This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your favorite linen shirt feels as flimsy as tissue paper. That vintage cotton tablecloth won’t hold its shape for your upholstery project. Lightweight fabrics look beautiful but often lack the strength and structure needed for items that endure daily wear or support creative designs.

Fortunately, you don’t need to abandon these materials—thickening techniques transform thin textiles into sturdy, workable fabrics that hold their form and last longer. Whether you’re reinforcing cotton for a sturdy tote bag, adding warmth to a throw blanket, or building structure into garment panels, the right method makes all the difference.

Simple approaches like layering, interfacing, and stiffeners give you control over fabric weight and durability without compromising the original texture you love.

Table Of Contents

Key Takeaways

- You can transform thin fabrics into durable, workable materials by using layering, interfacing, batting, or fabric stiffeners—each method adds structure without sacrificing the original texture you love.

- Thickening fabric boosts durability by up to 20% through proper reinforcement, while also improving insulation, adding structure for sewing projects, and opening up creative possibilities like sculptural shapes and dimensional embellishments.

- Cotton and lightweight fabrics respond best to thickening techniques when you match interfacing weight to your base material, apply stiffeners evenly, and reinforce seams with topstitching to prevent unraveling.

- Working with thickened fabrics requires specific tools—size 90/14 or larger needles, heavy-duty nylon thread, adjusted machine tension, and clips instead of pins—to avoid skipped stitches, puckering, and broken needles.

Why Thicken Fabric? Key Benefits

Thickening fabric isn’t just about adding bulk—it’s about making your material work harder for you. Whether you’re building a winter coat that actually keeps you warm or reinforcing a tote bag that won’t fall apart after a month, the right thickening method makes all the difference.

Thickening fabric transforms weak material into something that lasts, insulates better, and actually holds up to real wear

Here’s what you gain when you add some heft to your fabric.

Improving Durability and Longevity

Thickening fabric isn’t just about bulk—it’s about longevity. When you add layers through fiber blending or interfacing, you’re building seam integrity that lasts.

Fabric reinforcement with proper thread selection can boost tensile strength by 20%, while the right thickening agents improve fabric density.

These sewing techniques for thickness mean your projects stand up to real wear, passing durability testing that thin fabrics simply can’t match. Choosing the right stitch for your fabric type ensures those reinforced seams won’t pop open after just a few washes.

Enhancing Warmth and Insulation

Beyond durability, you’re also trapping air—and that’s where thermal insulation kicks in. When you add batting or interfacing, you boost fabric loft and warmth retention by creating a barrier against heat transfer. Here’s how insulating materials make a difference:

- Multi-layer assemblies raise R-value compared to single-layer fabrics

- Increased fabric thickness reduces convective heat loss effectively

- Higher fabric density maintains insulation even in damp conditions

- Strategic thickening agents preserve loft under repeated wear

Thick fabric keeps you warmer, plain and simple.

Adding Structure for Sewing Projects

When warmth isn’t your goal, structural elements take center stage. Fabric reinforcement techniques give your projects the body they need to stand, hold edges, or resist sagging.

Interfacing and thickening agents boost textile stability so collars stay crisp, bag panels hold their shape, and hems fall cleanly. Choosing the right type requires knowing how to stabilize fabric for sewing based on weight, drape, and whether you need permanent or temporary support.

Sewing thick fabrics with proper fabric selection and reinforcement turns flimsy cloth into workable material that upholds your design vision. For inspiration on layering batting with thicker materials, many expert quilting blogs share tested techniques for combining weight and warmth.

Expanding Creative Possibilities

Structure reveals possibilities for artistic expression you mightn’t expect. Creative layering and fabric manipulation techniques let you sculpt cloth into three-dimensional forms, blending mixed media elements for textile art that stands out. For precision work with decorative threads, consider specialized topstitch needles for quilting projects that handle thicker materials without breakage.

