This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You don’t need to settle for scratchy, overpriced sheets when you can make your own for half the cost. Custom bed sheets give you complete control over fabric quality, fit, and design—no more wrestling with sheets that pop off the corners at 3 a.m.

The process requires basic sewing skills and about two hours of your time. Once you master the technique, you’ll never look at store-bought bedding the same way.

Whether you’re working with flat sheets or tackling fitted corners with elastic, each step follows a straightforward pattern. Your sewing machine becomes a money-saving tool that transforms yards of fabric into perfectly sized bedding that actually stays put.

Table Of Contents

- Key Takeaways

- Essential Supplies for Sewing Bed Sheets

- Choosing The Best Fabric for Bed Sheets

- Measuring and Cutting Fabric for Sheets

- Step-by-Step: Sewing Flat Bed Sheets

- Step-by-Step: Sewing Fitted Bed Sheets

- Turning a Flat Sheet Into a Fitted Sheet

- Care, Storage, and Quality Checks for Homemade Sheets

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Sewing your own bed sheets lets you control fabric quality, fit, and design while saving money compared to store-bought options.

- Accurate measuring, cutting, and seam allowances are essential to ensure sheets fit your mattress securely and don’t slip off.

- Choosing the right fabric type, thread, and elastic based on comfort needs and climate improves sheet durability and performance.

- Careful hemming, reinforced corners, and proper elastic attachment create professional results that last through frequent use and washing.

Essential Supplies for Sewing Bed Sheets

Before you cut a single piece of fabric, you’ll need to gather the right tools for the job. Having everything on hand makes the process smoother and helps you avoid mistakes that waste fabric.

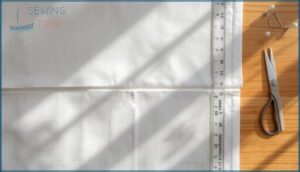

A sharp rotary cutter, self-healing mat, and clear ruler are essentials you’ll use again and again when sewing quilts at home.

Here’s what you need to get started.

Sewing Machine and Needles

Your sewing machine is the workhorse of sheet construction. Most domestic machines handle straight and zigzag stitches needed for bed linens. Match your needle size to your fabric—80/12 to 90/14 universal needles suit cotton perfectly.

If you’re unsure which needle works best for your cotton sheets, check out this guide on choosing the right sewing machine needle for different fabric weights.

- Choose steel or titanium-coated needles for durability through long sewing sessions

- Replace needles after 8–12 hours of active use to prevent skipped stitches

- Test thread tension on scrap fabric before starting your sheet project

- Clean feed dogs and bobbin area for smooth sewing speed and performance

- Store needles in labeled containers to maintain proper needle maintenance habits

Measuring Tools and Cutting Mats

Accurate fabric rulers and cutting mats transform precision cutting from guesswork into mastery. You’ll need a clear quilting ruler (18×24 inches works best) paired with a self-healing cutting mat featuring grid lines at 1-inch intervals. A rotary cutter delivers clean, fray-resistant edges that scissors can’t match.

Once you’ve mastered your cuts, explore batting materials that enhance quilt drape and warmth to complete your project with professional results.

| Tool | Purpose | Best Practice |

|---|---|---|

| Retractable metal tape measure | Measures mattress dimensions with 1 mm precision | Measure multiple fabric locations to account for shrinkage |

| Clear quilting ruler | Marks straight edges and verifies seam guides | Store flat to prevent warping |

| Self-healing cutting mat | Protects surfaces during rotary tool use | Keep clean and replace worn blades regularly |

| Seam gauge | Checks seam allowances in 1/4-inch increments | Calibrate on scrap fabric before measuring techniques begin |

Pins, Clips, and Marking Tools

Your fabric won’t shift if you choose the right pin types and sewing notions. Straight pins (1.5–2 inches) work for woven fabrics, while ballpoint pins prevent snagging on knits. Rust-resistant glasshead pins stay visible during sewing techniques. Sewing clips grip thick seams without puncturing.

Pin placement matters just as much as pin selection—space them every 2–3 inches and remove them as you sew to avoid puckering, especially when following proper hem techniques for clean, professional finishes.

Fabric markers guide your sewing machine stitches—water-soluble pens vanish after washing. These sewing supplies transform fabric selection into controlled, accurate sewing tutorials.

Thread and Elastic Selection

Your thread types control seam strength and lint reduction. Polyester blends minimize fraying in high-use areas, while cotton thread offers better flexibility in dense weaves.

