This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

When you’re sewing, the bobbin sits snugly in its case, holding the bottom thread that’ll interlock with your top thread. As you sew, the machine’s hook mechanism catches the top thread and weaves it with the bobbin thread, creating a tight, neat stitch.

You’ll want to wind your bobbin evenly, check its tension, and keep it clean. Different machines use different bobbin types—from Class 15 to Class 66—so know your machine’s specs.

Curious about bobbin secrets that’ll level up your sewing game? bobbin works its magic bobbin thread machine’s specs sewing game

Table Of Contents

Key Takeaways

- You’ll master your sewing by understanding that a bobbin is the tiny thread spool positioned beneath your machine’s needle, responsible for supplying the bottom thread that interlocks with the top thread to create perfect stitches.

- You’ll want to choose the right bobbin type for your specific machine, paying attention to compatibility with materials like plastic, metal, or aluminum, and matching the precise size and shape recommended in your machine’s manual.

- You’ll need to focus on proper bobbin threading and tension control, which are critical for preventing sewing issues like thread jams, uneven stitches, or tangled fabric—small adjustments can dramatically improve your sewing results.

- You’ll keep your bobbins in top condition through regular maintenance, including cleaning the bobbin case, storing them in a cool, dry place, checking for wear, and replacing them when they show signs of damage to ensure smooth, professional-looking sewing projects.

How Does a Sewing Machine Bobbin Work?

Ever wondered what makes your sewing machine tick?

At the heart of every stitch is the humble bobbin, a small but mighty spool tucked beneath the sewing machine mechanisms, holding the lower thread, dancing in perfect sync with the upper thread to create seamless stitches.

Different machines use various bobbin types—Class 15, Class 66—crafted from plastic, metal, or aluminum.

Each bobbin is like a precise puzzle piece, ensuring your fabric comes together just right.

Proper bobbin winding and threading are your secret weapons for smooth, professional-looking seams.

Mastering your bobbin’s rhythm means taking control of your sewing destiny, one perfectly formed stitch at a time.

Bobbin Basics

You’ve probably seen a bobbin before, nestled in your sewing machine.

It’s the tiny spool that holds your bottom thread.

It’s the tiny spool and works magic with the top thread to create perfect stitches every time.

Definition and Function of Bobbins

Those tiny spools hiding in your sewing machine hold more power than you might think! Bobbins are the unsung heroes of your stitching world, responsible for creating perfect seams by supplying the lower thread. They work magic behind the scenes, ensuring your projects come together flawlessly. Choosing the right sewing machine bobbins can substantially impact the quality of your stitches.

- Provide the bottom thread for every stitch

- Interlocking with the top thread seamlessly

- Maintaining tension throughout your sewing project

- Enabling precise and professional-looking results

Types of Bobbins (Class 15, Class 66, Etc.)

Sewing machine bobbins come in different types, and knowing the right fit is your ticket to smooth stitching.

Class 15 bobbins, small and flat, work with most modern machines, while Class 66 types suit older Singer models. Industrial sewists might grab a Class L, and some European machines prefer the metal-sided Class M.

Your bobbin’s compatibility can make or break your sewing project, so check your machine’s manual before grabbing just any spool.

Think of it like finding the perfect dance partner – precision matters! Choosing the correct bobbin type, such as prewound bobbins, is essential for effective thread management and tension control.

Materials: Plastic, Metal, Aluminum

When exploring bobbin materials, you’ll discover a world of options: lightweight plastic, sturdy metal, and versatile aluminum.

Each material brings unique advantages to your sewing machine, balancing durability, cost, and performance.

Whether you’re a budget-conscious crafter or a precision-driven sewist, understanding bobbin material differences can elevate your stitching game.

Sizes and Shapes

After diving into bobbin materials, let’s explore their dimensions.

Your sewing machine’s bobbin isn’t a one-size-fits-all deal. From tiny quarter-inch circles to robust inch-wide discs, bobbin sizes vary wildly.

