This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Denim tears through standard sewing machine needles like they’re made of paper. The heavyweight twill weave that makes jeans nearly indestructible also demands serious engineering from your machine—most home models bog down or skip stitches when they hit those thick seams where four or six layers converge.

You need a machine built with enough motor torque to punch through 12-ounce denim without hesitation, a sturdy metal frame that won’t vibrate across your table, and a presser foot that can actually lift high enough to accommodate bulky seam allowances.

The difference between the best sewing machine for jeans and a standard model isn’t just about convenience—it’s about whether your stitches hold or your project ends up in the donation pile.

Table Of Contents

- Key Takeaways

- Key Features of Sewing Machines for Jeans

- Important Considerations When Sewing Denim

- How to Choose The Right Sewing Machine

- Top 9 Sewing Machines for Jeans

- 1. Singer Heavy Duty Sewing Machine 4423

- 2. Brother Heavy Duty Sewing Machine

- 3. Janome Heavy Duty Sewing Machine

- 4. Brother Project Runway Sewing Machine

- 5. Janome Computerized Sewing Machine Magnolia

- 6. Juki TL-2010Q Sewing Quilting Machine

- 7. Juki Industrial Straight Stitch Machine

- 8. Singer Heavy Duty Sewing Machine

- 9. Brother Strong Tough Sewing Machine

- Tips for Sewing Jeans and Heavy Denim

- Benefits of Heavy-Duty Sewing Machines for Jeans

- Maintenance and Care for Denim Sewing Machines

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- You need a machine with at least 1.0-1.5 amps of motor power, a metal frame for stability, and an extra-high presser foot lift (7-8mm minimum) to handle multiple denim layers without stalling or skipping stitches on thick seams.

- Match your needle size to fabric weight—90/14 for standard jeans, 100/16 for heavyweight denim, and 110/18 for multi-layer intersections—and pair with polyester thread at Tex 40-60 to prevent breakage and maintain seam durability.

- Heavy-duty machines like the Singer 4423 and Brother ST371HD deliver 800-1,100 stitches per minute with adjustable presser foot pressure and walking foot compatibility, giving you the speed and control needed for professional topstitching and seam reinforcement.

- Regular maintenance matters more with denim work—clean the bobbin area after every 2-3 bobbins, replace needles every 4-6 hours of sewing, and keep tension settings between 4-6 to prevent lint buildup and ensure consistent stitch quality on heavyweight fabrics.

Key Features of Sewing Machines for Jeans

Not every sewing machine can wrestle denim into submission. You need a machine built with the right combination of power, precision, and control to punch through multiple layers without breaking a sweat.

Not every sewing machine can wrestle denim into submission—you need power, precision, and control to punch through multiple layers without breaking a sweat

Here’s what separates machines that can handle jeans from those that’ll give up halfway through your hem.

Dedicated Denim Needle Compatibility

When you’re sewing heavy denim, needle breakage isn’t just frustrating—it’s a project killer. That’s why dedicated denim needle compatibility matters so much. Your machine needs to accept system 130/705 H-J jeans needles, which feature reinforced shafts that won’t buckle under pressure.

To minimize issues, understanding needle types is essential for the best results.

- Needle sizing matches fabric thickness: 90/14 for standard jeans, 100/16 for heavyweight denim

- Reinforced construction prevents deflection through belt loops and pocket seams

- Medium ball tip pierces tightly woven fabric without shredding threads

- Blue color-coding ensures you’re installing the right needle type

- Compatible machines handle sizes 80/12 through 110/18 for complete versatility

Powerful Motor and Metal Frame

Denim demands more than a standard motor can deliver. Heavy-duty sewing machines like the Brother ST371HD pack motors 60% stronger than basic models—that’s the difference between punching through seam intersections and grinding to a halt.

| Component | Standard Models | Heavy-Duty Models |

|---|---|---|

| Motor Power | 0.3-0.5 amps | 1.0-1.5+ amps |

| Frame Material | Plastic housing | Die-cast metal |

| Operational Speed | 600-800 SPM | 1,100+ SPM |

Metal construction matters just as much: die-cast frames absorb vibration while maintaining alignment, unlike plastic housings that flex under pressure. Metal frame durability extends machine lifespan dramatically—we’re talking decades versus years. The Singer 4423’s full metal internal frame prevents component misalignment even at maximum speed, while its powerful motor maintains 1,100 stitches per minute through multiple denim layers.

This combination of power output and sturdy construction gives you control over challenging fabrics without compromising stitch quality. For peak performance, consider investing in a heavy duty sewing machine.

Adjustable Presser Foot Pressure

You can’t force thick fabric through a machine without proper pressure control—that’s where adjustable presser foot pressure becomes your secret weapon. Machines like the Singer 4452 and Brother CS7000X let you dial settings between 4 and 6 for denim feeding, preventing bunching in multi-layer seams by 50%.

