This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You pick up your sewing machine’s instruction manual and spot a button labeled “embroidery mode.” Your machine doesn’t transform into an embroidery powerhouse by flipping a switch. The difference between sewing machines and embroidery machines runs deeper than a feature toggle.

Sewing machines drive fabric through feed dogs to construct seams and hems. Embroidery machines lock fabric in hoops and trace computerized patterns with pinpoint precision. One builds garments from raw material. The other decorates finished pieces with logos and monograms.

Understanding which machine matches your project goals prevents you from wrestling with equipment that can’t deliver the results you need.

Table Of Contents

Key Takeaways

- Sewing machines construct garments through feed dogs that move fabric to create seams and hems, while embroidery machines lock fabric in hoops and trace computerized patterns for decorative stitching.

- Sewing machines offer 30-100 utility stitches for garment construction, whereas embroidery machines provide 100-10,000+ built-in designs with automated tension control and pattern editing capabilities.

- Combination sewing-embroidery machines deliver dual functionality in one unit, letting you switch between construction work and decorative projects without buying separate equipment.

- Your project goals determine which machine you need—construction tasks demand a sewing machine’s fabric handling strength, while logo placement and monogramming require an embroidery machine’s precision pattern work.

Core Functions of Sewing Vs Embroidery Machines

Understanding what each machine actually does is the first step in making the right choice. Sewing machines and embroidery machines serve different purposes, and knowing these differences helps you match the tool to your projects.

If you’re leaning toward decorative work, browsing embroidery machines for sale can show you the range of multi-needle options and design capabilities available today.

Let’s break down how these machines function and where each one excels.

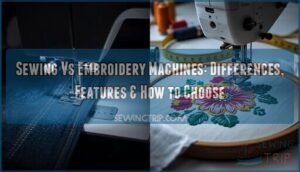

Purpose and Applications

The heart of the sewing vs embroidery comparison lies in function. Sewing machines construct garments and utility items by joining fabric pieces—think hemming trousers or assembling cushion covers. Embroidery machines focus on decorative stitching, adding monograms and logos to finished pieces. Crafting projects differ: sewing builds structure, while embroidery elevates textile art through visual embellishment.

| Machine Type | Primary Use | Typical Output |

|---|---|---|

| Sewing Machines | Fabric construction and repairs | Seams, hems, closures |

| Embroidery Machines | Decorative embellishment | Monograms, logos, patterns |

| Combination Units | Both construction and decoration | Complete garments with custom designs |

Stitch Types and Capabilities

Understanding what each machine actually stitches separates function from form. Sewing machines deliver basic utility stitches—straight seams, zigzags, and blind hems—with some models offering 50 to 100 stitch options for creative flexibility. Embroidery machines run specialized embroidery modes with hundreds or thousands of built-in designs stored digitally.

Thread control differs too: sewing relies on feed dogs, while embroidery techniques use hoop-guided vector paths. Design editing capabilities let you resize patterns before stitching begins.

| Feature | Sewing Machines | Embroidery Machines |

|---|---|---|

| Stitch Variety | 10-100 utility and decorative stitches | 100-10,000+ embroidery designs |

| Primary Technique | Feed dog driven straight and zigzag stitching | Hoop-guided decorative embroidery techniques |

| Thread Control | Manual tension adjustment for fabric compatibility | Automated tension for dense pattern work |

| Design Editing | Limited pattern adjustment | Resize, rotate, combine designs on screen |

| Fabric Compatibility | Wide range with proper needle selection | Requires stabilizers for embroidery machine features |

Construction Vs Decorative Focus

Your machine’s job shapes its DNA. Construction-oriented sewing machines tackle garment construction with sturdy feed dogs, high presser foot lift, and needles rated for denim or canvas. They prioritize fabric handling and stitch precision through reinforced seams.

Machine durability matters most when building; embroidery techniques shine when personalizing. Embroidery machines chase visual flair using decorative stitching, hoop compatibility, and rapid pattern selection.

| Focus | Construction Machines | Decorative Machines |

|---|---|---|

| Primary Goal | Durable seams and garment construction | Visual appeal through embroidery techniques |

| Key Strength | Fabric handling with heavy materials | Decorative stitching and pattern customization |

| Build Priority | Machine durability and sewing efficiency | Thread trimming and stabilizer support |

Key Features Compared

You can’t pick the right machine without understanding what separates these two tools in practical terms.

Knowing the domestic sewing machine price range for each type makes it easier to find one that fits both your projects and your wallet.

The differences show up in how many stitches you get, how much workspace you have, and what kind of technology runs the show. Let’s break down the key features that matter most when you’re comparing options.

Stitch Options and Patterns

Stitch variety separates these machines at the most fundamental level. Sewing models deliver 30 to 100 utility stitches for garment construction and repairs.

Embroidery machines offer 100 to 200 built-in embroidery designs and decorative stitching options. Pattern scaling adjusts designs to fit your project. Density control prevents puckering on embroidery patterns and designs.

Thread options expand through USB imports on computerized embroidery centers.

