This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Last month, a seamstress posted a photo of her torn vintage silk—the culprit wasn’t cheap thread or operator error, but a universal needle plowing through delicate fibers like a bulldozer through lace. Thread tension looked perfect, machine settings checked out, yet every seam puckered like accordion pleats. The fix took five seconds: swapping to a 60/8 microtex sharp transformed her disaster into impeccable French seams.

Last month, a seamstress posted a photo of her torn vintage silk—the culprit wasn’t cheap thread or operator error, but a universal needle plowing through delicate fibers like a bulldozer through lace. Thread tension looked perfect, machine settings checked out, yet every seam puckered like accordion pleats. The fix took five seconds: swapping to a 60/8 microtex sharp transformed her disaster into impeccable French seams.

Most sewers blame their machines when projects go sideways, but 80% of stitch problems trace back to needle mismatch—wrong size, wrong point, or a dull tip pushing fabric instead of piercing it. A sewing machine needle chart eliminates guesswork by mapping fabric weights to specific needle types and sizes, turning trial-and-error into precision work.

When you understand which needle geometry suits jersey versus denim, your stitches lock consistently, skipped loops vanish, and fabric damage becomes a distant memory.

Table Of Contents

Key Takeaways

- Needle mismatch causes 80% of stitch problems—wrong size, point type, or dull tips create puckering, skipped stitches, and fabric damage that sewers mistakenly blame on their machines.

- The dual numbering system (like 80/12 or 90/14) measures needle diameter in European millimeters and American scale, directly dictating which fabric weights and thread types will produce clean stitches without breaking or leaving visible holes.

- Replace needles every 6-8 hours of sewing time or immediately when switching between fabric types, since worn needles show warning signs like thread breaks, popping sounds, and snags long before sewers notice the damage.

- Matching needle geometry to fabric structure—ballpoint for knits, sharps for wovens, stretch for elastics—eliminates guesswork and transforms inconsistent results into professional-quality seams every time.

Sewing Machine Needle Types

Choosing the right needle type makes all the difference between smooth sewing and constant frustration. Each needle design fulfills a specific purpose, from managing delicate knits to powering through multiple layers of quilting cotton.

Here are the five essential needle types you’ll reach for again and again.

Universal Needles

Think of universal needles as your sewing Swiss Army knife—they’re the go-to choice for everyday projects. Their slightly rounded tips pierce most woven and knit fabrics without snagging, delivering consistent stitch quality across medium-weight materials like cotton, linen, and blends.

You’ll find these sewing machine needles in common sizes like 80/12 or 90/14, making needle selection straightforward for general work. The needle material—usually steel—manages moderate sewing speeds while maintaining proper fabric tension.

Their thread compatibility spans cotton, polyester, and all-purpose threads, which is why experienced sewers keep several universal needle types on hand for adaptable stitching needs.

Ball Point Needles

While universal needles manage general sewing, your knit fabrics need a gentler approach—that’s where ballpoint needles come in. With their rounded tips, they slip between threads instead of cutting through them. These specialized ballpoint needles prevent runs and snags by parting fibers rather than piercing, securing proper stitch formation without damaging delicate knits.

You’ll achieve professional results when you match needle size to fabric weight:

- Size 70/10 for lightweight jersey and delicate tricot

- Size 80/12 for standard t-shirt knits and interlock

- Size 90/14 for heavier sweater knits and ponte roma

- Size 100/16 for thick fleece and bulky knit fabrics

- Regular needle maintenance secures consistent fabric compatibility

Ball point tips maintain needle durability across various sewing machine needle types, making them essential for anyone working with stretchy materials.

Stretch Needles

Ballpoint needles work well for most knits, but when dealing with high-stretch synthetics like Lycra or swimwear, stretch needles are the better choice. They prevent the frustrating skipped stitches that ballpoints can’t always avoid. The modified scarf and special eye design of stretch needles accommodate fabric stretch while maintaining needle flexibility during elastic recovery. You’ll notice the difference immediately when sewing elastic materials—no more thread breaks or puckering.

