This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your grandmother’s Morse zig zag machine might outlast anything you’ll buy at a big-box store today. These all-metal workhorses from the 1950s and 60s weren’t designed for planned obsolescence—they were built when sewing machines weighed more than a toddler and came with service manuals thicker than phone books.

But here’s the catch: buying a vintage Morse means you’re trading modern conveniences for raw mechanical reliability. You’ll need to master tension dials, hunt down replacement belts, and learn maintenance skills most sewers have never touched.

The real question isn’t whether these machines can sew—they absolutely can—but whether you’re ready to work with a machine that demands respect, regular oil changes, and a bit of elbow grease in exchange for decades of dependable stitching.

Table Of Contents

Key Takeaways

- Morse zig zag machines from the 1950s-60s are all-metal workhorses built for decades of use, but you’ll trade modern conveniences for raw mechanical reliability that demands regular maintenance and hands-on adjustment skills.

- These vintage machines deliver solid stitch quality on medium to heavy fabrics like denim and cotton, though they run louder (60-85 dB) than modern machines and require manual threading without automatic guides.

- Finding replacement parts and service manuals is a real challenge since Morse machines are orphaned vintage equipment, making you dependent on forums, third-party restorers, and luck at estate sales or auction sites.

- You’ll find functional Morse models priced between $75-$150 on platforms like eBay, making them worth considering only if you’re ready to master mid-century mechanics and perform your own troubleshooting and repairs.

Morse Zig Zag Sewing Machine Overview

You won’t find Morse sewing machines sitting on store shelves anymore, but that doesn’t mean they’ve disappeared. These vintage zig zag models pop up at estate sales and online marketplaces, and some sewers swear by them decades later.

Let’s look at which Morse models you’re likely to encounter and what makes them collectible today.

Notable Morse Zig Zag Models (MZZ, 4100, 4300, 550)

You’ll find four standout Morse Zig Zag models when diving into vintage restoration: the compact MZZ, the mid-range 4100, the sturdy 4300, and the premium 550. Each sewing machine review shows different stitch width ranges and frame weights.

The Morse Fotomatic series delivered automated zigzag functionality that collectors prize for historical significance.

Understanding these vintage Morse machines helps with model comparison and proper sewing techniques during machine collecting. The collector’s guide also relies on scientific study summaries to verify the historical accuracy of the machines.

Rarity and Collectibility

These Morse Zig Zag machines aren’t easy to track down, which makes them desirable for vintage sewing machine collecting. Model variants like the 4100 and 4300 show up sporadically in specialist auctions, and vintage prices depend heavily on collectibility factors you can’t ignore:

- Original accessories and manuals boost auction trends markedly

- Production serial ranges help verify authentic antique sewing machines

- Scarcity levels vary widely between models, affecting what you’ll pay

Key Features and Specifications

You want to know what makes a Morse Zig Zag tick before you decide if it’s worth your time and money. These machines pack some interesting design choices that set them apart from the usual vintage suspects.

Let’s break down the technical specs and build quality that define these Japanese-made workhorses.

Zig Zag Stitch Capabilities

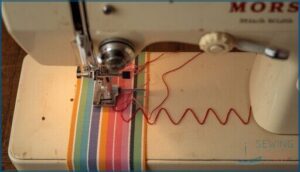

You’ll find adjustable stitch width controls right on the front of the Morse Zig Zag, letting you dial in everything from tight utility seams to wide decorative zig zag patterns on the fly.

The machine executes genuine zigzag stitching across woven and knit fabrics when you’ve got your thread tension dialed in properly, though sewing speed and fabric compatibility matter more than you’d think for consistent results.

Construction and Design Details

What really sets these machines apart is their heavy-duty build—we’re talking all-metal body construction that tips the scale past 30 pounds. The entire undercarriage moves mechanically to create that zigzag motion through steel linkages and a cam system design, not flimsy plastic gears.

These machines pack serious weight—over 30 pounds of all-metal construction with steel linkages that move the entire undercarriage mechanically

You’ll spot Toyota casting marks on the base, plus that unmistakable vintage aesthetics with painted enamel and chrome trim that screams mid-century craftsmanship. The machine’s durability is also reflected in its precision manufacturing process.