Circular shapes dominate, but some machines rock elongated designs.

Pro tip: match your bobbin’s size and shape precisely to your machine’s specs.

A custom bobbin case can help you keep these little thread guardians organized and ready for action.

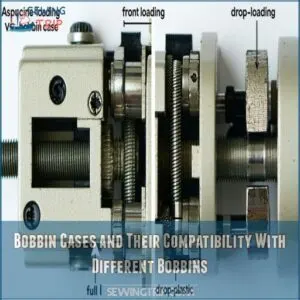

Bobbin Cases and Their Compatibility With Different Bobbins

Every sewing machine harbors a unique bobbin case that demands careful matching.

Front-loading and drop-in cases have distinct quirks – choose wisely to prevent threading nightmares.

Metal or plastic, removable or built-in, your bobbin case is the unsung hero of smooth stitching. Consult your machine’s manual like a treasure map to discover perfect bobbin compatibility and keep your sewing adventures drama-free. Bobbin case compatibility is crucial for smooth stitching.

Bobbin Threading

Ready to master the art of bobbin threading? You’ll soon discover that threading your bobbin correctly is the secret sauce to creating smooth, professional-looking stitches every time.

Threading The Bobbin

Now that you know bobbin basics, let’s master threading like a pro sewing ninja.

Threading your bobbin isn’t rocket science—just follow these steps:

To verify your bobbin is wound correctly, make sure to check the thread tension.

- Locate your bobbin winder on the machine

- Select compatible thread for smooth winding

- Secure thread end on the bobbin pin

- Wind evenly, keeping tension consistent

Your threads will thank you later.

Importance of Proper Threading

Thread consistency, tension control, and smooth stitches are deeply connected to understanding the thread path. Check out a detailed sewing machine thread path guide for more information.

Master these, and you’ll transform your sewing from amateur to awesome.

- Perfect thread consistency

- Balanced tension control

- Jam-free sewing performance

- Smooth, professional-looking stitches

Troubleshooting Bobbin Threading Issues

Most sewing machine bobbin problems, like birds nests or thread breaks, stem from threading issues.

Quick fixes include checking bobbin tension, ensuring even thread placement, and watching for skipped stitches.

To avoid these issues, you can invest in a high-quality sewing machine bobbin.

If simple adjustments don’t solve bobbin threading troubles, it might be time to replace your bobbin or seek professional help.

Tips for Even Winding

Anyone can master bobbin winding with the right technique.

Keep your thread tension consistent by guiding it evenly across the bobbin surface.

Watch your winding speed and see that the thread follows the guides smoothly. Different bobbin sizes require careful attention to prevent tangles.

Pro tip: A perfectly wound bobbin means fewer sewing machine headaches and smoother stitches every time. Your sewing success starts here!

Bobbin Tension

Ever wondered why your stitches look wonky or loose?

Getting the right bobbin tension is like finding the perfect balance in a sewing dance, and it’ll make the difference between a professional-looking project and a tangled mess.

Understanding Bobbin Tension

Nail down your sewing machine’s bobbin tension, and you’ll discover the secret to picture-perfect stitches. Bobbin tension is like a tightrope walker balancing delicate threads, making or breaking your sewing project’s success.

- Feel the power of precision threading

- Conquer those pesky tension problems

- Transform your sewing from amateur to pro

- Master the art of thread control

Your bobbin case holds the key to stitch quality. Different bobbin sizes, materials, and machine compatibilities all play significant roles in achieving that flawless finish you’re after.

Importance of Correct Tension for Proper Stitching

Get ready to decode the secret language of bobbin tension. Your stitches tell a story, and tension is the narrator.

To master proper stitching, it’s vital to understand and control bobbin tension adjustment.

Unbalanced tension can turn your masterpiece into a mess. The top and bottom threads must dance in perfect harmony – too tight creates puckered seams, too loose leads to loopy disasters.

Your bobbin thread’s tension is the key to stitch perfection.

