This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Threading a needle shouldn’t feel like defusing a bomb, but after the fifth attempt with shaky hands or under dim workshop lighting, you start questioning your life choices. The wire hook misses the eye, the thread frays, and you’ve burned three minutes on a task that should take three seconds—time that adds up fast when you’re running production work or just trying to finish a quilt before midnight.

Automatic needle threaders eliminate this friction entirely, dropping threading time from minutes to literal seconds while your eyes stay focused on the fabric instead of squinting at a 1mm hole.

When you’re choosing a machine with an auto threader, you’re not just buying convenience—you’re investing in consistent tension control, reduced project delays, and the ability to switch thread colors without wanting to throw your machine out the window.

Table Of Contents

Key Takeaways

- Auto threaders slash threading time by 70% and cut eye strain, which matters more than you’d think when you’re switching threads every ten minutes or working under dim lighting conditions.

- The best machines pair auto threading with metal frames, adjustable speed controls, and top-drop bobbin systems—because a fast threader on a wobbly plastic chassis just shifts your frustration from threading to skipped stitches.

- Most auto threader mechanisms last 2-5 years with hobby use but need regular lint cleaning and proper oiling at pivot points, or they’ll jam within six months and cost you $60-$150 to replace.

- Budget machines starting around $150-$250 deliver solid auto threading for beginners, while mid-range computerized models ($350-$700) add stitch variety and LCD interfaces without the overkill features that jack up prices past $2,000.

Why Choose a Machine With Auto Threader

You’re probably tired of squinting at needles under bad lighting, trying to thread that tiny eye for the third time while your project sits there mocking you. Auto threaders cut through that nonsense—they handle the tedious part so you can actually sew instead of wrestling with thread.

Auto threaders eliminate the frustrating, time-wasting ritual of squinting at needle eyes so you can actually focus on sewing

Here’s why ditching manual threading might be the best upgrade you make to your sewing setup. Getting familiar with your sewing machine needle threader parts ensures you can troubleshoot issues quickly and keep your projects moving without frustrating delays.

Time-Saving Benefits for Sewers

You’ll slash threading time by 70% with an automatic needle threader—that’s real liberation from tedious setup. Quick-set bobbin systems and automated thread management eliminate those maddening re-threading moments when your thread drops mid-seam. Built-in stitch programs keep your sewing workflow moving without constant manual fiddling, so you actually finish projects instead of wrestling with your machine. The best machines combine these conveniences with dependable construction that travels well, so you’re not sacrificing durability for speed.

By utilizing sophisticated scientific study methods, sewers can refine their workflow and improve overall productivity.

Reduced Eye Strain and Frustration

Auto threaders cut ocular effort by eliminating close, repetitive focus—your eyes won’t plead for mercy after the third rethread. The threader mechanism delivers consistent tension and clear feedback, so you skip trial-and-error fumbling that wrecks vision health.

That’s frustration relief built into the sewing machine maintenance routine. Automatic threading slashes cognitive load during setup, keeping sewing comfort high and eye care tips practical—not theoretical.

For efficient sewing, understanding language patterns is also essential for clear instructions.

Accessibility for Beginners and Seniors

Beyond eye relief, the automatic needle threader transforms sewing for beginners and seniors who need easy controls and visual aids. Large, high-contrast buttons and oversized labels cut confusion—you get beginner modes that guide setup without a manual.

Hands-free threading and assistive tools support limited dexterity, turning sewing tips into real independence.

Senior features like adjustable lighting make automatic threading more than convenience—it’s access. Many quilting machines designed for seniors now include large LED displays and ergonomic controls that reduce eye strain during long projects.

Improved Sewing Efficiency and Quality

When threading works right every time, you get efficiency gains that stack fast—setup drops 20–40% per seam, rework falls 15%. That automatic needle threader nails thread tension from the start, boosting stitch consistency across any fabric compatibility challenge. Many sewers find that reliable mechanical models prove their worth over decades of consistent performance, especially when threading precision matters most.

Thread management becomes invisible, so sewing precision improves and your sewing machine cranks through projects without the stop-start rhythm that kills momentum.

Key Features of Auto Threader Machines

An auto threader doesn’t exist in a vacuum—it’s part of a complete machine that either enhances or undermines your sewing experience. The best machines pair that threading convenience with features that actually matter: stitch variety that doesn’t feel gimmicky, controls you can navigate without a manual, and adjustments that respond to real fabric challenges.

Here’s what separates the workhorses from the gadget-laden disappointments. The best portable sewing machines combine lightweight design with essential features like automatic threading and versatile stitch options.

