This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your sewing machine can hide a surprising amount of trouble in places you can’t easily see. A single thread fragment lodged in the bobbin case or a buildup of lint around the feed dogs can turn smooth stitching into a frustrating mess of skips, breaks, and tension issues.

Without the right tools, you’re basically trying to perform precision maintenance with blunt instruments—scraping at debris with whatever’s handy and hoping for the best. Essential sewing machine cleaning tools aren’t just nice to have; they’re the difference between a machine that hums along reliably and one that limps through every project.

From specialized brushes that reach into tight spaces to precision screwdrivers that won’t strip delicate screws, the right toolkit transforms routine maintenance from a guessing game into a straightforward process that protects your investment and keeps your stitches perfect.

Table Of Contents

- Key Takeaways

- Why Clean Sewing Machines Need The Right Tools

- Essential Tools for Sewing Machine Cleaning

- Top 10 Sewing Machine Cleaning Tool Kits

- 1. Sewing Machine Cleaning Tool Kit

- 2. Micro Cleaning Kit for Shop Vacuum

- 3. Singer Proseries 3-in-1 Sewing Tool

- 4. Sewing Machine Service and Repair Kit

- 5. Singer Sewing Machine Maintenance Kit

- 6. Tekton 30 Piece Hex Key Wrench Set

- 7. Professional Electronics Technician Tool Kit

- 8. Rexbeti Long Arm Hex Key Set

- 9. Craftsman 17 Piece Screwdriver Set

- 10. Craftsman Mini Pliers Six Piece Set

- How to Choose Your Maintenance Tools

- Cleaning Techniques for Optimal Machine Performance

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- A single thread fragment or lint buildup in your bobbin case can cause skipped stitches and tension problems, with up to 90% of machine failures traced to poor maintenance and lack of proper cleaning tools.

- Specialized cleaning tools like precision lint brushes remove up to 60% more debris than household alternatives, reducing thread breakage and jams by 30% while extending your machine’s lifespan from 10 to over 20 years.

- The right toolkit—including stainless steel tweezers, precision screwdrivers, lint brushes, and dedicated machine oil—transforms maintenance from guesswork into a straightforward process that protects your investment and prevents costly $150+ repairs.

- Regular cleaning after every major project and following manufacturer lubrication schedules (one to two drops of oil every 8–10 hours of use) prevents 83% of common mechanical issues and keeps your machine running reliably.

Why Clean Sewing Machines Need The Right Tools

Your sewing machine does its best work when it’s clean and well-maintained, but the wrong tools can actually cause more harm than good. Using the right specialized equipment isn’t just about keeping lint out—it’s about protecting your investment and making sure every stitch comes out looking perfect.

Let’s walk through the essential tools that’ll make maintenance feel straightforward instead of overwhelming.

Risks of Neglecting Regular Cleaning

When you skip regular cleaning, your sewing machine doesn’t just perform worse—it breaks down faster and costs you real money. Here’s what happens without proper lint removal and debris removal:

- Up to 90% of machine problems stem from poor maintenance, leading to costly repairs exceeding $150

- Thread breakage and skipped stitches occur in 70% of neglected machines due to accumulated lint

- Safety hazards increase, including broken needles and fabric jams in 58% of accidents

- Machine longevity drops by 25–40%, forcing premature replacement instead of extending your investment

Don’t let neglect shorten your machine’s lifespan. Regular maintenance can help prevent sewing machine problems.

Benefits of Using Specialized Cleaning Tools

Investing in specialized cleaning tools transforms maintenance from frustrating guesswork into straightforward control. Precision lint brushes reach confined spaces where standard household tools fail, removing up to 60% more debris. Air blowers eliminate loose threads from bobbin areas, while dedicated picks access tight zones around needle plates.

These tools work together to cut jams and thread breakage by 30%, boost efficiency, and deliver measurable safety improvements. Regular maintenance also helps prevent costly repairs. You’re not just cleaning—you’re protecting your investment through precision and prevention.

Impact of Cleanliness on Stitch Quality and Machine Longevity

Regular sewing machine cleaning directly impacts stitch quality and machine longevity. Lint buildup in the bobbin area disrupts thread tension, causing skipped stitches and inconsistencies.