Adjusting Bobbin Tension

When your stitches look wonky, it’s time to play tension detective.

The bobbin case screw is your secret weapon for perfect seams.

Here’s how to become a tension master:

- Locate the tiny adjustment screw on your bobbin case

- Clockwise turn tightens thread tension

- Counterclockwise turn loosens thread tension

- Always test stitches after each tiny twist

Patience is key – small adjustments can transform messy loops into magazine-worthy seams.

Tips for Maintaining Consistent Tension

Thread tension isn’t just a sewing machine’s quirk – it’s the secret sauce of perfect stitches.

Keep your bobbin thread smooth by winding uniformly, replacing worn bobbins, and storing them carefully.

Compatible bobbins and quality materials are one’s allies in maintaining that tension sweet spot, ensuring one’s projects look professionally crafted every single time.

Mastering the bobbin winding process will also substantially contribute to that consistent tension.

Bobbin Work Techniques

Ready to transform your sewing from basic to brilliant?

With bobbin work techniques, you’ll discover creative possibilities.

that’ll make your projects pop and your fellow crafters wonder how you did it.

Bobbin Work for Machine Stitching and Embroidery

Ready to discover creative sewing magic? Bobbin work lets you flip the script on traditional stitching. By using decorative threads in your bobbin, you’ll transform fabric from the back side, creating eye-catching textures and designs.

To achieve this, make sure to choose the right bobbin size and type compatible bobbin cases for your machine model:

- Select unique, eye-catching threads

- Position your fabric strategically

- Adjust machine settings carefully

- Experiment with stunning patterns

Brave sewists know: true artistry happens when you’re willing to play!

Free Motion Bobbin Work

Discover your sewing machine’s creative potential with free motion bobbin work!

By disengaging feed dogs, you’ll gain full fabric control.

Trace bold designs on the back, choose bright bobbin threads for visibility, and stitch slowly.

Master this technique by practicing consistent stitch density and experimenting with different fabric choices.

Pro tip: Keep your movements smooth and your tension balanced for stunning, personalized results that showcase your unique style.

Bobbin Work for Quilting and Embroidery

Your quilting and embroidery journey gets a creative boost with bobbin work, transforming ordinary projects into extraordinary masterpieces.

Master this technique by diving into these essential steps:

- Trace intricate designs onto fabric’s interfacing

- Disengage feed dogs for seamless free-motion quilting

- Stitch slowly, following your carefully planned pattern

- Secure thread ends by bringing them to the project’s back

This magical technique breathes life into machine quilting and hand embroidery, letting you explore new dimensions of textile artistry with precision and imagination.

Using Different Threads and Materials

Discover your inner artist with bobbin thread magic!

Experiment with metallic, variegated, and textured threads to transform ordinary stitching into extraordinary designs.

Match thread weight to your bobbin case for smooth sailing.

Test different fabrics – from whisper-soft silks to rugged denims – and watch how specialty threads dance across your project.

Tension is key, so wind carefully and let your creativity flow.

Bobbin Maintenance and Care

Your sewing machine’s bobbins need regular TLC to keep your stitches smooth and your projects looking professional.

By learning a few simple maintenance tricks, you’ll help your bobbin stay in top shape.

and prevent those frustrating sewing machine hiccups that can turn a fun project into a fabric nightmare. Bobbin maintenance is key.

Cleaning and Maintaining Bobbins

After perfecting bobbin work techniques, keeping your bobbins pristine is key.

Regular bobbin cleaning prevents thread jams and promotes smooth stitching.

For best results, clean the bobbin case every 1-3 months or after 10-15 projects.

Grab a small brush to sweep away lint from your bobbin case, and consider a drop of light oil for metal bobbins.

Store them in a cool, dry spot to maintain their precision and extend their life.

Replacing Bobbins

A sewist’s bobbin is their trusty sidekick, and knowing when to swap it out can save your project from disaster. Replacing bobbins isn’t just maintenance—it’s an art form that keeps your machine humming smoothly.

