This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You slice through fabric with your rotary cutter, leaving a clean line across the mat beneath—yet minutes later, that cut has vanished. Self-healing cutting mats seem almost magical, closing up after each blade pass like nothing ever happened.

But there’s real materials science at work here, not wizardry. These mats use a clever combination of thermoplastic polymers and elastomeric materials that literally push cut surfaces back together. When your blade separates the tiny particles in the mat’s semi-solid surface, the material’s inherent elasticity pulls those particles back into alignment.

Understanding how this healing mechanism works—and what can damage it—helps you choose the right mat and keep it performing for years of precise cutting projects.

Table Of Contents

- Key Takeaways

- What Are Self-Healing Cutting Mats?

- How Do Self-Healing Mats Work?

- The Science Behind Self-Healing Technology

- Top 5 Self-Healing Cutting Mats

- Benefits of Using Self-Healing Mats

- Choosing The Right Self-Healing Mat

- Common Uses for Self-Healing Mats

- Cleaning and Maintaining Your Mat

- Proper Storage and Care Tips

- How Long Do Self-Healing Mats Last?

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Self-healing cutting mats work through densely packed micro-particles suspended in a semi-solid matrix that absorbs blade impact and closes cuts through viscoelastic behavior, with thermoplastic polymers flowing under pressure to fill wounds while elastomeric materials pull displaced particles back together.

- The healing mechanism relies on three key properties: capillary action that draws repair material into microcracks, material memory that allows polymer chains to spring back to their original shape, and microcapsules containing healing agents that rupture under blade stress to seal gaps before solidifying.

- Mat longevity depends directly on proper care—storing flat away from heat and sunlight prevents warping and material degradation, while regular cleaning with mild soap (never harsh chemicals) and rotating the mat to distribute wear can extend its functional life from three to ten years.

- Quality mats typically achieve 75-95% recovery rates for shallow cuts, but you should replace them when deep gouges no longer close, grid markings fade beyond use, or the surface shows persistent warping despite proper maintenance.

What Are Self-Healing Cutting Mats?

Self-healing cutting mats aren’t magic—they’re engineered surfaces that close up after you slice through them. These specialized mats use unique materials and construction methods that set them apart from ordinary cutting boards.

Here’s what makes them different and why crafters, quilters, and precision workers rely on them.

Definition and Primary Purpose

A self-healing cutting mat is your workspace guardian—a specialized cutting surface designed to absorb blade strikes and bounce back without permanent grooves. Think of it as a protective shield between your sharp tools and your table.

These mats serve four essential roles:

- Protecting work surfaces from damage during craft applications

- Absorbing cuts through sophisticated self-healing mat technology

- Minimizing visible blade marks on the cutting surface

- Extending tool life with forgiving mat materials.

When writing about the benefits of self-healing mats, it’s necessary to follow proper research paper guidelines.

Key Materials: PVC Vinyl and Plastic Cores

Your cutting mat’s magic starts with two engineered layers working in harmony. The outer surface uses PVC vinyl materials—a thermoplastic chosen for its chemical resistance and low friction that lets blades glide smoothly.

Beneath that sits a soft plastic core made from self-healing polymers and thermoplastic elastomers. These core materials absorb your cuts, then use elastic recoil to close microscopic gaps, making self-healing cutting mats remarkably durable.

The durability of these mats can be further understood through research methodology that analyzes material science.

Multi-Ply Layered Construction

Those two primary layers? They’re actually built from multiple stacked plies bonded through precise interply adhesion. Each ply in this layered structure adds resilience—spreading blade force across a tighter network that resists groove formation.

Ply material science shows how alternating firmness and flexibility activate healing mechanisms: micro-scratches close as material flows between layers, giving self-healing cutting mats their composite durability and long-lasting performance.

How They Differ From Regular Cutting Mats

Unlike standard cutting mats that trap grooves after each slice, self-healing mats use self-healing polymers in a multi-layer composite—absorbing blade pressure and closing micro-cuts through material science reflow. That cutting surface stays smooth while regular mats accumulate permanent damage.