Motor Performance and Build Quality

Under the hood, you’ll encounter a belt-driven motor system that delivers steady power consistency across decades of use. When properly maintained, these vintage Morse machines prove their mettle:

- Motor efficiency stays reliable with 120V AC household power—no adapters needed

- Gear durability shines through machined metal linkages that resist wear

- Frame stability comes from cast steel construction that dampens vibration

- Belt tension adjusts smoothly for consistent stitch width during zigzag work

Regular sewing machine maintenance keeps everything humming along nicely.

Sewing Performance and Usability

A vintage machine can look great sitting on your workbench, but the real test comes when you thread it up and start sewing. You need to know if the Morse can handle your fabric projects, whether it’s easy enough for regular use, and if it’ll shake your table apart or purr along quietly.

Let’s break down how these machines actually perform when you put them to work.

Stitch Quality on Various Fabrics

You’ll get solid stitch density across cotton and denim—around 12 stitches per inch—with consistent fabric tension that holds up on medium-weight materials. The Morse Zig Zag manages lightweight synthetics without thread breakage, and seam integrity stays strong even at wider zigzag settings.

Fabric feed is smooth when you keep the machine clean and oiled, which is key for vintage sewing machines like this one.

Ease of Use for Modern Sewers

You’ll need patience threading this beast—no automatic guides here. The Morse Zig Zag demands manual dexterity and a solid grip on vintage sewing machines, but once you master the basics, it’s surprisingly straightforward:

- Threading paths require careful attention to tension discs and take-up levers

- Bobbin winding needs handwheel disengagement—easy to forget

- Stitch selection uses mechanical dials instead of push-button convenience

Maintenance tips and sewing machine troubleshooting skills become your best friends.

Noise Level and Stability During Operation

Expect the Morse Zig Zag to hum like a determined workhorse—60 to 75 dB during normal runs, spiking to 85 dB on heavy zigzag passes.

Vibration analysis shows moderate table wobble unless you mount it on something solid.

Acoustic performance trails modern machines with noise reduction tech, but regular sewing machine maintenance—belt checks, proper lubrication—keeps stability tests respectable. It’s loud, sure, but predictably so.

Maintenance and Longevity

Here’s the truth about keeping a Morse zig zag running: these machines weren’t built with planned obsolescence in mind. You can maintain one for decades if you know what you’re doing, but there are a few realities you need to face first.

Let’s break down what it actually takes to keep your vintage Morse in fighting shape.

Cleaning and Lubrication Requirements

Your Morse sewing machine thrives when you clean and oil it every 8 to 12 sewing hours. Brush lint from the bobbin area, wipe metal parts with alcohol, then apply light sewing machine oil sparingly to designated points.

Track maintenance scheduling in service logs to catch patterns and prevent timing problems. This vintage sewing machine restoration ritual takes minutes but extends your machine’s life for decades.

Common Maintenance Issues

Even well-loved vintage sewing machines throw curveballs when old lubricant hardens into gunk. Your Morse sewing machine maintenance tips boil down to catching trouble early:

- Belt replacement and motor repair stop mid-project shutdowns

- Oil leakage stains fabric unless you address worn gaskets

- Feed dog wear and rust prevention keep stitches even

Master sewing machine repair basics and your sewing machine restoration becomes straightforward, not scary.

Availability of Parts and Manuals

Tracking down replacement parts for vintage restoration turns detective work into reality—legacy suppliers and used parts markets offer your best shot at component replacement. Official manuals are scarce. Your repair resources come from third-party restorers and sewing machine clubs who’ve scanned everything. Check forums and Facebook groups where sewers share PDFs for free. Belts and tension assemblies pop up on auction sites occasionally.

| Resource Type | Where to Find It |

|---|---|

| Scanned Manuals | Sewing machine clubs, forums |

| Common Parts | Vintage marketplaces, auctions |

| Model-Specific Help | Facebook groups, communities |

| Service Guides | Third-party restorer networks |

User Experiences and Community Insights

You’ll find plenty of opinions about Morse machines if you spend time in sewing forums and vintage machine groups. Some owners have kept their Morse zig zags running for decades without major issues, while others ran into frustrations that sent them looking for replacements.

Let’s look at what actual users and collectors have to say about living with these machines long-term.

Long-Term Reliability Reports

You’ll rarely find formal durability testing or reliability metrics on these machines—most performance trends come from owner testimonies scattered across forums. Some users report smooth operation after 40-plus years with basic sewing machine maintenance, while others faced timing headaches and endless tension tweaks.

Parts scarcity complicates any restoration or repair services, making failure analysis tough. Without standardized maintenance schedules or Morse history documentation, you’re gambling on prior ownership luck.