- Catch wear before it catches you off guard

- Protect your precious sewing investments

- Become a bobbin replacement pro

Check your machine’s manual for the perfect bobbin match. Look for telltale wear signs like cracks or rough edges. Keep spare bobbins handy to keep your creative momentum rolling without interruption.

Storing Bobbins

Now that you’ve learned about replacing bobbins, let’s tackle their storage.

Keeping these tiny thread-holders in top shape means finding the right home.

Bobbin storage containers are your best friend – they protect from dust and keep things organized.

Choose from specialized boxes, magnetic strips, or thread racks that match your sewing style.

Pro tip: Label your containers by thread color or type. This saves time and prevents mix-ups.

Your bobbins will thank you, and your sewing projects will run smoother than a well-oiled machine.

Tips for Prolonging Bobbin Life

Want your sewing machine’s bobbins to last longer?

Keep them clean, test tension regularly, and use compatible thread.

Store them in a cool, dry spot away from moisture.

Watch for wear signs like fraying or uneven winding.

Replace bobbins when they start showing their age to keep your stitching smooth.

Frequently Asked Questions (FAQs)

How does a sewing machine bobbin work?

Inside your sewing machine, the bobbin holds the bottom thread.

It’s tucked beneath the needle, spinning and looping to create each perfect stitch you sew.

The bottom thread dances with the needle’s top thread.

What is a sewing bobbin?

Like a medieval scroll tucked away in a craft arsenal, a bobbin’s your sewing machine’s secret weapon.

a tiny spool holding bottom thread

that dances with the top thread to create perfect, interlocking stitches.

What is a bobbin and how does it work in sewing?

A bobbin is your sewing machine’s secret thread hero.

It’s a tiny spool nestled beneath the needle that holds the bottom thread.

It helps create perfect stitches by interlocking with the top thread.

How do you put a bobbin in a sewing machine?

Struggling to load your bobbin?

First, open the machine’s compartment.

Place the bobbin in the case with thread unwinding clockwise.

Gently pull the thread through the tension guide to secure it properly.

Does a sewing machine need a bobbin?

You’ll definitely need a bobbin in your sewing machine.

Without it, your machine can’t create stitches,

as the bobbin provides the essential bottom thread that interlocks with the top thread to form a complete stitch.

Why are sewing machine bobbins so popular?

With 90% of sewists loving bobbins for their versatility, you’ll find these tiny spools are your secret weapon.

They’re compact, customizable, and critical for creating flawless stitches.

in everything from quilts to couture.

How does a sewing machine grab the bobbin thread?

A shuttle hook rotates around the bobbin, catching the needle’s thread loop and pulling it through to create an interlocking stitch underneath your fabric, seamlessly connecting top and bottom threads.

How does a sewing machine work step by step?

A sewing machine transforms fabric into stitches through a synchronized dance of motor, needle, and bobbin.

Electric power drives rhythmic movements, threading top and bottom threads into perfect, interlocking connections.

That creates seamless garment construction.

Is the bobbin supposed to spin?

No, the bobbin shouldn’t spin constantly.

In most sewing machines, it moves smoothly and steadily within the bobbin case, creating tension as the upper thread interlocks during stitching.

Smooth movement guarantees consistent stitch quality.

Does the bottom bobbin go through the needle?

The bobbin doesn’t pass through the needle.

Instead, it sits in a case below the needle, releasing thread.

That thread intertwines with the top thread to create a locked stitch as the needle moves up and down.

Conclusion

Understanding how a sewing machine bobbin works isn’t rocket science—it’s about mastering the details.

You’ll become a pro by practicing proper threading, maintaining consistent tension, and keeping your bobbins clean.

Whether you’re a beginner or seasoned sewer, knowing the ins and outs of how a sewing machine bobbin works will elevate your craft. sewing machine bobbin

Remember, every stitch tells a story, and your bobbin’s the unsung hero making that narrative possible. bobbin’s the unsung hero