This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You line up your rotary cutter, press down with confidence, and watch in horror as your stretchy fabric shifts, bunches, and leaves you with a wavy mess instead of a straight edge. That frustration ends today.

Cutting stretchy fabric straight isn’t about wrestling the material into submission—it’s about understanding how these fabrics behave and working with their natural properties. The difference between a crooked cut and a clean line comes down to three things: the right tools, proper preparation, and a steady cutting technique.

Once you know how to stabilize the fabric, align your cuts with the grainline, and apply even pressure, you’ll transform those wobbly edges into precise cuts every single time.

Table Of Contents

- Key Takeaways

- Essential Tools for Cutting Stretchy Fabric

- Preparing Stretchy Fabric Before Cutting

- How to Mark Stretchy Fabric for Straight Cuts

- Step-by-Step Guide to Cutting Stretchy Fabric Straight

- Tips to Prevent Distortion and Uneven Edges

- Common Mistakes and Troubleshooting

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Cutting stretchy fabric straight requires three core elements: sharp tools (rotary cutters or micro-serrated scissors), proper stabilization (weights, spray adhesive, or interfacing), and alignment with the grainline to prevent distortion during and after cutting.

- Pre-washing eliminates 2-5% shrinkage in cotton-spandex blends, while steam ironing and laying fabric completely flat before cutting locks in stability and prevents the wavy edges that come from cutting warped material.

- Mark your cuts with washable soap slivers or chalk, secure the fabric with pattern weights rather than pins, and apply steady, controlled pressure without pulling or lifting the material as you cut along the grainline.

- Test your fabric’s stretch direction before cutting—two-way stretch moves crosswise with a stable lengthwise grain, while four-way stretch moves equally in all directions, requiring different pattern alignment strategies for proper drape and fit.

Essential Tools for Cutting Stretchy Fabric

The right tools make all the difference when you’re working with stretchy fabrics. Without them, you’ll fight distortion, jagged edges, and fabric that seems to have a mind of its own.

Let’s look at the essential cutting tools that’ll give you clean, straight edges every time.

Professional Heavy Duty Fabric Scissors

Sharp tools make all the difference when taming stretch fabrics. You’ll want fabric scissors with high-carbon steel blades—they slice cleanly through jersey and spandex without snagging or distortion. Look for ergonomic grips that won’t cramp your hand during long cutting sessions, and choose models with micro-serrated edges for enhanced fabric grip on slippery materials.

Proper scissor maintenance matters: clean your blades after each project and schedule regular blade sharpening to maintain cutting accuracy. With the right tools and sewing techniques, you’ll achieve professional results every time you tackle fabric preparation.

- High-carbon steel blades deliver ultra-sharp, clean cuts through multiple fabric layers without snagging or distorting stretch materials

- Ergonomic bent handle design reduces hand fatigue and allows smooth tabletop cutting for better accuracy on long cuts

- Excellent value at an affordable price point, plus includes a bonus measuring tape for added convenience

- Screw nut may rust over time and require frequent adjustments to maintain proper blade tension

- Large, heavy design might feel awkward or uncomfortable for users with smaller hands

- Durability concerns with limited long-term performance data, and the ultra-sharp blades require extra caution during handling

Rotary Cutters Vs. Scissors

While scissors offer precision on curves and intricate notches, rotary cutters deliver enhanced cutting accuracy on long, straight edges with stretch fabrics. Your choice affects fabric control and cutting speed. Rotary cutters need proper blade maintenance and a stable mat, plus careful safety precautions around exposed blades.

Consider these fabric cutting techniques:

- Rotary cutters excel on lightweight jersey and ponte knits with continuous, clean cuts

- Scissors provide better ergonomic design for thick layers and delicate curve work

- Both tools require sharp blades to prevent fraying and maintain cutting fabric precision

June Tailor Shape Cut Ruler Tool

Once you’ve chosen your rotary cutter, pairing it with the June Tailor Shape Cut Ruler boosts your cutting accuracy on stretch fabrics. This transparent plastic tool cuts strips from half an inch to twelve inches and manages squares, triangles, and chevrons when flipped.

You’ll appreciate its tool ergonomics during long projects, though it has a slight learning curve. For best results with fabric stabilization, lay it flat on your cutting mat and secure with weights before cutting.

Regular ruler maintenance keeps edges sharp and measurements precise on jersey and spandex.

