This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ll face fraying edges, uneven cuts, and fabric that pulls instead of slicing cleanly. Regular scissors lack the sharp, precise blades that fabric demands.

Think of it like using a butter knife to carve a turkey – technically possible, but messy results guaranteed. The blade angle and sharpness of regular scissors aren’t designed for textile fibers, which means you’ll struggle with clean cuts, especially on delicate materials.

While they work in a pinch, dedicated fabric scissors make all the difference between amateur-looking projects and professional results that’ll make you proud.

Table Of Contents

- Key Takeaways

- Can Regular Scissors Cut Fabric?

- Disadvantages of Using Regular Scissors on Fabric

- Benefits of Using Fabric Scissors on Fabric

- Types of Fabric Scissors

- Features of High-Quality Fabric Scissors

- Caring for Your Fabric Scissors

- Replacing Your Fabric Scissors

- Storing Fabric Scissors Properly

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- You can cut fabric with regular scissors, but you’ll get messy results – They create frayed edges, uneven cuts, and struggle with thick materials because their dull blades crush fibers instead of slicing cleanly.

- Fabric scissors deliver professional-quality cuts that regular scissors can’t match – Their sharp, precision blades slice through textile fibers without fraying, giving you clean edges and smooth cuts every time.

- Different fabric projects need different scissor types – Use dressmaker’s shears for garments, pinking shears to prevent fraying, and embroidery scissors for detailed work near delicate designs.

- Proper care extends your fabric scissors’ life and performance – Clean them after each use, never cut non-fabric materials, sharpen them every 6-12 months, and store them in protective sheaths to maintain their razor-sharp edge.

Can Regular Scissors Cut Fabric?

Yes, regular scissors can cut fabric, but they’re like using a butter knife to carve a turkey – technically possible, yet far from ideal.

When you’re caught without proper sewing scissors, everyday scissors work as temporary solutions for light fabrics like cotton. However, they’ll struggle with thicker materials and multiple layers.

Regular scissors lack the specialized cutting techniques that fabric scissors provide. Their duller blades create poor edge quality, leading to fabric damage through fraying and uneven cuts.

While scissors for sewing feature sharp, aligned blades designed for textiles, regular scissors weren’t built for this purpose. For superior results, consider scissors with durable stainless steel blades designed for fabric.

Think of fabric alternatives this way: you can hammer a nail with a wrench, but a proper hammer makes the job easier and delivers better results every time. Using the right tool for the job is crucial, and in this case, fabric scissors are the best choice for cutting fabric efficiently and effectively.

Disadvantages of Using Regular Scissors on Fabric

While you can technically cut fabric with regular scissors, you’ll face several problems that affect your project’s quality.

Regular scissors create frayed edges, uneven cuts, and struggle with thick materials because their blades aren’t designed for fabric’s unique properties.

Fraying and Uneven Cuts

Regular scissors create jagged fabric edges because their blunt blades crush fibers instead of slicing cleanly.

**Sharp fabric scissors slice cleanly through fibers while regular scissors crush and tear, creating messy, frayed edges that ruin your projects.

This fiber displacement causes material damage and edge imperfection that ruins your projects.

The wrong cutting angle leads to fabric degradation, making clean cut fabric impossible.

Your fabric fraying gets worse with each snip, turning precise seams into messy disasters.

Dull Blades Struggle to Cut Cleanly

Dull scissors fabric cutting becomes a frustrating chore when blades lack proper sharpness.

You’ll notice increased cutting force needed as worn edges crush fibers instead of slicing cleanly.

This blade wear creates fabric damage through tearing rather than precise cuts.

Poor edge quality results from inadequate sharpness, making even basic cutting fabric tasks difficult.

Fabric scissors maintain superior performance longer.

For slippery fabrics, consider scissors with serrated blade edges.

Benefits of Using Fabric Scissors on Fabric

When you switch from regular scissors to fabric scissors, you’ll immediately notice cleaner, more precise cuts that don’t fray or damage your material.

Fabric scissors feature sharper blades made from high-quality steel that maintain their edge longer, making every cut smooth and professional.

Benefits of Using Fabric Scissors on Fabric – Introduction, is implied in the context that using fabric scissors has several advantages, including the fact that they provide precise cuts.

Clean Cuts Without Fraying

When you use fabric scissors, their precision blade sharpness and optimized cutting angles create clean cut fabric edges every time.

