This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

That worn-out backpack sitting in your closet doesn’t need to look boring forever. A single iron-on patch can transform it from drab to distinctly yours, whether you’re covering a stubborn stain, showing off your personality, or joining the growing movement of people who repair instead of replace.

The process takes about 15 minutes, but there’s a catch: get the temperature wrong or skip the prep work, and you’ll end up with edges that curl up after the first wash. The good news? With the right backpack material—like cotton, canvas, or denim—and proper technique, you can create a bond strong enough to survive years of daily use.

Success comes down to understanding what makes iron-on adhesive stick and following a handful of critical steps that most tutorials gloss over.

Table Of Contents

Key Takeaways

- Iron-on patches work best on cotton, canvas, and denim backpacks with heat-activated adhesive applied at 270-350°F for 10-15 seconds, but nylon and coated fabrics either reject the bond or warp under direct heat.

- Success depends on pre-cleaning the surface to remove oils and dirt, using a pressing cloth to prevent scorching, and applying firm pressure to edges first before working center outward.

- After application, let the patch cool completely for 2-5 minutes without bending the fabric, then reinforce lifting edges with fabric glue or backstitch around the perimeter for long-term durability.

- Wash patched backpacks inside-out in cold water on gentle cycle and air-dry flat instead of using a dryer, since heat weakens adhesive bonds and causes edges to peel over time.

Can You Iron a Patch Onto a Backpack?

Yes, you can iron a patch onto a backpack, but success depends on the fabric you’re working with and the type of patch you choose. Not every backpack material accepts heat-bonded patches equally, and some won’t hold them at all.

Before you fire up that iron, you need to know what you’re dealing with.

Check the fabric care label first, then review how to properly iron cashmere to avoid damaging those delicate fibers.

Suitable Backpack Materials for Iron-on Patches

Cotton and canvas backpacks are your best bet for iron-on patches because they handle high heat settings around 400°F without melting, and their tight weave lets adhesive grip deep into the fibers for lasting patch durability.

For detailed guidance on working with different fabric types and heat settings, check out this step-by-step curtain hemming guide that covers heat-sensitive materials.

Denim works great too, thanks to its heavyweight cotton construction and textured twill surface that creates a mechanical lock.

If you’re working with heavier denim or want to reinforce seams that take a beating, check out the best stitch for denim to ensure your project holds up long-term.

Polyester backpacks can work with lower heat and synthetic-friendly adhesives, but skip nylon backpacks and coated fabrics—they’ll reject the bond or warp under the iron, leaving you with peeling patches and potential fabric damage.

For further insight into characteristics of suitable fabrics, reviewing authoritative guidance can help you choose the right material for your project.

Types of Iron-on Patches

Once you’ve confirmed your backpack material works with heat, it’s time to pick the right patch style. Different iron-on patch materials deliver unique looks and durability levels, so matching the patch type to your bag’s fabric compatibility and your design goals matters more than you might think.

- Embroidered patches use raised stitching on fabric for classic logos and letters, bonding through heat-activated adhesive at medium to high iron temperatures

- Woven patches show finer details and text with flat, tightly woven threads that hold gradients better than embroidery while resisting daily flex

- Sublimated patches print photo-quality images directly into fibers, offering complex artwork and vivid colors that won’t crack through dozens of washes

For more information on full color printed patches, check out the latest customization options and care tips available online.

Pros and Cons of Iron-on Method

Each patch type brings its own bonding personality, and the iron-on method matches that speed-first mindset—but it’s not perfect. Heat-activated adhesive makes application a breeze, giving you solid fabric adhesion on cotton or canvas in under 30 seconds flat.

If you ever need to undo a patch or fix a mistake, check out how to remove dry hot glue from fabric for techniques that won’t damage your project.

The catch? Patch durability drops when synthetic fabrics can’t handle your ironing techniques, and longevity factors like rough washes slowly chip away at adhesive strength over time.

Choosing The Right Patch and Placement

Before you fire up that iron, you need to make sure your patch and backpack are actually going to work together. The wrong combination can lead to a patch that won’t stick, or worse, a melted mess on your favorite bag.

Let’s walk through how to choose the right patch, match it to your backpack’s fabric, and figure out exactly where it should go.

