This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

That embroidered patch from your favorite band isn’t destined for the trash just because it peeled off your jacket. Most iron-on patches survive multiple applications when you remove and reapply them correctly—the adhesive reactivates under heat, giving you several chances to relocate or salvage them.

The catch? Success depends on adhesive quality, fabric type, and your removal technique. Premium patches with thermoplastic backing handle six to eight reuses, while budget versions usually fail after two attempts.

You’ll need to assess the patch condition, clean off old adhesive residue, and match your iron’s heat setting to both the patch material and your fabric. Strategic reapplication saves money and keeps your custom designs alive.

Table Of Contents

Key Takeaways

- You can reuse iron-on patches multiple times if you remove them carefully with controlled heat and the adhesive backing stays intact—premium patches handle six to eight reuses while budget versions typically fail after two or three attempts.

- Success depends on three critical factors: using the right heat setting (250°F for delicate adhesives, 320°F for premium thermoplastic), completely removing old adhesive residue with rubbing alcohol, and matching your technique to both the patch type and fabric compatibility.

- When the original adhesive weakens, you can restore bonding strength by reheating at 140°C for 30-40 seconds, applying fabric glue or fusible webbing, or reinforcing edges with polyester thread stitching for permanent hold through dozens of washes.

- Extend patch life after reapplication by waiting 24 hours before washing, turning garments inside out and using cool water below 40°C, air drying flat instead of using high heat, and avoiding fabric softeners that compromise adhesive bonds.

Can You Reuse Iron-on Patches?

Yes, you can reuse iron-on patches, but success depends on how well you remove them and whether the adhesive is still in good shape. The key is working carefully so you don’t damage the patch or the glue backing during removal.

If the fabric under your patch has embroidery you want to save or remove, check out how to carefully remove embroidery stitches without damaging the material underneath.

Before you try reusing one, it helps to understand what affects whether a patch will stick again.

Factors Affecting Patch Reusability

Patch reusability hinges on several material conditions you can control.

Adhesive quality determines how many heat cycles your patch survives—premium thermally activated adhesives handle 6 to 8 reuses, while budget versions fail after two or three attempts.

Premium adhesives survive six to eight reuses, while budget versions fail after just two or three heat cycles

Fabric thickness and type matter too: polyester blends grip better than cotton, which absorbs moisture and weakens the bond during each reapplication.

For more details on factors affecting patch reusability, review expert guidance customized for different materials.

Types of Iron-on Patches and Adhesives

Understanding your patch type shapes your reuse strategy.

Embroidered iron-on patches use polyester thread on twill backing with hot-melt adhesive film—these survive removal best because the thick fabric holds its shape.

Printed patches feature inkjet designs on thin cotton with weaker glue formulas, losing bond strength after one reapplication.

Check heat settings on your iron: low (250°F) works for delicate adhesives, medium-high (320°F) reactivates premium thermoplastic coatings without scorching fabric compatibility.

For more details, you can learn about the thermoplastic adhesive materials used in iron-on patches.

Benefits and Limitations of Reusing Patches

Reusing patches saves you the effort of starting fresh with new designs, but adhesive strength drops with each application—especially on stretchy fabrics where fabric compatibility was optimized for smooth surfaces.

You’ll notice color fading and edge lifting after multiple wash cycles. Adhesive residue buildup creates reuse challenges that weaken the bond during patch reuse techniques, so durability tests show iron on patch removal impacts patch longevity substantially.

How to Remove Iron-on Patches Safely

Removing an iron-on patch without tearing the fabric or ruining the design takes the right tools and a careful hand.

Heat loosens the adhesive bond, but you’ll need to work slowly to protect both the patch and the garment underneath. Here’s what you need and how to safely lift that patch free.

Tools and Materials Needed

Before you start pulling patches off your favorite jacket, gather the right gear to protect both the patch and the fabric underneath. You’ll need a few basic tools and materials to safely remove iron-on patches without damaging your garment.

If you’re working with denim that already has tears or distressing, check out how to make rips in your jeans to understand the fabric’s structure before removing any patches from damaged areas.

- Ironing board and protective cloths to create a stable, heat-safe workspace

- Seam ripper or dull knife to gently lift patch edges without tearing fabric

- Adhesive remover or rubbing alcohol to dissolve sticky residue left behind

Heat-Based Removal Techniques

Three reliable heat methods make patch removal straightforward when you use the right temperature and timing. Apply heat at 180 to 230 Celsius for 5 to 15 seconds to soften adhesive without scorching fabric—this is your safest route for reuse methods.

| Heat Tool | Best Application |

|---|---|

| Iron | Large patches on sturdy cotton |

| Hair dryer | Delicate fabrics like silk |

| Heat gun | Vinyl-backed patches needing quick release |

| Steam | Loosening stubborn adhesive residue |

Move your heat source continuously across the patch surface to prevent hotspots that char edges or melt backing materials.

Preventing Damage to Patches and Fabric

Precision matters most when you’re protecting both patch and fabric during removal. Shield delicate textiles with parchment paper between iron and patch material selection to prevent scorching, while keeping heat at 150 to 180 Celsius for safe adhesive removal.