Pair stretch needles with stretch stitches for the best sewing machine needle selection, and you’ll master even the trickiest elastic fabrics.

| Fabric Type | Recommended Needle Size |

|---|---|

| Lycra/Spandex | 75/11 or 90/14 |

| Swimwear | 75/11 |

| Athletic wear | 75/11 or 90/14 |

| Power mesh | 75/11 |

| Elasticized knits | 90/14 |

Sharps Needles

When tightly woven fabrics start giving your universal needles trouble, sharps needles cut through with surgical precision. Their razor-sharp point needles pierce densely woven materials without deflection, making them essential for heavy fabric sewing and delicate work on microfiber or silk. The extra-strong shaft resists bending under pressure, which is critical for needle breakage prevention when you’re stitching through multiple layers.

For sewing machine accuracy, match your needle size to fabric weight—75/11 for lightweight materials, 90/14 for medium fabrics. Proper fabric piercing techniques combined with the right needle types guarantee clean stitching every time, transforming your sewing machine needle selection from guesswork into mastery.

Quilting Needles

Quilting needles slice through layer upon layer of batting and fabric like a hot knife through butter, turning what could be a frustrating wrestling match into smooth, controlled stitching. Their tapered shaft and sharp point prevent fabric shifting when you’re working with multiple batting materials, while the slightly larger eye accommodates thicker threads without compromising thread tension.

- Designed for precise stitch patterns across complex quilt sandwiches

- Features a reinforced blade that resists deflection through dense layers

- Excels with both hand-guided and machine quilting techniques

Match your needle sizes to your fabric selection—80/12 for lightweight quilts, 90/14 for heavier projects.

Quick Reference Chart

You don’t need to memorize these combinations—just bookmark this quick reference chart and you’ll know exactly which needle to grab every single time.

This needle comparison acts as your fabric selector and stitch optimizer, matching the right needle size and needle types to your material without guesswork.

| Fabric Weight | Recommended Needle Size |

|---|---|

| Lightweight (Silk, Chiffon) | 60/8 to 70/10 |

| Medium (Cotton, Linen) | 80/12 to 90/14 |

| Heavyweight (Denim, Canvas) | 100/16 to 110/18 |

| Knits (Jersey, Interlock) | 70/10 to 90/14 Ballpoint |

| Specialty (Leather, Vinyl) | 90/14 to 100/16 Sharp |

Your thread guide follows naturally—finer threads pair with smaller sewing machine needle sizes, while heavier threads demand larger ones. This size converter helps you understand sewing machine needle types and uses, guaranteeing every stitch forms correctly.

What Do The Size Numbers Mean?

Those two numbers stamped on every needle—like 80/12 or 90/14—aren’t random codes, but a precise measurement system that tells you exactly how thick your needle is and which fabrics it can manage. The first number represents the European system, measuring the needle’s diameter in hundredths of a millimeter—so a 90 needle is 0.9 mm thick. The second number follows the American system, ranging from 8 to 18. Both systems track the same thing: needle thickness.

Here’s how these needle sizes guide your sewing:

- Fabric thickness determines your starting point—lightweight silks need 60/8 needles, while denim demands 100/16 or larger

- Thread weight must match your needle size—finer threads require smaller eyes to prevent slipping and maintain stitch quality

- Sewing speed improves with proper sizing—the right needle types eliminate drag and skipped stitches

- Stitch quality depends on this balance—oversized needles leave visible holes, undersized ones break thread

- Your needle size guide stays consistent across brands—these measurements are universal standards

Master this system and you’ll know exactly which sewing machine needle to reach for every time.

How Often Should I Change My Needle?

Most sewers wreck at least one project before they realize their needle’s been dulling for hours—and once you spot thread breaks or skipped stitches, the damage is already done. The industry standard for needle replacement is every 6-8 hours of sewing time, but that’s just your baseline. Heavy fabrics like denim and canvas accelerate needle wear signs dramatically, sometimes requiring changes after just one or two projects.

Watch for these clear indicators that your sewing machine needle needs immediate replacement:

- Thread breakage, skipped stitches, fabric snags, popping sounds during sewing, or visible puncture holes larger than your thread diameter

Your sewing frequency matters too—if you’re tackling synthetic materials or multiple fabric layers, you’ll burn through needles faster than someone working with cotton quilting weight. Smart needle care means keeping spares in every needle size you use regularly. Think of needle troubleshooting and machine maintenance as prevention, not reaction, because that $3 needle protects hundreds of dollars in fabric and countless hours of work.

