This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Choosing a stabilizer is essential for enhancing your archery performance. Start by understanding the types available: front, sidebar, and twin stabilizers. Each offers unique benefits, such as reducing torque, dampening vibrations, and improving balance and noise reduction.

Choosing a stabilizer is essential for enhancing your archery performance. Start by understanding the types available: front, sidebar, and twin stabilizers. Each offers unique benefits, such as reducing torque, dampening vibrations, and improving balance and noise reduction.

Consider factors like length and weight to balance stability and maneuverability; longer stabilizers suit target archery, while shorter ones are ideal for hunting. Materials matter too, with durability and vibration absorption being key. Adjustability allows customization for different conditions.

With the right stabilizer, you’ll notice better accuracy and less strain. Dive deeper to grasp all the nuances and optimize your archery setup for success.

Table Of Contents

- Key Takeaways

- Understanding Bow Stabilizers

- Factors to Consider

- Choosing the Right Length

- Selecting the Appropriate Weight

- Importance of Adjustability

- Front Stabilizers Vs. Sidebar Stabilizers

- Dampening Vibrations and Noise

- Complementing Accessories

- Selecting the Right Material

- Consulting With Experts

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Don’t get stuck in a rut! Think of picking the perfect stabilizer as a dance – it’s all about finding the right partner to complement your moves and keep you balanced on the dance floor.

- Like a fine wine, stabilizers come in a dizzying array of flavors (materials, lengths, weights, etc.). But don’t just chug the first bottle you see! Experiment and savor the nuances to discover your personal taste for peak performance.

- Forget one-size-fits-all! Every archer is a unique snowflake, so spend some quality time getting to know yourself – your shooting style, strength, and stabilization needs. It’s the key to finding your soulmate stabilizer.

- Perfection takes practice, babe! Keep an open mind, stay flexible, and don’t be afraid to get your hands dirty experimenting with different setups. With patience and persistence, you’ll master the art of stabilization.

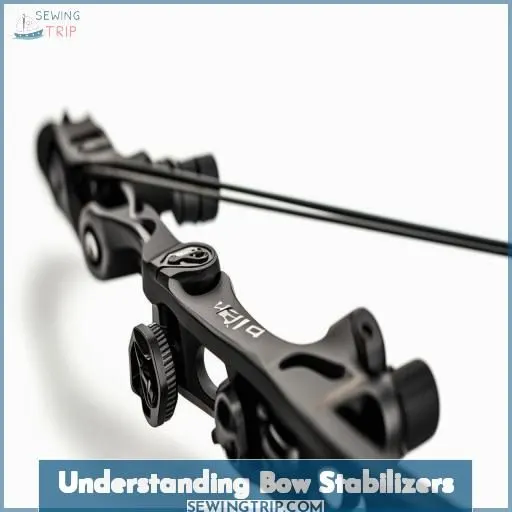

Understanding Bow Stabilizers

When selecting a bow stabilizer, consider the different types available, like front, sidebar, and twin stabilizers, as they serve distinct purposes. Stabilizers offer significant benefits, including reduced torque, vibration dampening, enhanced balance, noise reduction, and overall improved performance.

Types of Stabilizers

When selecting a stabilizer, you have three main options: 1) Front stabilizers, 2) Sidebar stabilizers, and 3) Twin stabilizers. Front stabilizers counterbalance weight and dampen vibrations. Sidebar stabilizers reduce lateral movement and torque. Twin stabilizers distribute weight evenly, offering superior stability in all directions – ideal for target archery. Understanding these types allows customization for your needs.

Benefits of Using a Stabilizer

Stabilizers offer numerous benefits that enhance your archery experience. They dampen vibrations, reducing hand and arm fatigue, while noise reduction improves stealth for hunting. Reduced torque and improved balance lead to tighter groups and enhanced accuracy. With proper stabilizer selection based on your needs, you’ll enjoy improved overall bow performance and consistency.

