This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your sewing machine bobbin parts include four essential components that work together beneath your fabric.

Your sewing machine bobbin parts include four essential components that work together beneath your fabric.

The bobbin holds your bottom thread and comes in three main types—A, L, and M styles—each designed for specific machines. The bobbin case houses the bobbin and controls thread tension through either front-loading or top-loading designs.

Your bobbin winder fills bobbins with thread, operating manually or automatically depending on your machine model. The tension mechanism guarantees proper thread flow between top and bottom threads.

When these sewing machine bobbin parts function correctly, you get perfect stitches. When they don’t, you’ll face thread tangles and skipped stitches that can make even simple projects frustrating.

Table Of Contents

Key Takeaways

- You’ll need to identify your specific bobbins type (A, L, or M style) since they’re not universal—each machine requires exact dimensions and compatibility for proper thread flow and tension control.

- You should maintain your bobbins parts regularly by cleaning lint from cases weekly, applying one drop of machine oil monthly, and inspecting for damage quarterly to prevent costly repairs and project delays.

- You can fix most bobbins threading problems by checking proper bobbin placement, adjusting tension settings through quarter-turn screw movements, and ensuring your upper thread correctly catches the bobbin thread.

- You’ll get professional-quality stitches when your bobbin case, winder, and tension mechanism work together—keep 5-10 spare bobbins pre-wound with different thread colors for uninterrupted sewing sessions.

Sewing Machine Bobbin Types

You’ll find that sewing machine bobbins aren’t one-size-fits-all components, as they come in distinct styles like A, L, and M types that match specific machine models.

Each bobbins type has unique dimensions and features that affect how your machine feeds thread, so you’ll need to identify your exact bobbin style for proper fit and smooth stitching performance.

A-Style Bobbin Description

A-Style bobbins are compact workhorses with specific A-Style Dimensions that fit snugly in older machines.

A-Style bobbins: the reliable veterans that keep your vintage machine stitching like a dream.

You’ll find these bobbin styles in both metal bobbin and plastic bobbin varieties.

Their limited Thread Capacity makes them perfect for detail work, while proper Machine Compatibility guarantees smooth stitching.

Check your bobbin size requirements and Tension Settings for peak performance.

L-Style Bobbin Features

L-Style bobbins pack impressive bobbin capacity into their compact design, making them perfect for extended sewing sessions.

You’ll find these sturdy workhorses in both plastic bobbin and metal bobbin versions, each offering excellent material durability.

Their flat profile guarantees smooth tension consistency across various thread types.

When selecting your L-Style bobbin, check bobbin compatibility with your machine’s front-loading case.

Bobbin size matters here – these bobbins maintain consistent performance whether you’re using cotton, polyester, or specialty threads, keeping your projects running smoothly.

M-Style Bobbin Characteristics

M-Style dimensions make these bobbins the heavy-duty champions of your sewing arsenal.

With nearly double the thread capacity of standard bobbins, they’re built for marathon projects.

Their metal bobbin construction and unique tack feature deliver rock-solid tension consistency.

Perfect for industrial machines, these workhorses keep you sewing longer with fewer interruptions for rewinding.

Bobbin Material Options

Your bobbin material choice affects every stitch you make. Plastic Bobbins offer affordability and lightweight handling, perfect for everyday projects. Metal Bobbins provide superior Material Durability and consistent Bobbin Weight for professional results.

Many sewers find plastic bobbins affordable and easy to use.

Consider these key factors when selecting sewing machine bobbin parts:

- Heat Resistance – Metal handles high-speed sewing better

- Thread compatibility – Smooth surfaces prevent snags

- Machine specifications – Check your manual first

- Project requirements – Match material to fabric weight

Bobbin Case Designs

You’ll find two main bobbin case designs that determine how you load thread into your sewing machine.

Front-loading cases require you to insert the bobbin from the front of the machine, while top-loading cases let you drop the bobbin in from above.

Front-Loading Bobbin Case

When your sewing machine uses a front-loading bobbin case, you’ll access it through the machine’s front panel.

This design requires careful bobbin insertion and proper case cleaning to prevent alignment issues.

Master these essential steps:

- Case removal – Pull the bobbin case straight out using the latch

- Tension spring check – Verify it moves freely without resistance

- Bobbin parts inspection – Look for lint buildup or damage

- Sewing machine bobbin parts alignment – Insert with thread feeding counterclockwise

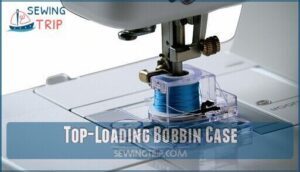

Top-Loading Bobbin Case

Right above your sewing machine’s needle plate, you’ll find the top-loading bobbin case offering clear visibility and easy bobbin case removal.

The top-loading advantages include quick thread changes and simple maintenance.

| Feature | Description | Benefit |

|---|---|---|

| Visibility | Clear view of bobbin | Easy monitoring |

| Access | Drop-in design | Simple loading |

| Materials | Plastic or metal | Durability options |

| Spring | Tension spring location varies | Consistent threading |

Most sewing machine parts work together seamlessly when your bobbin sits properly.