Grid markings remain legible cycle after cycle, and mat durability depends on responsive PVC cores instead of static vinyl. It’s cutting mat comparison at the molecular level.

How Do Self-Healing Mats Work?

The magic of self-healing mats lies in their unique material structure, not in any mystical repair process.

These mats work through a combination of tiny compressed particles and material properties that allow cuts to close naturally.

Let’s break down the four key mechanisms that make this “healing” happen.

Tiny Particle Semi-Solid Surface Structure

Think of it this way: you’re not cutting through a solid slab. Your self-healing cutting mats contain densely packed micro-particles suspended in a semi-solid matrix. This unique structure lets the surface absorb blade impact through viscoelastic behavior, so shallow cuts barely leave a trace. Here’s what makes this self healing technology work:

Self-healing cutting mats work because densely packed micro-particles in a semi-solid matrix absorb blade impact through viscoelastic behavior, letting shallow cuts close naturally

- Particle size determines how tightly the surface closes after each cut

- Matrix stiffness controls how much give your blade encounters

- Capillary action draws selfhealing polymers into microcracks for rapid repair

- Temperature affects recovery speed—warmer rooms help healing

- Microcrack repair happens as particles rearrange to fill grooves automatically

Cut Absorption and Quick Fill-in Mechanism

When your blade strikes the surface, self-healing polymers flow into the micro crack instantly. This fill efficiency determines how quickly cuts vanish—usually within minutes.

Self-healing mats absorb impact through their viscoelastic layer, minimizing material fatigue over repeated cycles.

Higher healing speed means better cut resistance, keeping your self-healing cutting mats functional longer. Self-healing technology relies on this rapid resealing to maintain a smooth workspace.

Material Memory and Recoiling Properties

Your mat remembers its original shape. When you cut, polymer chains shift but don’t break—they spring back through viscoelastic recovery. This recoiling mechanism closes gaps within minutes as thermoplastic domains rearrange and fill micro-voids.

Self-healing mat technology depends on this molecular mobility to resist material fatigue. That’s how cutting mat maintenance stays minimal while surface restoration happens automatically with each slice.

Why Cuts Close and Surface Restores

Surface Restoration happens because your blade creates micro-cuts that trigger a chain reaction. Here’s how Cutting Dynamics drive the Healing Process:

- The thermoplastic surface flows under pressure, filling wounds as the blade withdraws

- Viscoelastic Properties pull displaced polymer back into microcracks through capillary action

- Material Science allows resealing at room temperature without external heat

- Self Healing Mats return to a low-energy state within minutes

That’s Selfhealing Mat Technology in action.

The Science Behind Self-Healing Technology

The materials in your cutting mat aren’t just static layers—they’re engineered to respond when you cut through them. This happens because of specific chemical and physical properties built into the mat’s structure.

Let’s break down the key scientific mechanisms that make self-healing technology actually work.

Thermoplastic and Elastomeric Matrix Properties

Your cutting mat’s magic lies in its matrix composition—a blend of thermoplastic and elastomeric materials working together.

When you cut, thermoplastic flow mobilizes polymer chains through localized heat, letting material resettle into gaps. Meanwhile, elastomeric recovery provides the bounce-back action, pulling cut edges together.

This dual-phase self-healing cutting mat technology is what separates ordinary surfaces from true self-healing mats that repair themselves after every slice.

Microcapsules and Healing Agents

Think of your cutting mat as a container filled with tiny repair capsules, each one ready to spring into action. When you cut through the surface, the microcapsule design uses a polymer shell that ruptures under stress, releasing a healing agent into the crack.

Viscosity control ensures the agent flows smoothly, filling gaps before it solidifies—transforming every self-healing cutting mat into its own repair crew.

Capillary Action in Microcrack Repair

Once those healing agents release, capillary flow takes over—drawing liquid into microcracks through surface tension and fluid dynamics. Your self-healing cutting mat uses interconnected microchannels that pull repair material deeper into damage faster than diffusion alone.