- Cuts a wide range of shapes and strip widths from 1/2 inch to 12 inches, making it versatile for different quilting projects

- Allows you to cut multiple fabric layers at once, saving significant time on repetitive cuts

- Transparent design lets you see your fabric and alignment clearly while cutting

- Feels somewhat flimsy and can bend when lifting it off fabric, which may affect precision

- Takes some practice to get comfortable with the different measurement markings and flipping technique

- Limited to 12×12 size cuts, so you’ll need to fold larger fabric pieces first

Cutting Mats and Pattern Weights

Your rotary cutter works best when paired with the right cutting mat and pattern weights. Self-healing cutting mats range from quarter-inch to half-inch thickness, with thicker options offering better durability and precision. These cutting mat materials grip fabric while protecting your blade and cutting surface.

Pattern weights in dome, flat, or chain styles distribute 10 to 20 grams of pressure to prevent shifting without pins piercing your stretchy material.

Preparing Stretchy Fabric Before Cutting

You can’t cut stretchy fabric straight if it’s not prepped properly. The material needs to be stable, flat, and predictable before you make that first cut.

Here’s what you need to do before your scissors or rotary cutter touch the fabric.

Pre-washing and Drying for Shrinkage

Before you cut, always pre-wash your stretchy fabric to avoid surprises later. Fabric shrinkage can range from 2% to 5% in cotton-spandex blends, which throws off your entire project.

Use cold water and a gentle cycle for best stretch recovery, then air dry or tumble on low heat. This simple fabric preparation step lets your material relax and stabilize, giving you accurate cuts every time.

Ironing and Laying Fabric Flat

Heat makes all the difference in fabric stability. Steam ironing at high heat relaxes fibers in cotton-spandex blends, letting stretch fabrics lie flat before cutting. Here’s your approach to proper fabric preparation:

- Press for 5 to 8 seconds per area using a tailor’s cloth to prevent shine

- Focus on grain alignment as you work across the surface

- Let the material cool completely before layout—this locks in flatness and prevents distortion

Fabric relaxation through controlled heat settings gives you the control you need.

Identifying Grainline and Stretch Direction

Your fabric’s hidden structure guides every cut. Pull the material in different directions to detect where it stretches most—usually crosswise, perpendicular to the selvage edge. The grainline runs parallel to that stable selvage, giving you a reference line for accurate alignment.

Misaligned grain creates fabric distortion that no rotary cutter or cutting mat can fix later.

| Test Method | What You’re Finding |

|---|---|

| Pull lengthwise | Minimal stretch along grainline |

| Pull crosswise | Greatest stretch direction |

| Check selvage | Stable reference edge |

| Observe knit patterns | Visual grain indicators |

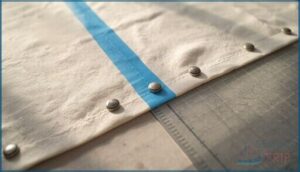

Stabilizing Techniques (Spray, Tape, Paper)

When stretch fabrics refuse to cooperate, fabric stabilizers become your secret weapon. These stiffening methods temporarily tame unruly material during cutting techniques, then wash away cleanly.

- Spray adhesives applied to the wrong side reduce movement without altering the weave—just let it dry completely first.

- Tape applications along cut lines keep edges aligned during fabric preparation.

- Paper backing underneath prevents shifting on your mat.

How to Mark Stretchy Fabric for Straight Cuts

Marking your fabric correctly is the foundation for getting a clean, straight cut. Without clear guidelines on the material, even the best tools won’t save you from crooked edges.

Here’s how to mark stretchy fabric so your cuts stay accurate from start to finish.

Using Rulers and Right Angle Tools

A transparent 90-degree right angle ruler is your best friend for cutting precision on stretch fabrics. Clear acrylic quilting rulers with grid lines let you see the fabric alignment beneath while marking. The June Tailor Shape Cut ruler offers angle guidance specifically for knits.

Pair sewing rulers with pattern weights for edge control along the grain line, and you’ll nail fabric alignment every time without distortion.

Marking With Soap Slivers or Chalk

When cutting techniques demand precision, you need fabric marking tools that won’t permanently commit to your stretch fabrics. Soap slivers and tailors chalk both create temporary marks you can brush or wash away easily.

Soap leaves thinner, more washable lines on jersey and knits, while chalk gives high-contrast visibility on dark fabrics. Choose based on your material—soap for stretchy surfaces, chalk for slippery ones near the fabric grainline.

Aligning Pattern Pieces Accurately

Once you’ve marked your lines, proper pattern placement keeps everything from warping out of shape. Grainline alignment determines how your finished piece drapes and fits, so you’ll want fabric orientation locked in from the start.

- Position your pattern’s grainline arrow parallel to the fabric’s lengthwise grain

- Secure pattern pieces with weights on your cutting mat to prevent shifting

- Match notches and markings for accurate seam matching later

- Align stretch direction with pattern arrows for precision cutting

Double-Checking Measurements

Before you make that first cut, run your measuring tape along the fabric at three separate points to catch any stretch or skew. Stretchy materials warp easily, so measuring tape checks at multiple spots reveal fabric variance you might miss with a single pass.