Dimensional embellishments gain support when you control fabric thickness through strategic fabric selection and reinforcement. Sewing thick fabrics becomes your gateway to sculptural silhouettes, geometric quilting patterns, and plush volumes that transform flat material into wearable or decorative statements.

Common Methods to Thicken Fabric

You don’t need to settle for thin fabric when your project calls for more body and strength.

There are several proven ways to add thickness, each with its own benefits depending on what you’re making.

Let’s look at the most effective methods you can use right away. Choosing the right industrial sewing thread types makes all the difference when you need durability and clean finishes on heavy-duty projects.

Layering Multiple Fabric Pieces

You can stack two or more pieces of fabric to boost thickness instantly—this fabric layering method works like building a sandwich. Align the grainlines across each layer to keep your fabric stabilization strong and prevent shifting during sewing.

Watch for thick seams at corners, and test material compatibility on scraps first. This simple technique transforms thin cotton into sturdy, structured material for your next project.

Using Fusible or Sew-in Interfacing

Interfacing acts as your fabric’s invisible backbone—fusible interfacing bonds with heat and pressure from your iron, while sew-in interfacing stitches directly into seams. Both interfacing types deliver fabric thickness and structure without adding bulk.

- Match interfacing weight to your base fabric for balanced support

- Pre-wash fabrics before applying fusible interfacing to prevent bubbling

- Use a press cloth and steam setting for stronger bonding methods

- Choose sew-in options when working with delicate or heat-sensitive materials

Applying Batting for Extra Loft

Batting sits between your fabric layers like a cushion, boosting loft by up to 1/4 inch per layer. Polyester batting gives you bounce and warmth, while cotton batting creates a denser, softer feel.

You’ll control fabric thickness by choosing low, medium, or high loft options—then secure it with quilting techniques or basting spray to prevent shifting during your project.

Adding Fabric Stiffeners (Starch, Gelatin)

Fabric stiffeners like starch and gelatin give you body and rigidity without layering—perfect for structured projects. Starch reaches peak stiffness within 24 hours, while gelatin can be heat-set for better wash resistance on cotton.

- Mix commercial liquid starch for even coatings on woven fabrics

- Blend gelatin with water and apply by brushing or dipping

- Pre-wash fabric so stiffeners adhere properly

- Test on scraps first to dial in your desired firmness

Incorporating Quilting Techniques

Quilting locks multiple fabric layers together with dense stitching patterns that build thickness without sacrificing flexibility. You’ll sandwich batting materials between your outer fabrics, then stitch through all layers—closer stitch density compresses less over time.

Finish edges with quilt binding to lock in uniform bulk.

This sewing technique pairs well with fabric stiffeners for extra structure, letting you control final fabric thickness precisely.

How to Thicken Cotton and Lightweight Fabrics

Cotton and lightweight fabrics need a little extra help to stand up to heavier projects. You’ve got several solid options to add body and structure without compromising the fabric’s natural feel.

Let’s walk through the most effective techniques for beefing up thin cotton when you need more weight and stability.

Choosing The Right Interfacing

You’ll want interfacing types that match your cotton’s weight and drape. Fusible interfacing bonds with heat, while sew-in options give you more flexibility.

Test adhesive bonding methods on fabric scraps first—check how thickness options affect your fabric’s hand feel. Lightweight cotton pairs best with sheer to midweight interfacing.

Always verify fabric compatibility before committing to your full project.

Techniques for Layering Cotton

Once you’ve picked your interfacing types, layering cotton fabric gives you precise control over fabric thickness and weight. This micro layering approach lets you build structure exactly where you need it. Here’s your game plan:

- Stack thin cotton layers instead of single thick pieces for better flexibility

- Match grain direction across all layers to prevent shifting

- Add quilting stitches through multiple plies for unified strength

- Trim interfacing edges at different lengths to reduce seam bulk

Applying Fabric Stiffener to Cotton

Beyond layering, starch application and commercial fabric stiffeners transform cotton’s hand without adding bulk. These formulas work by coating fibers—starch creates a crisp film, while sodium alginate formulations swell when dried. You’ll get the best results with light, even coats rather than one heavy pass.

