This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Regular maintenance prevents costly breakdowns, maintains consistent stitch quality, and extends your machine’s lifespan substantially.

You’ll avoid the frustration of skipped stitches, thread breaks, and timing issues that plague neglected machines.

Simple tasks like removing lint, oiling moving parts, and changing needles make the difference between a machine that hums along smoothly and one that fights you every step of the way.

Think of maintenance as insurance for your creativity—a small time investment that pays dividends in reliable performance and professional-quality results.

Table Of Contents

- Key Takeaways

- Why is Maintenance Important for Your Sewing Equipment?

- Benefits of Regular Maintenance and Care

- Essential Tools for Sewing Equipment Maintenance

- How Often Should You Clean and Maintain Your Sewing Machine?

- Step-by-Step Guide to Cleaning Your Sewing Machine

- The Importance of Needles in Sewing Machine Maintenance

- What is a Sewing Machine Service and How Often Should You Get One?

- Tips for Making Your Sewing Machine Last

- The Importance of Proper Sewing Equipment Maintenance

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- You’ll protect your investment – Regular maintenance extends your machine’s lifespan by up to 50% and prevents costly breakdowns that can cost hundreds to repair.

- You’ll maintain professional stitch quality – Clean machines with proper lubrication deliver consistent, even stitches, while neglected equipment produces skipped stitches and thread breaks.

- You’ll save money on repairs – Simple daily cleaning and oiling every 8-10 hours prevents expensive mechanical failures and keeps your machine running smoothly.

- You’ll reduce frustration and downtime – Well-maintained machines work reliably when you need them, eliminating project delays caused by mechanical problems and poor performance.

Why is Maintenance Important for Your Sewing Equipment?

Your sewing machine is more than just a tool—it’s your creative partner that deserves proper care.

Your sewing machine deserves the same love you put into every stitch.

Think of sewing machine maintenance as preventive medicine** for your equipment.

Without regular attention, lint accumulates in critical areas, oil dries up, and precision parts begin to wear down.

Proper sewing equipment care directly impacts your User Experience and Sewing Efficiency.

A well-maintained machine delivers Stitch Consistency project after project, while neglected equipment produces uneven stitches and frequent thread breaks.

Following a maintenance schedule isn’t just about Equipment Safety—it’s about protecting your investment and ensuring Machine Longevity.

Regular sewing machine maintenance prevents costly repairs and keeps your machine running smoothly for years.

When you clean lint from the bobbin area and oil moving parts, you’re investing in sewing machine reliability.

This proactive approach saves time, reduces frustration, and maintains the precision your projects demand.

Your machine works harder when it’s properly maintained.

Benefits of Regular Maintenance and Care

Taking care of your sewing machine isn’t just a nice-to-have task—it’s essential for keeping your projects looking professional and your equipment running smoothly.

Regular maintenance delivers three major benefits that directly impact your sewing experience and wallet.

Protecting Your Investment

Your sewing machine represents a significant financial investment that deserves proper protection through consistent equipment care.

Regular sewing machine maintenance prevents costly repairs and guarantees your machine retains its value over time. Investment safety starts with simple daily cleaning routines that preserve internal mechanisms.

Proper maintenance also involves using the right sewing machine oil to lubricate moving parts.

- Machine longevity increases dramatically when you follow manufacturer-recommended maintenance schedules

- Asset protection requires consistent upkeep including regular oiling and lint removal from critical components

- Sewing durability depends on preventive care rather than waiting for problems to develop into expensive repairs

Maintaining Stitch Quality

Perfect stitches aren’t luck—they’re the reward of consistent maintenance. When you neglect your machine, you’ll notice skipped stitches, uneven tension, and poor thread quality ruining your projects.

Tension Control requires clean tension discs free of lint buildup. Thread Quality depends on proper needle maintenance—change needles every 8-10 hours to prevent breaks. Regular cleaning prevents fabric handling issues that cause irregular Stitch Length.

Proper maintenance also involves using the right thread quality matters to guarantee smooth operation. Needle Care and Fabric Selection work together when your machine runs smoothly.

Clean feed dogs grip fabric evenly, while proper lubrication guarantees consistent performance across different materials.

| Maintenance Impact | Stitch Result |

|---|---|

| Clean tension discs | Balanced stitches |

| Fresh needles | No thread breaks |

| Lint-free feed dogs | Even stitch length |

| Proper lubrication | Smooth fabric feed |

| Regular cleaning | Professional finish |

Extending The Lifespan of Your Machine

Proper sewing machine care dramatically extends Machine Longevity, with manufacturer studies showing well-maintained units lasting 50% longer than neglected ones.

