This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Start by washing flannel in cold water on a gentle cycle with mild detergent. Skip fabric softener, as it can interfere with the fabric’s natural texture.

Tumble dry on low heat or air dry to avoid excessive shrinkage. Some sewers prefer to pre-shrink flannel by washing it twice, especially for garments that’ll see frequent washing.

After pre-washing, press the fabric gently with a warm iron to restore its smooth surface. This simple step saves you from the heartache of watching your carefully crafted project shrink after its first wash.

Smart preparation makes all the difference in achieving professional-looking results.

Table Of Contents

- Key Takeaways

- What is Flannel and Why Pre Wash It?

- The Importance of Pre Washing Flannel

- How to Prewash Flannel Fabric

- Cutting Flannel Fabric After Prewashing

- Sewing Tips for Flannel Fabric

- Quilting With Flannel and Cotton

- Helpful Notions for Sewing With Flannel

- Tips for Pressing Flannel Fabric

- Washing and Drying Flannel Fabric

- Other Creative Uses for Flannel

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Always pre-wash flannel before cutting – You’ll prevent up to 10% shrinkage and avoid your finished project puckering or distorting after its first wash

- Use cold water and a gentle cycle – You’ll minimize excessive shrinkage while removing manufacturing chemicals that can affect the fabric’s natural softness

- Skip fabric softener and tumble dry on low – You’ll maintain flannel’s texture and prevent damage from high heat while controlling shrinkage

- Press gently after pre-washing – You’ll restore the fabric’s smooth surface and ensure accurate cutting for professional-looking results

What is Flannel and Why Pre Wash It?

Many sewers learn the hard way that flannel’s cozy appeal comes with a catch – it shrinks dramatically during the first wash.

Flannel’s loose weave and raised fibers create that beloved softness, but they also make it prone to significant shrinkage, distortion, and fraying compared to tightly woven cottons.

Flannel’s cozy texture comes with a price—it shrinks, distorts, and frays like nobody’s business.

Without proper flannel fabric preparation, your finished project might end up looking like it belongs on a doll rather than a person.

Skip prewashing flannel and you might end up with a project that’s two sizes too small.

Prewashing flannel before sewing prevents these unwelcome surprises by maximizing shrinkage upfront.

This essential step guarantees your garments and quilts maintain their intended size and fit after repeated laundering.

The process also addresses dye bleeding concerns and removes manufacturing residues that can affect fabric softness.

When you wash flannel before sewing, you’re basically giving your project insurance against post-construction disasters.

Taking time to properly shrink flannel fabric saves countless headaches later, ensuring your hard work pays off with professional-looking results.

The Importance of Pre Washing Flannel

Pre-washing flannel fabric prevents costly sewing mistakes that can ruin your projects.

Flannel’s loose weave makes it prone to significant shrinkage and fraying, which can distort your finished items if you skip this vital step. You’ll save time and frustration by addressing these issues upfront rather than discovering them after hours of careful stitching.

Here’s why prewashing flannel fabric is essential for project success:

- Shrinkage Prevention – Flannel can shrink 10% or more during its first wash, potentially ruining garment fit

- Dye Setting – Dark flannels often bleed color, which washing flannel before sewing helps control

- Fabric Softening – Pre-washing creates the desired soft hand feel that makes flannel so appealing

- Fraying Reduction – Controlled washing minimizes loose threads that can worsen during construction

- Project Success – Proper flannel fabric preparation guarantees your finished items maintain their intended size and appearance

Taking this extra step during flannel fabric preparation guarantees your sewing projects will look professional and last longer.

How to Prewash Flannel Fabric

Now you’re ready to tackle the actual prewashing process, which requires careful attention to water temperature and gentle handling.

You’ll want to use lukewarm water with mild detergent, avoiding hot water that can cause excessive shrinkage and damage to flannel’s loose weave structure, which is a complete concept in the care of flannel.

Gentle Prewashing Method

Start with lukewarm water and mild detergent when you prewash flannel fabric.

Choose a gentle cycle to minimize agitation and prevent excessive fraying. Skip fabric softeners completely—they’ll interfere with the fabric’s natural texture.

Place your flannel in a mesh laundry bag for extra protection during washing. This simple step prevents tangling and reduces stress on the fibers.

After washing, gently squeeze out excess water without wringing. Air drying works best for maintaining flannel’s softness and preventing shrinkage.

Flannel, like cotton and linen, may experience noticeable fabric shrinkage, so prewashing is key. These flannel washing tips guarantee your fabric stays in perfect condition for sewing projects.

Cases Where Pre Shrinking is Necessary

Imagine this scenario: you’re halfway through your dream quilt when disaster strikes—your flannel backing puckers while the cotton top stays put.