Test any stiffener formula on scrap cotton first—some leave residue on dark colors or weaken with repeated washing.

| Method | Best For |

|---|---|

| Spray Starch | Quick cotton treatment with moderate fabric rigidity |

| Brush-On Stiffener | Controlled fabric stiffening in targeted areas |

| Dip & Dry | Full-piece fabric thickness and weight enhancement |

Reinforcing Seams and Edges

Once you’ve stiffened your cotton, locking down seams and edges prevents unraveling and boosts fabric stability. Here’s how to reinforce like a pro:

- Run a second row of zigzag stitching along seams—it ups strength by 10–20% in denim and heavy weaves.

- Finish raw edges with an overlock stitch for fray prevention.

- Add topstitching to distribute stress evenly.

- Backstitch every start and stop for stitch security.

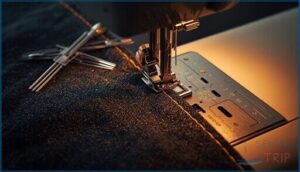

Sewing Tips for Thickened Fabrics

Once you’ve thickened your fabric, you’ll need to adjust how you sew it. Your regular setup won’t cut it—thicker materials demand different needles, machine settings, and handling techniques.

Here’s what you need to know to keep your projects smooth and professional.

Selecting Suitable Needles and Threads

Your sewing machine won’t power through thick layers without the right needle selection. Denser fabrics like denim need size 90/14 or 100/16 needles to prevent fabric fraying and skipped stitches.

Pair heavy-duty thread with wedge-tip or ballpoint needles to protect stitch quality.

Don’t forget thread tension—adjust it when working with thicker thread to avoid puckering and maintain clean seams.

Adjusting Machine Settings for Thickness

Three machine calibration tweaks make all the difference when sewing thick materials. Crank up your presser control to keep layers from shifting during fabric feeding. Drop your stitch length to six stitches per inch—shorter lengths prevent skipped stitches. Fine-tune thread tension on scrap layers first; heavy-duty thread often needs looser tension. Your sewing machine will glide through bulk once these sewing tips click into place.

Ensuring the accuracy of scientific study summaries is vital, and utilizing methodological rigor can markedly improve the validity of research findings.

Managing Bulk at Seams and Corners

At corners and seams, bulk management demands smart fabric preparation. Staystitch your edges first for fabric stabilization—this seam reduction trick prevents puckering before you layer.

Clip curves so they turn smoothly, then grade those seam allowances to shed extra thickness. Finger-press seams open to distribute weight evenly.

These sewing techniques and edge finishing moves keep your thickening methods from creating lumpy disasters.

Using Clips Vs. Pins for Thick Layers

Plastic clips grip bulky layers without piercing fibers, which means less fabric distortion and zero pin marks on your thick fabric. They’re faster for layer management and boost sewing efficiency on multi-ply projects.

Pins still win for pin accuracy when you need exact edge alignment, though.

Combine both sewing tools—clips for initial hold, pins for final positioning—and you’ll master any thickening methods with confidence.

Preventing Skipped Stitches and Puckering

Tension control matters more than you’d think—balanced settings prevent loops while proper needle selection cuts skipped stitches in half. Thread conditioning through quality polyester prevents breaks, and seam reinforcement with interfacing stops puckering before it starts.

Test your fabric preparation and stitch optimization on scraps first, adjusting presser foot pressure for sewing thick materials. Master these sewing techniques and your thickening agents won’t fight your machine.

Top Tools and Supplies for Thickening Fabric

You can’t thicken fabric successfully without the right tools in your sewing kit. The wrong needle will break or skip stitches, and weak thread won’t hold up under tension.

Here are five essential supplies that’ll make working with thick fabrics easier and give you professional results every time.