This fabric guidance capability ensures consistent stitch regulation, giving you mastery over heavyweight materials that defeat basic machines.

High Presser Foot Lifter

Once you’ve mastered pressure control, you’ll hit a wall without adequate clearance. Heavy-duty sewing machines with high presser foot lifters give you roughly 7–8 mm of vertical space—enough to slide six to seven denim layers underneath without jamming. This extra lift transforms bulky seam handling at hemlines and waistbands, where standard machines choke.

- Denim layer capacity expands to 6–7 sheets, conquering multi-fabric intersections

- Feed and stitching improve when the foot sits level over thick seam ridges

- Jeans-focused machines with 21–22 mm industrial-grade lift obliterate fabric compression issues

Stitch Length and Width Variation

Without precision control over your stitch dimensions, even the strongest machine can’t deliver clean seams on jeans.

Heavy-duty sewing machines offer stitch length up to 4–6 mm and zigzag width reaching 6–7 mm, giving you the range to adjust edge finishing, topstitching precision, and seam strength.

These stitch adjustment capabilities separate true denim-capable machines from basic models, ensuring your stitch patterns match fabric weight and construction demands.

Heavy-Duty Thread Handling

When your machine advances beyond Tex 60 thread, hook capacity and tension balance become critical bottlenecks—domestic machines often struggle with Tex 70 or heavier, causing looping under thick seams.

Industrial capability accommodates bonded nylon thread and heavy-duty polyester up to Tex 120 for prominent topstitching, while adjustable thread tension settings around 4–6 match needle size to thread strength without puckering multilayer denim.

Important Considerations When Sewing Denim

Sewing denim isn’t like working with cotton sheets—you’re pushing needles through fabric that can weigh up to 21 ounces per square yard, which means your machine needs to be built for the fight.

The difference between smooth sailing and constant jams comes down to a handful of mechanical factors that separate hobby machines from denim workhorses.

Let’s break down what really matters when you’re tackling thick, unforgiving fabric.

Motor Strength for Thick Fabrics

Think of motor power as the backbone of your heavy-duty sewing machines—without adequate ampere requirements, you’re dead in the water. For denim and jeans, you’ll need at least 1.0-1.5 amps to punch through multiple layers consistently.

- The Singer 4423 delivers 0.7 amps at 1,100 stitches per minute with 60% more piercing force

- Industrial motors pack 550-750 watts—nearly ten times domestic power for continuous operation

- Performance benchmarks prove stronger torque measurements prevent needle deflection in dense twill weaves

Motor ratings determine whether you conquer thick fabrics or struggle constantly.

Presser Foot Options for Denim

Your choice of presser foot dramatically shifts control on denim sewing projects. Walking foot attachments—projected to drive a USD 780 million specialty feet market by 2025—synchronize top and bottom feed for consistent layer movement.

Compensating feet keep topstitching straight over thick seam ridges, while Teflon feet reduce drag on heavy-duty fabrics.

Dial foot pressure between 4 and 6 to grip jeans-weight material without distortion, ensuring your stitches never skip.

Needle Size and Type Selection

Your needle size determines whether you’ll power through heavyweight denim or watch seams skip. Match 90/14 needles to standard jeans, 100/16 to utility-weight fabric, and 110/18 to multi-layer seams—proper sizing cuts needle breakage by 75%.

Pair dedicated denim needles with thread weights from Size 46 polyester to Tex 70, boosting seam durability by 40%. Swap needles every eight hours to maintain stitch integrity.

Stitch Options for Durability

Stitch selection transforms jeans from weekend wear into decade-long workhorses. Flat-felled seams enclose raw edges and deliver twice the strength of plain seams, while premium denim builds demand 13 stitches per inch on critical zones to resist slippage.

- Set construction stitches at 3.5 mm for standard denim to reduce puckering

- Use chain stitches on heavy-duty seams for greater breaking strength

- Pair Tex 70–80 thread with reinforced stitch patterns for lasting durability

Frame Construction and Longevity

Metal vs. Plastic frame construction separates weekend sewers from serious denim builders. Heavy Duty Sewing Machines with mostly metal internal components maintain Structural Stability through thousands of stitches, with well-maintained models delivering 5 to 25 years of service.

Motor Strength alone won’t carry you—a Durable Metal Frame resists flex when punching through 16-ounce fabric, protecting your investment and your timelines.

How to Choose The Right Sewing Machine

Choosing the right sewing machine for denim isn’t about finding the fanciest model—it’s about matching the machine’s capabilities to your specific needs and skill level. You’ll want to weigh factors like whether you prefer straightforward mechanical controls or computerized precision, how much workspace you need, and what speed feels comfortable for your projects.

Let’s break down the key considerations that’ll help you make a confident decision.