Regular Cleaning removes debris that causes premature wear, while Oil Maintenance reduces friction between moving parts.

You’ll also need timely Part Replacement of worn components. This thorough sewing machine upkeep approach maximizes your investment’s lifespan.

Essential Tools for Sewing Equipment Maintenance

Having the right tools transforms maintenance from a chore into a simple routine that keeps your machine running smoothly.

You’ll need specific items like lint brushes, screwdrivers, and quality oil to properly care for your sewing equipment and prevent costly repairs.

Prym Machine Oil 20ml Lubricant

With precision oiling, your machine transforms from a temperamental workhorse into a reliable companion. Prym Machine Oil 20ml Lubricant delivers exceptional oil benefits through its resin and acid-free formula, ensuring peak sewing performance without residue buildup.

This specialized sewing machine oil provides superior lubrication tips for equipment longevity. The precision spray nozzle makes sewing machine lubrication effortless, targeting specific oiling sewing parts without mess.

Regular machine care with this lubricant maintains smooth operation and extends your investment’s lifespan through proper sewing machine maintenance and dedicated sewing machine care, ensuring the longevity of your machine as a valuable investment.

Klein Tools 6-in-1 Stubby Screwdriver

While quality oil keeps your machine running smoothly, you’ll need the right screwdriver for proper maintenance access.

Klein Tools’ 6-in-1 Stubby Screwdriver transforms into whatever you need for sewing machine care. Its interchangeable shaft handles Phillips and slotted screws plus two nut driver sizes – perfect for opening machine casings and removing panels.

The cushion-grip handle gives you control in tight spaces around your machine’s components. This multi tool eliminates fumbling through drawers searching for the right size when you’re focused on screw removal during routine upkeep.

Here’s what makes this hand tool indispensable for sewing equipment upkeep:

- Compact design fits easily in your sewing kit without taking up valuable space

- Multiple tip options handle various fastener types found in sewing machines

- Enhanced grip provides better torque for stubborn screws during tool maintenance

- Durable construction withstands regular use in your sewing machine maintenance routine

This sewing machine screwdriver becomes your go-to companion for accessing internal components safely and efficiently.

White Chenille Stems 350-Pack

While screwdrivers handle mechanical adjustments, White Chenille Stems 350-Pack serves a different purpose in your sewing machine maintenance toolkit.

These flexible craft supplies aren’t just for DIY projects—they’re perfect for detailed sewing equipment upkeep. You’ll find their 6mm x 12" dimensions ideal for reaching tight spaces during regular cleaning routines.

Bend these stems into custom shapes to clean intricate areas where lint brushes can’t reach. Their soft texture won’t scratch delicate machine components, making them excellent for sewing tool care.

Thread one through needle holes or around tension discs to remove stubborn debris. Creative applications extend beyond basic maintenance.

Use them to organize small screws during disassembly or mark threading paths for complex machines. The white color helps you spot dirt and oil residue easily.

For thorough sewing machine care tips, keep several stems handy. They’re particularly useful for chenille care around bobbin cases and feed dogs, ensuring your equipment stays in peak condition.

Singer Angled Edge Lint Brush

When you’re ready to tackle sewing machine maintenance, the Singer Angled Edge Lint Brush becomes your secret weapon against stubborn debris.

This specialized tool features high-quality nylon bristles and a uniquely angled edge that reaches tight corners other brushes can’t access.

Here’s why this brush transforms your lint removal routine:

- Reaches impossible spaces – Gets into bobbin areas and feed dog crevices effortlessly

- Gentle yet effective – Won’t damage delicate machine components during cleaning

- Saves repair costs – Prevents lint buildup that causes expensive mechanical problems

- Improves stitch quality – Clean machines produce consistently even stitches

- Extends machine life – Regular brush maintenance prevents premature wear

The angled design makes sewing machine cleaning more thorough than standard brushes.

You’ll find it essential for proper lint removal and ongoing sewing machine upkeep.

Tool storage is simple – most machines include a compartment for brush maintenance supplies.

Zoom Spout Sewing Machine Oiler

The Zoom Spout Sewing Machine Oiler delivers professional-grade lubrication with its durable stainless steel construction and non-gumming formula.

You’ll appreciate how its precision nozzle reaches tight spaces for accurate oil application without waste or mess.

This tool makes sewing machine oiling effortless, ensuring proper machine lubrication every time.