Bobbin Case Compatibility

Finding the perfect bobbin case match for your machine isn’t guesswork—it’s about precision.

Different machine brands require specific bobbin size and case materials to function properly.

Your sewing machine bobbin case compatibility depends on several factors:

- Bobbin size must match your machine’s specifications exactly

- Case materials affect durability and tension discs performance

- Machine brands often use proprietary bobbin cases and bobbins

- Case maintenance guarantees long-term compatibility and smooth operation

To guarantee the right fit, consider bobbin case options for your machine.

Bobbin Winder Functions

Your sewing machine’s bobbin winder fills empty bobbins with thread so you don’t have to wind them by hand.

Understanding how manual and automatic winders work helps you choose the right winding method for your specific machine and thread type.

Manual Bobbin Winder

Hand-crank winder mechanisms put you in the driver’s seat when electricity isn’t available.

You’ll control winding speed and tension control with each turn, preventing messy tangles.

The thread guide keeps everything aligned while you work.

Winder maintenance stays simple—just keep it clean and lubricated.

Your sewing machine bobbin winder becomes dependable backup equipment that never fails when you need it most.

Automatic Bobbin Winder

Modern automatic bobbin winders revolutionize your sewing experience with precise Winding Speed control and advanced Thread Sensors.

These Motor Types deliver consistent Tension Control while eliminating guesswork.

Automation Benefits include hands-free operation and perfect thread distribution every time.

Your sewing machine bobbin winder becomes a reliable partner, turning bobbin winding from tedious chore into effortless precision for all sewing machine parts maintenance.

Bobbin Winder Compatibility

Bobbin winder compatibility depends on your sewing machine models and bobbin brands.

Check your manual for winder motor specs and spindle size requirements before purchasing. Different machines need specific winder tension disks and arm movement patterns.

Key compatibility factors include:

- Winder spindle size – Must match your compatible bobbins exactly

- Automatic shut-off features vary between sewing machine brands

- Winder arm movement differs across manufacturers

- Bobbin brands often require specific winder motor specs.

Always verify compatibility first.

Bobbin Thread Tension

You’ll need to master bobbin thread tension to achieve professional-quality stitches that won’t pucker or skip.

Proper tension balance between your top thread and bobbin thread creates even, secure seams that’ll hold up to regular use and washing.

Proper Thread Tension Techniques

Perfect thread tension creates balanced stitches that look identical on both fabric sides.

Your sewing machine’s delicate dance between upper and bobbin thread determines whether you’ll get professional results or frustrating tangles.

Master these fundamentals:

- Match thread types to fabric weight—lightweight threads for delicate materials, heavy-duty for denim and canvas

- Check bobbin thread path through the tension spring—it should glide smoothly without catching or jerking

- Test fabric effects on scraps first—different materials require unique tension settings for ideal results

Tension troubleshooting starts with understanding that your sewing machine parts work together.

When bobbin tension feels right, your stitches flow effortlessly without puckering or loose loops.

Thread Tension Adjustment

When tension troubleshooting reveals unbalanced stitches, it’s time for expert adjustments.

Locate the flat-head screw on your bobbin case and turn clockwise to tighten bobbin tension. Make quarter-turn adjustments, testing each change on fabric scraps.

Fabric impact affects stitch quality, so adjust accordingly. Mark your original screw position before starting.

Remember: bobbin weight influences tension needs. Most sewing machine troubleshooting requires patience and small incremental changes for ideal thread tension balance.

Common Thread Tension Issues

Looking for thread problems? Three issues scream tension troubleshooting time: looping thread underneath your fabric, puckered seams, and constant thread breakage during sewing.

- Uneven stitches appear when your bobbin case tension doesn’t match your sewing speed

- Bobbin winding problems create inconsistent thread delivery to your needle

- Dirty sewing machine parts cause erratic bobbin problems and poor stitch quality

Clean and adjust for smooth operation.

Bobbin Maintenance Tips

You’ll extend your sewing machine’s life and prevent costly repairs by maintaining your bobbins parts regularly.

Clean bobbins cases remove lint buildup while proper lubrication keeps the mechanism running smoothly for years of reliable stitching.

Cleaning Bobbin Cases

After you’ve perfected your thread tension, it’s time to tackle those grimy sewing machine bobbin cases.

Start with case disassembly by removing the bobbin holder carefully. Use a small brush for lint removal from tight corners. Cotton swabs dipped in gentle cleaning solutions work wonders on stubborn debris.

For specialized tools, consider exploring options for bobbin case products. This preventative care stops bobbin problems before they start.

Regular sewing machine maintenance keeps your sewing machine repair bills low.

Lubricating Bobbin Parts

Keep your bobbin parts running smoothly with proper oil application. A single drop of quality sewing machine oil on moving parts prevents friction and extends component life.