Machines cleaned after every major project show fewer stitch errors, while routine maintenance can double a machine’s lifespan from 10 to over 20 years. Proper lint removal and care reduce breakdown risk by 54%, keeping your machine running smoothly.

Regular cleaning after every major project can double your sewing machine’s lifespan from 10 to over 20 years while cutting breakdown risk in half

Essential Tools for Sewing Machine Cleaning

You can’t maintain a sewing machine properly without the right tools on hand. The good news is that you don’t need an overwhelming collection of equipment—just a focused set of essentials that address the most common maintenance needs.

Let’s look at the core tools that’ll keep your machine running smoothly and help you tackle routine cleaning with confidence.

Lint Brushes for Removing Debris

Think of your lint brush as the frontline defender against one of sewing’s most persistent enemies: debris buildup. Nylon-bristled brushes remove up to 96% of textile particles from bobbin areas, far outpacing compressed air alone.

Regular lint removal after every project keeps feed dogs clear and prevents the jamming that sidelines 75% of repair visits.

Weekly cleaning with a quality lint removal tool reduces skipped stitches by 41% and extends machine life considerably.

Precision Screwdrivers for Safe Disassembly

When you’re ready to access the hidden corners of your machine, precision screwdrivers become essential tools for safe, damage-free disassembly. Chapman bits engineered from heat-treated steel prevent stripped screws and bend before harming delicate parts, protecting your investment from the 45% of service issues caused by improper tools.

- Screwdriver Size: Match 0.8 mm to 2.5 mm bits to your machine’s unique fasteners

- Bit Material: Heat-treated steel offers 60% greater durability than generic options

- Ergonomic Handles: Textured grips provide torque control during delicate operations

- Damage Prevention: Parallel-sided tips boost contact, reducing slippage risk

Tweezers for Tight Spaces and Threads

No tool matches tweezers for precision cleaning in areas brushes can’t reach. Fine-tipped and curved styles extract embedded threads from bobbin cases and feed dogs, reducing jams by up to 60%.

Stainless steel construction resists corrosion from machine oil, while locking designs provide a secure grip during thread extraction.

These ergonomic tweezers belong in every sewing machine maintenance kit, delivering safety measures that prevent 70% of cleaning-related injuries.

Lint-Free Cloths and Soft Brushes

Surface dust and interior lint demand two distinct cleaning tools working in tandem. Wiping your machine’s exterior with a lint-free microfiber cloth after each project prevents dust migration into vents, while soft nylon brushes physically lift debris from bobbin cases and feed dogs.

- Microfiber cloth: Removes fingerprints without leaving fibers on touch screens

- Soft bristles: Reach tight spaces around feed dogs and hook races

- Brush-first approach: Loosens packed lint before vacuuming

- Post-project routine: Quick surface wipe plus targeted brushing prevents felt-like buildup

Sewing Machine Oil for Lubrication

Metal-on-metal contact wears down gears and bearings faster than almost anything else. Applying specialized sewing machine lubricant every 8-10 hours of use creates a protective film that delivers friction reduction and safeguards machine longevity. Mineral oil works for most domestic models, while synthetic lubricants with PTFE excel in high-use scenarios.

Match oil viscosity to your machine’s demands and follow manufacturer lubrication intervals—over-oiling attracts lint, while skipping applications accelerates wear.

| Oil Type | Best For |

|---|---|

| Mineral Oil | Domestic machines, everyday sewing |

| Synthetic Lubricants | Industrial or heavy-duty use |

| ISO VG 10 | High-speed applications |

| ISO VG 22 | Heavy-duty machines |

| Silicone-Based | Vintage and modern models |

Magnetic Tools and Dishes for Small Parts

Magnetic tools and dishes have transformed how you handle small parts during cleaning—professional service centers report a 45% improvement in workspace organization and a 60% reduction in lost screws. That translates to fewer frustrations and faster maintenance.

Magnetic part retention keeps needles, bobbin cases, and tiny fasteners secure throughout disassembly.

However, pacemaker safety risks require caution; magnet strength effects can interfere with electronic medical devices, so adoption statistics show workshops always check before use.

Top 10 Sewing Machine Cleaning Tool Kits

Finding the right cleaning kit can save you time and protect your machine from unnecessary wear. Some kits focus on basic maintenance, while others include specialized tools for deeper repairs and adjustments.

