond the initial purchase price, titanium rotary blades deliver exceptional value that transforms your crafting experience.

Transform your crafting with titanium blades that deliver three times the cutting power of ordinary steel.

These cutting-edge tools feature titanium coated blades that are three times harder than steel, providing superior cutting precision on every project.

The enhanced hardness reduces friction when slicing through multiple fabric layers, preventing the blade from getting gummed up with adhesives or sticky materials.

This results in a smoother cutting experience, making it ideal for various crafting projects.

Titanium vs steel blades shows clear advantages in material versatility – you’ll effortlessly cut through thick denim, delicate silks, and heavy upholstery fabrics with consistent performance.

The ergonomic benefits include reduced hand fatigue during extended cutting sessions, while titanium blade benefits extend to cost efficiency through longer-lasting sharpness.

Testing revealed that precision cuts matter when using titanium blades.

These rotary blade advantages make titanium rotary blades worth the investment for serious crafters seeking professional results.

Durability of Titanium-Coated Blades

Titanium coated blades pack serious staying power that’ll change your cutting game.

These workhorses resist wear three times better than regular steel, giving you exceptional edge retention that saves money over time.

The titanium coating creates superior material hardness that fights off nicks and damage while delivering outstanding rust resistance.

The blades are often coated using physical vapor deposition to guarantee a strong bond.

Your blade lifespan extends dramatically with titanium vs steel blades.

This wear resistance means fewer replacements and better long-term cost efficiency for serious crafters.

- Material Hardness – Three times harder than uncoated steel

- Edge Retention – Maintains sharpness through extensive use

- Rust Resistance – Protects stored blades from corrosion

- Wear Resistance – Handles tough materials without dulling

- Long-Term Cost – Fewer replacements save money over time

Sharpness of Titanium-Coated Rotary Cutters

You’ll immediately notice the difference when you first use titanium rotary blades. The initial sharpness cuts through fabric like butter, requiring minimal cutting pressure compared to standard steel blades.

The moment you pick up titanium blades, you’ll wonder how you ever cut fabric without them.

This titanium coating creates a harder surface that maintains its razor-sharp edge far longer than uncoated alternatives.

Here’s how titanium rotary blades stack up against steel:

| Feature | Titanium Blades | Steel Blades |

|---|---|---|

| Initial Sharpness | Superior razor edge | Good but dulls quickly |

| Edge Retention | 3x longer lasting | Frequent replacement needed |

| Cutting Pressure | Minimal effort required | Increased force needed |

| Material Resistance | Handles tough fabrics | Struggles with dense materials |

| Sharpening Needs | Less frequent | Regular maintenance required |

The blade performance difference becomes obvious after cutting multiple fabric layers. While steel blades lose their cutting efficiency quickly, titanium coating preserves blade sharpness through hundreds of cuts, making them worth the investment.

When to Use Titanium-Coated Rotary Cutters

When you’re tackling heavy-duty fabrics like denim or canvas, titanium-coated blades deliver the cutting power you need.

These blades maintain their blade sharpness three times longer than standard steel, making them perfect for frequent cutting sessions without constant replacements.

You’ll appreciate titanium rotary blades when working with intricate patterns that demand precision.

The enhanced blade durability means clean cuts through multiple fabric layers without the blade losing its edge.

Whether you’re slicing through delicate materials like silk or powering through thick batting, these blades handle it all.

Titanium-coated blades excel at avoiding fraying, especially when cutting through challenging materials.

The superior hardness reduces the pressure you need to apply, which means less hand fatigue during long crafting sessions.

If you’re a quilter working with fabric layers regularly or a seamstress handling various material weights, investing in titanium blades pays off.

They’re particularly valuable for professionals who can’t afford inconsistent cuts or frequent blade changes, making them a great choice for those who need consistent results and want to minimize hand fatigue.

Where to Buy Titanium-Coated Rotary Cutters

You’ll find titanium-coated rotary cutter blades through several reliable channels. Online retailers like Amazon and specialized sewing websites offer the widest selection, often with competitive pricing and customer reviews to guide your choice.