Mechanical Vs Computerized Models

When you’re deciding between mechanical machines and computerized sewing for jeans, think about your priorities. Mechanical machines deliver frame durability and straightforward control—perfect if you’re tackling heavy-duty sewing machine work exclusively.

Computerized sewing offers stitch precision, automation benefits, and broader application fit, though you’ll face a steeper learning curve. Your choice hinges on whether you value raw power or programmable versatility.

Free Arm and Extension Table Benefits

Beyond choosing your machine type, you’ll gain serious control with a free arm and extension table combo. These features transform how you conquer tubular denim sewing on trouser legs, sleeves, cuffs, and hems while boosting seam quality and support accuracy. The ergonomic advantages cut fatigue, and workflow efficiency jumps when you can pivot between configurations in seconds.

What this dual setup delivers:

- Tubular access – Slip narrow jeans legs around a 10–12 cm free arm for circular stitching without bunching fabric layers or risking skipped stitches.

- Flatbed stability – Extension tables expand your work surface to 300–600 cm², keeping heavy denim panels level and preventing downward drag during long seams.

- Precision topstitching – Reduced contact area on the free arm sharpens maneuverability, so you nail 2–3 mm edge distances on waistbands and pocket openings.

- Ergonomic relief – Supported fabric at table height promotes neutral wrist and shoulder postures, cutting trapezius strain during repetitive tasks.

- Rapid task switching – Detach the extension table in seconds to reveal the free arm, moving seamlessly from flat yoke assembly to tubular hem finishing on a single pair of jeans.

Speed and Stitching Efficiency

With your workspace sorted, speed becomes your productivity weapon—but only if your machine’s motor power matches denim’s demands. Domestic heavy-duty models hit 800–1,100 stitches per minute, while industrial units clock 3,000–5,000, driving four to six times the throughput. Needle penetration force spikes to 39 N on thick weaves, so you’ll need powerful motors and ideal stitch length settings—around 3 mm—to maintain feed mechanism efficiency and thread performance without breakage.

| Feature | Impact on Efficiency |

|---|---|

| Maximum stitch speed | 800–1,100 SPM domestic; 3,000–5,000 SPM industrial |

| Needle penetration force | Up to 39 N on heavyweight denim layers |

| Stitch length settings | 3 mm reduces resistance by ~17% versus 2.5 mm |

| Feed mechanism usage | Walking foot synchronizes layers, cuts slippage |

| Thread performance | Quality thread + correct tension prevent high-speed breaks |

User-Friendliness for Beginners and Experts

When you’re picking a machine that won’t fight you, easy-to-grasp controls and feature automation separate confidence-builders from headaches. Computerized models with preset denim support flatten the learning curve—68% of beginners rate clear LCD interfaces as “easy” to operate, and automatic needle-threading shaves 35% off setup time.

Here’s what drives sewing machine usability for jeans:

- One-step buttonhole functions cut garment-construction time by 23% for novices versus four-step systems.

- Electronic speed control reduces fabric-handling errors by 27% when topstitching heavy denim.

- Adjustable stitch presets lower operating errors by 29% among beginners on thick fabrics.

- Needle up/down buttons speed corner pivoting by 18% on denim seams.

- Quick-start guides lift first-project completion rates from 54% to 81%.

Market trends confirm it: computerized machines dominate household sales, and 72% of beginners hit consistent stitch quality faster with digital controls than manual mechanical dials. Yet experienced users working primarily with jeans favor mechanical models for direct tactile feedback—58% cite simpler adjustment of key sewing machine settings.

Your choice hinges on whether you prize automation or hands-on control when tackling denim’s bulk.

Essential Accessories for Denim Sewing

You’ll need the right arsenal to conquer thick seams. Denim needles—sizes 90/14 and 100/16—punch through tightly woven fabric, while heavy-duty needles up to 200 handle topstitching threads.

Presser feet like walking-foot attachments keep layers aligned, and leveling aids lift the foot over bulky intersections.

Fabric clips marked at 3/16″, 1/4″, and 3/8″ hold edges flat, and ergonomic tools reduce hand strain during long projects.

Top 9 Sewing Machines for Jeans

You’ve got the knowledge to choose a sewing machine that can handle denim—now let’s look at the machines that actually deliver.

Each option below brings specific strengths to the table, whether you’re tackling repairs, custom jeans projects, or heavy-duty construction work. Here are nine machines that won’t flinch when you feed them multiple layers of heavyweight fabric.

1. Singer Heavy Duty Sewing Machine 4423

The Singer 4423 stands as a workhorse for denim handling, delivering 1,100 stitches per minute through a motor that’s 60% stronger than standard models.

You’ll work with 23 stitch options, including a one-step buttonhole, while the heavy-duty metal frame keeps everything stable when powering through multiple denim layers.