Factors to Consider

When choosing a bow stabilizer, consider the length, weight, material, and adjustability to find the ideal setup for your shooting style and preferences. The appropriate stabilizer length balances stability and maneuverability, while the weight reduces torque and vibrations, with adjustable features allowing for customization based on conditions.

Length of the Stabilizer

You’ll want to choose a stabilizer length that suits your shooting style and setup preferences. Longer stabilizers enhance stability but compromise maneuverability. Consider customization options like length adjustments to fine-tune vibration management and balance accessory weight for ideal performance. The right length depends on your technique and personal needs.

Weight of the Stabilizer

Weight distribution is equally important for stability maintenance. Heavier stabilizers absorb vibrations better and reduce torque, though excessive weight can hinder maneuverability. Assess your strength and shooting style—bowhunters often prefer lighter setups for unobstructed movement, while target archers prioritize vibration absorption and sight picture steadiness over mobility.

Material of the Stabilizer

The material of your stabilizer markedly influences its performance. Aluminum provides sturdiness, while carbon shines in vibration absorption. Consider maintenance requirements – rubber demands less cleaning. Compare the stabilizer’s material with your accessories’ array, v-bar mount, and sight setup to guarantee compatibility and peak performance. Ultimately, select a material that aligns with your durability and dampening needs.

Adjustability of the Stabilizer

Consider stabilizers with adjustable features, as they allow you to customize the setup. You can:

- Experiment with weight distribution

- Fine-tune the vibration dampening materials

- Adapt to different shooting conditions

- Optimize for various disciplines like 3D target or ground blind hunting

- Minimize muscle fatigue and torque during extended sessions

Western bowhunters and target archers alike benefit from the versatility adjustable stabilizers offer.

Choosing the Right Length

Your shooting style and technique play a key role in determining the ideal length for your bow stabilizer. Target archers generally benefit from longer stabilizers that provide superior stability, while hunters may prefer shorter lengths for better maneuverability in the field.

Shooting Style and Technique

Your shooting style and technique play a vital role in determining the ideal stabilizer length. A longer stabilizer enhances stability but may hinder maneuverability. Conversely, a shorter stabilizer allows for better bow control, especially in tight quarters. Consider your grip stability, bow orientation, and limb alignment when choosing the appropriate length.

| Style | Length |

|---|---|

| Beginner | Shorter |

| Intermediate | Medium |

| Advanced | Longer |

Hunting Vs. Target Archery

The length you choose depends on whether you’re hunting or target archery. For hunting, where maneuverability is essential, shorter stabilizers around 6-10 inches are better. Target archers often prefer longer stabilizers, typically 10-15 inches, for enhanced stability. Your accessories like sights or quivers also impact the ideal length for counterbalancing the bow’s weight.

Maneuverability and Stability

You’ll need to strike the right balance between maneuverability and stability when selecting your stabilizer length. Shorter stabilizers offer enhanced maneuverability, perfect for hunting where quick movements are key. Conversely, longer stabilizers prioritize stability, an advantage in target archery where precision trumps agility. Ultimately, choose a length that aligns with your shooting style and stabilization needs.

Selecting the Appropriate Weight

The weight of your bow stabilizer plays a pivotal role in achieving ideal balance and mitigating torque and vibration. Heavier stabilizers generally provide greater stability, but it’s imperative to take into account your individual shooting technique and strength to guarantee a comfortable and controlled draw cycle.

Balancing the Bow

To balance your bow, select a stabilizer weight that’s appropriate for your strength and shooting style. Heavier weights provide better stability, while lighter ones improve maneuverability. Customization is crucial; experiment with different weights until you find the ideal balance for your needs. A well-balanced setup, supplemented by accessories, provides exceptional stability and control during your shots.

Reducing Torque and Vibration

Choosing the right stabilizer weight is essential for reducing torque and vibration. 1) Heavier stabilizers provide better balance and stability, minimizing bow movement. 2) Lighter options allow more maneuverability for hunting situations. 3) Vibration dampeners absorb shocks, protecting your hands and enhancing accuracy. 4) Consider accessory compatibility to maintain overall bow balance.