Local craft stores such as Jo-Ann Fabrics and Michaels stock popular brands like OLFA Endurance blades, plus you can examine products firsthand before buying. Brand websites provide direct access to the latest titanium alloy blades with detailed specifications and warranty information.

The Fabric Hut offers 5-blade packs at $50, while Quilters Select sells individual 45mm titanium-plated blades for $19.99. WAWAK Sewing Supplies and Love Sew cater specifically to quilters with curated selections. Many users find that Olfa blades are sharper and easier to change than some alternatives.

Before purchasing, compare prices across multiple sources and check compatibility with your rotary cutter model. Many online stores offer bulk purchasing options that reduce per-blade costs. Reading customer reviews helps identify which titanium coating performs best for your specific cutting needs.

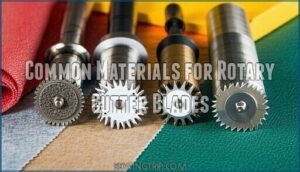

Common Materials for Rotary Cutter Blades

Understanding blade materials helps you make smarter cutting decisions for your projects.

Different materials offer unique benefits depending on your specific needs and budget.

Here are the three main blade material categories you’ll encounter:

- Steel Blades – Carbon steel and high-strength steel options provide reliable performance at reasonable prices.

- Carbide Blades – Tungsten carbide blades deliver exceptional edge retention and durability.

- Ceramic Blades – Ultra-hard ceramic materials maintain sharpness longer than traditional steel but require careful handling due to brittleness.

High-strength steel lasts longer than basic carbon steel, making it ideal for frequent use.

These tungsten blades handle demanding cutting tasks without losing their sharp edge quickly.

Titanium alloy blades and titanium-coated options bridge the gap between affordability and performance.

When comparing blade materials, consider your cutting frequency and fabric types.

This blade material comparison shows that alternatives explored beyond basic steel often justify their higher upfront costs through extended lifespan.

Factors to Consider When Purchasing a Rotary Cutter

When you’re shopping for a rotary cutter, you’ll need to evaluate several key factors that directly impact your cutting experience and project results.

Consider the blade diameter, material composition, safety features, handle design, and available accessories to find the right tool for your specific needs, including evaluating complete concepts.

Blade Diameter

Blade diameter directly impacts your cutting control and precision.

Smaller diameters like 28mm excel at detailed work and curves, while larger diameters such as 60mm power through multiple fabric layers without blade wobble.

The popular 45mm size offers versatile performance for most projects.

You can purchase various cutter sizes online.

Diameter precision matters – mismatched blades create uneven cuts that compromise your work quality and safety.

Blade Material

After selecting the right diameter, blade material determines your cutting experience.

Steel vs. titanium represents the biggest choice in blade composition.

Titanium coating creates blades three times harder than standard steel blades.

This material hardness translates to superior rust resistance and reduced material flexibility, keeping edges sharper longer while handling tough fabrics effortlessly.

For those seeking these blades, it’s worth exploring options for purchasing titanium blades.

Key blade materials offer distinct advantages:

- Titanium blades slice through multiple fabric layers without losing their edge, saving you time and frustration

- Steel blades provide reliable performance at budget-friendly prices for occasional crafters

- Coated options combine durability with precision, giving you professional results every time

Safety Features

When cutting precision matters, safety features shouldn’t be an afterthought.

Smart rotary cutters protect you from razor-sharp blades while maintaining control during intricate projects.

- Locking mechanisms prevent accidental blade deployment during storage

- Retraction systems automatically shield the blade when released

- Ergonomic handles provide secure grip and reduce hand fatigue

- Blade guards protect fingers from the cutting path

- Safety triggers require deliberate pressure to engage the blade

Always consider additional safety products when using rotary cutters.

Blade Handle

Your cutter’s handle determines whether you’ll breeze through projects or battle hand cramps.

Ergonomic handles with soft grip materials reduce hand fatigue during extended cutting sessions.

The right handle size fits your palm naturally, while safety mechanisms prevent accidental blade exposure.

