This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your fabric scissors just snagged on what should’ve been a smooth cut through silk, leaving a jagged edge instead of the clean line you expected. That telltale resistance? It’s not the fabric—it’s the invisible layer of lint, adhesive residue, and microscopic fibers coating your blades.

Most sewers don’t realize that even premium shears lose up to 40% of their cutting efficiency after just three months of regular use without cleaning. The culprit isn’t dullness; it’s buildup creating friction that drags against delicate materials and throws off your precision.

Learning how to clean fabric scissors properly takes less than ten minutes but transforms how your tools perform, protecting both your investment and the quality of every project you touch.

Table Of Contents

- Key Takeaways

- Why Clean Fabric Scissors Regularly?

- Supplies Needed for Cleaning Fabric Scissors

- Step-by-Step Guide to Cleaning Fabric Scissors

- How to Remove Sticky Residue and Rust

- Proper Lubrication and Reassembly Tips

- Safe Storage and Handling of Fabric Scissors

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Regular cleaning every few weeks removes lint, adhesive residue, and microscopic fibers that can reduce your scissors’ cutting efficiency by up to 40% within just three months of use.

- Most buildup problems can be solved with household items like mild dish soap, 70% isopropyl alcohol for sticky residue, and white vinegar for rust, followed by thorough drying and a single drop of light machine oil at the pivot joint.

- Proper storage in dry, climate-controlled spaces with blade guards or sheaths prevents moisture damage, rust formation, and accidental nicks that compromise cutting precision far more than normal use.

- You’ll need to sharpen fabric scissors every 6-12 months with moderate use, but keeping blades clean between sharpenings extends their lifespan dramatically and maintains the precision cuts essential for quality sewing projects.

Why Clean Fabric Scissors Regularly?

You might think fabric scissors only need a quick wipe now and then, but lint and residue build up faster than you’d expect. Left unchecked, that buildup affects everything from your cutting precision to the lifespan of your blades.

Regular cleaning also protects the unique design features that make fabric scissors different from regular scissors, ensuring those precision-ground blades stay true to their purpose.

Let’s look at exactly why regular cleaning matters for your fabric scissors.

Clean blades help you get the precise, professional cuts needed for advanced sewing techniques like appliqué and piecing.

Effects of Dirt and Residue on Scissors

Neglect takes a toll fast. Hair, lint, and sticky residue wedged between your blades slow cutting efficiency and force you to use more muscle with every snip. That friction doesn’t just tire your hand—it causes blade damage by scratching steel surfaces and accelerating metal corrosion.

If you notice sluggish performance or uneven cuts, check out this guide on troubleshooting sewing machine thread cutters to restore precision and extend blade life.

Over time, debris trapped near the pivot invites rust formation, turns smooth scissor maintenance into a battle, and dulls those once-sharp blades you rely on. Regular scissor maintenance checks can help prevent these issues and keep your scissors in good condition.

Benefits of Regular Cleaning for Fabric Projects

Clean blades transform your sewing workflow. Regular cleaning scissors routines boost cutting efficiency by reducing drag, so you’ll glide through pattern pieces with less effort. Precision cutting improves too—debris-free fabric scissors deliver cleaner edges that match seams perfectly and minimize fraying.

You’ll also support fabric hygiene by removing fiber buildup that harbors bacteria. This simple tool maintenance habit extends scissor longevity, keeping your shears performing consistently across years of projects.

Preventing Rust and Corrosion

Beyond keeping blades sharp, regular scissor maintenance shields your tools from moisture damage. Rust prevention begins with simple habits: wipe fabric fibers away after each session, because trapped debris holds humidity against steel and accelerates corrosion control failures.

Storing your tools in a dry case and applying protective oil—especially important for premium sewing scissors—creates a barrier that stops oxidation before it starts.

Four metal protection essentials include:

- Apply light machine oil to the pivot monthly

- Store scissors in dry locations away from steam

- Use silica gel packets in storage cases

- Dry blades immediately after any wet cleaning.