Personal Preference and Strength

When selecting the appropriate weight for your stabilizer, consider your personal strength and shooting preferences. A heavier stabilizer offers better stability but requires more strength. Take into account weather conditions, stabilizer care, and budget considerations. Make certain your choice complements your bow’s maintenance needs while meeting your aesthetic preferences for ideal performance (Source).

Importance of Adjustability

Adjustability in a bow stabilizer is vital for customizing the setup to your distinctive needs, enabling you to achieve ideal balance and performance. You can alter the weight distribution to suit varying shooting conditions and experiment to find what suits you best .

Customizing the Stabilizer Setup

Customizing your stabilizer setup is essential for achieving ideal bow performance. Adjusting the weight distribution, experimenting with stabilizer length, and balancing accessory weights can greatly enhance your shooting experience. Consider these aspects:

- Custom weight distribution: Refine stability and balance.

- Dampener material comparison: Improve vibration absorption.

- Stabilizer length experimentation: Find the perfect balance for maneuverability.

Keep these in mind to tailor your setup effectively.

Adapting to Different Shooting Conditions

Adjusting your stabilizer based on shooting conditions is crucial. In windy conditions, choose thinner stabilizers to reduce wind resistance and enhance maneuverability (Source). Position your stabilizer to complement other accessories for desirable balance . Compare materials like carbon for vibration reduction and ascertain a dampener is included . Experimentation remains key to perfecting your setup .

Experimenting With Weight Distribution

When adjusting damping for different shooting conditions, experiment with weight distribution by trying various mounting options. This approach helps you find the ideal balance and vibration dampening. Consider your stabilizer’s color selection and aesthetic appeal, ensuring it complements your bow and other accessories. Tailoring these elements enhances your overall performance and shooting experience .

Front Stabilizers Vs. Sidebar Stabilizers

When choosing between front stabilizers and sidebar stabilizers, consider how each type stabilizes your bow differently. Front stabilizers help reduce bow torque and vibrations by balancing weight forward, while sidebar stabilizers enhance stability and reduce lateral movement, especially for archers who consistently miss in the same direction .

Stabilizing in Different Directions

Choosing between a front stabilizer, sidebar stabilizer, and twin stabilizer depends on your needs. Front stabilizers extend forward, improving balance and reducing vibrations. Sidebar stabilizers counteract lateral movement, adding stability. Twin stabilizers offer multi-directional stabilization, ideal for target archers. Each type helps in vibration dampening and noise reduction, enhancing your overall shooting experience .

Reducing Bow Torque and Lateral Movement

Front stabilizers and sidebar stabilizers play important roles in reducing bow torque and lateral movement. Front stabilizers extend the bow’s length, counteracting wind resistance and leveraging dampener effectiveness to absorb vibrations. Sidebar stabilizers, positioned laterally, enhance balance by distributing weight and combating torque. Choose durable materials and confirm accessory compatibility to maintain effective shooting performance.

Enhancing Overall Stability

To enhance overall stability, consider front stabilizers for balancing weight and dampening vibration along your shooting axis. Meanwhile, sidebar stabilizers help counteract lateral movement, reducing torque and improving balance. Choose based on your shooting style and specific needs; front stabilizers excel in straightforward balance, while sidebars provide effective torque reduction and refined weight distribution for more precise control .

Dampening Vibrations and Noise

Choosing a stabilizer with a dampener not only reduces vibrations, thus minimizing hand and wrist strain, but also markedly improves your arrow flight and accuracy. This guarantees a more comfortable shooting experience and enhances your overall performance.

Choosing a Stabilizer With a Dampener

Choosing a stabilizer with a dampener can significantly improve your shooting experience by reducing vibrations and noise. Dampeners are crafted from materials like rubber or gel, which absorb shock and promote stability. Consider the following key factors:

- Dampener materials: Select high-grade, long-lasting materials.

- Dampener effectiveness: Evaluate its efficiency in reducing vibrations.

- Dampener weight: Verify that it doesn’t disrupt the balance of your bow.