Sharp fabric scissors slice through fibers with surgical precision, delivering professional results that regular scissors simply can’t match.

Sharp scissors fabric technology prevents fraying by slicing through fibers instead of tearing them. Using the right best scissors is vital for achieving professional results.

Here are five cutting techniques that guarantee perfect edge finishing:

- Hold fabric taut – Keep material stretched to prevent bunching during cuts

- Use long, smooth strokes – Avoid choppy motions that create jagged edges

- Match scissors to fabric types – Heavy denim needs different blades than silk

- Keep blades perpendicular – Maintain 90-degree angle for cleanest cuts

- Cut away from your body – This technique gives better control and visibility

Sharper and More Durable Blades

Fabric scissors consistently outperform regular scissors through superior blade materials like carbon steel or titanium.

These materials maintain edge retention far longer than standard stainless steel. The precise blade angle creates cutting precision that slices cleanly through fibers without crushing them.

Sharp scissors fabric cutting requires proper sharpness maintenance, but quality fabric scissors hold their edge through countless projects. Professional scissor sharpening services can restore even well-used blades to factory specifications, ensuring superior blade performance and edge retention.

Types of Fabric Scissors

You’ll find three main types of fabric scissors designed for specific cutting tasks in your sewing projects.

Each type features specialized blades and handles that make cutting different fabrics easier and more precise than regular scissors.

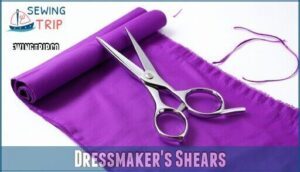

Dressmaker’s Shears

When you’re ready to tackle serious fabric cutting projects, dressmaker’s shears become your best friend.

These heavy-duty fabric scissors feature long, sharp blades that glide through multiple fabric layers without struggle.

Their ergonomic handles reduce hand fatigue during extended sewing sessions.

Quality blade sharpness and proper scissor maintenance guarantee these sewing scissors outperform regular scissors in fabric cutting techniques every time.

For superior results, investing in high-quality Dressmaker Shears is essential for professional sewing tasks.

Pinking Shears

Pinking shears create zigzag edges that lock fabric fibers together, preventing fraying better than standard fabric scissors.

Their serrated blades require specific cutting techniques for maximum sewing accuracy and fabric precision. Understanding the proper use of pinking shears involves studying pinking shear techniques.

Here are five pinking tips for fraying prevention:

- Cut with smooth, continuous strokes

- Use sharp blades for clean zigzag patterns

- Test on fabric scraps first

- Choose appropriate blade spacing for material weight

- Maintain steady pressure throughout cuts

Using these tips and understanding the proper technique will help in achieving maximum sewing accuracy.

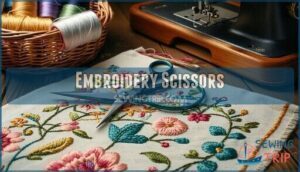

Embroidery Scissors

While pinking shears handle edges beautifully, embroidery scissors tackle the finest details.

These tiny powerhouses feature small, sharp tips perfect for delicate thread cutting without damaging your fabric. You’ll appreciate their precision when working close to intricate designs where needle safety matters most.

Here’s what makes quality embroidery scissors special:

- Ultra-sharp points slice through threads cleanly near fabric surfaces

- Lightweight design reduces hand fatigue during detailed work

- Spring-loaded action makes repetitive snipping effortless

Regular scissor sharpening keeps these fabric scissors performing at their peak for all your embroidery tips and sewing projects. The choice of embroidery scissors is essential for achieving professional-looking results in various sewing tasks.

Features of High-Quality Fabric Scissors

You’ll notice that top-quality fabric scissors have three essential features that set them apart from regular scissors.

These tools include perfectly aligned handcrafted blades, longer cutting edges for smooth cuts, and ergonomic handles that reduce hand strain during extended use.

They are designed to provide smooth cuts and comfort during use.

Aligned Handcrafted Blades

When you invest in quality fabric scissors, handcrafted blades make all the difference in cutting precision.

These scissor blades undergo precise alignment during manufacturing, ensuring perfect contact along their entire edge.

This blade design prevents fabric bunching and delivers consistent fabric quality results.

Proper handcrafted construction means your scissors maintain blade sharpness longer, requiring less frequent scissors maintenance.

The choice of scissors depends on understanding best fabric cutting techniques and tools.

It is essential to consider the best fabric cutting techniques when selecting scissors.