Hoop and Workspace Differences

Embroidery hoop size dictates your workspace layout from the start. Machines accept hoops ranging from 4 by 4 inches to 8 by 12 inches, demanding flat clearance requirements around the embroidery machine.

Embroidery arms extend outward and add vertical space needs. Your stabilizer and hooping process require unobstructed access. Fabric tension stays consistent only when the embroidery hoop sits level on a stable surface during operation.

Built-in Technology and Controls

Microprocessor controls separate modern computerized sewing and computerized embroidery machines from mechanical models. Touch screen interfaces let you select patterns and adjust speed control with a tap.

Automatic tension systems respond in real time during operation. Stitch editors allow mirroring and resizing designs on the machine itself.

Wireless connectivity brings firmware updates and pattern downloads directly to your workspace. Sewing technology advances put precision at your fingertips.

Machine Types and Variations

Both sewing machines and embroidery machines come in several configurations that affect how you’ll use them.

Manual models operate without power, while electronic versions offer increasing levels of automation and control.

Understanding these variations helps you match machine capability to your actual workbench needs.

Manual, Electronic, and Computerized Models

You’ll find three main sewing machine types, each with distinct machine controls and capabilities.

Manual models rely on hand cranks for sewing speed, while electronic sewing machines use motorized thread management and push-button stitch selection.

Computerized sewing offers the most sophisticated sewing technology advances, with touchscreen interfaces, USB connectivity, and precise stitch precision across hundreds of patterns. Model comparison reveals clear tradeoffs between simplicity and automation.

Domestic Vs Industrial Machines

Domestic sewing machines target home users with portable designs under 25 kilograms, moderate motor power, and adaptable stitch options for garments and hobby projects. Industrial sewing machines deliver higher speed control, heavy-duty fabric handling, and exceptional durability tests for continuous textile production.

Machine size differences shape your workspace needs:

- Domestic sewing uses flat bed areas suitable for everyday garments

- Industrial sewing requires larger working beds for bulky materials

- Sewing machine types vary by torque and gearing strength

- Industrial sewing machines feature servo motors for heavy fabrics

Combination Sewing-Embroidery Machines

Combo machines blend sewing and embroidery functions into one unit, letting you tackle both everyday repairs and decorative projects without swapping equipment. Hybrid models switch modes via control panels, activating embroidery hoops or standard presser feet as needed.

| Feature | Sewing Mode | Embroidery Mode |

|---|---|---|

| Stitch speed | Moderate to fast | High stitches per minute |

| Workspace | Flat bed for garments | Hoop track with clearance |

| Thread tension | Manual or auto adjust | Automatic per design |

| Needle type | Universal or ballpoint | Sharp embroidery needles |

| Primary use | Construction and mending | Decorative fill patterns |

Multi tasking capability makes these sew embroidery combo units ideal for hobbyists who want dual functionality. You save space and gain machine integration for projects that mix utility stitches with machine embroidery details. For a wide range of options, consider reviewing the available combo sewing and embroidery machines.

Ease of Use and Learning Curve

Getting started with either machine type requires different skill sets and patience levels.

Sewing machines generally offer a more straightforward path for beginners, while embroidery machines demand more technical understanding upfront. Here’s what you need to know about the learning process for each.

Setup and Operation Differences

Sewing machines feed fabric through while you guide it, but embroidery machines lock fabric in a hoop and move it automatically. The contrast shapes your entire workflow.

Sewing machines let you guide fabric through feed dogs, while embroidery machines lock fabric in hoops and move it automatically

Key operational differences include:

- Fabric stabilization: Embroidery requires stabilizer placement and hoop alignment before starting, while sewing relies on feed dogs.

- Thread tension: Embroidery demands precise adjustments for satin and fill stitches to prevent puckering.

- Design loading: Machine embroidery needs digitized files transferred via USB for stitch optimization.

Beginner Friendliness

Understanding user interface simplicity matters when choosing your first machine. Sewing machines offer straightforward controls and minimal setup, making sewing techniques accessible for crafting for beginners.

Embroidery machines demand pattern selection and hoop positioning, adding complexity. Look for automatic thread management, noise reduction features, and built-in learning resources.

Combination sewing and embroidery models give you flexibility, but machine portability and operation ease should guide your decision.

Typical Starter Projects

Once you’ve chosen your machine, you’ll want to test it on real projects. Beginner projects for a sewing machine include pillowcases, tote bags, and simple aprons—all use straight seams and woven fabric choices.

Embroidery designs work best on flat items like tea towels, baby bibs, or key fobs that fit a 4×4 hoop. These sewing basics and crafting tips build confidence with both sewing techniques and embroidery.

Beginners can find inspiration and guidance by exploring simple sewing projects for beginners.

Maintenance and Care Considerations

Your machine won’t run itself into the ground if you give it the proper attention it needs.

Sewing machines and embroidery machines have different maintenance demands based on how they operate and what they’re built to do. Here’s what you need to know to keep your equipment in working order for years.