This microcrack repair depends on pore size and viscosity, completing before the agent gels. That’s why your cutting mat seals quickly after every slice.

Healing Efficiency and Material Recovery

Just as capillary action speeds up repairs, material recovery in Self Healing Mats is measured by efficiency metrics—how well the cutting mat rebounds after each slice. Most SelfHealing Cutting Mats boast recovery rates between 75–95% for shallow cuts, but repeated healing cycles slowly lower this number.

You’ll notice:

- Quick damage restoration for daily use

- Reliable work surface protection

- Consistent material handling over time

Top 5 Self-Healing Cutting Mats

Now that you understand the science behind self-healing technology, you’ll want to choose a mat that actually delivers on those promises.

The market offers dozens of options, but not all mats heal equally well or hold up under regular use. Here are five cutting mats that consistently perform well across different crafting needs and budgets.

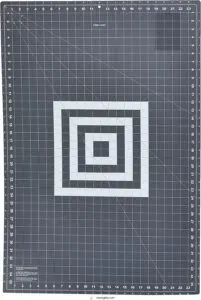

1. La Canilla Self Healing Cutting Mat

You’ll find La Canilla’s mat delivers a solid, double-sided surface with five PVC layers that improve mat durability for quilting, scrapbooking, and vinyl crafts. This self-healing cutting mat measures 23.62 by 17.72 inches—slightly smaller than advertised—but it still provides excellent cutting efficiency with grid markings in both centimeters and inches.

User reviews often highlight its thicker-than-expected construction and reliable performance across various craft applications, though the higher cost compared to other cutting mats may give you pause during product comparison.

- Five-layer PVC construction provides excellent durability and self-healing performance that extends the mat’s lifespan

- Double-sided design with both metric and imperial measurements gives you flexibility for different project requirements

- Thicker build quality offers a stable cutting surface that protects your work table from rotary cutters and craft knives

- Actual dimensions (23.62 x 17.72 inches) are smaller than the advertised 24 x 18 inches, which may disappoint if you need exact sizing

- Higher price point compared to similar cutting mats on the market

- Thicker profile than some users expect, which could affect storage in tight spaces

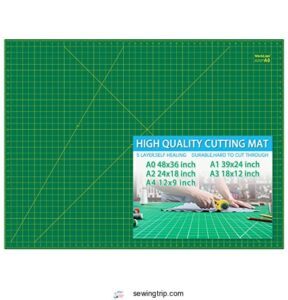

2. WorkLion Self Healing Cutting Mat

WorkLion’s self-healing cutting mat offers a multi-layer design built for serious rotary cutting and repeated use. You’ll notice the healing mechanism works through pressed PVC particles that absorb blade marks and close quickly after each cut.

Product reviews highlight its cutting accuracy with clear grid markings, though mat durability varies based on blade pressure and cutting mat care habits.

WorkLion features include a non-slip surface and double-sided layout, giving you flexibility for quilting, scrapbooking, and vinyl work without damaging your table.

- Self-healing surface helps extend the mat’s life by closing up blade marks after cuts

- Double-sided design with clear grid markings gives you measurement guides and dual work surfaces

- Large size (47.2″ x 35.5″) handles big quilting projects and fabric pieces without repositioning

- May arrive rolled up and struggle to lay completely flat on your work surface

- Self-healing feature doesn’t always work as advertised—some users report permanent scarring and blade damage

- Durability questions with mixed customer feedback on whether it holds up to regular use over time

3. Fiskars Self Healing Cutting Mat

Fiskars offers a self-healing cutting mat that’s earned solid marks in cutting mat care communities for its multi-layer PVC construction and memory-retaining core. The healing technology uses pressed particles that close after rotary cutters pass through, protecting both your blades and table.

You get options in mat size—ranging from compact 12×18 inches to expansive 24×36 inches—so you can match your workspace and project scale. Grid markings help with precision, making it a reliable crafting accessory for quilting, scrapbooking, and vinyl work with various crafting tools.