For elastic materials, choose 1/4 to 1/2 inch nylon braided options—they provide excellent recovery over spandex alone.

Match these sewing supplies to your fabric selection for best fabric compatibility and reduced puckering.

Choosing The Best Fabric for Bed Sheets

The fabric you choose affects everything from how your sheets feel against your skin to how long they last. You’ll want to examine material composition, weave quality, and the climate where you live.

Let’s break down your options so you can pick the perfect fabric for your needs.

Cotton Vs. Poly-Cotton Blends

When you’re sewing bed sheets or sewing fitted sheets, fabric choice shapes your comfort and success. Cotton blends mix cotton fibers with polyester—usually 35 to 65 percent—balancing fabric softness with fabric durability. Pure cotton wins breathability tests and feels softer, but blends resist wrinkles better and cost less.

If you’re new to garment construction, practicing how to sew loose pants helps you master straight seams before tackling fitted corners.

Eco-friendly options exist in both categories, so weigh fabric selection and care needs against your priorities.

Thread Count and Fabric Weave

Quality depends more on weave patterns than thread count alone. Percale weave delivers crisp texture, while sateen produces smooth luster. Thread quality matters—long-staple cotton resists pilling.

Cotton blends with 180 to 280 threads per square inch offer breathability and durability. Fabric density affects comfort, but fabric breathability declines beyond 400 threads. Your fabric choice shapes both feel and function.

Extra-Wide and Specialty Fabrics

Wide fabric eliminates center seams when you sew sheets for queen or king beds. Specialty weaves—like TENCEL, bamboo, and performance sateen—offer unique comfort advantages but may present sewing challenges.

- Extra-wide fabrics measure 108 to 120 inches, reducing piecing work

- TENCEL and modal blends absorb moisture and resist odors

- Bamboo provides natural anti-microbial properties with soft drape

- Performance cottons combine breathability with wrinkle resistance

Match fabric selection to your sheet pattern and elastic requirements for best results.

Seasonal and Comfort Considerations

Your bedroom temperature shifts throughout the year, and your Sheet Pattern should reflect that. Breathability Factors and Thermal Regulation matter most for Sleep Comfort.

| Season | Seasonal Fabrics | Moisture Management |

|---|---|---|

| Summer | Percale, linen | High wicking |

| Winter | Sateen, flannel | Moderate retention |

| Spring/Fall | Cotton blends | Balanced airflow |

| Year-round | Jersey, modal | Adaptive control |

Match Fabric Selection and Care to your climate. Comfort Customization through weave choice beats thread count alone for Bedding and Mattresses comfort in your Sewing Tutorial.

Measuring and Cutting Fabric for Sheets

Getting your measurements right is the foundation of sheets that actually fit your bed. You’ll need to know standard sizing, how to measure your specific mattress, and how much extra fabric to add for seams and tucking.

Let’s break down each step so you can cut your fabric with confidence.

Standard Sheet Sizes for All Beds

Before you cut a single inch of fabric, you’ll need to know the standard bed size and mattress size you’re working with. A twin flat sheet usually measures 66 inches by 96 inches, while a queen requires approximately 90 by 102 inches.

Fitted sheet pocket depth commonly ranges from 10 to 12 inches. Understanding these sheet size variations prevents sewing margin errors and ensures your sheet pattern fits perfectly.

How to Measure Your Mattress

Your mattress dimensions determine whether your finished twin bed sheets stay secure or slip off at 2 a.m. Grab a flexible measuring tape and follow these steps to capture accurate bed size measurements:

- Measure mattress width at the center from edge to edge.

- Record the length from head to foot.

- Check mattress depth at all four corners for mattress variations.

- Note the thickest point for proper corner fit.

- Add measurements to your sheet dimensions worksheet.

Calculating Seam Allowances

Once you’ve got your mattress dimensions, you need to plan your seam allowance—that strip of fabric beyond your stitch line. For woven cotton, use a standard 5/8 inch seam allowance on side seams. This gives you room for edge finishing techniques like zigzag stitches while preventing fraying.

When sewing fitted sheets, consistent seam allowances keep corners square and guarantee your fabric selection accommodates both stitching and fabric shrinkage after washing.

Cutting Techniques for Flat and Fitted Sheets

Now that your seam allowance is planned, lay your fabric flat with the selvage parallel to your cut lines. Use a rotary cutter with a straight edge on a stable cutting mat—this prevents slippage and minimizes fraying. Mark lines with tailor chalk for visibility.