Four key protection steps for successful iron on patches reuse:

- Test heat tolerance on hidden fabric first

- Apply gentle pressure—never force patch edges

- Cool completely before handling to prevent tearing

- Remove adhesive residue immediately with rubbing alcohol for clean fabric care and maintenance

Cleaning and Preparing Patches for Reuse

Once you’ve removed your patch, don’t slap it onto a new spot just yet. The back of that patch is probably covered in old glue and fabric fuzz that’ll wreck your second bond.

Here’s how to clean and prep it so it actually sticks again.

Removing Residual Adhesive

After you pull the patch off, sticky residue often clings to both the patch back and fabric surface. For adhesive removal, apply rubbing alcohol with a cotton swab for 30 to 60 seconds to dissolve the glue.

Use gentle scraping with a plastic tool at a 45-degree angle for stubborn spots. This adhesive removal method protects fabric while preparing your patch for adhesive repair and reapplication.

Inspecting Patch Condition

Before you reapply, check your patch for damage. Look closely at edges—fraying appears within 2 millimeters in 60 percent of patches.

Surface cracks signal weakened adhesive quality, especially on glossy finishes. Test fabric compatibility by flexing the patch; lifting corners mean poor reuse safety.

A thorough visual inspection of your iron-on patches determines if you can safely remove and reapply them again.

Cleaning Patch Surface and Edges

A clean patch surface guarantees strong adhesive contact and extends reuse life—don’t skip this step. Wipe from center to edges using a soft damp cloth to lift dust without bending fibers.

- Use a microfiber cloth with mild soap solution for stubborn grime during patch removal techniques

- Run a soft brush along the edge cleaning zone to loosen lint without fraying threads

- Avoid harsh scrubbers that damage embroidery or adhesive removal areas

- Let the patch surface air dry completely before fabric prep to prevent moisture trapped under backing

- Test on a hidden area first to guarantee gentle handling preserves colors and materials

This prep work makes iron on patch reuse possible and helps you remove ironon patch residue safely.

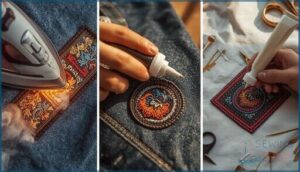

Best Methods to Reapply Iron-on Patches

Once you’ve cleaned your patch and removed old adhesive, you’re ready to reattach it. The method you choose depends on how much adhesive remains and how long you need the patch to last.

Here are three reliable ways to get your patch back on fabric.

Reheating Original Adhesive

If your patch backing still feels sticky after you remove it, you can often reactivate that original adhesive with controlled heat.

Set your iron to medium—around 140°C—and press for 30 to 40 seconds through parchment paper. This thermal rebonding technique softens the glue just enough to reapply the patch without adding new layers, though strength may drop about 20 percent.

Using Fabric Glue or Fusible Webbing

When reheating doesn’t hold, fabric glue or fusible webbing gives your iron-on patches a fresh start. Apply a thin layer of washable fabric glue across the back, let it tack for 30 seconds, then press for 40 seconds at 140°C.

Fusible webbing bonds permanently—just cut a piece to match your patch, sandwich it between patch and fabric, then iron for 15 seconds.

Sewing for Extra Durability

When glue alone won’t cut it, reinforced stitching locks your patch in place for good. Thread selection matters—polyester withstands stress better than cotton. Run a straight stitch 2mm inside the patch edge, then backstitch at corners. For heavy duty interfacing underneath, use a size 90 needle.

Seam finishing with an overcast stitch prevents fraying on embroidery edges. To ensure a strong hold, follow these steps:

- Double-stitch all seam lines for twice the hold.

- Backstitch wide at start and end points.

- Match thread weight to your fabric type.

- Apply fabric reinforcement at high-wear zones.

- Test tension on scrap before final pass.

Tips to Extend Patch Life After Reuse

Once you’ve reapplied your patch, the real work begins—keeping it stuck.

A reused patch won’t have the same grip as a fresh one, so you need to treat it with care.

Here’s how to protect your patch and make it last as long as possible.

Caring for Reapplied Patches

Your success with reapplied patches depends on immediate attention and ongoing vigilance. Press edges firmly for 10 to 15 seconds to lock adhesive bonds.

Wait 24 hours before laundering—this waiting period lets adhesive cure fully. Store spare patches in cool, dry spaces away from sunlight to preserve their sticking power.

Check patch edges regularly for lifting and repress with low heat when needed.

Washing and Drying Recommendations

Gentle washing preserves your hard work. Turn garments inside out and use cool water below 40 degrees Celsius to protect adhesive bonds during fabric care.

Follow these laundry tips when you remove, reuse, and reapply iron on patches:

- Select delicate cycles to minimize mechanical stress on patch edges

- Air dry flat instead of using high dryer settings

- Skip fabric softeners that compromise adhesive protection

Reinforcing With Stitching

Stitch patterns lock your reapplied iron on patches in place when adhesive weakens. Choose polyester or heavy-duty thread that won’t snap under stress, then sew a zigzag or backstitch border around patch edges.