- Extra-large 24″ x 36″ surface handles oversized fabric pieces and long strips without repositioning

- Multi-layer construction with memory-retaining core automatically closes cuts, keeping the surface smooth for years

- Double-sided with angle guides (30, 45, 60 degrees) and clear measurement grids for precise cutting

- Strong plastic smell out of the box that may bother sensitive users

- Can arrive warped at the corners or with sticky residue from packaging

- Requires careful storage and hand washing to maintain flatness and avoid damage

4. Olfa Self Healing Cutting Mat

Olfa cutting mat designs stand out for their dense substrate and engineered surface layer that closes micro-tears quickly after rotary cutters or craft knives pass through. You’ll find thickness options like the portable 1.5mm version—ideal for fabric cutting and quilting projects—plus double-sided layouts with grid markings for measuring accuracy.

The self-healing cutting mat surface protects your rotary blades and keeps them sharper longer, making Olfa a trusted choice among crafters using weaving tools and precision cutting techniques.

Proper mat care—storing flat, avoiding heat—extends durability for years of reliable crafting.

- Self-healing surface reseals after cuts, extending the mat’s usable life and keeping your cutting area smooth

- Double-sided design with grid lines makes measuring and cutting accurate without constant repositioning

- Compact 6×8 inch size is easy to store and transport, perfect for classes or crafting on the go

- Not compatible with fixed blade utility knives, limiting the types of cutting tools you can use

- Requires flat storage away from sunlight to prevent warping, which takes up dedicated space

- At 1.5mm thickness, you may need shims to use it with certain die cutting machines

5. Fiskars Rotating Cutting Mat

An eight-inch rotating mechanism gives you 360-degree control when you’re trimming hexagons or squaring up blocks—no more repositioning your fabric mid-cut.

The Fiskars self-healing cutting mat features bias lines at 30, 45, and 60 degrees, boosting cutting accuracy for star and triangle shapes. Its PVC surface absorbs blade strikes and closes micro-cuts quickly, extending mat durability and keeping rotary cutters sharp.

You’ll appreciate the tool compatibility with standard craft blades and the crafting versatility for quilting, scrapbooking, and fabric cutting projects.

- 360-degree rotating base lets you pivot your fabric instead of awkwardly shifting your hands, reducing strain on repetitive cuts

- Self-healing surface bounces back from blade marks and keeps your rotary cutter sharper longer

- Pre-marked bias lines at 30, 45, and 60 degrees make triangle and star cutting way more accurate

- Actual cutting area is only 7 inches despite the 8-inch label, which can feel cramped on anything beyond charm squares

- Rotation mechanism may need occasional maintenance or lubrication after heavy use

- Too small for larger quilt blocks or projects that need more workspace

Benefits of Using Self-Healing Mats

Now that you understand how these mats work, let’s talk about why they’re worth adding to your workspace. Self-healing mats do more than just close up after cuts—they actively protect your tools, surfaces, and budget.

Here are five key benefits that make them essential for any cutting project.

Protects Work Surfaces From Damage

Your self-healing cutting mat acts as a guardian for your workspace, absorbing blade cuts within its layered surface rather than transferring damage to your desk or table. This Surface Protection prevents scratches, gouges, and needle marks from accumulating on your workstation.

The cutting mat’s dense core maintains flatness during Material Cutting and Shaping tasks, while its resilient construction resists warping—delivering lasting Workstation Durability and eliminating the need for frequent Mat Maintenance or protective layer replacements.

Keeps Rotary Blades and Tools Sharp

Your rotary blade stays sharper because the mat’s resilient surface absorbs each cut without adding friction or embedded debris. Unlike hard mats that dull edges quickly, the self-healing cutting mat’s semi-solid structure lets your blade glide cleanly through the top layer.

- Multi-layer construction guides uniform cuts, preserving blade geometry

- Reduced direct contact minimizes edge wear on rotary cutters

- Regular mat rotation prevents grit buildup that compromises Blade Sharpness

- Proper Tool Maintenance and Care extends Edge Retention for precision cutting

This efficient design maintains Cutting Efficiency across countless cutting techniques.