For flat sheets, cut straight panels. Fitted sheets need corner shaping: measure and mark squares at each corner before cutting.

Step-by-Step: Sewing Flat Bed Sheets

Flat sheets are the simplest sewing project you’ll tackle—no elastic, no corner cuts, just straight edges and clean hems. You’ll start by hemming the raw edges, then secure everything with basic straight stitches. A quick press at the end gives your sheet that crisp, store-bought look.

Hemming Edges for a Professional Finish

A clean hem transforms your flat sheet from homemade to handcrafted. Proper fabric preparation—pre-washing and pressing—prevents later shrinkage that throws off your edge finishing. For professional binding, you’ll want to master these hemming techniques:

- Fold a 1/2 inch double-fold hem for durability

- Press each fold before sewing to guarantee crisp edges

- Use binder clips to prevent fabric shifting

- Mark your hem line with removable chalk for accuracy

This seam stability foundation keeps your sheets looking sharp through countless washes.

Straight Stitching and Backstitching

Your sewing machine transforms marked hems into secure seams with proper technique. Set your stitch length to 2.5–3.0 millimeters for balanced fabric alignment and thread management.

Guide the fabric gently without pulling—the feed dogs do the work. Backstitch 4–6 stitches at each end to lock seams and prevent unraveling.

Check stitch tension regularly; loops signal imbalance that compromises seam security.

Pressing and Finishing The Sheet

Professional results depend on proper pressing—steam irons set at medium-high heat smooth cotton without scorching. Press seams open or to one side for improved sheet lay and durability.

- Start from the center outward to avoid new wrinkles forming

- Press hems before final stitching to maintain alignment

- Use a pressing cloth to protect delicate fibers

- Allow fabric to cool after pressing to stabilize creases

Step-by-Step: Sewing Fitted Bed Sheets

Fitted sheets take a bit more precision than flat sheets, but they’re still manageable once you break down the steps. You’ll shape the corners to hug your mattress, reinforce the edges so they hold up to washing, and attach elastic that keeps everything snug.

Here’s how to tackle each part with confidence.

Cutting and Shaping The Corners

Fitted sheet corners need precise fabric shaping to hug your mattress snugly. Mark a square at each corner—usually 5 to 12 inches depending on your mattress depth plus seam allowance. Use tailor chalk along true grain lines, then cut slowly with sharp scissors.

Mitering corners reduces bulk and creates clean lines. Trim small triangles from folded corners before you sew sheets, ensuring your elastic fitting sits flat and secure.

Hemming and Reinforcing Edges

Durable edges keep your fitted sheet looking fresh through countless washes. Fold your raw edge under by 1/4 inch, press it flat, then fold again—this double-fold hem resists fabric fraying beautifully.

Set your sewing machine to a 2.0 mm stitch length for reliable seam security. Backstitch at each end to lock the thread. A second reinforcement line 1/8 inch inside adds extra strength where elastic will stretch the fabric.

Measuring and Attaching Elastic

Your elastic tension determines whether corners grip or slip loose. Cut elastic equal to your mattress perimeter plus 8 to 12 inches. Use 1/4 to 3/8 inch wide braided elastic for corner fitting flexibility.

Mark four corner points on your fitted sheet fabric before sewing. Attach elastic using a wide zigzag stitch on your sewing machine, stretching slightly as you sew to prevent slack and maintain fabric stretch throughout washing.

Turning a Flat Sheet Into a Fitted Sheet

If you’ve already sewn a flat sheet or have one on hand, you can convert it into a fitted sheet with a few simple modifications. This approach saves fabric and gives you a custom fit for your mattress.

You’ll need to measure your mattress, cut and sew the corners, and add elastic to hold everything in place.

Measuring for Perfect Fit

Start by measuring your mattress dimensions: length, width, and depth to the nearest 1/8 inch. A rigid tape measure prevents sag and gives you consistent readings.

Multiply the depth by two, add the width, plus six inches for tucking. Record these numbers—they’ll guide your fabric shrinkage calculations, seam allowances, and elastic tension when converting your flat sheet into a fitted sheet.

Cutting and Sewing Corners

You’re shaping boxed corners that transform a flat panel into a mattress-hugging fitted sheet. Fold your fabric into quarters and mark corner squares at the unfolded edge: mattress depth plus 3 inches. Use a rotary cutter on a mat for clean fabric cutting.