Compare those distances against your pattern’s marked dimensions, especially along the grainline and stretch direction, to confirm cutting precision before committing to the blade.

Step-by-Step Guide to Cutting Stretchy Fabric Straight

Now that you’ve marked your fabric, it’s time to actually make the cut. The steps below walk you through the entire process, from setting up your workspace to making that final slice.

Follow each one carefully, and you’ll end up with clean, straight edges every time.

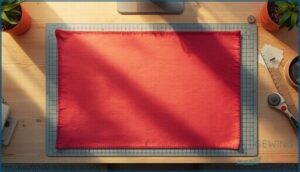

Placing Fabric on a Flat, Stable Surface

Your workspace sets the stage for success. Choose a clean, level table with enough room to spread your fabric without forcing it into tight corners. Surface preparation matters more than you might think—it prevents shifting and keeps your cuts true.

- Use a self-healing cutting mat with grid lines for alignment

- Position your fabric’s selvage parallel to the table edge

- Clear away clutter that could snag or distort the material

- Verify your cutting surface is dry and lint-free

- Check that your mat lies flat without bubbles or warping

A stable workspace gives you control from the start.

Securing Fabric With Weights or Tape

Once your fabric lies flat, lock it down. Pattern weights work wonders for fabric stabilization—most weigh between 0.5 and 2 ounces each, giving you steady weight distribution without shifting. Space them along pattern edges and at corners.

If you prefer tape application, use painter’s tape along straight-cut lines (not across grain) to prevent puckering while improving cutting accuracy and edge control.

| Method | Best For | Key Benefit |

|---|---|---|

| Pattern weights | Large fabric pieces | Even pressure, no residue |

| Painter’s tape | Pattern edges, rulers | Anchors without damage |

| Non-slip mat | Slippery stretch knits | Prevents fabric movement |

Cutting With a Rotary Cutter or Scissors

Your blade choice transforms your cut. Rotary cutters glide through stretch fabrics with precision—just replace blades every 6 to 12 months for clean edges. Pair them with a cutting mat for protection.

Scissors work too, especially micro-serrated ones that grip slippery knits.

Keep fabric grip methods consistent: don’t lift the material as you cut, and let cutting speed control follow the fabric’s natural resistance.

Maintaining Steady, Even Pressure

Pressure control separates clean cuts from wavy disasters. Your hand movement should feel deliberate, not forced—think of guiding rather than pushing your rotary cutter along the cutting mat.

Here’s how to maintain that control:

- Keep your blade sharp to reduce required force

- Use short, controlled strokes instead of long sweeps

- Distribute weight evenly across your cutting tools

- Let your non-slip cutting surface do the stabilizing work

- Match your speed to the fabric tension you’re managing

These sewing tips prevent the drift that ruins edges.

Tips to Prevent Distortion and Uneven Edges

Stretchy fabric has a mind of its own, and without the right approach, you’ll end up fighting distortion at every turn. The key is working with the fabric’s natural properties instead of against them.

Work with stretchy fabric’s natural behavior instead of fighting it, or you’ll battle distortion at every cut

Here are four strategies that’ll keep your cuts straight and your edges clean from the first slice to the final stitch.

Avoiding Fabric Stretch During Cutting

When you pull or tug while cutting, you’re fighting the fabric’s natural behavior. Keep one hand flat on the material to maintain fabric tension without stretching it. Your rotary cutter should glide smoothly—no sideways pressure.

Weights anchor edge stability better than pins, and cutting with steady speed gives you stretch control. This approach keeps stretchy fabrics honest and your cutting alignment true.

Cutting Along The Grainline

Your grainline alignment determines whether your finished piece hangs straight or twists. Locate the selvage edge and position your pattern so the grainline arrow runs parallel to it.

This grain verification step prevents fabric distortion even in stretch fabrics. Use your rotary cutter along this established line, securing the material with fabric weights.

Cutting accuracy improves when you respect the stretch direction and follow the weave’s natural path.

Using Fabric Stabilizers for Slippery Materials

Slippery stretch fabrics respond well to temporary stabilizers that add control without altering the finished garment. Spray adhesives, applied from 6–12 inches away, create a non-slip surface on your cutting mat, while lightweight fusible interfacing provides edge control during rotary cutter work. These interfacing materials wash out cleanly after construction.