Longer Blades

Longer blade length transforms your fabric cutting experience completely.

Extended blades deliver smooth cuts through multiple fabric layers without repositioning your scissors.

The sharp edge maintains consistent fabric glide from start to finish.

Unlike shorter blades that require choppy cuts, longer fabric scissors types provide cutting ease across wide materials.

This blade design reduces hand fatigue while ensuring smooth cuts every time, providing a significant improvement in overall fabric cutting experience with smooth cuts.

Comfortable Handles

Choosing fabric scissors with ergonomic handles transforms your cutting experience from painful to pleasant.

Quality scissors feature design elements that reduce hand fatigue during extended use.

Key comfort features include:

- Soft cushioning with rubberized grip materials

- Finger loops that provide secure control and stability

- Handle materials like molded plastic with contoured shapes.

Ergonomic design guarantees a comfortable grip throughout long projects.

Caring for Your Fabric Scissors

Your fabric scissors need regular care to maintain their sharp cutting edge and prevent damage to your fabrics.

Clean the blades after each use, avoid cutting paper or other materials, and sharpen them regularly to guarantee they continue making precise cuts through multiple fabric layers.

Proper Cleaning

Once you’ve invested in quality fabric scissors with aligned blades and comfortable handles, keeping them clean becomes your next priority. Regular fabric care starts with proper scissor maintenance after each cutting session.

Your fabric scissors need attention after every project. Lint, thread fibers, and fabric residue build up on the blades, affecting their performance. Here’s how to maintain peak cutting condition:

- Wipe blades with a soft, dry microfiber cloth after each use to remove fabric fibers

- Clean stainless steel scissors with water to remove adhesive or dirt buildup

- Apply a small amount of oil to the pivot point periodically for smooth operation

- Remove oil residue before use to prevent fabric staining

- Use rubbing alcohol to eliminate stubborn adhesive residue from blade surfaces

These cleaning tips guarantee your scissors stay sharp and precise. Blade sanitizing and handle hygiene prevent contamination between projects. Proper scissors lubrication keeps the pivot smooth while regular cleaning extends blade life substantially. To prevent damage and guarantee longevity, following proper scissor maintenance tips for peak performance is vital. Regular maintenance ensures your scissors remain in good condition, and by doing so, you can enjoy long-lasting and efficient cutting experiences.

Avoid Cutting Non-fabric Items

Your fabric scissors deserve dedicated blade protection through proper scissor maintenance.

Never cut paper, plastic, or wire with your fabric shears—this causes fabric cutting problems and blade damage.

Keep separate regular scissors for non-fabric tasks.

This fabric safety practice prevents tool degradation and maintains sharp cutting techniques.

Mixed-use scissors lose precision, creating fabric damage during projects.

Dedicated fabric scissors outperform scissors vs rotary cutter comparisons when properly maintained through careful scissors care.

Regular Sharpening

Beyond keeping fabric scraps away from your shears, maintaining sharp blades requires regular attention.

When cutting requires excessive pressure or creates a sawing motion, it’s time for professional sharpening. Sharp scissors guarantee precise, effortless cuts through various fabric types while preventing fraying.

Here’s your blade maintenance routine:

- Sharpness Testing – Check cutting performance monthly by slicing through fabric scraps

- Professional Edge Refining – Schedule scissor sharpening services every 6-12 months based on usage

- Cutting Optimization – Inspect blades regularly for dullness using proper sharpening tools when needed

Replacing Your Fabric Scissors

Quality fabric scissors don’t last forever. Even premium cutting tools eventually show wear signs that signal replacement time.

Your blade angle may shift, causing uneven cuts on different fabric types. Handle ergonomics deteriorate as cushioning compresses. Scissor materials like carbon steel maintain sharpness longer, but constant use takes its toll.

| Warning Sign | Impact on Performance | Replacement Timeline |

|---|---|---|

| Blades pull fabric | Fraying, uneven edges | Immediate |

| Handle discomfort | Hand fatigue, poor control | Within 3 months |

| Visible nicks/chips | Snagging delicate materials | Immediate |

| Loose pivot screw | Unstable cutting techniques | Within 1 month |

Don’t wait until your fabric cutting tools fail mid-project. Professional seamstresses replace their fabric scissors every 2-3 years with regular use. Scissors sharpening helps extend life, but worn handles and damaged blades need fresh tools.

Storing Fabric Scissors Properly

You’ll protect your fabric scissors’ sharp blades and extend their lifespan by storing them in protective sheaths or secure cases.