This reinforcement technique works across any fabric selection and transforms a heat-only bond into mechanical strength you can trust through dozens of washes after you remove and reapply.

Creative Ways to Reuse Old Iron-on Patches

Once a patch has served its time on one garment, you don’t have to toss it or hide it in a drawer. Worn-out patches can find new life on different fabrics, mixed into creative projects, or combined with other materials to make something completely fresh.

Here’s how to get more use out of patches that won’t stick on their own anymore.

Upcycling Clothing and Accessories

Old patches breathe fresh life into worn garments when you approach upcycling with purpose. Apply iron-on patches to cover denim tears, refresh faded tote bags, or hide stains on jackets—each fix transforms textile waste into sustainable fashion.

Reuse patches by layering them on thrifted finds for creative reuse that embraces eco-friendly choices. Remove outdated patches from one item and reapply them elsewhere, building fashion recycling habits that reduce waste.

Patch Collages and Textile Art

Fabric layering builds textile design that transforms leftover embroidered patches into visual stories. Arrange reused iron-on patches on stabilized canvas using collage techniques that merge color, texture, and mixed media elements.

- Layer patches of different weights—thin cotton with wool felt—to create dimension.

- Combine patch arrangement with decorative stitching for texture and rhythm.

- Add beads or fabric paint alongside patches for hybrid compositions.

- Frame finished collages on stretcher boards for wall display.

DIY Craft and Repair Projects

Reuse ironon patch pieces to fix ripped jeans, holes in backpacks, or worn elbows on jackets. Iron on patch reuse transforms garments through smart Fabric Selection and controlled Ironing Techniques that maintain Adhesive Strength.

Use Crafting Tools like fabric scissors to reshape patches for precise coverage. Removing ironon patches from old clothing creates custom Patch Design Tips for repair work—stitch edges for secure hold that withstands daily wear.

Frequently Asked Questions (FAQs)

Can you take iron-on patches off and reuse them?

Yes, you can remove and reuse iron-on patches if the adhesive backing stays intact.

Success depends on gentle removal techniques, fabric compatibility, and whether you’re willing to add fresh glue or stitching for reattachment security.

Can you restick iron-on patches?

You can restick iron-on patches if the adhesive remains tacky after removal. Clean both surfaces, then reapply with proper heat.

Dense embroidery or thick backing reduces reattachment success compared to lightweight designs.

How to remove and reapply iron-on patches?

To remove iron-on patches safely, apply low to medium heat through a thin cloth, then gently peel from edges.

Reapply by reheating the original adhesive or adding fabric glue before pressing firmly.

How to make iron-on patches stick again?

Did you know iron-on patches can survive up to 25 washes before the adhesive weakens?

For patch revival, clean both surfaces, use adhesive remover, and reapply with fresh glue or fusible webbing—proper fabric preparation ensures strong bonding techniques.

Can iron-on patches be reapplied?

You can reapply iron-on patches with proper preparation. Reheating original adhesive or adding fusible webbing restores adhesion on cotton and denim.

Sewing edges after reapplication increases durability and ensures fabric compatibility for long-term reuse.

Can you iron on a patch twice?

Most iron-on patches tolerate a second application if you reheat carefully and prep the surface right.

Success hinges on adhesive quality, fabric type, and whether you add reinforcement like fabric glue or stitching.

Can you iron a patch over a patch?

Yes, you can iron a patch over a patch on compatible fabrics like cotton or denim.

Use medium heat with a pressing cloth to prevent scorching and guarantee proper adhesive bonding between layers.

Is there a backing on an iron-on patch?

Most iron-on patches feature a heat-activated adhesive backing—a thin thermoplastic layer that melts under high temperatures.

Some include removable paper backing, while hybrid designs combine adhesive materials with stitched edges for enhanced fabric compatibility and durability.

How long do iron-on patches typically last?

Most iron-on patches hold strong through 25 washes before adhesive longevity weakens.

Patch durability depends on fabric impact, heat exposure, and care—denim extends lifespan factors while high dryer heat accelerates wear on reuse ironon patch applications.

Can iron-on patches be applied to all fabrics?

Not every fabric works well with iron-on patches. Cotton and denim handle heat and adhesive best, while polyester blends need lower settings.

Delicate materials like silk or leather won’t bond safely.

Conclusion

Patch preservation puts power in your hands—literally. When you can you reuse iron-on patches with proper heat control and adhesive care, you’re refusing throwaway culture one design at a time. Your favorites don’t expire after one wear.

They survive, shift, and strengthen across jackets, bags, and projects you haven’t imagined yet. Master removal without tearing. Clean backing thoroughly. Reapply with confidence. You’ve just turned temporary decoration into permanent potential.

- https://www.jiameilabels.com/resources/how-to-reuse-patches-for-your-jacket-and-shirt.html

- https://www.paddyspatches.com/blogs/news/how-to-remove-iron-on-patches-a-step-by-step-guide

- https://www.bluesusanmakes.com/how-to-reuse-a-uniform-patch-save-your-old-ones-and-save-money/

- https://www.rockler.com/learn/steam-soften-glues

- https://libres.uncg.edu/ir/uncg/f/J_Su_Exploring_2022.pdf