- Spray starch transforms slippery knits into manageable yardage that holds its shape under fabric scissors

- Tear-away stabilizers prevent stretching at cut edges without leaving permanent residue on delicate materials

- Water-based adhesives offer safe fabric prep for synthetics prone to heat damage or discoloration

- Pattern weights paired with stabilizer spray eliminate fabric shift during marking and cutting operations

- Light interfacing stops satin and mesh from distorting while you guide your rotary cutter along rulers

Handling Four-Way Vs. Two-Way Stretch

Knowing your fabric’s stretch direction is crucial to avoid warped seams and twisted hems. Two-way stretch fabrics run crosswise with a stable lengthwise grain, while four-way stretch moves equally in all directions. Always test a swatch before cutting to understand your fabric’s behavior. Aligning pattern pieces with the dominant stretch ensures consistent elastic recovery and proper drape.

| Stretch Type | Stretch Direction | Grain Alignment Strategy |

|---|---|---|

| Two-Way Stretch | Crosswise only | Align pattern lengthwise on stable grain |

| Four-Way Stretch | Width and length | Flexible layout; follow pattern markings |

| Woven with Elastane | Minimal stretch | Treat as stable; mark grainline carefully |

| Knit Fabrics | Varies by construction | Test swatch; note dominant stretch factors |

Working with stretchy fabrics requires attention to fabric behavior at every stage. Cutting techniques for knit fabrics depend on recognizing how elastic recovery affects the finished piece. Two-way materials need grainline respect, while four-way options offer layout freedom. When sewing stretch fabrics, always test the material’s stretch before positioning pattern pieces on the fabric grainline and bias.

Common Mistakes and Troubleshooting

Even experienced sewers hit snags when cutting stretchy fabric. Maybe your line went crooked, or the material bunched up halfway through.

Here’s how to spot the most common problems and get back on track.

Recognizing and Fixing Crooked Cuts

Precision matters when working with stretch fabrics. If your raw edges don’t align when fabric’s folded, or if stripe patterns slope more than a few millimeters across the piece, you’ve got a crooked cut.

Check grain alignment by laying the fabric flat on your cutting mat.

Small distortions within your seam allowance can be corrected with edge trimming using a rotary cutter—just measure twice and trim once for cutting accuracy.

What to Do if Fabric Warps or Bunches

When stretch fabrics warp or bunch, remove your weights and lightly press the section with a steam iron on low. Re-lay the fabric flat on your cutting mat, then secure it with pattern weights at multiple points along the edge.

For stubborn bunching, apply a temporary stabilizer or low-tack spray adhesive. This fabric stabilization approach restores proper alignment and prevents further distortion during cutting.

Managing Fraying and Raw Edges

Once your fabric is flat and cut, you’ll want to protect those raw edges from unraveling. Stretch fabrics need edge finishing to maintain their shape and prevent fray.

Here are four fray prevention methods that work:

- Zigzag stitch the raw edge with fabric scissors nearby for trimming stray threads

- Serge or overlock immediately after using your rotary cutter

- Apply clear fray preventer along the fabric edge on your cutting mat

- Use stabilization methods like lightweight interfacing for extra fray resistance

Improving Accuracy With Practice

With fray control behind you, turn your focus to building muscle memory through consistent practice techniques. Set up timed cycles on your cutting mat with measurement feedback after each pass.

Working with varied stretch fabrics using your rotary cutter along the grainline, you’ll see accuracy retention improve steadily. Deliberate repetition sharpens your eye and refines your sewing techniques session after session.

Frequently Asked Questions (FAQs)

Can you cut stretchy fabric without a mat?

You can skip the cutting mat if you’re in a pinch, but you’ll sacrifice some control.

A smooth, stable surface with weights helps, though blade protection and fabric slippage become real concerns without that grippy foundation.

How do you cut thick stretchy fabrics?

Use heavy duty blades or sharp rotary cutters designed for thick knit cutting. Pre-wash thick fabric prep prevents distortion, then secure it flat with weights. Align stretch fabric grain before cutting with steady, controlled pressure.

Should you use pins on stretchy fabric?

Pattern weights offer better fabric stability than pins when sewing stretchy fabrics. Pins can cause fabric snag and distortion in knit fabric cutting.

If pin placement is necessary, choose ballpoint pins and align with the stretch direction for cutting accuracy.

What blade size works best for stretch fabric?

In the details, a 28 mm rotary cutter blade excels for lightweight stretch fabrics, offering edge quality and control. For heavyweight knits, switch to 45 mm for smooth cutting speed.

Do you cut stretch fabric on fold?

Yes, you can cut stretch fabrics on fold for symmetry alignment when the fabric has stable recovery. Just verify proper grain placement along the selvage edge before folding to maintain accuracy.

Conclusion

The next time you spread stretchy fabric across your cutting mat, you won’t feel that familiar dread—you’ll recognize exactly what needs to happen. You’ve learned how to cut stretchy fabric straight by mastering the tools, prep work, and techniques that prevent distortion before it starts.

Those wavy edges and bunched cuts? They’re behind you now. Your rotary cutter will glide clean and true, delivering the precision your projects deserve every single time.