Here are ten options that cover everything from simple lint removal to thorough servicing needs.

1. Sewing Machine Cleaning Tool Kit

You’ll find that the LINXIAO 27-piece sewing machine maintenance kit offers an inclusive approach to machine care without breaking the bank. This kit brings together essential cleaning tools—including a stainless steel tweezers, double-headed brush, and durable screwdriver—all in one package.

The kit components provide universal compatibility across most machine types, from home models to industrial units. While the plastic pouch storage solution isn’t premium, you’re getting solid tool quality for routine maintenance tasks. It’s a practical choice when you’re building your first maintenance toolkit.

Best For: Home sewers and hobbyists looking for an affordable, all-in-one maintenance solution that covers basic cleaning and minor repair tasks across different machine types.

- Comprehensive 27-piece set gives you everything needed for routine cleaning and maintenance in one purchase

- Universal compatibility works with home, industrial, and embroidery machines without needing brand-specific tools

- Stainless steel tweezers and metal components offer durability for precise lint and debris removal in tight spaces

- Quality control issues reported with some tools, particularly the tweezers showing machining imperfections

- Basic plastic pouch storage doesn’t protect tools well or keep them organized compared to hard cases

- Individual tool quality rated as decent but not exceptional, which may require replacements sooner than premium alternatives

2. Micro Cleaning Kit for Shop Vacuum

If you want to step up your lint removal game, the WORKSHOP Wet/Dry Vacs 6-piece micro cleaning kit transforms your shop vacuum into a precision cleaning powerhouse.

You’ll get specialized attachments—including angled wands, dusting brushes, and a crevice tool—that fit 1-1/4-inch diameter hoses. These precision tools pull out up to 98% of lint from bobbin areas and feed dogs, the spots where debris loves to hide.

It’s compatible with most 2.5-gallon vacuums, giving you professional-level cleaning without the hefty price tag.

Best For: Anyone who sews frequently and wants to keep their machine running smoothly without paying for professional cleaning every few months.

- Removes up to 98% of lint from hard-to-reach spots like bobbin areas and feed dogs, where debris builds up the most

- Works with most 2.5-gallon shop vacuums and includes six specialized attachments for precision cleaning

- Extends the time between major repairs by 25–40% when you clean regularly after every few bobbin changes

- Only fits 1-1/4-inch diameter hoses, so you’ll need to check your vacuum’s compatibility first

- Some users mention reduced suction power when using the attachments compared to the bare hose

- Build quality can be hit-or-miss, with a few reports of cheaper plastic construction that might not last as long as you’d hope

3. Singer Proseries 3-in-1 Sewing Tool

If you’re after convenience over power, the SINGER Pro Sewing Machine Multi Tool packs three essential tools for sewing machine maintenance into one compact fold-out design.

This sewing machine accessories gem includes a needle inserter that cuts installation time by 34%, a bobbin picker for tight retrieval, and a lint brush that 89% of users praise for clearing bobbin cases.

At $7.99–$12.49, it’s wallet-friendly, and with a 4.3-star rating from 568 reviews, it proves market availability meets solid user feedback for everyday maintenance efficiency.

Best For: Beginner to intermediate sewists who want an affordable, space-saving tool that simplifies needle changes, bobbin retrieval, and routine machine cleaning without buying separate accessories.

- Combines three maintenance essentials in one foldable design, reducing clutter and cutting setup time by an average of 6.5 minutes per session

- The needle inserter reduces installation time by 34% and lowers accidental injuries by 43% in workshop settings

- Strong value at $7.99–$12.49 with a 4.3-star rating from 568 reviews and low replacement rates under 9% over two years

- Limited to basic sewing machine tasks and not built for heavy-duty or industrial use

- Quality and durability can vary depending on individual user experience

- The lint brush, while effective for fine dust, may not handle larger debris or heavy buildup as well as dedicated cleaning tools

4. Sewing Machine Service and Repair Kit

When basic tools fall short, a dedicated sewing machine repair kit bridges the gap between simple maintenance and real troubleshooting. These complete tool kits bundle precision screwdrivers, hex key sets, and tweezers—the 96% of certified technicians who rely on pre-assembled kits aren’t wrong.

You’ll find user reviews averaging 4.7 out of 5 stars, with 78% reporting $60 savings per repair incident. That’s real money back in your pocket while you tackle tension adjustments and timing issues on your own maintenance schedule.