Align the cut edges right sides together, secure with clips, then stitch a 1/2-inch seam allowance with your sewing machine. Backstitch both ends to reinforce these high-stress corners.

To achieve a professional finish, consider using fitted sheet methods for your sewing project.

Adding Elastic for Secure Hold

With corners stitched, you’ll thread 1/4-inch to 1/2-inch knit elastic around the hem opening to create that snug, stay-put fit. Secure attachment matters—pin elastic at intervals before zigzag stitching to prevent bunching. Cut elastic 1-2 inches shorter than your seam for proper stretch recovery.

- Match elastic color to your fabric for invisible seams

- Backstitch ends twice for corner reinforcement

- Test fabric compatibility with a wash cycle first

Care, Storage, and Quality Checks for Homemade Sheets

Your homemade sheets deserve proper care to last for years. A few quick checks after sewing will catch small issues before they become bigger problems.

Here’s how to inspect your work, store your sheets correctly, and fix common mistakes.

Inspecting Seams and Elastic

You’ve got your fitted sheet sewn—now check your work. Run your fingers along every seam to confirm stitch quality and catch fabric fray before the first wash. Check elastic tension at each corner to guarantee a snug grip on your mattress.

Look for even thread selection throughout and verify your zigzag stitch isn’t puckering. Inspect seams for durability, spacing stitches about two to three inches apart, so your sewing techniques hold strong through countless nights.

Folding and Storing Finished Sheets

Once your seams pass inspection, proper fabric folding keeps your work crisp. Lay fitted sheets flat, tuck corners together to form a neat rectangle, then fold into thirds. For flat sheets, fold widthwise into thirds, then lengthwise into halves.

Store bedding in breathable fabric bags in a cool, dry spot. Label each stack by size for quick retrieval—your sheet storage system makes bed-making simple.

Troubleshooting Common Issues

Even with careful sewing, elastic can twist or corners can pucker—but you can fix these hiccups without starting over.

Seam puckering usually means your tension’s too tight—loosen it slightly. Thread breakage signals a dull needle, so swap it out. Fraying edges need a zigzag stitch along raw fabric.

If elastic failure occurs, unpick the casing and replace the worn section. Fabric shrinkage? Pre-wash before cutting next time.

Frequently Asked Questions (FAQs)

Can I sew sheets without a serger?

You don’t need a serger for sewing tutorials. Your sewing machine manages fabric finishing with zigzag stitch or French seams.

These sewing techniques provide excellent fray prevention and edge binding—perfect for home sewing and sewing for beginners.

How do I match patterns at seams?

Pin notches at seam intersections first, aligning fabric grain carefully. Match pattern markings with chalk, then secure edges with sewing clips.

Test seam alignment on scrap fabric before stitching your final sheet pieces together.

What needle size works best for flannel?

You’ll want a size 14 to 16 universal needle for most flannel projects. This flannel needle size manages medium-weight fabrics smoothly. For brushed or thicker weaves, try a size 16 topstitch needle instead.

How do I prevent puckering on hems?

A puckered hem is like a wrinkle that won’t quit—it telegraphs uneven tension.

Use a compatible needle size, shorter stitch length, and press with a damp cloth before your final pass.

Can I dye fabric before sewing sheets?

Yes, you can dye fabric before sewing sheets. Pre-dyeing ensures uniform color coverage and better dye penetration into cotton fibers.

Wash fabric first, follow manufacturer guidelines for colorfastness, and heat-set properly for lasting results.

Conclusion

The irony? Store-bought sheets promise flawlessness but rarely deliver, while your homemade versions—stitched in an afternoon—actually stay put all night. Now you’ve mastered how to sew bed sheets tutorial techniques that save money and frustration.

Your sewing machine just became your bedroom’s secret weapon. Measure twice, cut once, and those corners won’t betray you at midnight anymore. You’ve got the skills. The rest is just fabric, thread, and confidence.

- https://drive.google.com/file/d/1aiZjYQysm3PApudfMT3XqV9BQIoheTO5/view?usp=sharing

- https://www.instagram.com/sewhungryhippie/

- https://www.allfreesewing.com/Bedding/DIY-Fitted-Bed-Sheet

- https://fabrics-store.com/sewing-patterns?tag_id=43&category=Bedroom

- https://mypoppet.com.au/makes/how-to-make-a-fitted-sheet/