Proper scissor care tips are also essential for extending the life of your scissors.

Supplies Needed for Cleaning Fabric Scissors

You don’t need a lot of fancy products to keep your fabric scissors in tip-top shape. Most of what you need is probably already sitting in your kitchen or bathroom cabinet.

Let’s walk through the essential supplies that’ll help you clean, protect, and maintain those blades properly.

Safe Cleaning Agents and Solvents

You’ll want gentle cleansers that won’t harm your blades or fabric. A mild pH-neutral dish soap manages everyday cleaning scissors tasks beautifully.

For sticky adhesive messes, 70 percent isopropyl alcohol removes residue without promoting rust. White vinegar manages corrosion for rust prevention.

Keeping your fabric scissors for dressmaking clean with these solutions helps maintain their sharpness and prevents fabric snags during precision work.

Skip harsh alkalies like ammonia—they’re overkill for scissor maintenance and can damage finishes. These cleaning solutions keep your sharp blades in tip-top shape while protecting your investment.

Essential Tools for Cleaning and Maintenance

Gathering the right equipment makes scissor maintenance straightforward and effective. You’ll need lint-free microfiber cloths for wiping blades without scratching, plus cotton swabs to reach tight pivot areas where residue hides. Small brushes dislodge compacted fibers before cleaning. Keep appropriately sized screwdrivers handy for tension adjustments. A quality sharpening stone restores cutting edges when routine cleaning isn’t enough to maintain performance.

Choosing The Right Oil for Lubrication

For ideal pivot care and blade protection, select light sewing machine oil or specialized scissor oil—both guarantee smooth lubrication without attracting lint. Avoid heavy oils that trap dust and compromise scissor maintenance.

- Light machine oil penetrates pivots cleanly, preventing sticking blades

- Wax-based scissor lubricants wash away debris while coating hinges

- Food-grade mineral oil works when blades might contact edibles

Skip coconut oil—it’s too thick for precision sharpening and cleaning needs.

Step-by-Step Guide to Cleaning Fabric Scissors

Now that you’ve gathered your supplies, it’s time to get those fabric scissors back in tip-top shape. The cleaning process isn’t complicated, but following the right sequence matters—you’ll want to work from dry debris removal to wet cleaning, then finish with thorough drying.

Let’s walk through each step so your scissors cut cleanly for years to come.

Removing Lint and Loose Threads

Before you tackle any wet cleaning or soapy water, start with the dry essentials—lint removal and thread management are your first defense in fabric care. Open your fabric scissors wide and gently wipe the entire blade length with a soft, dry microfiber cloth. This fabric scissor maintenance routine clears accumulated fibers from cutting surfaces and the pivot area where lint loves to hide.

For stubborn buildup—especially after cutting fleece or flannel—use a small nylon brush to sweep debris from blade edges and recesses. This scissor care and handling step keeps your cutting action smooth and prevents that frustrating drag you feel when threads get trapped between blades. Make wiping part of your routine scissor maintenance tips, and you’ll notice cleaner cuts every time.

| Tool | Best For |

|---|---|

| Microfiber cloth | Daily fiber cleanup after each sewing session |

| Soft brush | Dislodging compacted lint from pivot joints |

| Cotton swab | Reaching tight spaces around the screw area |

Washing Blades With Soapy Water

Think of soapy water as the gentle workhorse in your scissor care and cleaning routine—it lifts oils and grime without harsh chemistry.

For effective blade cleaning techniques, follow these scissor maintenance tips:

- Mix warm water (around 30–40°C) with mild, pH-neutral dish soap to protect steel from corrosion

- Wipe blades with a damp cloth rather than submerging, keeping moisture away from the pivot

- Rinse thoroughly and dry immediately to prevent water spot formation and flash rust

Drying and Preventing Water Damage

After washing, you’re not done until every drop is gone—water damage prevention starts with thorough drying. Use a soft, clean cloth to wipe blades completely, paying special attention to the pivot joint where moisture hides and rust begins.