The oiler works with various lubricant types and maintains consistent flow control for effective sewing machine care.

Regular use prevents friction and wear, making it essential for thorough sewing machine upkeep.

Its reliable design supports consistent sewing machine cleaning routines and long-term sewing machine maintenance schedules.

Microtex Sharp Needles Size 90/14

Your sewing machine needles work harder than you might think.

When they’re dull or wrong for your fabric, they create more problems than solutions.

Microtex Sharp Needles Size 90/14 solve this challenge with their ultra-fine points that pierce tightly woven fabrics without causing snags or pulls.

These needles excel at sewing machine maintenance by preventing thread tension issues and maintaining consistent stitch quality.

Their sharp design reduces friction, which means less stress on your machine’s internal parts.

You’ll notice fewer skipped stitches and cleaner thread lines.

Proper needle selection matters for sewing machine upkeep.

Size 90/14 handles medium-weight materials perfectly, from cotton to silk.

Replace them every 8-10 hours of sewing for ideal needle care.

When your fabric choice demands precision, these needles deliver.

Smart needle replacement keeps your sewing machine needles working smoothly, protecting your investment in quality sewing machine needle care.

How Often Should You Clean and Maintain Your Sewing Machine?

Consistency is the cornerstone of sewing machine maintenance success. Your cleaning schedule depends entirely on how often you use your machine and what materials you work with.

Daily Cleaning should happen after heavy use sessions, while Machine Inspection can catch problems early. Here’s your maintenance roadmap:

- Heavy users (2-3 hours daily): Clean weekly, oil every 8-10 hours

- Regular sewers (5-8 hours weekly): Monthly cleaning with Thread Management checks

- Occasional crafters: Clean every 6 months or after major projects

- Professional settings: Follow strict schedules regardless of visible issues

Bobbin Care requires attention every 2-3 bobbin changes to prevent lint buildup. Oil Change frequency varies by model—consult your manual for specifics. Most machines need sewing machine oil every 8-18 hours of active use.

Regular cleaning prevents costly repairs and maintains sewing machine upkeep standards that protect your investment for decades. Regular maintenance also involves checking for sewing machine issues to guarantee peak performance.

Step-by-Step Guide to Cleaning Your Sewing Machine

Cleaning your sewing machine properly guarantees it runs smoothly and produces quality stitches every time you sew.

Following these two essential steps will keep your machine in excellent working condition and prevent costly repairs down the road, ensuring you can sew with quality results every time.

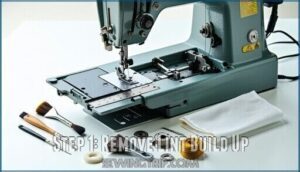

Step 1: Remove Lint Build Up

Before lint becomes your machine’s worst enemy, start with proper preparation. First, unplug your machine for safety. Remove the needle and presser foot to access tight spaces. Open the bobbin case with a small screwdriver for thorough cleaning.

| Area | Tool | Technique |

|---|---|---|

| Bobbin case | Lint brush | Gentle circular motions |

| Feed dogs | Small brush | Light brushing strokes |

| Thread path | Tweezers | Careful extraction |

| Tension discs | Soft cloth | Gentle wiping |

| Hook race | Lint brush | Detailed cleaning |

Focus your lint removal efforts on the bobbin area where debris accumulates most. Use your lint brush to clear thread bits from feed dogs and tension mechanisms. This sewing machine cleaning routine prevents jamming and maintains smooth operation for your sewing machine upkeep. Regular maintenance involves checking for sewing machine cleaner products to guarantee superior performance.

Step 2: Oiling

Every sewing machine requires proper lubrication to maintain peak performance and prevent costly breakdowns.

The right oil types and lubrication tips will keep your machine running smoothly for years.

Proper oiling techniques promote friction reduction and maximum machine performance:

- Apply high-quality sewing machine oil – Use only clear, fine oil specifically designed for sewing machines.

- Follow your machine’s oiling schedule – Most machines need sewing machine lubrication every 8-10 hours of use.

- Wipe excess oil immediately – Remove any surplus oil with a soft cloth to prevent fabric stains and mechanical issues during your next project.

Machine oiling isn’t just maintenance—it’s protecting your investment.

Regular oil application keeps internal parts moving freely, reducing wear and extending your machine’s lifespan substantially.

Understanding the sewing machine oiling process is vital for maintaining your equipment.