The extra-high presser foot lifter gives you clearance for thick seams, and adjustable pressure prevents puckering.

At 14.5 pounds, it balances portability with solid construction, backed by a 25-year warranty on mechanical parts.

Best For: Home sewers and hobbyists who regularly work with denim, canvas, and other heavy fabrics and want a fast, reliable machine that can handle thick seams without slowing down.

- Powerful motor delivers 1,100 stitches per minute through multiple layers of denim with a heavy-duty metal frame that stays stable at high speeds

- Extra-high presser foot lifter and adjustable pressure settings handle thick fabric stacks like folded hems and flat-felled seams without puckering

- 25-year warranty on mechanical parts plus automatic needle threader and top drop-in bobbin make setup and long-term ownership hassle-free

- Foot pedal can be overly sensitive for beginners trying to control speed on detailed work

- Thread tension adjustment takes practice to dial in correctly, especially when switching between different fabric weights

- Some users report bobbin jamming and thread breaking issues that require troubleshooting

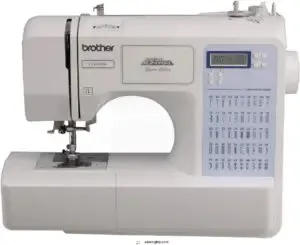

2. Brother Heavy Duty Sewing Machine

The Brother ST371HD operates at 850 stitches per minute with a metal needle plate that accommodates up to six layers of denim without deflection. You’ll work with 50 built-in stitches and a 7-point box-feed system that grips heavyweight fabrics far better than basic 4-point designs.

The included walking foot synchronizes upper and lower feed dogs for precise seam control, while size 14 heavy-duty needles pierce thick intersections cleanly.

At 10.14 pounds with a reinforced frame, it delivers consistent denim stitch quality through multi-year heavy-duty sewing projects.

Best For: Sewers who regularly work with denim, canvas, and other heavyweight fabrics and need a reliable machine that can handle multiple thick layers without struggling.

- Handles up to six layers of denim with 850 stitches per minute and a reinforced metal frame that won’t bog down on thick seams

- Comes with a walking foot and 7-point feed system that grips and moves heavy fabric evenly, preventing shifting on bulky projects

- Includes 50 stitches, heavy-duty needles, and a 25-year chassis warranty for long-term durability

- Built-in LED work light is too dim for detailed work on dark fabrics like indigo denim

- No automatic thread cutter, so you’ll need to manually snip threads between seams

- Power connector is fragile and can be easily damaged if bumped or pulled during use

3. Janome Heavy Duty Sewing Machine

The Janome HD3000 features a 1.0 amp motor and an all-metal frame, allowing it to punch cleanly through three to four denim layers at 860 stitches per minute. It offers 18 stitches with a one-step buttonhole and a 5-piece feed dog system, which grips heavyweight fabric better than the HD1000’s 3-piece design.

The machine includes a 6.5mm stitch width for wide topstitching, adjustable presser foot pressure, and an extra-high lift to clear bulky seams. Weighing 18.7 pounds, it anchors solidly for sustained heavy-duty sewing without vibration.

Best For: Home sewers who regularly work with thick fabrics like denim, leather, and canvas and need a reliable machine that can handle multiple layers without slowing down.

- Powerful 1.0 amp motor and sturdy metal frame punch through 3–4 layers of denim at 860 stitches per minute without skipping stitches

- 5-piece feed dog system and adjustable presser foot pressure give you better control over heavyweight fabrics than lighter machines

- Extra-high presser foot lift and free arm make it easier to maneuver around bulky seams and hem tubular jean legs

- Limited harp space and no walking foot or free-motion capability make it less suitable for quilting projects

- Three-step buttonhole process is slower and less convenient than one-step systems on other machines

- Stitch selector display can be hard to read without extra lighting, which might frustrate you during longer sewing sessions

4. Brother Project Runway Sewing Machine

You’ll find 80 built-in stitches and 10 auto-size buttonholes on the Brother CS5055PRW, engineered for garment makers who need denim-ready versatility. Its aluminum chassis keeps vibration minimal while the 7-point feed dog grips heavyweight fabric through 1/4-inch seam layers. With seven snap-on presser feet and adjustable pressure settings, you’ll tackle jeans hems and topstitching with precision.

The LCD display, automatic needle threader, and 850-stitch-per-minute speed deliver beginner-friendly design without compromising control. Users rate it 4.3 stars for reliable denim performance.

Best For: Beginner to intermediate sewers who want to tackle a wide range of projects from simple garments to heavier fabrics like denim without spending a fortune.

- 80 built-in stitches with 10 auto-size buttonholes give you plenty of creative options for different projects and fabric types.

- Handles thick fabrics like denim reliably with its 7-point feed dog system and adjustable presser foot pressure.