Selecting Patch Size and Design

You want your iron-on patch to grab attention without looking jammed onto every spare inch of fabric. Size matters—a 2 to 3 inch design works well on smaller backpacks, while 3 to 4 inches suits medium bags without crowding zippers or seams.

When exploring design options and material types for backpack customization, consider these shape selection and color choices:

If you’re working with iron-on designs, knowing how to safely remove them from different fabrics helps you experiment with styles without worrying about permanent mistakes.

- Embroidered patches offer bold, textured logos that stand out

- Custom patches in simple shapes sit flatter on curved panels

- High-contrast colors pop against busy patterns or camo prints

Matching Patch Adhesive to Backpack Fabric

When matching adhesive types to your backpack, you’re tapping into fabric compatibility that makes or breaks patch durability.

Heat-activated adhesive on cotton or canvas withstands heat settings up to 350 degrees, but polyester needs gentle 270 to 300 degrees to avoid scorch marks.

Nylon? Skip standard iron-on patches—those smooth fibers reject most adhesive technology, so you’ll want specialized patch attachment techniques instead.

Deciding on Patch Placement for Best Results

Smart patch placement keeps your backpack looking good without sabotaging functionality or durability.

- Patch visibility on the upper front panel draws attention while leaving room for other designs or reflective strips

- Style balance across both sides prevents a lopsided, cluttered appearance when you spread patches evenly

- Structural considerations mean avoiding high-stress areas like carry grips where flexing fabric cracks adhesive bonds

- Functional placement keeps zippers, compression straps, and pockets accessible without bulk or snags

- Aesthetic planning starts with laying patches loosely first, measuring from seams, and photographing your layout before committing with heat

Preparing Your Backpack for Iron-on Application

You can’t just slap a patch on a dusty backpack and expect it to stick. A clean, smooth surface makes all the difference between a patch that stays put for years and one that peels off after a few wears.

Before you fire up your iron, you’ll need to prep your workspace and get that fabric ready for a solid bond.

Cleaning and Drying The Backpack Surface

A grimy backpack won’t bond properly with your iron-on patch, so you need to clean the surface before you grab the iron. Empty all pockets, shake out crumbs, then brush away dust with a soft cloth. For stubborn stains, mix mild detergent with lukewarm water and spot-clean the patch zone using a sponge or old toothbrush.

| Surface Prep Step | Material Safety Tip |

|---|---|

| Remove loose dirt | Avoid bleach on nylon backpack |

| Spot-clean stains | Test cleaner on hidden area |

| Rinse soap residue | Use fragrance-free detergent |

| Air-dry completely | Keep away from direct heat |

Drying techniques matter because trapped moisture turns to steam under heat and ruins adhesive bonding. Pat the cleaned area with a microfiber towel, then let it air-dry flat for several hours. Check for cool or damp spots with your hand before moving forward.

Fabric protection during drying means skipping the tumble dryer and keeping your backpack away from direct sunlight, which preserves both color and shape for solid fabric and textile decoration results.

Smoothing Out Wrinkles and Setting Up Work Area

Wrinkles block full contact between adhesive and fabric, so you need to flatten your backpack panel before you heat the iron-on patch. Lay the backpack on a sturdy ironing board or heat-safe table, then slide a folded towel inside to create a firm surface.

Here’s your work surface preparation checklist for solid fabric and textile decoration results:

- Clear nearby clutter like plastic or loose straps to prevent snagging the hot iron

- Position the backpack so the patch placement area is closest to your dominant hand

- Gently stretch the panel with your hands to pull out light creases

- Keep the iron cord routed behind your work surface to avoid shifting mid-press

- Set all tools—pressing cloth, towel, patches—within arm’s reach for quick access

Run a dry iron over the empty patch zone for five to ten seconds using small circles, which relaxes fibers and smooths wrinkles without leaving heat rings on nylon. Let the preheated area cool briefly, then you’re ready for proper ironing technique and heat control.

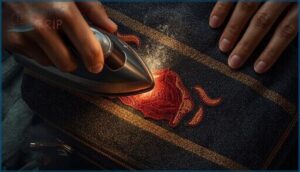

Step-by-Step Guide to Ironing on a Patch

Now that your backpack’s clean and ready, it’s time to get that patch locked in place. The actual ironing process takes precision, but it’s not complicated if you follow the right steps.