Proper storage prevents blade damage from contact with other tools and keeps the cutting edges aligned for precise fabric cuts, which helps to extend their lifespan and maintain precise fabric cuts.

Protective Sheaths/sleeves

Sharp fabric scissors need protection when they’re not snipping away at your latest project.

Protective sheaths and sleeves act like armor for your blades, preventing nicks and maintaining that razor-sharp edge you’ve worked hard to preserve through scissors sharpening and maintenance.

Quality scissor guards come in various sleeve materials designed specifically for fabric scissors protection.

Here’s what you should look for:

- Blade Covers – Hard plastic or leather sheaths that completely cover cutting edges

- Storage Pouches – Soft fabric sleeves that slip over the entire scissor body

- Protective Cases – Rigid holders with secure closures for travel or workshop storage

- Scissor Guards – Simple plastic clips that cover just the tips and pivot point

These accessories prevent blade damage and extend your scissors’ lifespan substantially.

Secure Cases or Pouches

Beyond protective sheaths, secure cases or pouches offer complete storage solutions for your fabric scissors.

Quality scissor holsters made from durable pouch materials like leather provide soft blade protection, while hard case designs prevent damage from drops.

Roll-up storage solutions offer lightweight portability for crafters on the go.

Zippered protective covers keep multiple pairs organized and secure, and it is essential to choose cases that accommodate your scissors ergonomics and handle design comfortably.

Proper storage preserves your investment in quality fabric cutting tools, ensuring they remain sharp and ready for precise work whenever you need them.

Frequently Asked Questions (FAQs)

Can you use normal scissors to cut fabric?

Like using a butter knife to cut steak, you can use normal scissors on fabric, but you’ll get jagged edges and fraying.

They work in emergencies but aren’t ideal for clean, precise cuts.

What kind of scissors are used to cut fabric?

You’ll need fabric scissors with long, sharp blades for clean cuts. Dressmaker’s shears work best for garments, while pinking shears prevent fraying. Embroidery scissors handle detailed work perfectly.

Why won’t my scissors cut fabric?

Your scissors probably have dull blades that can’t slice through fabric fibers cleanly.

Regular scissors aren’t designed for textiles and will snag, pull, or create jagged cuts instead of smooth ones.

How do you know if scissors are for fabric?

You can tell if scissors are made for fabric by checking for longer, sharper blades, pointed tips, and ergonomic handles.

Look for terms like "fabric shears" or "dressmaker’s scissors" on packaging or blades.

How often should I sharpen my fabric scissors?

You should sharpen your fabric scissors every 6-12 months with regular use, or when they start snagging fabric. Heavy users might need sharpening every 3-6 months to maintain clean cuts.

What thickness of fabric can my regular scissors handle?

Like a seamstress from the Victorian era wielding basic shears, you’ll find regular scissors handle lightweight fabrics like cotton and silk well.

They’ll struggle with thick denim, canvas, or multiple fabric layers.

Should I invest in both bent and straight blade fabric scissors?

You don’t need both types initially.

Start with straight blade fabric scissors for most projects.

Add bent-handle shears later if you frequently cut large pieces or need better visibility when working flat.

What fabrics work best with regular scissors?

Regular scissors work best on lightweight fabrics like quilting cotton, thin linen, and basic cotton blends.

You’ll get cleaner cuts on these materials since they’re less dense and won’t dull your blades as quickly.

How often should fabric scissors be sharpened?

Ironically, your sharpest tools become dull fastest.

You’ll need professional sharpening every 6-12 months with heavy use, or annually for occasional sewers.

Quality fabric scissors maintain their edge longer than cheaper alternatives, which is a key factor in professional sharpening needs.

Whats the price difference between regular and fabric scissors?

You’ll pay $3-15 for regular scissors, while fabric scissors cost $20-

The higher price reflects superior blade steel, precision engineering, and ergonomic handles designed for cutting textiles.

Conclusion

Professional seamstresses replace their fabric scissors every 2-3 years to maintain cutting precision.

While you can use regular scissors to cut fabric in emergencies, the results will disappoint you.

Fabric scissors deliver clean, fray-free cuts that protect your materials and save time.

They’re designed specifically for textile fibers, ensuring professional-looking projects.

Invest in quality fabric scissors, maintain them properly, and store them correctly.

Your sewing projects will improve dramatically when you use the right tools for the job.