- Beginner-friendly features like automatic needle threader, LCD display, and quick-set bobbin make setup and learning curve much easier.

- Some users struggle with the automatic needle threader—it doesn’t always work smoothly despite being a convenience feature.

- No carrying case included, so you’ll need to buy one separately if you plan to transport it to classes.

- The needle stays in the down position when you stop sewing, which can be annoying if you prefer it to stop in the up position.

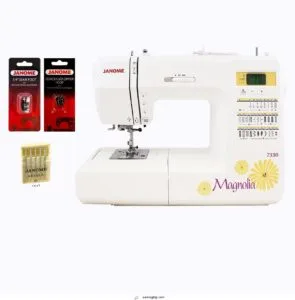

5. Janome Computerized Sewing Machine Magnolia

At 18.2 pounds with an aluminum frame, the Janome Magnolia 7330 delivers motor capability that punches through six layers of denim without stalling—your ticket to belt loops and jeans hems that won’t quit. Its computerized controls let you dial in stitch width to 7 mm and length to 5 mm, perfect for topstitching that pops.

The 7-piece feed system feeds fabric like the Janome HD3000’s heavy-duty cousin, while extra-high presser foot lift clears bulky seams.

User-friendliness shines through automatic threading and LED lighting on dark indigo.

Best For: Home sewers ready to tackle jeans construction and heavy denim projects who want computerized convenience without sacrificing punching power.

- Handles six layers of denim cleanly thanks to an 18.2 lb aluminum frame and 7-piece feed system that won’t stall on belt loops or thick seams

- Extra-high presser foot lift gives you the clearance needed for bulky jeans hems and seam intersections

- Computerized controls with automatic threading and LED lighting make setup fast and stitching through dark denim easy to see

- Button placement gets complaints from some users who find the layout awkward during operation

- The manual leaves much to be desired—several users report unclear instructions that lead to confusion

- Not built for industrial or daily heavy-duty work; this is a capable home machine, not a commercial workhorse

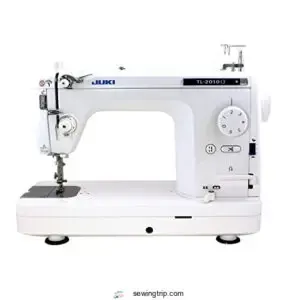

6. Juki TL-2010Q Sewing Quilting Machine

When you’re ready for a machine that rivals workshop equipment, the Juki TL-2010Q locks in 1,500 stitches per minute on straight stitching—ideal for jeans with topstitching that needs military precision. Its aluminum die-cast frame absorbs vibration while you blast through heavy fabrics, and the knee lifter frees both hands for quilting applications or handling thick pocket seams.

Speed control drops to 200 stitches per minute when your heavyweight denim demands it, plus the automatic thread trimmer cuts prep time in half during production runs.

Best For: Sewers and quilters who work with heavy fabrics like denim or need professional-grade speed and precision for production sewing, quilting projects, or garment construction.

- Blazing fast speed up to 1,500 stitches per minute with industrial-grade aluminum frame that stays stable even at maximum speed

- Knee lifter and automatic thread trimmer let you work hands-free and cut down prep time during long sewing sessions

- Handles multiple layers of heavy fabric like denim without skipping stitches, thanks to adjustable presser foot pressure and microcomputer-controlled mechanism

- Straight stitch only—no zigzag or decorative stitches, so you’ll need another machine for versatility

- Light quality could be better and may require an additional lamp for detailed work

- No dedicated scant 1/4″ foot included, which means quilters might need to buy extras or adjust their technique

7. Juki Industrial Straight Stitch Machine

Step up to an industrial straight stitch machine when you’re serious about scaling your denim production. These workhorses push 5,500 stitches per minute through multiple fabric layers—far beyond hobby-machine limits—and their servo motors deliver consistent torque for penetrating heavyweight jeans without stalling.

You’ll handle alterations, uniform sewing, and high-volume garment runs with the same reliability found in factory floors.

Expect a rigid table-and-stand setup that dampens vibration during extended sessions, plus a knee lifter that lets you manipulate bulky denim legs hands-free while maintaining professional topstitching standards.

Best For: Garment factories, alteration shops, and serious sewists who need to punch through multiple denim layers at industrial speeds while maintaining professional topstitching quality over thousands of pairs of jeans.

- Blazing 5,500 stitches per minute with servo-motor torque that powers through heavyweight denim without stalling, cutting production time dramatically compared to domestic machines.

- Rock-solid table-and-stand construction with knee lifter lets you guide bulky jeans legs hands-free while the rigid platform kills vibration during marathon sewing sessions.

- Lower long-term costs thanks to cheap repair parts (presser feet run about $5–7), energy-sipping servo motors, and durable industrial needle systems that stay available.