Mixed Fabric Projects demand prewashing flannel to prevent this nightmare scenario. When Garment Fit Matters, like in pajamas or shirts, you can’t afford post-sewing surprises.

Quilting Considerations become critical when combining flannel with cotton or other materials that won’t shrink. Dimensional Stability requires prewashing flannel that’ll shrink up to 10% while your other fabrics stay unchanged.

Preventing Distortion means treating flannel shrinkage before cutting, not after construction. Even premium flannel needs this prep work—fabric shrinkage doesn’t discriminate by price tag.

Skip this step, and you’ll learn why preventing flannel shrinkage matters the hard way.

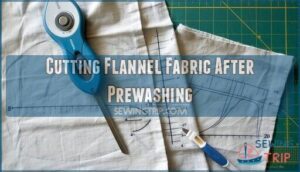

Cutting Flannel Fabric After Prewashing

Once you’ve finished prewashing flannel, cutting becomes your next critical step.

Sharp scissors or rotary cutters work best on flannel’s soft fibers, giving you clean edges without pulling or distorting the fabric.

A cutting mat provides stability and protects your work surface during this process.

Pay attention to fabric grain when placing your pattern pieces – flannel’s loose weave makes grain alignment even more important than with other fabrics.

Mark the grain line clearly on each piece before cutting.

Pattern placement matters too, especially with directional prints or nap.

Cut one layer at a time to maintain accuracy, as flannel’s thickness can cause shifting when doubled.

To guarantee accuracy, it’s helpful to understand fabric grain and selvage.

After cutting, check edges for excessive fraying from the prewashing process.

Trim any loose threads immediately to prevent them from tangling during sewing.

Handle your cut pieces gently to avoid stretching – flannel’s relaxed weave makes it prone to distortion until it’s sewn into place.

Sewing Tips for Flannel Fabric

Once you’ve pre-washed your flannel, you’ll need to adjust your sewing technique to handle this soft, stretchy fabric successfully.

Flannel requires specific needle choices, stitch settings, and handling methods to prevent stretching, puckering, and fraying during construction.

Choosing The Right Sewing Needle

Most sewers overlook needle selection, but choosing the right sewing needle prevents fabric damage and skipped stitches.

For flannel fabric, use size 80/12 or 90/14 universal needles depending on fabric thickness. Thicker flannel requires larger needles like 100/16.

Quality needle brands like Schmetz guarantee consistent performance after prewashing and shrinkage adjustments. Flannel’s tendency for significant fabric shrinkage means pre-washing is essential.

Optimal Stitch Length for Flannel

Once you’ve chosen the right needle, adjust your stitch length to 3.0-3.5mm for flannel sewing projects. This longer flannel stitch length prevents fabric distortion and puckering that shorter stitches cause.

The loose weave of flannel responds better to longer stitches, reducing bunching and skipped stitches. You’ll notice smoother seams and less stress on the fabric fibers when preparing fabric for sewing.

Remember to address flannel’s tendency to fray by using pinking shears or a serger.

Wider Seam Allowance for Flannel

Flannel fabric’s loose weave makes it prone to fraying, so you’ll need wider seam allowances to compensate for this natural tendency.

Unlike tightly woven cotton, flannel requires extra room to maintain structural integrity and prevent unsightly fraying edges.

Here’s how to handle seam allowances with flannel:

- Use at least 5/8 inch seam allowances instead of the standard 1/2 inch for better fabric stability

- Add an extra 1/4 inch for high-stress areas like armholes and curved seams where fraying occurs fastest

- Finish raw edges immediately with pinking shears or zigzag stitches to prevent unraveling during construction

This approach provides fraying prevention while ensuring your finished project maintains its shape after prewashing and regular use.

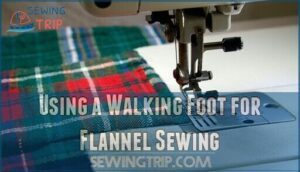

Using a Walking Foot for Flannel Sewing

When sewing with flannel fabric, a walking foot becomes your best ally for achieving professional results.

This specialized presser foot grips both the top and bottom layers of fabric, ensuring they feed through your machine at the same rate. You’ll notice fewer puckered seams and straighter stitching lines, especially when working with thick layers or quilt binding projects.

Many sewers find specialty sewing products helpful for this task.

Benefits:

- Even stitching across all flannel layers without shifting

- Preventing slippage that causes uneven seams and puckering

- Fabric feeding control for consistent results on thick materials

- Thick layers management when combining flannel with batting

- Quilt binding precision for professional-looking finishes

Preventing Fraying on Finished Flannel Items

Once you’ve mastered the walking foot technique, preventing fraying becomes your next priority. Flannel fabric’s loose weave makes it particularly susceptible to fabric fraying prevention challenges, but proper seam finishing techniques can save your projects.