Smart needle care means keeping spares in every size—that three-dollar needle protects hundreds in fabric and countless hours of work

Fitting a New Needle

Swapping out a needle takes about thirty seconds, but installing it wrong can wreck your tension, snap threads mid-seam, or send that tiny metal shaft tumbling into your machine’s inner mechanics. Start by tucking paper under the presser foot—that’s your safety net if the needle drops during removal. Loosen the needle screw, pull the old needle out, and grab your fresh replacement.

Here’s your quick-check installation guide:

| Step | Action | Why It Matters |

|---|---|---|

| Orientation | Flat side faces back | Guarantees proper needle alignment |

| Insertion | Push up until it stops | Prevents thread tension issues |

| Tightening | Secure needle screw firmly | Stops mid-stitch needle movement |

Needle alignment determines whether your sewing machine maintenance pays off or backfires. Match your needle size and needle types to your fabric before installation—your sewing technique depends on it. Store spare needles organized by size for faster swaps. When needle selection and machine calibration work together, you’ll notice smoother stitching and zero frustration.

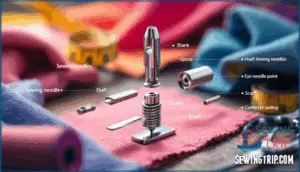

Anatomy of a Sewing Machine Needle

Every tiny piece of a sewing machine needle has a job to do, and knowing what each one does turns confusing needle charts into simple choices. The shank—that flat-backed top section—locks your needle into position without wobbling. Below it, the shaft carries a groove that shepherds thread toward the eye, where precise eye design matches thread weight to prevent needle breakage. At the business end, needle point types determine how cleanly you pierce fabric, while the scarf creates space for your machine’s hook to grab thread mid-stitch.

Understanding needle anatomy transforms needle selection from guesswork into strategy:

- Shaft materials affect durability—chrome-plated steel resists corrosion and heat buildup during extended sewing sessions

- Scarf functions vary by needle types, with deeper indentations preventing skipped stitches on stretchy fabrics

- Eye design directly impacts thread compatibility—too small causes fraying, too large creates unsightly holes

- Needle point types range from sharp (wovens) to ballpoint (knits), matching fabric structure to minimize damage

Match these components to your fabric and thread, and you’ll sidestep frustration before it starts.

Sewing Machine Needle Brands

When component knowledge meets brand reputation, your sewing machine needle selection becomes foolproof. Groz-Beckert and Schmetz dominate the market with precision engineering across 47 textile sectors—Schmetz alone generated €29.1 million in 2024, proving their durability under industrial and home conditions. Organ Needle Co. shipped 2,797 global exports with a 14% market share, offering reliable thread compatibility at competitive prices. Klasse specializes in home sewing machine needles with color-coded shanks for quick size identification, a product innovation that simplifies sewing machine maintenance and repair.

These brands invest heavily in customer support and R&D, developing specialized needle types for embroidery, denim, and technical fabrics. Brand comparison reveals consistent quality, but your fabric weight and sewing machine brands and models determine which performs best. For peak performance, consider using high speed needles to boost your sewing experience.

How to Choose Sewing Machine Needle Sizes

Choosing the right needle size isn’t guesswork—it’s about matching your fabric weight and thread to the needle’s diameter. Getting this pairing right prevents skipped stitches, thread breaks, and fabric damage while guaranteeing clean, professional results.

The following considerations will help you select the correct needle every time you sit down at your machine.

Needle Size Selection

Think of needle size as the gatekeeper between your thread and fabric—get it wrong, and even the smoothest machine will stumble. Match your needle size to what you’re working with:

- Fabric thickness dictates diameter—delicate silks need 60/8, while canvas demands 110/18

- Thread weight must pass cleanly through the eye without fraying

- Sewing speed increases heat, so durable needles prevent mid-project breaks

- Stitch quality suffers when mismatched needles create puckers or skipped loops

Needle Type Considerations

Your fabric selection drives everything—but needle type solidifies the win. Ballpoint needles slip between knit fibers without snagging, while stretch needles use specialized scarfs to lock stitch formation on Lycra. Universal needles manage most wovens, but microtex sharps pierce silk cleanly. For denim, blade-point designs prevent deflection and maintain thread tension through thick layers.

Match sewing machine needle types to your material, and you’ll avoid skipped stitches and frayed threads every time. Understanding the right needle size options is essential for achieving professional results.