Extends Blade Lifespan and Reduces Costs

Fewer blade replacements mean real savings when you invest in a quality self-healing cutting mat. Your rotary cutters last longer because the mat’s resilient surface prevents micro-dulling that shortens blade longevity.

Over time, mat durability combined with reduced tool maintenance translates to lower costs per project.

Smart cutting techniques and regular tool maintenance and care boost both cutting efficiency and cost savings for quilters, crafters, and designers.

Provides Accurate Cuts With Grid Markings

Your self-healing cutting mat doubles as a measurement tool with durable grid markings printed right on the surface. These grids give you precision cutting references—1 cm and 1/8 inch subdivisions—so you nail fabric cutting layouts without pulling out extra rulers.

Grid accuracy turns complex shapes into quick cross-checks, boosting your crafting efficiency while the mat durability keeps those lines visible through countless projects.

Durable for Multiple Crafting Applications

Your cutting mat manages everything from fabric cutting for quilts to vinyl weeding without breaking down. The self-healing cutting mat resists rotary blade damage across hundreds of cuts, maintaining surface integrity whether you’re trimming leather or scoring cardstock.

This mat versatility means you won’t juggle multiple protective surfaces—one durable workspace accommodates all your crafting materials, boosting cutting efficiency while extending tool longevity through consistent performance.

Choosing The Right Self-Healing Mat

You can’t just grab any mat off the shelf and expect it to work for your projects. The right self-healing mat depends on what you’re cutting, how much space you have, and what features actually matter for your craft.

Here’s what to look for when you’re shopping.

Selecting Appropriate Size for Your Projects

Your project scope determines what mat dimensions you actually need. Quilting projects and fabric cutting with rotary cutters work best on 24×36-inch surfaces, giving you room for full-width layouts.

Smaller hobby work fits nicely on 12×18-inch mats—they’re portable and easier to store.

A self-healing cutting mat around 18×24 inches balances workspace efficiency with storage solutions for most tabletop tasks.

Thickness Options: 3mm Vs 5mm

Mat thickness affects your cutting accuracy and how long your blade stays sharp. A 3mm self-healing cutting mat offers portability for fabric cutting and smaller crafting tools, while 5mm versions provide better rigidity for rotary cutters tackling high material density work.

The thicker option resists indentations and blade wear more effectively, but 3mm mats display grid lines with sharper clarity for precise measurements.

Surface Types: Green, SupaSeal, Heavy-Duty

Green mats deliver budget-friendly Work Surface Protection with 2.5 to 3.5 mm Mat Thickness and bright Cutting Surfaces for visibility.

SupaSeal versions strengthen your self-healing cutting mat with enhanced Healing Agents and deeper Surface Durability, spanning 3.0 to 5.0 mm for serious Crafting and DIY Projects.

Heavy-duty options—4.5 to 5.5 mm thick—use sophisticated Material Comparison engineering and Protective Gear-grade construction, resisting abrasion and high blade pressure in professional settings.

Anti-Glare and Anti-Static Features

Bright overhead lighting can turn your cutting mat into a mirror, triggering Eye Strain and making grid lines vanish. That’s where Glare Reduction and Static Control transform your Work Surface Protection into a precision tool for Crafting and DIY Projects:

- Anti-glare Surface Finish keeps measurement marks crisp under any lamp

- Static Control prevents vinyl scraps from clinging during Material Handling

- Reduced reflections help you spot faint pencil lines instantly

- Less static buildup means fewer dust specks invading your selfhealing cutting mat

Common Uses for Self-Healing Mats

You’ll find self-healing mats in studios, workshops, and craft rooms across dozens of creative fields. These adaptable surfaces work with nearly any precision cutting tool, from rotary cutters to craft knives.

Let’s look at the most popular applications where self-healing mats really prove their worth.

Quilting and Rotary Cutting

When you’re working on quilting projects with rotary cutters, a self-healing cutting mat becomes your foundation for fabric preparation. The smooth surface lets your rotary tools glide through multiple fabric layers cleanly while protecting your blade from dulling.