Quality blade grip guarantees cutting control without slips.

Many users find that ergonomic handles reduce fatigue during extended use.

| Handle Feature | Benefit |

|---|---|

| Ergonomic Design | Reduces hand strain during long projects |

| Non-slip Grip | Prevents accidents and improves blade comfort |

| Safety Lock | Protects against accidental cuts |

Blade Accessories

Essential accessories enhance your rotary cutter’s performance and extend blade lifespan.

Self-healing cutting mats protect titanium coating from damage while quilting rulers guide precise cuts.

Blade storage cases prevent dulling between projects, and oil applicators keep mechanisms smooth.

These tools, including blade sharpeners, maintain peak blade sharpness and maximize your rotary cutter blades’ efficiency and blade performance substantially.

Best 45mm Rotary Cutters

You’ll find that 45mm rotary cutters offer the perfect balance between precision and versatility for most fabric cutting tasks.

These popular models from OLFA and Fiskars combine reliable performance with user-friendly features that make them ideal for quilters and crafters working with multiple fabric layers.

OLFA Ergonomic Rotary Cutter, 45mm

This titanium-coated powerhouse delivers cutting precision that transforms your crafting experience.

The OLFA ergonomic grip reduces hand fatigue during extended sessions while maintaining blade safety through reliable guard mechanisms.

User reviews consistently praise its material compatibility across various fabrics.

- Titanium coating extends blade sharpness three times longer than standard steel

- Ergonomic design prevents hand strain during marathon quilting sessions

- Safety features include blade guard and secure locking mechanism for accident prevention

Fiskars Classic Stick Rotary Cutter, 45mm

While OLFA excels in ergonomics, Fiskars takes a different approach with their Classic Stick design. This 45mm rotary cutter features a sleek, minimalist profile that many crafters prefer for its simplicity and control.

The titanium coating on Fiskars blades delivers exceptional blade sharpness that lasts three times longer than standard steel. You’ll notice how smoothly it glides through multiple fabric layers without requiring extra pressure.

The Cutter Pressure Control feels natural in your hand, while the Classic Cutter Safety features include a retractable blade and secure lock mechanism.

- Clean cuts through eight layers of quilter’s cotton effortlessly

- Titanium-enhanced blade performance reduces hand fatigue during long sessions

- Alternative Handle Grips work well for different cutting angles

- Blade Change Difficulty remains minimal with the straightforward design

Fiskars Comfort Loop Rotary Cutter, 45mm

The Fiskars Comfort Loop design puts cutting control right in your palm.

Its unique loop handle creates Alternative Comfort Grips that reduce strain during extended projects.

The titanium coating on these 45mm blades delivers superior blade performance compared to standard steel options.

Comfort Loop Ergonomics shine when you’re tackling thick fabric stacks.

Loop Cutter Safety features include an automatic blade cover.

While the Fiskars Cutter Price runs higher than basic models, the Blade Change Ease and rotary cutter blades quality justify the investment, offering Comfort Loop design benefits.

Fiskars Trigger Rotary Cutter, 45mm

You’ll love how the Fiskars Trigger Rotary Cutter puts cutting control at your fingertips.

This 45mm powerhouse features an ergonomic design with a smooth trigger mechanism that activates the blade only when squeezed. The angled swivel head gives you perfect visibility, while adjustable blade depth guarantees precision cuts every time.

Many users find Fiskars blades last longer, especially beginners.

- Trigger Mechanism: Squeeze-to-cut design provides ultimate safety and control

- Blade Compatibility: Works with standard 45mm rotary cutter blades including titanium coating options

- Safety Features: Automatic blade retraction and protective storage case included

Best 60mm Rotary Cutters

You’ll find 60mm rotary cutters handle thick materials and multiple fabric layers more efficiently than smaller blades.

These larger cutters work best when you’re cutting through quilt sandwiches, heavy denim, or several layers at once.

OLFA Ergonomic Rotary Cutter, 60mm

Heavy-duty cutting demands serious equipment.

The OLFA ergonomic 60mm rotary cutter delivers exceptional cutting precision with its titanium coating that makes blades three times harder than steel.