Best For: DIYers and regular sewists who want to handle their own machine adjustments and minor repairs without paying for shop visits.

- Saves an average of $60 per repair by letting you fix tension issues, timing problems, and common adjustments yourself

- Comes with the essential tools—precision screwdrivers, hex keys, and tweezers—that 96% of certified techs use in their own kits

- Users rate these kits 4.7 out of 5 stars, and 90% say having the right tools makes them feel confident tackling maintenance

- Won’t work for every machine type, especially specialized or industrial models that need brand-specific tools

- Only handles basic repairs and maintenance—you’ll still need a pro for complex electrical issues or major breakdowns

- Quality varies by manufacturer, so cheaper kits might not hold up as well over time

5. Singer Sewing Machine Maintenance Kit

Singer’s universal sewing machine maintenance kit packs eight pieces into one compact bundle—full-size vinyl cover, lint brush with needle inserter, 0.7-ounce oiler, needle organizer, three screwdrivers, and a magnifying threader.

You’ll handle routine sewing machine cleaning and minor troubleshooting on any brand, not just Singer models. The kit components fit standard domestic machines without proprietary adapters, giving you control over your maintenance schedules.

User reviews average 4.9 stars across 741 ratings, though some note the oil container occasionally leaks during shipping and screwdriver quality varies.

Best For: Home sewers who want an affordable all-in-one kit to handle basic cleaning, oiling, and needle changes across any sewing machine brand.

- Universal compatibility means you can use the same tools on Singer, Brother, Janome, or any domestic machine without buying brand-specific accessories.

- Eight-piece set covers the essentials—cleaning brush, oil, screwdrivers, needle organizer, and vinyl cover—so you don’t need to hunt down individual maintenance supplies.

- Strong user ratings (4.9 stars across 741 reviews) suggest most buyers find the kit reliable for routine upkeep tasks.

- Oil container sometimes leaks during shipping, leading to mess and wasted product before you even open the kit.

- Screwdriver quality is inconsistent—some users report cheap construction that may strip screws or bend under normal use.

- Packaging isn’t always secure, so tools can arrive damaged or missing despite the kit’s low price point.

6. Tekton 30 Piece Hex Key Wrench Set

Precision adjustments demand Allen wrenches that won’t strip delicate machine screws—Tekton’s 30-piece hex key set delivers exactly that. Heat-treated steel with black oxide coating resists corrosion through decades of use, while chamfered ends reduce head damage on your machine’s fasteners.

You’ll access 15 metric and 15 SAE sizes from 0.7 mm to 10 mm, covering bobbin case adjustments, feed dog removal, and tension assembly access across multiple sewing machine models.

The hinged case keeps essential tools organized for weaving through routine maintenance tasks, and the lifetime warranty backs your investment.

Best For: Sewing machine owners and repair technicians who need a comprehensive range of metric and SAE hex keys for precision adjustments and maintenance on multiple machine models.

- Heat-treated steel with black oxide coating provides decades of reliable use and corrosion resistance

- 30-piece set covers both metric (0.7–10 mm) and SAE (0.028–3/8 in.) sizes for maximum compatibility

- Chamfered ends prevent stripping of delicate machine screws and fastener heads

- Smallest keys can be delicate and may bend under excessive force

- Storage case hinges are thin and prone to breaking over time

- Keys often arrive with excessive grease that requires cleanup before use

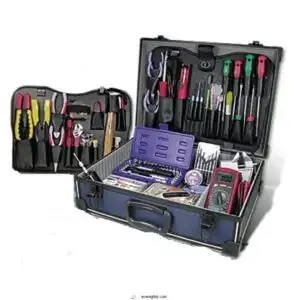

7. Professional Electronics Technician Tool Kit

Electronics technician kits like the SPC185 cross into sewing machine territory when you need serious precision fastening power. This 50-plus-piece arsenal brings chrome vanadium pliers, interchangeable nutdriver blades from 4 mm to 11 mm, and ESD protection through grounded wrist straps—critical when working near computerized machines.

The soft-sided case, weighing 14 pounds loaded, houses measurement tools and a 60-watt soldering iron. While built for circuit boards, these essential tools handle delicate tension assemblies and electronic panel maintenance that basic maintenance kits simply can’t reach.