Grid markings guide your quilting techniques for precise seam allowances.

With proper mat maintenance—clearing lint and rotating regularly—you’ll maintain crafting safety and cutting accuracy for years.

Scrapbooking and Cardmaking

Your paper crafting sessions need a stable base that won’t damage cardstock or dull blades during die cutting. Self-healing cutting mats protect your workbench and studio organization while supporting intricate card design with clear gridlines for alignment.

- Gridlines help you center sentiments and place embellishments precisely on scrapbook layouts

- The resilient surface absorbs blade marks from paper trimming without permanent indentations

- Smaller portable sizes fit perfectly in your craft section alongside other crafting supplies

These crafting materials and techniques keep your cutting mats performing smoothly across countless projects.

Vinyl Crafting With Awls and Weeding Tools

Vinyl cutting demands precision that only a self-healing mat can deliver. When you’re wielding weeding tools or practicing awl techniques to punch starter holes, you’ll appreciate how the mat protects your workbench accessories while keeping cuts clean.

These crafting materials and techniques transform your craft section into a safe workspace, and routine mat maintenance ensures your cutting mats stay smooth across hundreds of projects. Crafting safety starts with the right crafting supplies beneath your blade.

Leatherworking and Precision Cutting Projects

Leather crafting pushes your cutting mats harder than most materials, but that’s exactly where self-healing surfaces shine. When you’re working with precision tools like rotary cutters or craft knives, the mat’s grid markings guide your leather cutting with angle accuracy you can measure:

- Edge finishing stays clean without substrate damage

- Rotary cutting techniques preserve blade sharpness longer

- Material selection improves when you can see cutting patterns clearly

Your tools stay sharper, your cuts stay truer.

Cleaning and Maintaining Your Mat

Your self-healing mat works hard to absorb thousands of cuts, but it won’t last long without basic upkeep.

A clean mat heals better because debris and buildup interfere with the particle structure that closes those cuts.

Here’s how to keep your mat performing like new for years.

Regular Debris Removal With Lint Rollers

You’ll want to sweep away dust and fibers regularly—that’s where a lint roller shines. Rolling across your cutting mat before and after each project lifts tiny paper scraps, thread, and fabric debris that pile up during crafting sessions.

This simple debris prevention habit keeps your mat surface care on point and protects work surfaces from impression marks caused by trapped particles between cuts.

Proper Cleaning With Mild Soap Solution

Once you’ve lifted surface debris, mix a mild soap solution—about 1 to 5 percent dish soap in warm water—for gentle cleaning of your cutting mat. Wipe with a soft cloth, then rinse to remove soap traces.

This mat maintenance habit protects work surfaces and extends your sewing aids without harsh chemicals. Dry completely with a clean towel to prevent warp, keeping your crafting essentials ready for precision cuts.

Avoiding Harsh Chemicals and Heat Exposure

After gentle cleaning, keep solvents like acetone or paint thinner away from your mat—they wreck chemical resistance and trigger mat degradation. Heat damage hits fast above 120°F, so avoid direct sun or hot surfaces.

These crafting essentials need surface protection through safe DIY project ideas: stick with mild soap, protect your work surfaces, and always use safety and protective gear when handling any cleaners.

Rotating and Flipping to Prevent Scarring

Beyond cleaning, regular mat rotation spreads out wear patterns across your cutting mat surface—flip it weekly and rotate between quadrants to prevent deep grooves. This scar prevention technique maintains cutting efficiency by distributing stress evenly, protecting work surfaces from concentrated damage.

Quilting mats especially benefit from flip maintenance, extending mat longevity while keeping your craft tool performing like new.

Proper Storage and Care Tips

Cleaning your mat is only half the battle—how you store it makes all the difference in keeping it flat and functional for years. A warped or damaged mat won’t heal properly, and it’ll throw off your measurements every time you cut.

Here’s how to store your self-healing mat the right way so it stays in working condition.