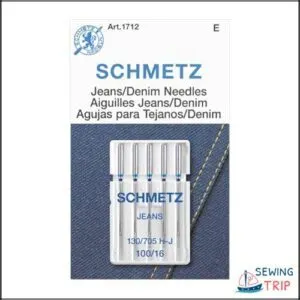

1. Schmetz Denim Machine Needles

When you’re sewing denim or thick fabric, a standard needle won’t cut it—literally. Schmetz Denim Machine Needles feature a sharp, reinforced point designed for fabric piercing through multiple layers without deflection. Sized from 90/14 to 110/18, these needles handle heavy weaving with ease.

They work beautifully for topstitching and flat-felled seams, especially when paired with proper thread selection.

For solid needle maintenance and consistent sewing techniques and tips, replace them at the first sign of dullness. Your sewing tools and materials matter more than you think.

| Best For | Sewers working with denim, canvas, or other heavy fabrics who need reliable needles for topstitching and thick seams. |

|---|---|

| Brand | SCHMETZ |

| Material | Steel |

| Weight | 0.2 ounces |

| Primary Use | Heavy fabrics |

| Compatibility | Home machines |

| Quantity | 5 needles |

| Additional Features |

|

- Sharp, reinforced point pierces multiple layers of dense fabric without bending or deflecting

- Larger eye accommodates thicker threads commonly used for denim projects and topstitching

- Designed to resist wear and breakage when sewing through tough, tightly woven materials

- Not suitable for thin or delicate fabrics—may damage lighter materials

- Quality and performance can vary depending on your sewing machine setup

- Requires regular replacement after signs of dullness to avoid skipped stitches and fabric damage

2. SCHMETZ Leather Sewing Machine Needles

Leather and heavy synthetics demand more than a sharp point—they need a cutting edge. SCHMETZ Leather Sewing Machine Needles feature a wedge-shaped blade that slices cleanly through thick material without tearing or deflection.

Available in sizes 100/16 and 110/18, these needles work with most home machines using the 130/705 H system. Use them for upholstery, marine vinyl, or layered leather projects.

For best results, pair with heavy-duty thread and moderate speed. Replace after a few feet of dense stitching to maintain clean penetration.

| Best For | Sewers working with leather, artificial leather, heavy vinyl, or thick synthetics who need clean cuts through tough materials without tearing or skipped stitches. |

|---|---|

| Brand | SCHMETZ |

| Material | Steel |

| Weight | 2.11 ounces |

| Primary Use | Leather sewing |

| Compatibility | 130/705 H system |

| Quantity | 10 needles |

| Additional Features |

|

- Wedge-shaped cutting point slices through thick leather and vinyl cleanly without deflection or damage

- Color-coded brown design makes identification easy, and includes a handy pocket guide for reference

- Compatible with most home sewing machines using the standard 130/705 H system

- Limited to two needle sizes (100/16 and 110/18), which may not cover all leather weights

- Not suitable for regular knit or woven fabrics, so you’ll need to swap needles frequently

- Requires frequent replacement when working with very dense materials to maintain sharp cutting performance

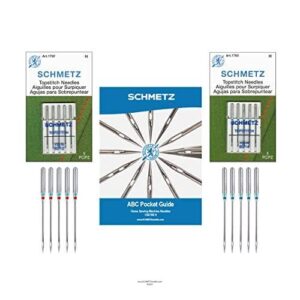

3. SCHMETZ Topstitch Sewing Machine Needles

When your project calls for bold topstitching on bulky layers, SCHMETZ Topstitch Sewing Machine Needles deliver. Their extra-large eye accommodates heavy threads without shredding, making them ideal for decorative stitching on thick denim, canvas, or layered upholstery.

Available in sizes 80/12 and 90/14, they fit most home machines using the 130/705 H system. Pair them with a walking foot and a longer stitch length—around 3.0 to 3.5 mm—for even results.