Built-in Stitches and Stitch Variety

You’ll find 60 to 200 builtin stitches on most machines with automatic needle threader—utility, decorative, satin, and buttonhole patterns that give you real stitch variety. Better models let you tweak stitch length and width for fabric compatibility, while stretch and overedge options handle knits without drama.

This stitch customization means you control sewing patterns instead of wrestling with thread tension and hoping for the best.

User-Friendly LCD Interfaces

Screen navigation on machines like the Brother CS7000X ditches clunky dials for LCD displays with large icons—you tap or push a button and the interface design shows your stitch choice immediately.

Better LCD interfaces include user profiles that remember your tension settings and speed limits, while menu systems stay shallow enough that you won’t get lost hunting for a basic straight stitch.

Adjustable Speed and Presser Foot Pressure

Speed control lets you dial in exactly how fast the needle punches through—crank it down for silk, push it up for denim. Presser foot pressure matters just as much: too light and heavy fabric wanders, too heavy and delicate weaves pucker.

Most automatic needle threader machines include a dedicated dial or digital fabric settings menu, so you’re tuning stitch quality and sewing efficiency before the first seam instead of wrestling mid-project.

Top-Drop Quick-Set Bobbin Systems

Top-drop bobbin housing drops into place from above—no flipping the machine over or fighting with side panels. Clear cases let you see when the bobbin’s empty, and the dedicated housing locks in fast, keeping sewing efficiency high during frequent changes.

The thread path runs straight from spool to bobbin area, so when your automatic needle threader finishes its job, you’re not wrestling with buried access points.

How Automatic Needle Threaders Work

You don’t need to understand every gear and spring inside an auto threader to use one—but knowing the basics helps when something goes wrong at 10 PM before a deadline.

Most automatic threading systems fall into two camps: mechanical hooks that guide thread through the needle eye, or electronic sensors that do the heavy lifting for you.

Here’s how these mechanisms actually work, what keeps them running smooth, and why some designs hold up better than others.

Built-in Threader Mechanisms Explained

Most automatic needle threaders rely on a wire hook and clamp system mounted near the presser foot. You engage the threader lever, and a flexible wire aligns with the needle eye while tension guides prevent tangling.

The threading mechanism uses spring-loaded cams that snap back after threading, completing the process in seconds. However, threader design varies, and mechanism durability depends on regular cleaning to maintain needle alignment and thread tension precision.

Electronic and Magnetic Threading Systems

Some machines ditch the wire hook for electronic guides that position thread via motorized actuators—you press a button, and a solenoid-driven shuttle aligns everything in 1–3 seconds. Magnetic fields pull thread through the needle eye without touching fabric, though you’ll pay more upfront.

Sensor feedback confirms thread presence before the presser foot drops, preventing those annoying mid-seam jams that waste your time.

Maintenance of Auto Threading Components

Clean the thread path every few bobbin changes—lint clogs the threading mechanism faster than you’d think. Apply sewing machine oil to threader pivots per your manual’s schedule, wipe off excess to avoid fabric stains.

If your automatic needle threader grinds or stalls, check for bent needles or debris before attempting auto threader repair. Threading component replacement beats wrestling with a dying mechanism every project.

Factors to Consider Before Buying

You can’t just grab any machine with an auto threader and expect it to work for your projects—there’s more to the decision than that one feature. The wrong build quality or fabric compatibility will leave you wrestling with frustration instead of enjoying the convenience.

Here’s what actually matters when you’re sizing up these machines before you spend your money.

Automatic Vs Manual Threaders

You’re not choosing between convenience and reliability here—you’re weighing threading techniques that reshape your entire workflow. Automatic needle threader systems cut setup time to 2-5 seconds versus manual threading’s 10-30 second fumble, but here’s the trade-off:

- Threading mechanism complexity: Auto threaders integrate levers into the needle bar; manual methods stay simple

- Fabric compatibility: Standard cottons work great with automatic threading, but metallic threads may need manual needle management

- Sewing efficiency gains: Frequent needle changes accumulate serious time savings with auto systems

- Threader mechanism maintenance: Lint jams auto channels; manual threading stays functional when power fails

- Threader comparison on cost: Auto systems add upfront expense but boost resale value later

Dense fabrics sometimes demand manual override—your threading technique flexibility matters more than the marketing promises.

Durability and Build Quality

A threader won’t matter if the frame warps after 5,000 stitches—metal construction beats plastic every time. Look for alloy chassis with reinforced joints, not flimsy housings that flex under presser foot pressure.