Reducing Hand and Wrist Strain

Reducing hand and wrist strain is essential for a comfortable shooting experience. Opt for dampener materials like rubber or carbon, known for their durability and effective noise reduction. These materials excel in dampening vibrations, thereby minimizing strain on your hand and wrist. Prioritize a stabilizer with these high-performance dampeners, ensuring a smoother, less jarring release every time (Source).

Improving Arrow Flight and Accuracy

Choosing a stabilizer with a dampener is essential for improving arrow flight and accuracy. These dampeners play an important role in vibration absorption and noise reduction, promoting a smoother release and better arrow trajectory. Enhanced flight stability and minimized hand strain are direct benefits, making them imperative for achieving precise shots and consistent performance.

Complementing Accessories

Ensuring balance when you’re equipping your bow with various accessories is critical, particularly when positioning the stabilizer to maximize performance. Consider the weight and size of these accessories to maintain harmony and achieve optimal stability during your shots.

Balancing the Bow With Other Accessories

Balancing your bow with other accessories is essential for effective performance. Consider:

- Stabilizer Compatibility: Verify that your stabilizer is compatible with your bow and existing accessories.

- Attachment Methods: Utilize secure, appropriate attachment points.

- Customization Options: Select adjustable weights and lengths to match your setup.

- Storage Solutions: Choose a design that facilitates convenient disassembly and storage without compromising visual aesthetics.

Positioning the Stabilizer for Optimal Performance

To position the stabilizer for superior performance, place it opposite other accessories to balance the bow efficiently. Verify the orientation maximizes stabilizer effectiveness by reducing torque and vibrations while considering wind resistance. This placement enhances your shooting accuracy and efficiency, making your bow setup cohesive and stable under varied conditions.

Considering the Weight and Size of Other Accessories

Balancing your bow is vital for ideal performance. Confirm that your stabilizer orientation complements other accessories. Place it wisely to counteract their weight. Consider the stabilizer’s thickness, length, and weight to sustain equilibrium. Using a stabilizer with a dampener can reduce vibrations, enhancing stability. Proper positioning and choosing the right stabilizer can substantially improve accuracy and comfort .

Selecting the Right Material

When choosing a bow stabilizer, prioritize materials that offer durability and strength, such as aluminum or carbon, to guarantee a long-lasting accessory. Consider vibration dampening properties to enhance your shooting experience and reduce noise.

Durability and Strength

When selecting a stabilizer, durability is key for long-term use. Opt for materials that withstand wear and tear while requiring minimal maintenance. Look for:

- Aluminum: Known for its strength and longevity.

- Carbon fiber: Lightweight yet highly durable.

- Rubber components: Adds resilience to survive frequent use.

Invest in a stabilizer that balances durability with performance.

Vibration Dampening Properties

Choosing the correct material for your stabilizer is vital for vibration reduction. Opt for dampening materials like carbon, rubber, and aluminum, which excel in shock absorption, helping to minimize hand and wrist strain. Here’s a quick comparison:

| Material | Vibration Reduction | Weight | Durability | Noise Reduction | Cost |

|---|---|---|---|---|---|

| Carbon | High | Light | High | Moderate | High |

| Rubber | Moderate | Moderate | Low | High | Low |

| Aluminum | Moderate | Heavy | High | Moderate | Medium |

Maintenance and Cleaning Considerations

Maintaining and cleaning your bow stabilizer secures excellent performance. Follow these steps:

- Storage Techniques: Store your stabilizer in a cool, dry place.

- Cleaning Methods: Wipe down with a damp cloth after each use.

- Maintenance Schedule: Inspect regularly for any wear or damage.

- Troubleshooting Issues: Check and tighten any loose weights or components.

Stay on top of these tasks to keep your equipment in great shape .

Consulting With Experts

Consult experienced archers to get personalized advice on the best stabilizer setups. Visit local archery shops to try different stabilizers and find the most suitable configuration for your needs .