Below, you’ll find exactly what you need to do, from firing up your iron to making sure every edge stays put.

Gathering Tools and Materials Needed

Before you press anything, round up the right gear so you don’t scorch your favorite bag. A standard household iron, an ironing board or thick towel, your iron-on patch, and a thin cotton cloth or parchment paper are your core needs. Here’s what each item does:

| Item | Purpose | Why You Need It |

|---|---|---|

| Iron | Melts heat-activated adhesive on fabric | Bonds patch to backpack surface |

| Ironing board or towel | Creates firm, flat work surface | Provides even pressure during application |

| Iron-on patch | Supplies design and adhesive backing | Adds custom look to your bag |

| Protective layer (cotton cloth or parchment paper) | Shields backpack and patch from direct heat | Prevents scorching and melted residue |

| Ruler or measuring tape | Checks patch alignment and spacing | Keeps design straight and centered |

Keep fabric glue or a heavy book nearby for extra reinforcement if your backpack material is slick or heavily used.

Preheating Iron and Setting Correct Temperature

Letting your iron reach a stable working temperature for 3 to 5 minutes before you touch the patch saves you from weak spots and re-dos.

Most cotton backpacks handle heat around 270°F to 350°F, while polyester needs a gentler 270°F to 300°F to dodge melting.

Turn off steam completely so dry heat activates the adhesive cleanly and bonds every corner.

Positioning The Patch and Using a Pressing Cloth

Once your iron’s warmed up, flip the patch adhesive-side down on your cleaned backpack spot and align it carefully using reference points for balance. Cover it with a thin cloth—cotton or parchment paper works—to shield both surfaces from scorching while heat distributes evenly.

This pressing cloth step keeps your fabric protected and your patch looking sharp, setting up strong adhesive strength for the bond you’re building.

Applying Heat and Pressure for Proper Adhesion

With your patch covered, press down firmly with the iron and hold steady for 10 to 15 seconds, letting that heat-activated adhesive melt into the fabric weave. Don’t glide—plant it and apply consistent pressure so the bonding process reaches every corner.

Here’s your game plan for solid adhesion methods:

- Press edges first to anchor the patch perimeter

- Work center outward using firm, even pressure techniques

- Maintain contact through the full heat application window

That steady approach ensures fabric compatibility and locks everything down tight.

Checking and Reapplying Heat if Needed

After 2 to 5 minutes of cooling, check patch adhesion by gently rubbing the edges—if corners lift or feel loose, you’ll need reheat techniques.

Lower heat settings to around 270°F to 300°F for fabric compatibility, cover with your pressing cloth, and press problem spots for another 10 to 15 seconds. That extra heat application usually reactivates the adhesive strength and locks down any gaps.

Tips for Securing and Caring for Your Patch

You’ve successfully pressed your patch onto your backpack, but the real work isn’t over yet. How you handle the patch in the next few hours, and how you care for it over time, determines whether it stays put or starts peeling off after a few washes.

Let’s cover the essential steps to lock in that adhesion and keep your patch looking sharp for the long haul.

Ensuring Strong Adhesion and Sealing Edges

Strong adhesive bonding starts with solid fabric preparation—clean surfaces let heat-activated adhesive grip every millimeter. You’ll want firm, even pressure for 15 to 45 seconds, focusing on edges where lifting happens first.

Edge reinforcement through a quick backstitch or thin bead of fabric glue around the perimeter takes patch durability from decent to bulletproof, especially where your backpack flexes most.

A quick backstitch or fabric glue around the edges transforms decent patch durability into bulletproof hold

Cooling and Handling After Application

Patience during the cooling phase locks in adhesive strength and keeps your patch from peeling prematurely. Let the bonded area sit undisturbed for 2 to 5 minutes until it’s completely cool to the touch—no bending, flexing, or stuffing your backpack yet. Then run a light fingertip along edges for bond testing:

- Wait at least 2 to 5 minutes before touching the patch

- Avoid bending or folding the warm backpack panel

- Use cool air from a fan to speed cooling safely

- Check edges gently with a fingertip, not fingernails

- Hang the backpack flat to prevent friction or strain

Moving too soon cracks the heat-activated adhesive and creates weak spots that compromise patch durability.