You’ll appreciate the ergonomic handles that reduce fatigue during extended sessions while maximizing cutting efficiency through thick materials.

| Feature | Specification | Benefit |

|---|---|---|

| Blade Size | 60mm diameter | Enhanced fabric capacity for thick layers |

| Handle Design | Contoured ergonomic | Superior handle comfort for both hands |

| Blade Technology | Titanium-coated steel | Extended blade longevity with ergonomic blade changes |

OLFA Straight Handle Rotary Cutter, 60mm

When simplicity meets performance, the OLFA Straight Handle Rotary Cutter delivers powerful cutting efficiency without extra frills.

This 60mm powerhouse features titanium coating that keeps rotary cutter blades sharp three times longer than standard steel options.

The lightweight aluminum construction reduces hand strain during extended projects, though ergonomics take a backseat to the streamlined design.

You’ll appreciate how blade sharpness remains consistent through multiple fabric layers, making pressure control effortless on your cutting mats.

User reviews consistently praise the reliable blade changes and durable construction.

The straight handle design offers precise control for quilters who prefer traditional grip styles over curved alternatives.

While it lacks ergonomic contouring, many crafters find the simple design perfectly balanced for accurate cuts.

This OLFA model proves that sometimes the best tool is the one that simply works – no bells, whistles, or complicated features required.

Fiskars Titanium Rotary Cutter, 60mm

Consistently delivering professional results, this Fiskars 60mm cutter transforms how you handle thick materials.

The titanium coating keeps blades sharper three times longer than standard steel, making it perfect for heavy-duty projects.

Here’s what sets it apart:

- Ergonomic Design – Curved handle with soft grip reduces hand fatigue during extended use

- Blade Changes – Switch blade positioning for left or right-handed cutting comfort

- Cutting Performance – Squeeze trigger mechanism provides smooth, controlled cuts through multiple layers

User Reviews consistently praise its cutting efficiency and blade sharpness.

The rotary cutter blades slice through denim and thick fabrics effortlessly, proving titanium coating delivers superior performance.

How to Use and Maintain Rotary Cutters

You’ll extend your rotary cutter’s lifespan and maintain peak performance by following proper blade replacement and maintenance practices.

Regular blade changes every 2-3 major projects, combined with proper storage and cleaning, guarantee your titanium blades deliver consistent, precise cuts.

This approach will maximize your investment, ensuring that your titanium blades continue to deliver consistent results.

Replacement Blades

Now that you’ve chosen your rotary cutter, keeping it performing at peak levels means staying on top of blade replacement. Sharp blades make the difference between effortless cutting and frustrating fabric struggles.

Titanium coating extends blade longevity substantially, but even the best rotary cutter blades eventually need replacing. Here’s what you need to know about blade replacement:

- Blade compatibility – Check your cutter’s specifications before purchasing aftermarket blades

- Bulk buying – Stock up on replacement blades to save money and avoid project interruptions

- Blade sharpness – Replace when you notice increased cutting pressure or frayed fabric edges

- Sharpening options – Consider professional sharpening services for premium titanium blades

- Blade disposal – Safely discard old blades in puncture-proof containers

Smart blade replacement keeps your cutting smooth and precise.

Additional Blades

Beyond replacement blades, smart quilters stock additional titanium blades for different projects.

Having specialty blades ready means you won’t interrupt your workflow when switching between delicate silks and heavy denim.

Blade Type: Cost: Fabric Uses:

- Standard Steel: $5-10 All-purpose, cottons

- Tungsten Carbide: $15-25 Denim, canvas, leather

- Titanium Coated: $10-20 Quilting cottons, silks

Smart blade storage keeps your collection organized and prevents accidents.

Consider these key factors:

- Blade compatibility – Check your cutter accepts different blade types before purchasing

- Blade sharpening services can extend titanium coating life substantially

- Blade disposal requires special containers since titanium blades stay razor-sharp longer

The titanium coating’s blade durability and blade longevity make stocking extras worthwhile for serious crafters.