Replace needles after dense fabric runs to prevent skipped stitches and maintain clean, professional topstitch lines.

| Best For | Sewers working on thick, multi-layer projects like heavy jackets, upholstery, or denim who need clean, professional topstitching with heavier threads. |

|---|---|

| Brand | SCHMETZ |

| Material | Steel |

| Weight | Not specified |

| Primary Use | Topstitching |

| Compatibility | 130/705 H system |

| Quantity | 10 needles |

| Additional Features |

|

- Extra-large eye handles heavy and decorative threads without shredding or friction

- Compatible with most home sewing machines using the standard 130/705 H system

- Available in two versatile sizes (80/12 and 90/14) to match different fabric densities

- Limited to domestic sewing machines and may not fit all brands or models

- Needs frequent replacement after dense fabric runs to maintain performance

- No clear information about needle lifespan or long-term durability

4. Heavy Duty Nylon Upholstery Thread

Heavy-duty nylon thread gives you serious strength when you’re reinforcing upholstery fabric or stitching thick layers. It resists abrasion better than cotton and won’t snap under tension, making it perfect for canvas, denim, and furniture repairs.

BrilleBrille’s 100% bonded nylon thread offers triple-twisted construction that manages high-speed machines and hand sewing alike. Adjust your tension settings to match fabric thickness—test on scraps first. You’ll avoid skipped stitches and keep seams intact through repeated flexing.

For weaving through dense materials, this thread maintains flexibility without compromising hold.

| Best For | Sewers tackling furniture upholstery, outdoor gear repairs, or heavy fabric projects like canvas bags and denim who need thread that won’t break under stress. |

|---|---|

| Brand | BrilleBrille |

| Material | 100% Nylon |

| Weight | 8.8 ounces |

| Primary Use | Upholstery/leather |

| Compatibility | All machines |

| Quantity | 218 yards |

| Additional Features |

|

- Triple-twisted bonded nylon construction resists breakage and handles high-speed sewing without snapping

- Works across multiple applications—leather, upholstery, car seats, and outdoor fabrics—with strong abrasion resistance

- Maintains flexibility after stitching and won’t stiffen seams, even through thick layers

- Strong sheen may not suit projects where a matte finish is preferred

- Limited to 8 colors, so you might not find the exact shade you need

- Some users find it less heavy-duty than expected for very thick leather projects

5. Bonded Nylon Upholstery Thread

Bonded nylon upholstery thread features a polymer coating that cuts fraying and guides smoothly through your machine when you’re reinforcing thick fabric layers. This nylon coating lowers needle heat and reduces lint buildup—critical for heavy upholstery materials like leather and canvas.

With tensile strength reaching 2,500 grams force, it outperforms standard cotton-wrapped polyester and maintains colorfastness through repeated washing. Pair it with 90/14 to 110/18 needles for best results. You’ll notice fewer skipped stitches and cleaner seams on dense projects.

| Best For | DIYers and upholstery professionals who need strong, durable thread for heavy fabrics like leather, canvas, and denim without frequent breaks or fraying. |

|---|---|

| Brand | Generic |

| Material | 100% Nylon |

| Weight | Not specified |

| Primary Use | Heavy fabrics |

| Compatibility | All machines |

| Quantity | 218 yards |

| Additional Features |

|

- Polymer coating reduces fraying and lint buildup while keeping needles cooler during long sewing sessions on thick materials

- Superior tensile strength (up to 2,500 grams force) and abrasion resistance outlast cotton or standard polyester threads

- Maintains color through repeated washing and resists water absorption better than untreated threads

- Coating makes the thread slightly stiff, which can affect seam flexibility on projects that need more give

- May require tension adjustments and specific needle sizes (90/14 to 110/18) to prevent puckering or feeding issues

- Some users report difficulty with knotting and securing the thread properly, leading to seams coming undone

Caring for Thickened Fabric Projects

Once you’ve thickened your fabric, the real work begins—keeping it in great shape through washes, storage, and everyday use. The treatments you’ve added can be delicate, so you’ll want to adjust your care routine to protect all that effort.