Cleaning and Oiling Requirements

Consistent machine maintenance keeps both sewing and embroidery machines running smoothly. Regular cleaning after each project removes lint and dust from the bobbin area and feed dogs, preventing tension problems.

Machine lubrication requires only a few drops of specialized sewing machine oil at indicated points monthly. Wipe excess oil to avoid fabric staining. Use a soft brush for dust prevention and schedule professional servicing annually for peak performance.

Needle and Thread Compatibility

Match your needle sizes to thread weight for smooth stitching. Medium threads around Tex 45 pair with 80/12 to 90/14 needles on most machines. Fine 60 weight thread needs smaller 60/8 to 80/12 needles.

Embroidery threads require specialized needles with larger eyes to prevent fraying at high speeds. Most home machines handle up to size 69 thread before tension systems struggle.

Storage and Longevity Tips

Protect your investment with proper storage and electrical safety practices. Climate control matters—keep machines between 60 and 80 degrees to prevent warped housings and rust.

- Use protective covers or hard cases to shield from dust and impacts during storage

- Run surge protectors to guard computerized embroidery machine components from voltage spikes

- Oil moving parts lightly before long-term storage solutions to prevent corrosion

Replace surge protectors every three to five years for reliable machine maintenance and care.

Choosing The Right Machine for You

Your decision between a sewing machine and an embroidery machine comes down to three critical factors. Each element shapes not just what you buy, but how well that machine supports you over time.

Consider your project scope, your financial boundaries, and the learning support you’ll need along the way.

Project Goals and Crafting Needs

Your goals drive every choice. Project Planning starts with fabric selection—will you construct garments on a sewing machine or add decorative flair with machine embroidery?

List required crafting tools, assess your skill level, and determine if you need design software. A sewing and embroidery combo suits diverse needs, while a dedicated sewing machine buying guide clarifies single-purpose options.

Budget and Cost Factors

Initial Costs separate basic sewing machines—usually $100 to $300—from home embroidery models that range $150 to $800.

Budget Planning must account for Ongoing Expenses like stabilizers and specialty thread, which embroidery consumes faster.

A Sewing and Embroidery combo balances versatility against price, while Price Comparison reveals that dedicated units deliver focused performance.

Accurate Machine Comparison protects against overspending on unused features.

User Experience and Support Availability

Customer Support determines whether your Sewing Machine becomes a trusted tool or a garage ornament. Technical Assistance and Warranty Options vary widely across brands like Singer Official Support and Janome Official.

- User Guides and Online Tutorials help you master Sewing and Embroidery Techniques faster than trial-and-error alone.

- Warranty coverage usually spans 1 to 5 years for manufacturing defects.

- Machine Maintenance and Care resources include live chat, phone support, and authorized service centers.

Frequently Asked Questions (FAQs)

Are embroidery machines the same as sewing machines?

Embroidery machines and sewing machines look similar, yet they’re built for completely different tasks.

Your sewing machine joins fabric pieces together, while embroidery machines stitch decorative designs on top of material.

Can I put embroidery thread in my sewing machine?

Yes, you can run embroidery thread through your sewing machine for decorative stitching, but use a size 75/11 embroidery needle.

Lower tension settings slightly, and avoid high-stress construction seams where thread strength matters.

Is there a sewing machine that also embroiders?

Many brands offer combination machines that handle both tasks.

Brother SE600 and SE2000 are dual function models with attachable embroidery units, letting you switch from garment construction to decorative stitching on one machine.

Can embroidery machines sew regular seams effectively?

Most embroidery machines can produce basic straight seams, but they struggle with stitch accuracy and fabric limits due to hoop constraints.

For reliable garment construction, you’ll get better seam quality using a dedicated sewing machine.

Which machine type is better for quilting?

Although machine embroidery adds decorative touches to quilt tops, sewing machines handle quilting speed, fabric thickness, and quilt size better.

Their consistent stitch density and machine portability make garment construction and piecing layers more efficient than embroidery machine weaving.

Do embroidery machines work with heavy fabrics?

You can embroider heavy fabrics with proper stabilizer types and needle selection. Use thick needles, sturdy backing, and adjust embroidery settings for fabric thickness to prevent puckering across dense material.

How much space does each machine require?

Think of your workspace like a parking spot: sewing machines fit in compact spaces around 14-18 inches wide, while embroidery machines demand garage-sized clearance at 18-24 inches to accommodate hoops and movement.

Are replacement parts expensive for both machines?

Replacement parts vary widely by machine type and build quality. Sewing machine components usually cost 5 to 180 dollars, while embroidery machine parts range from 50 to 250 dollars.

With industrial sewing machines demanding the highest replacement fees, the cost can significantly vary based on the specific needs of each machine.

Conclusion

Which machine moves your projects forward? The difference between sewing machines and embroidery machines determines whether you construct garments or add decorative details.

Sewing machines build seams and hems through feed dogs. Embroidery machines lock hoops and trace computerized designs.

Match your equipment to your primary goal. Construction work demands a sewing machine. Logo placement and monogramming require embroidery capability. Your project list reveals which machine belongs in your workspace.