Your best defense against fraying starts with edge treatments during construction. Serging provides the strongest protection, while zigzag stitching works well without specialized equipment. Higher stitch density creates more secure seam finishing for areas that’ll see heavy use.

| Method | Durability | Equipment Needed | Best For |

|---|---|---|---|

| Serging | Excellent | Serger/Overlock | All flannel projects |

| Zigzag Stitch | Good | Standard machine | Basic edge finishing |

| Pinking Shears | Fair | Pinking shears | Temporary protection |

| Fray Check | Good | Liquid sealant | Small details/repairs |

Fabric stabilizers applied before cutting also help control fraying. Quality flannel naturally resists fraying better than cheaper alternatives. After prewashing, inspect seams regularly and re-finish worn edges to maintain your handmade items’ longevity through repeated washing techniques.

Quilting With Flannel and Cotton

After you’ve picked up a few sewing tips, quilting with flannel and cotton brings its own set of quirks.

Start by prewashing both fabrics—trust me, flannel fabric loves to shrink more than your favorite jeans. This fabric prewash guide helps you avoid surprise shrinkage and colorfastness concerns later.

Use high-quality, tightly woven flannel and always check for pattern matching before cutting.

Flannel’s warmth makes it ideal for cozy winter projects.

Pinking shears help with seam bulk reduction and keep fraying in check. Choose lightweight quilt batting to prevent your quilt from feeling like a weighted blanket.

Keep an eye on quilting density—too tight and things get stiff, too loose and the layers shift.

Helpful Notions for Sewing With Flannel

Having the right tools makes sewing flannel much easier and prevents common frustrations.

You’ll want sharp needles, proper cutting tools, and a few specialty items to handle flannel’s unique challenges like fraying and lint buildup.

Schmetz Universal Sewing Needles Size Eighty Twelve Two Cards Twenty

Your machine needs reliable needles for flannel’s unique challenges.

The Schmetz Universal Size 80/12 needles offer the perfect balance for medium-weight fabrics like flannel.

These twenty needles feature slightly rounded points that glide through both woven and knit materials without snagging delicate fibers.

Their precision-ground tips and high-quality steel construction guarantee consistent stitching while resisting heat buildup.

You can purchase Schmetz 80/12 needles online.

The 0.8mm blade diameter handles flannel’s loose weave beautifully, preventing skipped stitches and thread breakage.

Compatible with most home sewing machines using system 130/705 H, these needles maintain proper thread tension adjustments throughout your project, ensuring a smooth sewing experience with medium-weight fabrics and providing consistent stitching.

SCHMETZ Universal Sewing Machine Needles Size 90 14 Carded

When choosing the right needle for flannel fabric, you’ll find SCHMETZ Universal Sewing Machine Needles Size 90/14 consistently deliver excellent results.

These German-engineered needles feature a slightly rounded point that glides through flannel’s loose weave without snagging or pulling threads. The 90/14 size works perfectly for medium-weight flannel while maintaining compatibility with most household sewing machines.

Their chrome-plated construction reduces friction and heat buildup during extended sewing sessions. You can find various Schmetz products online.

Replace needles every 8-10 hours to maintain peak performance when working with flannel’s fibrous texture.

Dust Off Compressed Gas Duster Pack of Four

You’ll want quality compressed air dusters for tackling flannel lint buildup in your sewing machine.

This four-pack keeps your bobbin area clean and prevents thread breakage from lint accumulation. Regular machine cleaning with air duster extends equipment life and maintains stitch quality throughout flannel projects.

- Removes stubborn flannel lint from hard-to-reach bobbin case areas

- Prevents thread breakage caused by lint buildup during fabric preparation

- Extends machine life through regular maintenance after prewashing sessions

- 100% ozone safe formula with safety bitterant for workshop use

Tips for Pressing Flannel Fabric

Proper pressing technique makes all the difference when working with flannel fabric. Set your iron to the cotton/linen setting and press gently on the wrong side to prevent distortion and maintain the fabric’s soft texture.

- Use a dry iron without steam to avoid shrinkage.

- Press on the wrong side of the fabric.

- Lift and press sections, don’t slide the iron.

- Consider using a pressing cloth or starch.

Your ironing temperature should stay consistent throughout the process. Steam usage can cause unwanted shrinkage, so stick with dry heat. A pressing cloth protects delicate flannel fibers while ensuring proper grain alignment.

Using specialty pressing tools can further enhance precision in challenging areas. Focus on preventing stretching by lifting the iron rather than dragging it across the surface. This prewashing and pressing combination creates the perfect foundation for your sewing projects.

Washing and Drying Flannel Fabric

The temperature of your water plays a vital role in flannel fabric care.

Cold water prevents excessive shrinkage and color bleeding, while hot water maximizes shrinkage if you’re prewashing strategically.