Here’s your essential lubrication routine:

- Apply oil sparingly – One drop per pivot point prevents over-oiling and residue buildup

- Choose the right lubricant types – Use only sewing machine oil, never household oils or WD-40

- Frequency matters – Oil monthly for regular users, quarterly for occasional sewers

Troubleshooting Bobbin Problems

Bobbin problems can derail your sewing project fast. Thread Snapping often stems from improper threading or damaged bobbin cases. Uneven Stitches signal tension issues between your upper thread and sewing bobbin.

Bobbin Jams require immediate attention—remove tangled thread carefully.

| Problem | Cause | Solution |

|---|---|---|

| Thread breaks | Wrong bobbin type | Check sewing machine bobbins compatibility |

| Stitches skip | Dirty bobbin cases | Perform case cleaning regularly |

| Tension Issues | Overwound bobbin | Consider bobbin replacement immediately |

Regular Bobbin Maintenance Schedule

Smart sewers follow a consistent maintenance routine that keeps their machines humming. Your sewing machine maintenance and care routine should include these essential steps:

- Weekly cleaning frequency: Remove lint from bobbin cases and check sewing bobbin condition

- Monthly oiling guidelines: Apply one drop of machine oil to bobbin winder mechanisms

- Quarterly inspection points: Examine bobbins for cracks and assess replacement timing

- Proper bobbin storage: Organize bobbins in cases to prevent damage prevention

- Annual bobbin organization: Replace worn bobbins completely

Frequently Asked Questions (FAQs)

What is the part that holds the bobbin called?

Ever wondered what cradles your bobbin while you’re stitching away?

The bobbincase is the metal housing that holds your bobbin securely in place, allowing smooth thread flow during sewing operations.

What to do when your bobbin won’t catch?

Check your bobbin’s placement first—it might be upside down or not seated properly.

Rethread your machine completely, ensuring the upper thread catches the bobbin thread.

Clean out any lint that’s blocking the mechanism.

Do all bobbins fit all sewing machines?

Think all bobbins are created equal? They’re not.

Each sewing machine needs its specific bobbin size and style.

Even machines from the same brand can require different bobbins, so always check your manual first.

What holds bobbin while thread is wound on it?

Your sewing machine’s bobbin spindle holds the bobbin firmly in place while you wind thread onto it.

This small but essential component keeps everything steady, ensuring even thread distribution for smooth, consistent stitching every time.

How do I choose the right bobbin?

Struggling with bobbin choices?

Check your machine’s manual for exact specifications since bobbins aren’t universal.

Even same-brand machines use different styles.

When in doubt, contact customer support or use manufacturer filters online.

What happens if a bobbin is overfilled?

Overfilled bobbins cause thread jamming, uneven stitches, and machine tension problems.

You’ll hear grinding sounds as excess thread tangles underneath.

Your needle might break, and fabric won’t feed properly through the machine, leading to machine tension problems.

Can I use non-brand-specific bobbins?

Generic bobbins aren’t universally compatible, even within the same brand.

Each machine requires specific sizes and styles.

Check your manual or use manufacturer filters to find the right match—wrong bobbins cause tension issues.

Why does my bobbin thread keep tangling?

Like a tangled ball of yarn, your bobbin thread creates chaos when tension’s too tight, machine’s threaded wrong, or bobbin’s damaged.

Check tension settings, rethread properly, and inspect your bobbin for nicks or rough edges.

How do I fix a jammed bobbin?

Turn off your machine and remove the bobbin case.

Gently pull out tangled thread with tweezers. Check for lint buildup and clean thoroughly.

Rethread the bobbin properly, ensuring it sits correctly before resuming sewing.

How many spare bobbins should I keep?

You should keep 5-10 spare bobbins on hand.

This lets you pre-wind different thread colors and swap them quickly without stopping mid-project.

Having extras prevents workflow interruptions when bobbins run empty unexpectedly, allowing for quick swaps.

Conclusion

Like a well-oiled clock, your sewing machine bobbin parts must work in perfect harmony to create flawless stitches.

You’ve learned about bobbin types, cases, winders, and tension systems that keep your machine running smoothly.

Regular maintenance prevents costly repairs and frustrating project delays, so clean your bobbin case monthly, check thread tension regularly, and replace worn parts promptly to ensure your machine continues to run smoothly.

Master these sewing machine bobbin parts, and you’ll transform from struggling beginner to confident seamstress who tackles any project with ease.

- https://www.thesprucecrafts.com/fixing-bobbin-thread-bunching-looping-tangling-2978069

- https://www.youtube.com/watch?v=GOlCy9yGG2Q

- https://www.reddit.com/r/sewhelp/comments/lhjfsp/bobbin_keeps_doing_this_and_jamming_so_i_cant/

- https://www.quora.com/Why-is-my-sewing-machine-bobbin-thread-not-pulling-out-as-of-its-locked

- http://www.melco-service.com/source1/Troubleshooting_Bobbin_Thread.htm