Collector and Enthusiast Reviews

You’ll find enthusiast feedback split down the middle on vintage sewing machine forums. Some collectors prize rare model hunting opportunities—calling Morse History fascinating despite the scandal. Others dismiss these antique sewing machines as orphaned curiosities without service networks.

Sewing community trends lean toward Singer or Pfaff models with better part availability. Vintage machine value depends entirely on your willingness to wrench solo.

Is The Morse Zig Zag Worth Buying Today?

So should you actually hunt down one of these vintage machines for your sewing room? The answer depends on what you need, what you’re willing to spend, and whether you’re ready to work with 1940s-era mechanics.

Let’s break down the real-world value of owning a Morse Zig Zag today.

Pros and Cons Compared to Modern Machines

The Morse Zig Zag Sewing Machine delivers vintage value through proven machine durability—many units from the 1940s still run strong. You won’t find modern computerized stitch variety or quiet motors, but you’ll get reliable zig zag sewing and straightforward mechanics.

Repair costs can climb since parts are scarce, while contemporary machines offer broader support networks.

For sewing machine reviews and sewing machine history buffs, it’s heritage craftsmanship versus convenience.

Ideal Buyers and Use Cases

You’ll thrive with a Morse if you’re among vintage collectors hunting period-specific machines or sewing educators demonstrating mid-century engineering.

Fabric artists and home decor crafters appreciate the sturdy zig zag for heavier materials, while small repairs become second nature.

Vintage sewing machines like these suit enthusiasts drawn to sewing machine history and sewing machine restoration—not beginners chasing one-button convenience.

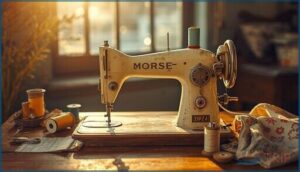

Where to Find and What to Pay

You’ll uncover Morse sewing machines through online marketplaces like eBay, where auction prices range from $50 to $200 depending on condition.

Vintage dealers and antique shops occasionally stock these antique collectibles, while collector forums connect you with restoration enthusiasts.

Expect functional models around $75-$150—fair territory for vintage sewing machines worth actual sewing, not just shelf decoration.

Frequently Asked Questions (FAQs)

Can the Morse zig zag handle thick denim?

Can vintage sewing machines tackle heavy-duty projects? The Morse zig zag shows mixed results with thick denim.

Needle penetration and presser foot pressure matter—test fabric pucker prevention on scrap fabric first before committing.

What needle types work best with Morse machines?

Your best bet for vintage sewing machines like these? Standard 15×1 needles.

Go with universal needles for everyday fabrics, ballpoint for knits, and heavier gauges (90/14 or 100/16) when tackling denim or canvas during sewing machine maintenance.

Does it support free motion quilting or darning?

Sure, your Morse can tackle free motion quilting—if you’re willing to wrestle with feed dog covers and hunt down a darning foot like it’s buried treasure.

Stitch control? Solid. Vintage accessories? Good luck finding them.

How does bobbin tension compare to modern machines?

Morse Zig Zag models demand more hands-on bobbin thread tension tweaks than modern machines. You’ll spend time balancing aging springs and worn bobbin cases—vintage machine maintenance that modern sewers rarely face with today’s self-regulating systems.

Are there common electrical problems with vintage motors?

Old motors are ticking time bombs—worn brushes cause sparking problems and voltage drops, degraded wiring risks shorts, and failed capacitors lead to motor failure during heavy sewing. Vintage repair demands patience and electrical know-how.

Conclusion

The proof is in the pudding—your Morse zig zag sewing machine review comes down to this: you’re either ready to wrench on a machine that’ll outlive you, or you’re not.

These tanks demand maintenance know-how and patience, but they reward you with stitches that won’t quit. If you’d rather master mechanics than chase warranty claims, grab one.

Just remember: vintage reliability isn’t plug-and-play. It’s earned through oil, adjustment, and respect for bulletproof engineering.

- https://www.quiltingboard.com/vintage-antique-machine-enthusiasts-f22/morse-zig-zag-machine-t198826.html

- https://sewchicpatterns.blogspot.com/2012/06/morse-sewing-machine-question-of.html

- https://thimblebook.com/2020/01/28/morse-fotomatic-4100-zig-zag-sewing-machine/

- https://www.youtube.com/watch?v=Fltf1Z5ZExQ

- https://www.reddit.com/r/sewing/comments/4cgd50/has_anyone_ever_used_a_morse_machine/