The Importance of Needles in Sewing Machine Maintenance

Your sewing machine’s needles deserve attention beyond their humble appearance.

These tiny workhorses directly impact every stitch you create, making needle care essential for superior machine performance.

When you neglect needle replacement, you’re inviting trouble—skipped stitches, fabric puckering, and poor stitch quality become unwelcome guests in your sewing room.

Smart needle selection matches your project’s demands.

Universal needles work for most fabrics, while ballpoint needles prevent runs in knits.

Sharp needles slice through woven fabrics cleanly, creating professional results.

Change needles every 8-10 hours of sewing or after completing major projects.

A dull needle can strain your machine’s motor and disrupt thread tension, causing inconsistent stitches.

A bent or damaged needle can throw off your machine’s timing entirely.

Quality sewing machine needles paired with proper thread create the foundation for excellent sewing machine maintenance.

When needle and thread quality work together, your machine runs smoothly, producing consistent, beautiful stitches that showcase your craftsmanship.

What is a Sewing Machine Service and How Often Should You Get One?

Professional sewing machine service involves a trained technician thoroughly inspecting, cleaning, and adjusting your machine’s internal mechanisms beyond what you can do at home.

While you can handle basic cleaning and oiling yourself, professional servicing guarantees your machine receives expert attention for peak performance and longevity.

What is a Sewing Machine Service?

Professional sewing machine servicing transforms your trusty stitching companion into a precision powerhouse. A qualified service technician performs thorough machine inspection, removing years of hidden lint and grime from internal components.

Professional service transforms your machine from tired workhorse to precision powerhouse.

This thorough equipment upkeep involves cleaning, lubricating, and calibrating timing mechanisms that you can’t reach during regular maintenance. Professional sewing machine repair addresses underlying issues before they become costly problems.

Consider these compelling reasons for professional sewing machine servicing:

- Peace of Mind: Expert technicians catch potential failures before your machine breaks mid-project

- Enhanced Performance: Your machine will run smoother and quieter than it has in years

- Cost Savings: Preventive maintenance costs far less than emergency sewing machine repair bills

- Professional Results: Properly calibrated tension and timing deliver consistently perfect stitches

Service scheduling guarantees your machine receives attention from specialists who understand its intricate mechanisms. Maintenance costs typically range from $75-$100, making professional sewing machine upkeep an affordable investment in your creative journey.

Regular machine servicing is vital to extend the lifespan of your sewing equipment and prevent unexpected breakdowns.

Frequency of Sewing Machine Servicing

Your sewing machine’s servicing frequency depends heavily on how much you use it.

Heavy users need annual professional maintenance, while occasional sewers can stretch it to every two years.

Servicing schedules follow simple math: machines running daily require yearly attention, but weekend warriors can wait longer.

Machine longevity improves dramatically with consistent maintenance intervals.

Professional servicing catches problems before they become expensive repairs.

Your sewing frequency determines the timeline—eight hours of weekly use means annual service, while monthly projects allow biennial visits.

Don’t skip scheduled maintenance; it’s cheaper than replacing worn parts later, as this can lead to more expensive repairs and affect machine longevity, emphasizing the importance of annual professional maintenance.

Where to Get a Sewing Machine Serviced and Cost

Once you know how often to schedule sewing machine servicing, finding the right spot is key.

Authorized Dealers and local Service Centers offer certified technicians and protect Warranty Options. Many Repair Shops and fabric stores provide professional servicing for various brands.

Expect a typical sewing machine maintenance cost between $75 and $130 in the U.S., depending on machine type and location.

Investing in regular sewing machine repair keeps your creativity flowing and your equipment reliable for years. Regular machine service checks are essential to extend the lifespan of your sewing machine.

Tips for Making Your Sewing Machine Last

How can you transform your sewing machine into a reliable companion that stands the test of time? Smart sewing machine maintenance isn’t just about fixing problems—it’s about preventing them entirely.

Machine longevity starts with these simple sewing hacks:

- Change needles every 8-10 hours of sewing to prevent fabric damage and maintain perfect stitches

- Use quality thread that matches your fabric type—cheap thread creates lint buildup and tension problems

- Apply oil regularly following your manual’s schedule to keep internal parts moving smoothly

Proper thread management and fabric care work hand-in-hand with regular oil application. Your sewing machine upkeep routine should include cleaning after each project and checking tension settings.

These sewing machine care habits prevent costly repairs and guarantee your equipment delivers professional results project after project. Consistent sewing machine servicing keeps everything running like clockwork. Regular maintenance schedules, including tasks like daily cleaning routines, are vital for extending the lifespan of your sewing machine.