Always Store Flat Away From Light

Storing your cutting mat flat is the single best way to prevent warping and preserve its self-healing surface. Light exposure accelerates material degradation in the PVC vinyl layers, causing yellowing and embrittlement that compromises performance. Think of it like protecting work surfaces from the sun—your quilting mats and craft tools deserve the same care.

- Store horizontally in a drawer or under a bed to prevent edge curling

- Keep away from windows and direct sunlight to avoid material degradation

- Cover with a cloth if storing in lit areas

- Flat storage maintains grid accuracy for precision cutting

- Prolonged light exposure weakens the thermoplastic matrix over time

Avoid Rolling or Bending The Mat

Rolling or bending your cutting mat distorts the grid alignment you depend on for precise fabric cutting and preparation. When you create curvature, you’re introducing stress points that accelerate core separation—think of it like creasing paper repeatedly until it tears.

For mat longevity and flatness maintenance, proper mat storage tips include keeping sewing accessories and crafting essentials completely flat, ensuring your cutting mats deliver accurate cuts every time.

Allowing New Mats to Acclimate Flat

When your new cutting mat arrives rolled or curled, you need to give it time to relax. Proper mat acclimation tips recommend laying your cutting mats flat for 24 to 48 hours before you make your first cut. This practice ensures grid marking accuracy and prevents surface warping that throws off your fabric cutting and preparation. Environmental humidity control also matters—keep conditions moderate (30–60%) during acclimation.

Essential flat storage methods for sewing accessories:

- Place the mat on a clean, level surface away from direct sunlight

- Use evenly distributed weights at edges to prevent curling

- Position the printed grid facing up to monitor straightness

- Maintain room temperature around 68–72°F during acclimation

- Test a scrap corner after acclimation to confirm surface responsiveness

Fixing Warped Mats With Weighted Flattening

If your cutting mat develops a warp, weighted flattening offers a proven mat restoration method. Place a rigid board over the warped zone and distribute weights evenly along the edges—this pulls the surface toward a flat plane without imprinting. Leave the setup undisturbed for 24 to 72 hours, checking progress with a straight edge.

| Step | Action |

|---|---|

| Setup | Position rigid board larger than warp area |

| Weighting | Apply even pressure at edges for 24–72 hours |

| Verification | Test flatness with straight edge after removal |

This damage repair technique works for most PVC cutting mats used in material cutting and DIY projects. If residual warp remains, repeat the process in smaller zones to prevent re-warping.

Proper flat storage and warp prevention habits—like avoiding heat and storing horizontally—keep your crafting essentials performing reliably for years.

How Long Do Self-Healing Mats Last?

A quality self-healing mat can last anywhere from three to ten years, depending on how you use it and care for it. The lifespan isn’t set in stone—factors like cutting frequency, blade pressure, and storage conditions all play a role.

Here’s what determines how long your mat will hold up and when you’ll need a replacement.

Factors Affecting Mat Lifespan

How long your cutting mat lasts depends on several factors you control. Cutting frequency and usage patterns matter most—daily cutting can wear your mat in 1 to 3 years, while hobby use extends it beyond 5 years.

Mat thickness, environmental impact like heat and UV exposure, and material degradation from harsh chemicals all affect durability.

Your sewing and crafting habits directly shape lifespan.

Signs It’s Time to Replace Your Mat

Your cutting mat shows clear Mat Wear Signs when deep gouges won’t close, even after resting overnight. Cutting Inaccuracy appears when grid lines drift more than 2 mm or measurements no longer align.

Material Degradation includes peeling surfaces, persistent warping, or embedded dust that resists cleaning.

Safety Concerns like slippery surfaces or mold growth signal Replacement Timing for your Sewing and Crafting projects.

Proper Care Extends Durability for Years

Once you’ve spotted replacement signs, smart Mat Maintenance can push that timeline back years. Regular Cleaning Tips like gentle soap wipes keep your cutting mat’s surface fresh, while proper Storage Methods—flat, away from heat—preserve its memory. Here’s how Care Techniques protect your Crafting Essentials and Materials:

- Remove debris weekly with a lint roller or soft brush

- Clean monthly with mild soap solution, never harsh chemicals

- Rotate and flip regularly to distribute wear evenly

- Store flat in cool spaces away from direct sunlight

These simple Durability Factors make your DIY Tools and Sewing Supplies and Notions last longer.