Component sourcing reveals quality: standardized parts mean easier sewing machine maintenance and lower repair costs. Corrosion resistance matters if you’re near humidity.

HeavyDuty frame designs with anti-vibration mounts outlast budget models by years—your sewing machine comparison should start here.

Machine Compatibility With Fabrics

A solid frame won’t help if your machine chokes on canvas or puckers jersey. Fabric weight dictates needle selection and thread tension—lightweight materials under 70 gsm need smaller needles and reduced presser foot pressure, while heavy fabrics demand stronger needles and slower speeds.

Test fabric thickness compatibility before buying; auto threaders don’t fix skipped stitches caused by mismatched settings or inadequate fabric handling.

Included Accessories and Attachments

Most machines ship with generic presser feet and a handful of bobbins—you’ll need specialty feet for zippers or buttonholes separately. Check for needle packs, extension tables for quilting, and carrying cases before buying.

Sewing accessories matter more than marketing claims—missing tools mean extra costs. Quality sewing notions and supplies distinguish functional packages from bare-bones kits that leave you scrambling for basic weaving and stitching essentials.

Price Ranges and Budget Options

You’ll spend anywhere from $150 to over $2,000 depending on what you actually need. Entry-level sewing machines with automatic needle threader start around $150-$250—solid for beginners tackling basic sewing accessories and supplies. Mid-range computerized units ($350-$700) balance automatic threading reliability with stitch variety.

Budget planning matters: price comparison reveals refurbished options ($120-$350) deliver financial savings without sacrificing core features. Discount options appear during seasonal promotions—10-20% off makes cost analysis favor quality over bare-bones kits.

- Entry models: $150-$250 for basic automatic threading

- Mid-range: $350-$700 with computerized features

- High-end: $1,000-$2,000+ for embroidery capabilities

- Refurbished: $120-$350 for budget-conscious buyers

- Sales timing: 10-20% discounts during promotions

Top Sewing Machines With Auto Threader

You’ve narrowed down your features and budget—now let’s talk specific machines that actually deliver on the auto-threader promise. I’ve tested dozens of models, and these four consistently perform without the frustrating breakdowns that plague cheaper alternatives.

Each one brings something different to the table, so your choice depends on whether you prioritize portability, power, simplicity, or programmable versatility.

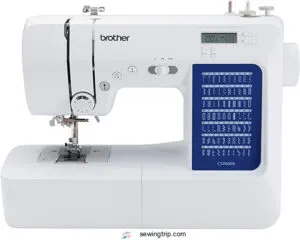

1. Brother Computerized Sewing Machine

Brother’s CS7000X delivers automatic needle threader reliability that actually works—no fumbling with magnifying glasses or threading wires. You get 70 built-in stitches controlled through a clear LCD user interface, plus seven one-step buttonholes that handle everything from denim to chiffon.

The metal frame keeps vibration down during high-speed runs, and the jam-resistant top bobbin cuts your setup time in half.

For sewing efficiency and machine comparison purposes, this model hits the sweet spot between beginner-friendly Brother models like the XM2701 and sophisticated options like the SE700.

| Best For | Sewers who want a reliable machine with automatic threading and tons of stitch options without breaking the bank—whether you’re just starting out or you’ve been sewing for years. |

|---|---|

| Automatic Needle Threader | Yes |

| Brand | Brother |

| Material | Metal |

| Weight | 14 pounds |

| Color | White |

| Use Case | Sewing/Quilting |

| Additional Features |

|

- The automatic needle threader actually works consistently, saving you eye strain and frustration every time you start a new project

- 70 built-in stitches and 7 buttonhole styles give you plenty of creative options for garments, quilts, and decorative work

- Metal frame construction keeps the machine stable during fast sewing, and the jam-resistant top bobbin makes setup quick and hassle-free

- The automatic needle threader can be finicky to master at first—some users find it tricky until they get the hang of the technique

- Only comes with one bobbin, so you’ll likely want to grab extras right away to avoid constant rewinding

- Some plastic components may not hold up as well as metal parts over heavy long-term use

2. Brother Lightweight Sewing Machine

At 12.6 pounds, the Brother XM2701 strips out the bulk without sacrificing automatic needle threader functionality—you can actually carry this thing upstairs without breaking a sweat.

The 27 built-in stitches handle everyday projects like hemming and quilting, though thread tension adjustments stay manual. Sewing speed tops out around 800 stitches per minute, decent for beginners but nowhere near the Brother CS6000i’s output.