Choose mild detergent without fabric softeners, as these can coat fibers and reduce flannel’s natural softness.

For drying methods, air drying preserves fabric integrity best.

If using a dryer, select low heat to prevent pilling and maintain texture.

Reshape your flannel fabric while damp to prevent distortion.

Shrinkage control requires understanding that flannel fabric naturally shrinks 5-10% during its first wash.

This shrinking flannel fabric characteristic makes prewashing essential for accurate project planning.

Dark colors may bleed initially, so wash separately or use color catchers.

Monitor fabric washing carefully – overdrying creates stiffness and excessive pilling.

Proper fabric drying maintains flannel’s cozy hand feel for your finished projects.

Other Creative Uses for Flannel

Once you’ve properly washed and dried your flannel fabric, don’t toss those leftover scraps! Flannel crafts offer endless possibilities for creative home decor projects.

Transform remnants into cozy baby items like burp cloths, receiving blankets, or soft toys that parents will treasure. Your prewashing efforts pay off here—these items won’t shrink after countless washes.

Consider upcycling flannel into practical cozy gifts: reusable hand warmers, book covers, or laptop sleeves. The fabric’s natural warmth makes perfect pot holders and oven mitts too.

For quilting enthusiasts, flannel scraps work beautifully in patchwork throws or table runners. You can even create custom gift wrap that recipients can reuse—much friendlier than wasteful paper.

Flannel projects extend beyond typical sewing ventures into headbands, scrunchies, and even pet bedding. With proper prewashing complete, these flannel fabric creations will maintain their softness and dimensions through years of use.

Frequently Asked Questions (FAQs)

Should flannel fabric be prewashed?

Yes, you should absolutely prewash flannel fabric.

It’ll shrink up to 10% and fray like crazy on the first wash, so getting that out of the way prevents your finished project from puckering or distorting later.

Should you wash flannel before sewing?

While some skip this step thinking it’s unnecessary, you should absolutely wash flannel before sewing.

It shrinks substantially – up to 10% – and pre-washing prevents your finished project from distorting later.

Should you prewash fabric before sewing?

You should prewash most fabrics before sewing to prevent shrinkage, remove chemicals, and test for color bleeding.

Natural fibers like cotton and linen need it most, while synthetics benefit from cleaning off manufacturing residues.

Do I need to prewash a sewing machine?

No, you don’t need to prewash your sewing machine. Clean it regularly by removing lint from the bobbin area and oiling according to your manual’s instructions for peak performance.

How do you wash flannel?

Getting your ducks in a row means washing flannel properly to prevent shrinkage and fraying.

Use lukewarm water with gentle detergent, wash on delicate cycle, then air dry or use low heat to maintain softness, following the concept of getting your ducks in a row to ensure the best results.

Do you wash flannel before cutting?

Yes, you should wash flannel before cutting to prevent shrinkage and fraying issues later.

Pre-washing removes chemicals, stabilizes the fabric, and guarantees your finished project maintains its intended size and shape after future washes, which helps prevent fraying.

Should you pre-wash flannel before sewing?

Picture yourself reaching for that soft flannel fabric – it’s tempting to cut right away, but you’ll want to pre-wash first.

Flannel shrinks substantially, so washing prevents your finished project from puckering or distorting later, which is a key consideration to ensure the quality of your finished project.

How to wash flannel for the first time?

Wash flannel in lukewarm water with gentle detergent, then soak for 5-10 minutes. Rinse thoroughly, squeeze out excess water gently, and lay flat to air dry completely.

Should I wash the flannel before making a baby blanket?

Always pre-wash flannel before sewing baby blankets. It’ll shrink up to 10% and may bleed dye. Use lukewarm water, gentle detergent, and air dry to prevent excessive shrinkage while removing chemicals.

How to pre-shrink cotton flannel?

Cotton flannel needs pre-shrinking to prevent post-sewing disasters.

Wash it in hot water, then dry on high heat.

This maximizes shrinkage before you cut and sew, saving you from wonky dimensions later.

Conclusion

Picture your flannel fabric as a garden that needs tending before it can bloom into beautiful projects.

Just as you wouldn’t plant without preparing the soil, you shouldn’t sew without knowing how to pre wash flannel before sewing.

This simple step transforms unpredictable fabric into reliable material that won’t surprise you later.

With proper pre-washing, pressing, and cutting techniques, your flannel projects will maintain their shape and beauty wash after wash, giving you confidence in every stitch.

- https://www.rockymountainflannel.com/pages/washing-instructions

- https://nancysnotions.com/spoiler-alert-flannel-shrinks/

- https://www.quiltingboard.com/main-f1/pre-wash-flannel-t19607.html

- https://www.quiltingdaily.com/top-tips-for-making-quilts-with-flannel/

- https://www.applegreencottage.com/sewing-with-flannel/