- No instructions included—you’ll be hunting down YouTube tutorials and online forums to figure out assembly and threading on your own.

- Overkill noise and footprint for hobbyists: this 48″ × 48″ setup demands dedicated floor space and produces industrial-level sound even with reduced-vibration designs.

- Cosmetic flaws like table scratches and varying finishes show up fresh from the factory, and you’re stuck with whatever table color happens to be in stock.

8. Singer Heavy Duty Sewing Machine

The Singer 4423 reclaims your attention with its 60%-stronger motor strength that punches 1,100 stitches per minute through layered denim—a speed that outpaces standard models stuck at 850.

Its metal frame locks down vibration during extended runs, and the stainless-steel bedplate glides heavyweight fabric without drag.

You get 23 stitch options, including a one-step buttonhole for finishing waistbands, plus adjustable presser-foot pressure that accommodates everything from 4-ounce chambray to 16-ounce workwear denim.

This heavy-duty workhorse bridges hobby and industrial territory at a mid-range price point.

Best For: Home sewists who regularly tackle thick fabrics like denim, canvas, and upholstery and want industrial-level speed without the footprint or cost of a true commercial machine.

- 60% stronger motor delivers 1,100 stitches per minute, letting you finish heavy-duty projects faster than standard machines

- Metal frame and stainless-steel bedplate keep the machine stable at high speeds and reduce friction when feeding thick layers

- Adjustable presser-foot pressure and 23 built-in stitches handle everything from lightweight cotton to 16-ounce denim

- Some users report the automatic needle threader breaks or stops working after light use

- Durability is hit-or-miss—a few units fail within months despite the “heavy-duty” branding

- No printed manual in the box; you’ll need to download it separately before your first project

9. Brother Strong Tough Sewing Machine

You’ll find the Brother ST371HD delivers 37 built-in stitches, 800 stitches per minute, and a metal needle plate that withstands up to six denim layers without hesitation.

Its free-arm configuration addresses cuffs and hems with precision, while manual tension and stitch-width dials—ranging up to 7 mm—let you dial in accuracy on 12- to 16-ounce fabric.

At 14.3 lb, this mechanical workhorse balances portability with heavy-duty stability, positioning it as a budget-friendly gateway to serious jeans construction without crossing into industrial territory.

Best For: Sewers who want to tackle thick denim projects and repairs without spending industrial-machine money, but who are comfortable with manual controls and don’t need computerized bells and whistles.

- Handles up to six layers of denim with a metal needle plate and 800 stitches per minute, giving you real power for hemming jeans and constructing heavy seams

- Comes with six presser feet right out of the box—including a nonstick foot and zipper foot—so you can topstitch, insert zippers, and finish waistbands without buying extras

- Free-arm design makes it easy to hem jeans legs and sleeves in tight circles, while manual tension and stitch-width dials (up to 7 mm) let you fine-tune every seam

- No electronic speed control or start/stop button means you’ll rely entirely on foot-pedal skill to keep a steady pace through thick seams

- At 800 stitches per minute, it’s noticeably slower than industrial machines (which often hit 1,500), so large denim projects will take more time

- The model has been discontinued in some markets, so finding replacement parts or accessories down the road might require hunting through remaining stock

Tips for Sewing Jeans and Heavy Denim

Sewing denim isn’t like working with cotton or jersey—you need to adjust your approach to handle the fabric’s weight and density. The right combination of needles, thread, and machine settings makes the difference between smooth seams and frustration.

Here’s what you need to know to tackle jeans and heavy denim like a pro.

Choosing The Right Thread and Needle

Matching the right needle and thread to your denim weight isn’t guesswork—it’s the foundation of seam performance that won’t fail.

For medium-weight denim around 10–12 oz, you’ll want a size 90/14 denim needle paired with polyester thread at Tex 40–45 for structural seams.

Heavy denim above 12 oz demands a 100/16 needle, while extra-heavy fabric or multi-layer intersections require 110/18 to prevent deflection and breakage.

Adjusting Stitch Settings for Denim

For clean seams on denim sewing, set your stitch length to 3.0–3.5 mm on medium fabrics and 3.5–4.0 mm on heavyweight denim to reduce needle heat and fabric drag.

Adjust thread tension incrementally—medium-weight denim generally needs 3.0–4.0, while heavy fabrics demand 4.0–5.0—and test each change on scrap material.

Pairing the correct needle size with adjustable thread tension and presser pressure ensures balanced stitches across thick layers without puckering.

Using a Walking Foot or Jeans Foot

A walking foot transforms denim sewing by adding a second set of feed dogs that move in sync with the lower feed, virtually eliminating layer shifting on multi-ply jeans. When tackling seam bulk at waistbands or flat-felled inseams, this even feed mechanism maintains stitch consistency that a standard presser foot can’t match. Confirm foot compatibility with your machine before investing—jeans demand that precision.