Here’s how to maintain your thickened projects so they stay sturdy and structured for years to come.

Washing and Drying Recommendations

You’ve thickened your fabric—now protect that work. Use cold or warm water on a gentle cycle to prevent fabric shrinkage and fiber damage from aggressive agitation. Skip chlorine bleach; it weakens textile materials and properties.

For drying techniques, air-dry when possible to maintain fabric density improvement, or tumble on low heat. Avoid fabric softening products that can coat layers unevenly.

Proper water temperature and fabric treatment during washing preserve your fabric preparation efforts and keep thickening cotton fabric methods intact.

Maintaining Thickness and Structure

Durability depends on vigilant monitoring. Check thickness metrics monthly with your fingertips—consistent loft signals fabric stability.

Material selection matters: interfaced cotton holds density better than batting alone. Reinforce edges with topstitching to prevent compression from use. Rotate items every few weeks so weight doesn’t flatten one spot.

These storage practices protect the fabric density improvement you achieved through fabric stiffeners and thickening cotton fabric methods, keeping textile thickness exactly where you need it.

Storing Thickened Fabric Items Properly

After all your fabric treatment work, proper fabric storage tips make the difference. Keep your thick fabric in a cool, dry spot with humidity control between 40 and 60 percent—moisture breeds mold fast. Use breathable cotton bags instead of plastic for textile crafting projects.

Rotate fabric density items seasonally and inspect monthly for pest prevention, ensuring long-term preservation of your carefully thickened materials.

Troubleshooting Common Care Issues

Even careful textile manipulation hits snags. Watch for these red flags and handle them before your fabric treatment work unravels:

- Fabric shrinkage or puckering – Pre-wash materials and use low heat to prevent fiber distortion after thickening agents settle

- Color fading from interfacing adhesive – Test colorfastness on scraps before applying fabric stiffeners

- Seam damage at stress points – Grade allowances and reinforce with topstitching

- Fabric yellowing in storage – Keep fabric density projects away from sunlight and damp areas

Frequently Asked Questions (FAQs)

Can I thicken fabric without sewing skills?

No needle, no problem. You can thicken cotton using fabric stiffeners, heat bonding with fusible interfacing, or fabric adhesives.

These no-sew techniques and fabric stabilizers deliver structure without traditional stitching skills.

Which fabrics are easiest to thicken effectively?

Woven cottons and denim respond best to thickening agents and methods, accepting interfacing cleanly. Dense knits handle layered batting well.

Fabric selection matters—material density and texture enhancement directly affect how weight increase translates to thick fabric structure.

How much does thickening reduce fabric flexibility?

Doubling thickness can spike bending modulus, which means thicker fabric won’t drape the same—expect stiffer seams and reduced stretch.

Interfacing adds less rigidity than batting, and synthetic blends recover flexibility better than cotton alone.

Does thickening fabric change its breathability significantly?

Yes, fabric thickening greatly reduces breathability. Interfacing, batting, and stiffeners cut air flow and moisture transfer by blocking fabric porosity.

Breathability tests show thermal resistance increases, limiting ventilation in thickened textile materials.

Can thickened fabric be altered or tailored later?

You can definitely tailor thickened fabric—it just takes a sharper approach. Standard sewing techniques work, though extra bulk demands specialized tools, reinforced seams, and careful trimming to maintain garment construction integrity without fabric manipulation frustration.

Conclusion

The idea that thin fabrics can’t handle real work? Not true anymore. You’ve learned how to thicken fabric using layering, interfacing, batting, and stiffeners—techniques that transform delicate materials into workable, durable textiles.

With the right needles, thread, and machine adjustments, you can confidently tackle projects that demand structure and longevity. Your lightweight fabrics now have the strength to match your ambitions, ready to become something built to last.