For rust protection and moisture control, open the scissors wide and dry behind the screw, then let them air-dry fully before storage or applying scissor oil.

How to Remove Sticky Residue and Rust

Sometimes fabric scissors pick up more than just lint—sticky tape residue, dried glue, or even rust spots can make your blades feel gummy and dull.

The good news is that you don’t need fancy products to tackle these stubborn problems. Here’s how to restore your scissors using simple household solutions that won’t damage the metal.

Using Isopropyl Alcohol for Adhesives

Sticky tape and glue can sabotage your fabric scissors faster than you’d expect. For adhesive removal, reach for 91 percent isopropyl alcohol—its solvent effectiveness dissolves pressure-sensitive residues that water can’t touch.

Apply it to a paper towel, wipe both blade surfaces thoroughly, and let the residue dissolution happen. This blade cleaning method works beautifully for cutting tool maintenance without damaging stainless steel, but remember alcohol safety: work in a ventilated space away from open flames.

Applying Vinegar or Specialized Rust Removers

When rust appears on your fabric scissors, white vinegar soaking offers a gentle acid treatment that won’t harm the blades. Submerge them in distilled white vinegar for 12 to 24 hours, then scrub lightly and rinse with soapy water. For blade restoration without harsh chemicals, try Evapo-Rust—a chelating rust remover that’s safe on skin and reusable. Both methods require thorough drying and immediate oiling afterward for proper rust prevention and blade maintenance.

- Soak rusty blades in white vinegar overnight to dissolve iron oxide buildup

- Use 5 percent acetic acid vinegar for standard rust; higher concentrations work faster

- Try commercial rust removers like Evapo-Rust for safer, fume-free blade restoration

- Rinse thoroughly after acid treatment to prevent flash rusting on bare metal

- Apply light oil immediately after drying to create a protective barrier for scissor care

Cleaning Techniques for Persistent Stains

Beyond vinegar and alcohol, certain stains demand specialized approaches. Blood or protein-based marks respond best to enzymatic cleaners—apply for 5 to 10 minutes, then blot.

For embedded grime in pivot points, ultrasonic cleaners combine detergent with cavitation bubbles for metal restoration without abrasive contact, ensuring blade sanitizing and stain removal that keeps your sharp scissors in tip-top shape.

| Stain Type | Treatment Method | Contact Time |

|---|---|---|

| Blood/protein residue | Enzymatic cleaner | 5–10 minutes |

| Embedded pivot grime | Ultrasonic detergent bath | Full cycle |

| Localized rust spots | Fine steel wool + mineral oil | As needed |

Proper Lubrication and Reassembly Tips

After cleaning your fabric scissors, the final step is putting everything back together so they work like new. A little oil goes a long way in keeping the blades moving smoothly, and checking the alignment ensures clean cuts every time.

Here’s how to finish the job right.

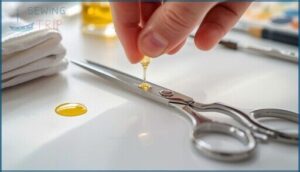

Oiling The Pivot Joint for Smooth Action

A thin film of light scissor oil at the pivot joint reduces friction and keeps your blades gliding effortlessly.

Open your scissors fully and place a single drop of sewing machine oil directly on the pivot point between the blades. Work it in by opening and closing several times, then wipe away excess—this simple pivot joint care step prevents stiffness and preserves smooth action.

Tightening Screws and Checking Alignment

After oiling, check your pivot screw adjustment using the simple drop test: open blades to 90 degrees and release. One blade should stop about two-thirds closed. If it falls completely, tighten the screw in tiny 1/8-turn increments until tension feels right.

Close your scissors gently and watch for even blade alignment along the full length—gaps signal misalignment that needs professional attention for proper sewing scissor maintenance.