The Importance of Proper Sewing Equipment Maintenance

Every piece of equipment benefits from consistent care, and sewing machines are no exception. When you prioritize sewing machine maintenance, you’re investing in machine longevity and sewing efficiency. Regular cleaning prevents lint buildup that causes 30% more breakdowns in neglected machines.

Equipment care directly impacts your results. Well-maintained machines deliver consistent stitches, while dirty mechanisms create tension problems and thread quality issues. You’ll also guarantee user safety by preventing mechanical failures that could cause injury.

| Maintenance Task | Frequency |

|---|---|

| Lint removal | Every 2-4 bobbin changes |

| Oil application | Every 8-10 hours of use |

| Professional service | Annually |

Your sewing equipment upkeep routine should include brushing out the bobbin case and oiling designated points. This regular cleaning keeps your machine running smoothly for years. Think of maintenance as insurance – a small time investment that protects your sewing machine reliability and prevents costly repairs down the road. Proper sewing machine maintenance is essential to extend the life of your equipment and guarantee peak performance.

Frequently Asked Questions (FAQs)

Do sewing machines need maintenance?

Yes, sewing machines absolutely need regular maintenance. You’ll prevent costly breakdowns, improve stitch quality, and extend your machine’s lifespan by up to 50% with proper care and cleaning.

Why should you keep your sewing machine clean and maintained?

Regular maintenance extends your sewing machine’s lifespan by up to 50%.

You’ll prevent costly breakdowns, maintain professional stitch quality, and protect your investment.

By removing lint buildup that causes premature wear and threading issues, you’ll ensure your machine continues to function properly, maintaining professional stitch quality.

What are the steps to maintain a sewing machine after each use?

After each sewing session, unplug your machine and remove the needle.

Use a lint brush to clear debris from the bobbin area and feed dogs.

Wipe down surfaces with a soft cloth, then cover the machine for protection.

How do you maintain a sewing machine?

Start by unplugging your machine and removing the needle and presser foot. Clean lint from the bobbin area using a brush, then oil designated points according to your manual.

Why should you service your sewing machine?

Regular servicing prevents breakdowns, maintains professional stitch quality, and extends your machine’s lifespan by up to 50%. It protects your investment while reducing repair costs.

Is sewing machine maintenance better than servicing a car?

Comparing maintenance isn’t apples-to-apples—your sewing machine needs gentler care than your car’s heavy-duty engine.

Both require regular attention, but sewing machine maintenance is simpler, cheaper, and you’ll handle most tasks yourself, making it a more personal process.

What is the importance of sewing machine maintenance?

Machine care prevents costly breakdowns, extends lifespan by 50%, and maintains professional stitch quality. You’ll save money avoiding major repairs while protecting your investment through simple cleaning and oiling routines.

How important is the maintenance of equipment?

Equipment maintenance isn’t just important—it’s absolutely critical for your sewing success.

Without regular care, your machine becomes a lint-filled disaster that’ll ruin projects, break down constantly, and cost you serious money in repairs.

Is it worth servicing a sewing machine?

Absolutely, it’s worth servicing your sewing machine. Regular maintenance extends machine lifespan by up to 50% and reduces breakdowns by 30%. Professional tune-ups prevent costly repairs and maintain stitch quality.

What are five important points on caring for a sewing machine?

Clean your machine after every project,

oil moving parts every 8-10 hours of use,

change needles regularly.

Store it covered in dry conditions.

Follow your manual’s specific maintenance schedule for peak performance.

Conclusion

Neglecting your sewing equipment is like skipping car maintenance—eventually, things will break down at the worst possible moment.

Understanding how important maintenance of your sewing equipment transforms your crafting experience from frustrating battles to smooth sailing.

Regular care prevents costly repairs, guarantees consistent results, and keeps your creative projects on track.

You’ll spend more time creating and less time troubleshooting when you prioritize proper maintenance habits for your valuable sewing tools, ensuring a more enjoyable and consistent experience.

- https://www.youtube.com/watch?v=czZVNkrT1j0

- http://www.schmetzneedles.com/

- https://thegnomestudio.com/keep-your-stitches-smooth-essential-sewing-machine-maintenance-tips/

- https://www.sewessential.co.uk/blog/how-to-fix-sewing-machine-stitch-quality-problems/

- https://www.reddit.com/r/sewhelp/comments/13lciup/what_are_factors_that_affect_stitch_quality/