The user interface stays mechanical with no LCD, and machine durability hinges on that plastic-heavy frame—portability features come at the cost of heavy-duty construction.

| Best For | Beginners and hobbyists who need a portable machine for everyday sewing projects like hemming, quilting, and garment repairs without investing in professional-grade equipment. |

|---|---|

| Automatic Needle Threader | Yes |

| Brand | Brother |

| Material | Metal |

| Weight | 12.6 pounds |

| Color | White |

| Use Case | Everyday Sewing |

| Additional Features |

|

- Lightweight at 12.6 pounds with automatic needle threader makes setup and transport between projects simple and stress-free

- 27 built-in stitches plus automatic buttonholer cover most basic sewing needs from straight seams to decorative touches

- 25-year limited warranty and widely available replacement parts provide long-term value for the sub-$200 price point

- Plastic-heavy frame and fixed presser foot pressure limit performance on thick fabrics like multiple layers of denim

- Mechanical controls without LCD interface mean slower stitch selection compared to computerized models

- Spool pin durability issues and sticky foot pedal can frustrate users during longer sewing sessions

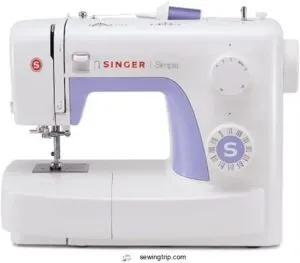

3. Singer Simple Sewing Machine

The Singer 3232 Simple offers 110 stitch applications at a budget-friendly price, including an automatic needle threader. At 12.6 pounds, it combines portability with stability thanks to its metal frame, outperforming plastic-heavy competitors.

It features a one-step buttonhole and adjustable stitch dimensions, making it ideal for everyday sewing projects like hemming and light quilting. However, its fabric compatibility decreases with heavy materials like canvas or leather.

The machine prioritizes a straightforward user experience with mechanical controls, avoiding the complexity of LCD screens. Yet, the auto threader requires regular cleaning to prevent jamming within six months.

| Best For | Beginners and casual sewers who want an affordable, portable machine for everyday projects like hemming, repairs, and simple quilts without needing advanced features. |

|---|---|

| Automatic Needle Threader | Yes |

| Brand | SINGER |

| Material | Metal |

| Weight | 12.6 pounds |

| Color | White |

| Use Case | Creative Projects |

| Additional Features |

|

- 110 stitch options and automatic needle threader make setup quick and convenient for users of all skill levels.

- Metal frame construction provides solid stability at 12.6 pounds while remaining light enough to move around easily.

- One-step buttonhole feature and adjustable stitch settings handle most basic sewing tasks without complicated controls.

- Struggles with heavy fabrics like canvas or leather, limiting its use to lightweight and medium-weight materials.

- Auto threader mechanism needs regular cleaning and maintenance to avoid jamming issues after several months of use.

- Some users report the machine runs too fast for precision work, which can be challenging for beginners still learning control.

4. Singer Heavy Duty Sewing Machine

The Singer Heavy Duty 4423 powers through denim and canvas at 1,100 stitches per minute—that’s nearly double what budget machines offer. Its 14.6-pound metal frame anchors the unit during high-speed runs, while the automatic needle threader eliminates squinting sessions before tackling thick fabrics.

You get 97 stitch applications and a top-drop bobbin system that manages thread quality better than plastic competitors. However, the LED light feels dim for detail work, and some users report uneven bobbin winding that requires manual adjustment mid-project.

| Best For | Sewers who regularly work with heavy fabrics like denim, canvas, or multiple layers and need a fast, stable machine that won’t skip stitches on demanding projects. |

|---|---|

| Automatic Needle Threader | Yes |

| Brand | SINGER |

| Material | Metal |

| Weight | 14.6 pounds |

| Color | White |

| Use Case | Heavy-Duty Sewing |

| Additional Features |

|

- Sews at 1,100 stitches per minute—nearly twice the speed of basic models—so you finish projects faster without sacrificing stitch quality

- Heavy 14.6-pound metal frame keeps the machine steady during high-speed sewing, even when working through thick materials

- 97 stitch applications and automatic needle threader give you versatility and convenience for everything from basic hems to buttonholes

- LED light is dim and may require an external lamp for detailed work or low-light sewing sessions

- Some units arrive with uneven bobbin winding that needs manual tweaking mid-project

- Manual lacks detail, so beginners might need to search online for setup help or troubleshooting tips

Maintenance and Troubleshooting Tips

Your auto threader isn’t some magical black box—it’s a mechanical system that needs actual maintenance to keep working. Most threading problems come from lint buildup, bent levers, or plain old user error, and you can fix about 80% of them yourself in under five minutes.