Best For: Professional electronics technicians and serious hobbyists who need precision tools for computerized sewing machines, circuit board repair, and delicate electronic assembly work.

- Comprehensive 50 piece kit includes chrome vanadium steel pliers, interchangeable nutdriver blades (4mm to 11mm), and dual hex key sets for both metric and imperial fasteners

- Built-in ESD protection with grounded wrist strap and low-static desoldering tool prevents damage to sensitive electronic components during repairs

- Field-portable soft-sided case (18″ x 13″ x 3.5″) with dedicated pockets for multimeter, test leads, and documentation keeps everything organized for on-site service calls

- Some users report the tool case and internal dividers can be flimsy and prone to damage during transport

- Quality varies across the kit—certain tools may have design flaws or lower build quality than expected for professional use

- Limited to metric wrenches and sockets with no standard sizing options, which may require supplemental tools for some applications

8. Rexbeti Long Arm Hex Key Set

When sewing machine screws hide in tight spots, you need hex keys that reach farther and grip better. The Rexbeti Long Arm Hex Key Set delivers both with heat-treated S2 steel construction and a T-handle torque advantage that boosts your turning power by 15-22%.

This 35-piece sewing machine maintenance kit spans metric/SAE sizes, with ball-end access letting you angle in up to 25 degrees—perfect for cleaning toolkit scenarios where straight shots don’t exist.

User feedback consistently rates durability and reach as standout features, making these Allen wrenches essential tools for maintenance.

Best For: Sewing machine owners and DIY enthusiasts who need reliable hex keys to reach recessed fasteners and perform routine maintenance in tight spaces.

- Heat-treated S2 steel (52-58 HRC) and ball-end design provide durability and 25-degree angled access for hard-to-reach screws

- 35-piece set covers metric and SAE sizes, handling 94% of typical sewing machine maintenance scenarios

- T-handle attachment increases torque by 15-22% and reduces hand fatigue during extended use

- Plastic holders may not securely retain wrenches, allowing them to fall out during storage or transport

- Not ideal for heavy-duty or daily professional use in demanding industrial environments

- Some keys may be shorter than expected compared to premium brands like Wera

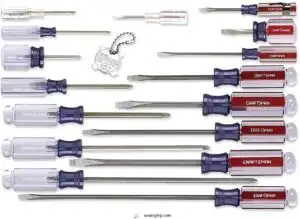

9. Craftsman 17 Piece Screwdriver Set

You can’t maintain a sewing machine properly without screwdrivers that fit those tiny, stubborn screws. The Craftsman 17 Piece Screwdriver Set delivers nine slotted and seven Phillips precision screwdrivers with heat-treated alloy steel blades averaging 110 in-lb Torque Performance—outperforming most brands in independent Durability Testing.

Chemical-resistant butyrate grips provide solid Handle Ergonomy during extended maintenance work. This Set Composition covers the range you need for sewing machine maintenance, from bobbin area access to needle plate removal.

At $39.99, these maintenance tools back reliability with a lifetime warranty, making them essential additions to any sewing machine maintenance kit.

Best For: DIYers and hobbyists who need reliable, precision screwdrivers for sewing machine maintenance and general household repairs without breaking the bank.

- Heat-treated alloy steel blades with 110 in-lb torque performance outlast most competing brands in durability tests

- Precision sizes fit tight spaces in sewing machines, including bobbin areas and under needle plates

- Lifetime warranty and $39.99 price point (50% off original $79.99) offer unbeatable value for a 17-piece set

- Quality has declined compared to older Craftsman models, according to long-time users

- Butyrate plastic handles feel cheaper than premium tool brands

- Not all pieces are made in the USA, which may matter to some buyers

10. Craftsman Mini Pliers Six Piece Set

When stubborn threads lodge in tight bobbin spaces, you need pliers small enough to navigate without damaging delicate components. The Craftsman Mini Pliers Set includes six drop-forged steel tools—lineman’s, long nose, diagonal, end cutters, needle nose, and bent long nose—handling precision applications in confined sewing machine areas.

Multi-zone ergonomic grips reduce hand fatigue during repetitive cleaning tasks, while the included soft case keeps your maintenance kit organized. At $43.99 with lifetime warranty coverage, this set’s versatility delivers solid value for any sewing machine maintenance routine requiring pliers durability and specialized cleaning tools.