Seeking Advice From Experienced Archers

To refine your choice, consult seasoned archers who can offer invaluable insights. Their experience with stabilizers for beginners, customizations, and maintenance can guide your decision. Consider these aspects:

| Factor | Expert Insight | Application |

|---|---|---|

| Customization | Tailor weights and length | Improved balance and accuracy |

| Maintenance | Tips on cleaning and upkeep | Longer lifespan for stabilizers |

| Accessories | Best complements for your bow | Enhanced overall performance |

| Budget Considerations | Quality vs. cost balance | Wise investment in effective equipment |

Visiting Archery Shops for Personalized Recommendations

When looking for personalized recommendations, visiting archery shops is invaluable. Experts can guide you on:

- Popular stabilizer brands and their features

- Stabilizer price range and what suits your budget

- Various stabilizer color options to match your gear

You can also inquire about warranty information and read customer reviews for informed decisions.

Experimenting With Different Stabilizer Setups

Experimenting with various stabilizer configurations allows you to refine your bow for peak performance. Test different combinations of stabilizer mass, length, and dampening materials to discover what’s most effective. Adjustable designs provide adaptability in different shooting environments. Balancing accessories can greatly enhance stability and precision.

| Try This | Not That | Notes |

|---|---|---|

| Light Weight | Heavy Weight | For enhanced control |

| Short Length | Long Length | Improves agility |

| Dampening Materials | No Dampeners | Reduces vibrations |

| Adjustable Designs | Fixed Designs | Offers flexibility |

| Balanced Setup | Unbalanced | Ensures precision |

Frequently Asked Questions (FAQs)

How to know which stabilizer to use?

To choose the right stabilizer, consider your bow’s weight, shooting environment, and accessories. Opt for a length and weight that enhance stability, and prefer materials like carbon for vibration dampening, aiming for balance and performance.

How to pick a stabilizer?

Choosing a stabilizer is like finding the perfect dance partner, ensuring balance, and elegance. Consider length, weight, material, and orientation. Opt for lightweight adjustable models with vibration dampeners if you aim for unmatched shooting performance and balance .

What stabilizer do I need?

Choose a stabilizer based on your bow’s balance needs. Consider one with adjustable weights, a dampener for vibration absorption, and appropriate length and weight for stability. Make sure it complements your other accessories for best performance.

Is a 12 inch stabilizer too long for hunting?

A 12-inch stabilizer isn’t too long for hunting if it suits your needs. It offers improved stability and vibration dampening. Consider your bow’s balance, the shooting environment, and personal preference when selecting stabilizer length .

How do stabilizers impact shooting in windy conditions?

In windy conditions, stabilizers improve shooting accuracy by reducing bow torque and dampening vibrations. Opt for a stabilizer with suitable thickness to balance wind resistance and guarantee steadier aims, enhancing overall performance .

What role does stabilizer weight play in bow balance?

Did you know properly adjusting your stabilizer’s weight can enhance bow balance by 15%? Heavier stabilizers provide more stability and dampen vibrations, essential for consistent shots and improved performance .

Are dampeners necessary for beginner archers?

Dampeners aren’t strictly necessary for beginners but they help reduce vibrations and improve comfort, preserving your hand and wrist health. For beginner archers, they enhance shooting experience and can aid in developing better form .

How do adjustable features enhance stabilizer performance?

You’ll hit the bull’s-eye when adjusting stabilizer weights – heavier provides rock-solid stability while lighter offers laser-focused agility. Tinker until you lock in your personal sweet spot for unshakable consistency.

What are the benefits of sidebar stabilizers for hunting?

Sidebar stabilizers reduce lateral bow movement, helping you remain steadier during hunting. They counteract torque, so you’ll have consistent, more precise shots when that trophy buck appears.

Conclusion

Ultimately, choosing the right stabilizer is a journey of self-discovery – one where you navigate factors like length, weight, and material to find your archery sweet spot.

With an open mind and willingness to experiment, you’ll open up a world of possibilities, honing your technique and unlocking newfound accuracy.

Let this thorough guide be your compass, steering you toward the stabilizer that optimizes your bow’s performance and propels your archery skills to new heights.