Washing and Maintenance Recommendations

Proper fabric care keeps your patch bonded and your backpack looking fresh. Wash in cold water temperature (60–80F) on a gentle cycle guidance setting, turning the bag inside out to shield the adhesive from drum friction.

Choose a mild detergent selection for nylon fabric care, skipping bleach entirely. Air-dry flat for hiking backpack maintenance—heat from dryers weakens fabric repair bonds and can lift edges over time.

Troubleshooting Lifting or Peeling Edges

Peeling corners signal weak patch adhesion from low heat activation or textured fabric resistance. Reheat lifted spots with a pressing cloth for 30–45 seconds of dry ironing and heat application, then let cool completely.

For stubborn edge repair, run a bead of fabric glue under the border or add reinforcement stitching just inside the woven edge—both lock down iron-on patch attachment when adhesive bonding alone won’t hold.

Frequently Asked Questions (FAQs)

Can you iron a patch onto a backpack?

Measure twice, cut once—that’s the golden rule when ironing patches onto backpacks.

You absolutely can iron patches on, provided your backpack fabric tolerates heat and your patch features heat-activated adhesive designed for secure bonding.

How to stitch a patch on a backpack?

Hand sewing patches onto your backpack with polyester thread and a whipstitch or straight stitch creates durable textile decoration that outlasts iron-on methods, especially on canvas and nylon fabrics that flex constantly.

Can you iron on a patch to a backpack?

Where there’s a will, there’s a way—you can iron-on patch onto backpacks made from cotton, canvas, or denim.

These fabrics handle heat-activated adhesive well, ensuring strong patch attachment when fabric compatibility and iron temperature match correctly.

How to put a patch on your backpack?

You can attach a patch to your backpack using iron-on patch application, sewing for fabric compatibility, or adhesive methods depending on backpack materials, ensuring patch attachment matches your backpack prep needs.

Do iron-on patches work on bags?

Iron-on patches stick well to canvas backpacks when heat-activated adhesive bonds with woven fabric.

Nylon and polyester bags need careful iron settings to prevent melting, though patch adhesion depends on fabric compatibility and proper application pressure.

Can I put an iron on patch on a nylon bag?

You can attach an iron-on patch to a nylon backpack, but heat damage prevention requires careful fabric compatibility checks.

Lower iron temperature settings and a pressing cloth protect against melting while heat-activated adhesive bonds to the nylon surface.

Can I use the iron-on patch on a zipper?

Think of the zipper as a bridge your patch shouldn’t cross. Ironing directly over zipper teeth risks melting plastic, warping sliders, and poor adhesive contact.

Position your iron-on patch beside the zipper instead, ensuring heat-activated adhesive bonds firmly to flat backpack fabric while protecting hardware from heat damage.

Do I need to wash the backpack before applying the patch?

Yes, prewash benefits are real—cleaning methods remove oils and grime that block heat-activated adhesive from bonding.

Fabric prep with a full wash or spot cleaning dramatically improves patch adhesion and custom patches’ long-term backpack maintenance and care.

How do I remove an iron-on patch if I make a mistake?

You can remove an iron-on patch by heating it gently with an iron on a low setting, using a pressing cloth for fabric protection. Once the adhesive softens, lift the edges with tweezers for easy patch removal.

Can I use the iron-on patch on a leather backpack?

Leather patching with iron-on methods isn’t reliable—heat can scorch the surface, and adhesive types struggle on leather care compared to fabric.

For patch durability on your backpack, sewing works better than ironing patches onto leather.

Conclusion

Most repairs feel like settling for less—but learning how to iron on a patch to a backpack does the opposite. You’re not just hiding damage; you’re reclaiming a piece of gear that already fits your life perfectly.

The 15 minutes you spend positioning, pressing, and sealing that patch saves money, keeps usable fabric out of landfills, and turns something ordinary into something unmistakably yours. That’s not compromise—that’s taking control.

- https://www.pinprosplus.com/post/heat-press-tips-for-iron-on-patches

- https://everlighten.com/blogs/blog/a-complete-guide-to-iron-on-custom-patches

- https://www.discoversalkan.com/pages/iron-on-patch-instructions

- https://www.thestudio.com/blog/how-to-put-patch-on-backpack/

- https://sewport.com/fabrics-directory/polyester-fabric