Techniques for Seam Reinforcement

Bar tacks at pocket corners and belt loops spread load across 3–5 mm of dense zigzag stitching, resisting pull-out forces that would tear single-row seams. Flat-felled seams enclose raw edges while stacking multiple fabric layers, offering enhanced breaking strength on inseams where stress peaks during movement.

Multi-row stitching along outseams distributes tension across parallel lines, and bonded nylon thread maintains consistent performance under repeated wear—essential jeans-making techniques for durable denim sewing.

Preventing Fabric Fraying

Raw edges won’t cooperate unless you finish them properly. A zigzag or overcast stitch wraps cut yarns at seam allowances, dramatically reducing fraying on jeans and heavy-duty denim.

Pinking shears or serger stitches add extra insurance before laundering. Sharp rotary cutters minimize edge pulling during cutting practices, while adjusting machine settings—like shorter stitch lengths—locks threads securely.

These denim sewing tips prevent unraveling and extend garment life.

Benefits of Heavy-Duty Sewing Machines for Jeans

Heavy-duty sewing machines aren’t just stronger versions of regular models—they’re built from the ground up to handle fabrics that would make standard machines struggle or fail. When you’re working with denim, especially multiple layers or heavyweight varieties, these machines give you the power and precision you need to create professional results without fighting your equipment.

Let’s break down exactly what you gain when you invest in a machine designed for the demands of denim sewing.

Enhanced Power and Speed

When you’re tackling heavyweight denim, power transforms your sewing experience from frustrating to easy. Heavy-duty machines deliver the muscle you need to blast through layers without hesitation, giving you the freedom to create without compromise.

- Motor horsepower jumps from 1/15 HP in domestic models to 1/2 HP or higher in industrial-grade machines, forcing needles through multiple denim layers with authority

- Stitch SPM reaches 4,000–8,000 on professional equipment versus around 1,000 on standard home machines, slashing production time dramatically

- Duty cycle shifts from 50% intermittent use to 100% continuous operation, letting you sew marathon sessions without overheating

- Vibration control and rigid construction maintain perfect stitch quality even at maximum speed on dense fabrics

Consistent Results on Thick Fabrics

Heavy-duty machines deliver uniform stitches across every seam thickness because their metal frames and powerful motors prevent the vibration and stalling that plague lightweight models. Your stitch length stays even when crossing bulky intersections—no more skipped stitches or needle deflection. Proper needle specifications paired with adjustable presser pressure give you control over feed consistency, while optimized stitch settings make every seam look professionally finished on heavy fabric sewing projects.

| Component | Impact on Consistency |

|---|---|

| Needle size (90/14–110/18) | Prevents thread breakage on thick seams |

| Presser pressure adjustment | Maintains even feed without fabric shift |

| Motor power (high torque) | Forces needle through jeans without stalling |

| Metal frame construction | Reduces vibration for uniform stitch length |

| Heavy-duty thread (Tex 40–60) | Delivers durable topstitching with consistent tension |

Versatility for Multiple Denim Projects

When your machine provides consistent stitches on thick fabric, you gain freedom to tackle garment alterations, home décor, and boutique services without swapping equipment. Over 34% of sewists alternate between jeans sewing and accessory projects on one platform—that’s the power of versatility.

You’ll find sewing machines for denim excel at:

- Customizing jeans and denim jackets from pattern downloads

- Creating denim cushions and slipcovers for home décor

- Switching between mixed fabrics without manual reconfiguration

- Providing boutique services like hemming and resizing

- Constructing bags, aprons, and non-garment denim projects

Your single machine becomes a complete workshop.

Increased Durability and Lifespan

Metal frame construction and upgraded motors deliver measurable longevity—heavy-duty domestic machines generally reach 1,000 to 1,500 operating hours before major service, double that of entry-level units.

With annual maintenance practices like lubrication and needle selection adjustments, mechanical models remain reliable past 15 years of denim work.

Warranty coverage often extends 25 years on the machine head, underscoring manufacturer confidence in long-term durability when sewing heavy fabric.

Maintenance and Care for Denim Sewing Machines

Your heavy-duty machine can power through denim like a champion, but only if you treat it right. Skip the maintenance, and you’ll find yourself wrestling with skipped stitches, broken needles, and tension nightmares when you need that machine most.

Here’s how to keep your denim workhorse running strong for years of perfect stitching.

Regular Cleaning and Lubrication

Your machine can’t conquer denim if lint buildup and thread residue are choking its performance. After every 2-3 bobbins, clean the bobbin area—especially after heavy duty sewing projects. Here’s your maintenance checklist:

- Dust exterior surfaces after each session

- Remove lint under the needle plate monthly

- Oil moving parts every 8-10 hours of use

- Schedule professional servicing annually ($55-$65)

Regular component cleaning prevents costly repairs and keeps your machine ready for action.