Safe Storage and Handling of Fabric Scissors

You’ve done the hard work of cleaning and maintaining your fabric scissors—now it’s time to make sure they stay in tip-top shape between uses.

How you store and handle your scissors directly impacts their longevity, sharpness, and safety. Let’s walk through the best practices to protect your investment and keep those blades ready for your next project.

Best Practices for Scissor Storage

Where you keep your scissors matters just as much as how you clean them. Proper Scissor Storage protects your investment and maintains cutting precision.

Follow these Dry Storage Tips for ideal Sewing Scissor Maintenance:

- Use Scissor Cases or sheaths to shield blades from nicks and scratches

- Store in climate-controlled rooms away from humid bathrooms or damp basements

- Organize with dedicated holders to prevent metal-on-metal contact with other tools

Secure Handling starts with smart Tool Organization and Storage.

Protecting Blades From Damage

Even gentle bumps can chip your sharp blades, so always use blade edge protection like felt sleeves or a protective case. Store scissors with blades closed to prevent contact damage, and wipe them dry after cleaning to stop metal corrosion prevention issues before they start.

Here’s your quick reference for sharpness maintenance:

| Protection Method | Purpose |

|---|---|

| Edge guards/sheaths | Shield from nicks |

| Blade closed storage | Prevent misalignment |

| Dry cloth wipe-down | Remove moisture |

| Cushioned transport case | Avoid drop damage |

| Light scissor oil application | Rust prevention barrier |

Proper scissor care means treating your blades like precision instruments—because that’s exactly what they are.

Safety Tips for Long-Term Care

Always wear Personal Protective Equipment when handling chemicals like solvents or rust removers, and guarantee proper Staff Training on Chemical Safety protocols before anyone approaches scissor care tasks.

Keep cutting tool safety top of mind: store sharp implements out of reach, maintain good Hand Tool Maintenance records, and post clear Injury Response procedures near your workspace.

Regular Tool Care and Maintenance sessions prevent accidents before they happen.

Frequently Asked Questions (FAQs)

How often should fabric scissors be sharpened?

Your fabric scissors need sharpening every 6 to 12 months with moderate use—sooner if you notice frayed edges or need extra force.

Heavy cutting demands sharpening every 3 to 6 months for peak cutting efficiency.

Can I use fabric scissors on paper?

You can, but it will dull your blades faster and risk fabric snags later.

Paper cuts reduce scissor durability and cutting efficiency, so keep dedicated paper scissors to preserve your fabric shears.

What causes scissor blades to become misaligned?

Your blades go out of whack when uneven blade wear, loose pivot screws, or cutting dense fabrics repeatedly shifts their alignment.

Improper lubrication creates uneven friction, while incorrect reassembly after cleaning compounds misaligned tips.

When should I replace fabric scissors completely?

Some people treat dull scissors like immortal pets—but metal fatigue wins eventually.

Replace fabric shears when rust removal fails, blade realignment proves impossible, or sewing scissors can’t hold an edge after professional sharpening.

Conclusion

A ten-minute cleaning routine can add years to your scissors’ lifespan—that’s the difference between replacing shears every season versus inheriting tools to your grandchildren. Now that you know how to clean fabric scissors properly, you’re protecting precision cuts and eliminating the frustration of dragged edges.

Treat your blades to monthly maintenance, store them carefully, and they’ll reward you with perfect performance through thousands of projects. Your fabrics deserve nothing less than spotless edges.

- https://proshearus.com/blogs/news/how-do-you-properly-clean-and-maintain-sewing-scissors

- https://www.wikihow.com/Clean-Adhesive-from-Scissors

- https://hanzo.com/how-to-clean-scissors-techniques-and-required-tools/

- https://www.jpscissors.com/blogs/hair-scissors/how-to-disinfect-sterilize-scissors

- https://454bags.com/blogs/bio-plastics/scissor-cleaning-maintenance