Proper Blade Changing Technique

Now that you’ve got your replacement blades ready, mastering proper blade changing technique keeps you safe and your cutter performing perfectly.

Follow these safety precautions for smooth blade replacement:

- Wear cut-resistant gloves and work slowly to prevent accidental cuts

- Use proper tool selection with the right screwdriver or mechanism for your model

- Store used rotary cutter blades in protective cases away from children

- Follow proper disposal methods – never toss old blades in regular trash

This step-by-step guide prevents troubleshooting issues later, ensuring a smooth and safe experience.

Frequently Asked Questions (FAQs)

Are titanium rotary cutters better than tungsten?

You’ll find titanium rotary cutters outperform tungsten blades in most crafting situations. Titanium’s three-times-harder coating stays sharper longer, cuts smoother through fabrics, and handles multiple layers better than tungsten alternatives.

Which rotary blades are best for cutting fabric?

You can’t judge a book by its cover, but titanium rotary blades consistently outperform steel alternatives.

They’re three times harder, stay sharper longer, and cut through multiple fabric layers with less pressure and friction, which makes them a better choice due to their performance.

Which rotary cutter blades are best?

Titanium-coated rotary blades outperform steel options substantially.

You’ll get three times longer sharpness, cleaner cuts through thick materials, and reduced hand fatigue.

They’re pricier upfront but save money long-term through fewer replacements, providing a significant advantage in terms of long-term cost efficiency.

What are rotary cutter blades made of?

Rotary cutter blades come in several materials, each with distinct properties.

You’ll find standard steel blades, which are affordable and widely available.

Titanium-coated blades offer superior hardness and durability, staying sharp three times longer than steel.

Can rotary cutter blades be sharpened?

Yes, you can sharpen rotary cutter blades using specialized sharpeners or whetstones.

However, titanium-coated blades maintain their factory sharpness three times longer than steel, often making replacement more cost-effective than sharpening.

What is the best rotary cutter for fabric?

You’ll want a rotary cutter with a comfortable grip, sharp titanium blade, and reliable safety mechanism.

Look for brands like Olfa, Fiskars, or Clover that offer ergonomic handles and smooth cutting action.

Are titanium rotary blades better than steel?

Despite the higher price tag, you’ll find titanium rotary blades outperform steel substantially.

They’re three times harder, stay sharp longer, cut through tough materials effortlessly, and reduce hand fatigue during extended use.

Do titanium rotary blades last longer?

Titanium rotary blades definitely last longer than steel ones.

You’ll get three times more use before needing replacement.

The titanium coating keeps them sharper longer, so you won’t need frequent blade changes.

Are titanium blades better?

You’ll find titanium blades outperform steel in every way. They’re three times harder, stay sharper longer, cut through tough materials effortlessly, and save money over time despite higher upfront costs.

Are carbide blades better than titanium?

Professional quilters at FabricCraft tested both blade types on identical materials.

Carbide blades typically outlast titanium by 40% and maintain sharper edges longer.

However, you’ll pay more upfront for carbide’s superior hardness and durability.

Conclusion

Sharpness enthusiasts and weekend warriors alike now know the truth: are titanium rotary blades better? Absolutely, if you’re slicing through fabric like a hot knife through butter on the regular.

These premium blades deliver three times the lifespan of steel alternatives, maintaining razor-sharp edges through countless projects.

However, casual crafters might find their wallets lighter without noticeable benefits. Your cutting frequency and material thickness determine whether titanium’s superior performance justifies the investment over standard options.

- https://www.thefabrichut.com/blogs/news/titanium-coated-rotary-blades-tested-and-reviewed-by-shadow-valley-quilts

- https://www.moores-sew.com/shop/quilters-select-45mm-pro-titanium-rotary-blades-3-pack

- https://inspiredquiltingbylealouise.com/rotary-blade-performance-review

- https://www.quiltingboard.com/main-f1/titanium-rotary-blades-%3B-t213223.html

- https://www.amazon.com/Titanium-Replacement-Fiskars-Quilting-Scrapbooking/dp/B07MXX2W2T