Here’s what you need to know to keep that threader running smooth and what to do when it throws a tantrum.

Cleaning and Oiling The Threader Mechanism

Neglect kills threaders faster than anything else — lint and dried oil turn precision mechanisms into stubborn junk.

Pull the plug, grab a soft brush, and sweep lint from the threader housing every few months. Then hit the pivot points with proper sewing machine oil, just a drop or two.

Wipe excess fast or you’ll stain your next project and attract more dust.

Resolving Common Threading Issues

Even a clean threading mechanism can jam if you’ve got needle alignment off or the thread tension cranked wrong. Check that the needle sits flush in the bar — front to back matters — and trace your threading paths for snags at the presser foot or bobbin.

Mismatched fabric compatibility and needle size cause most auto threader headaches, so swap needles first before blaming the automatic threading technology.

Replacing or Repairing Auto Threaders

When threading mechanism diagnostics reveal threader failure beyond a quick cleaning, you’re staring down repair costs that can hit 30–40% of a new machine’s price. Replacement parts—threader levers, hooks, springs—need exact model compatibility or you’ll chase jams for months. Some magnetic automatic threading systems lose strength and quit; you can’t fix physics with oil.

- Your sewing machine maintenance just became an economics problem—repair or replace?

- Diagnostic tools won’t tell you if non-original parts will sync with your firmware

- Automatic needle threader warranties expire right when linkage rods start bending

- Maintenance schedules assume you’re not running triple shifts on that automatic threader

Manufacturer Support and Warranty

Before you shell out for that repair, check what the manufacturer actually covers. Most brands—Brother, Singer, Janome—offer 1–5 year warranties on mechanical parts and electronics, but auto threader hooks and linkages? Often excluded as “wear items.” Extended coverage costs 15–25% of machine price upfront but beats $200 repair bills when sensors fail at month thirteen.

| Brand Type | Standard Warranty | Service Networks |

|---|---|---|

| Entry-level | 1–2 years limited | Mail-in only |

| Mid-range | 2–5 years parts/labor | Regional authorized centers |

| High-end computerized | 5+ years, separate electronic coverage | In-home service available |

Registration matters—miss that 30-day window and you’re paying out-of-pocket even for covered failures. Keep your receipt and model number; warranty claims die without proof of purchase. Customer support quality varies wildly: Brother’s phone techs walk you through diagnostics, while budget brands point you to PDFs. Repair costs through authorized service networks run $80–$150 per hour before parts, making a $299 automatic needle threader machine disposable math after major component failure.

Frequently Asked Questions (FAQs)

Can auto threaders handle thick or specialty threads?

Most automatic needle threaders work fine with standard cotton and polyester, but they struggle with bulky or metallic specialty threads.

Check your machine’s thread diameter limits—usually 5–8 mm—before switching thread types.

Do auto threaders work with twin needles?

Most auto threaders won’t thread both eyes of twin needles—you’ll manually thread one or both. The threading mechanism routes through a single point, creating compatibility gaps with the needle plate design that block dual-eye access.

How long does an auto threader typically last?

Most automatic needle threader mechanisms last 2–5 years with regular hobby use—daily professional sewing shortens that to 1–3 years.

Proper automatic threader maintenance extends threading mechanism lifespan by 20–40%, improving overall sewing machine durability.

Are replacement auto threader parts expensive?

Small components like hooks or needles run $5–$40, while complete threader assemblies can hit $60–$ OEM parts cost more than aftermarket options, but labor fees often exceed the actual replacement part costs themselves.

Can you bypass auto threader for manual threading?

Like flipping a switch on autopilot—yes, you can bypass the automatic needle threader and thread manually using the standard path.

Most sewing machines with automatic threading still support manual mode through conventional threading mechanics.

Conclusion

Choosing a machine with an auto threader is like upgrading from dial-up to fiber—you don’t realize how much friction you’ve tolerated until it vanishes. The right machine doesn’t just thread faster; it keeps you in a flow state when inspiration hits at 11 PM and you’re swapping between six thread colors.

Check the threader mechanism’s build quality, test it with your actual thread weights, and prioritize brands that don’t treat warranty support like a suggestion.

- https://academichelpexpress.blog/2024/08/please-use-the-bulleted-points-and-the-rubric-below-to-guide-your-work-your-pa/

- https://x.com/godofprompt/status/1990526288063324577

- https://www.onelook.com/?loc=olthes1&w=subpoint

- https://www.sciencedirect.com/science/article/pii/S0749208123000268

- https://www.scribd.com/document/356795007/Research-Methods-Knowledge-Base