Proper Needle Replacement

Even the best needle choice won’t deliver clean stitches if the needle itself is worn, bent, or has a burr on the tip. Needle wear signs include skipped stitches, popping sounds during fabric penetration, or visible thread fraying. Replace your sewing machine needle every 6-8 hours of sewing—or immediately when switching between heavy denim and delicate silks.

Needle inspection takes seconds: roll the flat shank side across glass to spot bends. Proper replacement schedules and damage prevention through careful storage maintain sewing performance and prevent troubleshooting headaches during critical projects.

Frequently Asked Questions (FAQs)

What is a sewing machine needle size chart?

The right needle transforms your work—it’s not just hardware, it’s precision matched to purpose.

A Sewing Machine Needle Size Guide decodes those number pairs, helping you select the correct needle size and type for fabric compatibility and thread selection, achieving perfect stitching every time.

What is a sewing machine needle guide?

A sewing machine needle guide clarifies needle types, sizes, and fabric compatibility to help you select the right tool for each project. It covers thread selection, machine compatibility, and needle material—preventing common sewing machine needle troubleshooting issues like skipped stitches or broken threads.

How do you identify a sewing machine needle?

Look for the flat shank at the top, a groove running along the shaft, and the eye near the tip. Needle Inspection reveals whether the point is sharp or dull—critical for Sewing Performance.

Thread Compatibility and Fabric Analysis depend on matching Needle Size and Needle Types to your Sewing Machine’s requirements.

How many needles are in a sewing machine?

Most sewing machines operate with a single needle at a time, though specialized models offer twin or triple needle configurations for decorative stitching.

Your needle selection and replacement frequency directly impact sewing efficiency, making proper needle size and needle types essential for maximum machine capacity.

What are the different types of sewing machine needles?

Universal needles work for most projects, but fabric compatibility matters. Ballpoint needles prevent snags in knits, while sharp needles excel with woven fabrics. Stretch needles manage elastic materials, denim needles power through heavy layers, and leather needles pierce tough hides. Quilting and topstitching needles offer specialized performance.

Needle materials and durability affect thread selection and sewing techniques across all needle types and sizes.

What do sewing machine needle numbers mean?

Those numbers indicate needle diameter—the European size (first number) and American size (second number). Smaller numbers like 70/10 are for delicate fabrics and finer thread compatibility, while larger sizes like 100/16 tackle heavyweight materials, achieving peak sewing performance and proper needle calibration for your sewing machine.

How do I know what sewing machine needle to use?

Start by matching your needle type to your fabric—ballpoint for knits, sharps for wovens, and denim needles for heavy materials.

Then check the needle size against your thread weight, confirming the eye accommodates smooth thread passage without breakage or skipped stitches.

What is a 90 14 needle used for?

A 90/14 needle suits medium-weight fabrics like denim, corduroy, and quilting cotton perfectly. This needle size guarantees proper needle thread compatibility and stitch quality factors while preventing needle breakage.

It’s your go-to choice for everyday sewing projects requiring balanced fabric weight considerations.

What is an 80/12 needle used for?

An 80/12 sewing machine needle size works beautifully for lightweight to medium-weight fabrics—think cotton, polyester, and linen.

It’s your workhorse for everyday projects, pairing well with standard thread weights while delivering clean stitch formation and proper needle thread tension without damaging delicate weaves.

What is a 100/16 needle used for?

Heavy fabrics like denim, canvas, and upholstery demand a 100/16 needle—thick enough to punch through dense layers without bending or breaking.

This heavy-duty upholstery needle accommodates thick thread usage and manages leather crafting with ease, making it essential for denim stitching and sturdy home décor projects.

Conclusion

A single wrong needle can sabotage weeks of careful work, turning flawless fabric into a puckered mess that no amount of pressing will fix. Your sewing machine needle chart transforms that chaos into control, matching fabric weight to needle geometry with surgical precision.

When you pair silk with a 60/8 microtex or denim with a 100/16 sharp, skipped stitches and broken threads become myths. The difference between amateur frustration and professional results isn’t talent—it’s knowing which tool belongs in your machine before the first stitch drops.

- https://www.sewjersey.com/blogs/quilting-tips/what-do-sewing-machine-needle-sizes-mean

- https://www.tolindsewmach.com/thread-chart.html

- https://www.bycurated.com/sewing-machine-needle-sizes/

- https://www.verifiedmarketreports.com/product/sewing-machine-needle-market/

- https://www.schmetzneedles.com/pages/sewing-machine-needle-chart