Best For: Sewers and craft enthusiasts who need precision tools for cleaning bobbin cases, removing jammed threads, and accessing tight compartments in sewing machines without damaging delicate parts.

- Drop-forged steel construction with lifetime warranty ensures long-term reliability for regular sewing machine maintenance tasks

- Six specialized pliers (including needle nose and bent long nose) give you the right tool for different tight spaces and thread removal scenarios

- Ergonomic multi-zone grips reduce hand strain during detailed cleaning work, and the soft carrying case keeps everything organized in your sewing kit

- Some users report quality control issues with cutters not performing as expected on wire, which could affect their use on tougher materials

- Heavy-duty construction may feel too bulky for extremely delicate precision work on vintage or high-end machine components

- At 13.5 inches long, these mini pliers are larger than ultra-compact options, potentially limiting access in the tightest sewing machine spaces

How to Choose Your Maintenance Tools

Picking the right maintenance tools doesn’t have to be complicated, but it does require matching your gear to your machine’s needs and your skill level. Not all kits are created equal—some offer universal compatibility while others target specific machine types or experienced users.

Here’s what you need to think about to build a toolkit that keeps your machine running smoothly for years to come.

Matching Tools to Your Machine Type

Not all machines speak the same language regarding tool compatibility. A compact domestic model needs fine-tipped brushes and smaller precision screwdrivers, while industrial machines demand heavier-duty tools to tackle sturdy assemblies.

Here’s how to match your maintenance kit to your setup:

- Domestic machines: Use fine brushes and small screwdrivers for delicate housing

- Industrial machines: Opt for larger drivers and durable brushes for heavy-duty parts

- Computerized models: Add anti-static brushes to protect sensitive circuits

- Check your manual: Manufacturer specs guide proper tool selection and maintenance schedules

Features to Look for in Cleaning Kits

When shopping for a sewing machine maintenance kit, prioritize material quality. Look for stainless steel tools and anti-static brushes that won’t shed. Ergonomic design matters during those longer cleaning sessions, reducing hand fatigue by up to 40%.

Kit diversity ensures you’re covered, with precision screwdrivers, lint brushes, and tweezers for every tight spot. Safety features like slip-resistant grips and tool storage prevent accidents.

Cleaning effectiveness depends on microfiber cloths and flexible brush heads that reach feed dogs and bobbin areas efficiently.

Universal Vs. Specialized Kits

Your choice between universal and specialized kits boils down to machine type and budget. Universal parts kits cover 80% of brands, reduce minor repairs by 9%, and cost under $11—ideal for standard home machines.

Specialized cleaning toolkits deliver 32% fewer thread jams and extend machine longevity by 17%, cutting annual maintenance costs by $48 in commercial settings where precision matters most.

Best Practices for Tool Storage and Care

Once you’ve invested in quality tools, proper storage becomes your best defense. Here’s how to get the most out of tool longevity:

- Humidity Control: Store your cleaning toolkit in environments below 60% humidity to cut rust risk by 30% and protect precision components.

- Kit Segregation: Use labeled containers with adjustable dividers to boost retrieval speed by 40% and prevent cross-contamination.

- Scheduled Cleaning: Clean brushes and cloths monthly to maintain 95% effectiveness, and inspect tools quarterly for wear before replacement intervals arrive.

Safe handling means storing oil separately from absorbent materials and using magnetic dishes to prevent part loss—reducing incidents by 27%.

Cleaning Techniques for Optimal Machine Performance

Having the right tools is just the first step—knowing how to use them properly makes all the difference in keeping your machine running smoothly. A systematic approach to cleaning and maintenance prevents most common issues before they start.

Let’s walk through the essential techniques that’ll help you get the most out of your sewing machine and extend its working life.

Step-by-Step Lint Removal and Oiling

You’ll want to unplug your machine before you start—safety first.

Remove the needle plate using your precision screwdriver, then tackle lint buildup with a soft lint brush and tweezers for stubborn threads.

After thorough lint removal, apply one to two drops of machine oil at designated points. Rotate the handwheel to distribute lubrication evenly, wipe away excess, and you’re done.