Quality Differences and Healing Cycle Limits

If you treat your cutting mat right, Mat Longevity hinges on more than just care—it’s built into the material. Higher-quality PVC mats like Olfa offer faster Recovery Speed and greater Healing Cycle counts, meaning thousands of cuts before scars stick.

Lower-grade Cutting Mats may lose their “memory” sooner, especially with heavy Craft Knives. Always check Cycle Limits for true Material Durability.

Frequently Asked Questions (FAQs)

How long does a self-healing cutting mat last?

Like a favorite pair of jeans, your mat’s durability depends on how you treat it.

Most cutting mats last three to five years with regular use, though maintenance tips and wear factors can extend that lifespan considerably.

How do you heal self-healing cutting mats?

Self-healing cutting mats don’t need manual healing—surface restoration happens automatically. The material science behind Fiskars and Olfa cutting mats allows elastic recovery after blades cut, though proper mat maintenance preserves this cut recovery ability.

Why is it called self-healing cutting mat?

The term captures the mat’s ability to close blade marks and restore its smooth cutting surface.

Tiny particles separate when you cut, then spring back together, minimizing visible damage over repeated use with cutting tools.

When should I replace my self-healing mat?

Think of your mat like a workhorse—once deep gouges won’t close, grid markings fade beyond use, or warping persists despite care, it’s time for replacement.

Performance decline signals retirement after years of faithful service.

Are self-healing mats safe for childrens crafts?

Most cutting mats pass toxicity tests and work well for child safety during craft supervision.

Check mat materials for phthalate-free labels, follow age recommendations, and supervise closely when kids use sharp tools.

Can self-healing mats be used for food preparation?

Most PVC-based cutting mats aren’t food-safe—they lack regulatory compliance for direct contact. Mat materials may leach plasticizers onto food.

Always choose certified food-grade cutting surfaces for sanitation and safety when using blades or craft knives near edibles.

How often should self-healing mats be replaced?

Your mat’s replacement frequency depends on wear factors like cutting efficiency and visible damage. Light crafters might replace every 2–3 years, while heavy users need new mats sooner—watch for deep gouges or reduced performance.

Do self-healing mats require any special treatment?

Like a blade that remembers its edge, your self-healing mat thrives with proper Mat Maintenance. Store cutting mats flat, avoid harsh chemicals during Special Care cleaning, and rotate regularly—these Storage Tips preserve Surface Durability and Healing Efficiency for years.

Are there environmentally-friendly options for self-healing mats?

Yes, you’ll find green alternatives made from recycled PVC or bio-based plastics. Some brands use low-VOC production methods and offer recyclable mats with take-back programs, reducing your crafting supplies guide footprint.

Can self-healing mats be used for fabric scissors?

Here’s the thing: you can, but it’s like using a sports car for grocery runs—not ideal. Self-healing mats work best with rotary cutters, not scissors.

Scissors may leave scoring marks and dull faster on dense mat surfaces.

Conclusion

A simple blade pass looks destructive, yet the mat beneath springs back intact—that’s the beauty of understanding how self-healing mats work. The thermoplastic polymers you once thought mysterious now make perfect sense: particles separate, then memory pulls them closed again.

Keep your mat flat, clean it gently, and avoid heat. Those small habits protect the material science doing the heavy lifting, giving you thousands of precise cuts without replacement costs or performance loss.

- https://en.wikipedia.org/wiki/Self-healing_material

- https://www.silhouetteschoolblog.com/2017/01/upcycle-old-silhouette-cutting-mats.html

- https://academichelpexpress.blog/2024/08/please-use-the-bulleted-points-and-the-rubric-below-to-guide-your-work-your-pa/

- https://www.ai-literacy.se/research-prompts.html