Needle and Thread Replacement

After 4-6 hours of denim sewing, needle dullness signs appear—skipped stitches, snagging, and popping sounds. Replace your sewing needle immediately.

Thread quality impact matters too: corespun threads reduce machine wear by 30% compared to cheap polyester.

Match needle size to denim weight—90/14 for lightweight, 100/16 for heavy-duty fabrics. This routine maintenance protects your investment and delivers perfect seams every time.

Tension Adjustment for Denim

When denim layers pile up, upper tension between 4 and 6 becomes your control point—start at midrange and test in half-number increments until the thread lock appears centered in the fabric.

Bobbin tension stays factory-set for most projects, but if you’re running heavy jeans thread through the needle, you’ll need to loosen the bobbin slightly to prevent seam puckering and thread breakage on heavyweight denim.

Following Manufacturer Guidelines

Your machine’s manual isn’t just paperwork—it’s your roadmap to warranty validity and performance optimization. Following manufacturer guidelines ensures safety adherence when lubricating heavy-duty sewing machines or replacing parts for denim work.

Stick to specified needle sizes, approved thread weights, and recommended repair protocols to maintain part compatibility. Ignoring these instructions voids coverage and compromises your machine’s ability to handle jeans long-term.

Frequently Asked Questions (FAQs)

What kind of sewing machine is needed for jeans?

The right tool for the job makes all the difference. You need a heavy-duty sewing machine with a strong motor, metal frame, and adjustable presser foot pressure to handle denim thickness and project scope efficiently.

What is the best stitch for sewing jeans?

A lockstitch delivers superior strength for jeans construction seams, with 11 stitches per inch boosting durability.

Topstitch length runs 0–0 mm for bold visibility, while bar-tack reinforcement stitches anchor high-stress pockets and fly zones.

Do you need a different sewing machine for denim?

You can tackle light- to medium-weight denim occasionally on standard machines, but frequent jeans sewing demands heavy-duty models.

Denim thickness matters—dense twill weaves stress underpowered motors, causing stitch quality issues and justifying investment in sturdy construction.

How much does a heavy-duty sewing machine cost?

Heavy-duty sewing machines range from around $185 for entry-level models to over $10,000 for industrial machines, with midrange options generally costing $500–$1,500 and used machines offering budget-friendly alternatives.

What is the difference between manual and computerized models?

Picture turning a dial with your hands versus tapping a screen. Mechanical machines offer straightforward, manual control with fewer electronics, while computerized models deliver automation benefits like stitch customization and digital interfaces—but demand higher cost and repair complexity.

Can I use denim sewing machines for other fabrics?

Absolutely—your denim sewing machine accommodates other fabrics with simple adjustments. Needle adaptation and presser adjustment enable fabric versatility from lightweight cotton to canvas. Motor control ensures consistent performance, though machine limitations exist with extremely delicate sheers requiring specialized settings.

Do sewing machines for jeans require special maintenance?

Yes. Denim generates significant lint buildup around feed dogs and bobbin areas, requiring cleaning after every project.

You’ll need to replace needles every 8–10 hours, adjust tension settings for thick fabric, and oil moving parts regularly.

How do I store denim projects when unfinished?

Think of your unfinished denim projects like resting dough—they need room to breathe. Fold jeans along existing seams and store them flat in breathable containers away from sunlight. Maintain cool, dry conditions below 60% humidity to preserve fabric integrity.

Can I sew stretch denim with these machines?

You can sew stretch denim with heavy-duty machines if you swap in the right needle and adjust settings.

Use stretch or universal needles, polyester thread, and moderate presser foot pressure for best results.

What fabric weight should beginners start with?

Beginners should target 8–9 oz denim—roughly 270–310 grams per square meter—offering weight ease for machine compatibility and needle selection.

This fabric type balances the learning curve with garment choice, teaching heavy-duty sewing fundamentals before tackling industrial-strength weaves.

Conclusion

Think of heavyweight denim as the proving ground where ordinary machines surrender and true workhorses thrive. The best sewing machine for jeans doesn’t just survive thick seams—it powers through them with relentless consistency, transforming stubborn fabric into professional repairs and custom creations.

You’ve seen the specs, studied the features, and discovered what separates capable machines from pretenders. Now grab that denim stack gathering dust and put your machine to work—those projects won’t finish themselves.

- https://sinofinetex.com/what-is-the-average-weight-of-jeans/

- https://fabricandflow.com/blogs/news/denim-weight-guide

- https://denimhunters.com/denim-wiki/denim-explained/denim-weight/

- https://www.dalstonmillfabrics.co.uk/fabric-blog/denim-weight-conversion-oz-to-gsm

- https://sanvt.com/blogs/journal/demim-oz-guide