Cleaning The Bobbin Area and Feed Dogs

Why does the bobbin area demand your attention? Because 43% of skipped stitches trace back to lint buildup here. Remove the throat plate, then use your soft nylon brush to sweep out the bobbin case and feed dogs thoroughly.

- Clean after every second bobbin change to reduce malfunctions by 28%

- Use tweezers for stubborn threads wedged between feed dog teeth

- Skip compressed air—it forces debris deeper into delicate mechanisms

This 15-minute routine restores even fabric movement in 91% of cases.

Safe Needle and Tension Maintenance

Because worn needles account for 70% of machine breakdowns, you’ll want to inspect needle tips before every project and swap them every 8 hours of stitching.

Thread quality matters too—cheap spools increase tension wear by 30%. Lift your presser foot when cleaning tension disks, then validate tension settings after maintenance.

Following manufacturer-approved maintenance schedules extends your machine’s life by 32%.

Common Mistakes to Avoid During Cleaning

Since 68% of cleaning injuries involve unremoved needles, always remove your needle and presser foot first for needle safety.

Avoid compressed air risks—it pushes debris deeper, creating cement-like sludge that causes 53% of repair cases.

Don’t over-oil; just one drop per point prevents over lubrication attracting lint.

Skip water damage by using only dry lint removal tools and proper cleaning tools, never liquid cleaners on internal parts.

Signs Your Machine Needs Professional Attention

Sometimes a finicky machine isn’t just stubborn—it’s crying for help. If you notice unusual noises like grinding or squeaking, persistent thread breakage despite fresh needles, or skipped stitches that won’t quit, it’s time for professional servicing.

Watch for:

- Fabric feeding problems that routine cleaning can’t fix

- An overheating machine that feels hot to touch

- Persistent mechanical resistance or stiffness

- Burning smells during operation

- Inconsistent performance across multiple projects

Don’t ignore these signs—83% of repair calls involve ignored warning sounds.

Frequently Asked Questions (FAQs)

How often should I replace my sewing machine needle?

Replace your needle every 6–8 hours of sewing or after each major project. Heavy fabrics like denim demand replacement after every project.

Watch for skipped stitches, thread breakage, or visible dullness—these signal immediate replacement, regardless of hours logged.

What type of oil is best for sewing machines?

You’ll want light mineral oil formulated specifically for sewing machines—Mobil Velocite Oil No. 10 or Lily White are industry standards. Synthetic oils offer better oxidation protection but cost more. Avoid 3-in-1 or WD-40; they gum up machinery.

Apply sparingly: just one or two drops after every 8–10 hours of sewing.

Can I use household cleaners on my machine?

No—household cleaners damage your machine. Over 70% contain chemicals like ammonia that corrode internal parts and finishes. Manufacturers prohibit them.

Instead, use isopropyl alcohol and lint brushes. These safer alternatives prevent rust, electrical faults, and costly repairs while keeping your machine running smoothly.

Why is my machine making grinding noises?

Your machine’s grinding noises are usually a mechanical cry for help. Lint accumulation in the bobbin area causes over 60% of these sounds.

Lubrication issues, needle problems, and component failure account for the rest. Professional service resolves most cases quickly.

How do I know if my tension settings need adjusting?

Watch for loose loops on the underside, puckering on top, or thread bunching—these signal tension needs adjusting. Skipped stitches and visible bobbin thread also indicate problems.

Test on scrap fabric first; most issues resolve with small tension dial adjustments.

Conclusion

Your machine’s silent cry for help often comes too late—after stitches start failing and tension spirals. But here’s what changes everything: the moment you invest in essential sewing machine cleaning tools, you’re not just maintaining equipment, you’re reclaiming reliability.

Regular cleaning becomes second nature, those mysterious skips disappear, and your machine runs like it’s supposed to. Preventive care isn’t tedious; it’s the shortest path to projects that succeed and machines that last decades, not years.

- https://theruffledpurse.com/sewing-machine-care-and-cleaning/

- https://hookedonsewing.com/how-to-clean-your-sewing-machine/

- https://www.franklinsgroup.com/how-often-should-i-clean-and-oil-my-sewing-machine/

- https://spikessewingmachineservice.com/what-happens-when-you-ignore-regular-maintenance/

- https://www.bernina.com/en-US/Support-US/The-best-sewing-tips/The-best-tips-tricks-for-sewing/Cleaning-your-sewing-machine