This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

When comparing the strongest hand stitch vs the strongest stitch on a sewing machine, you’ll find the backstitch reigns supreme for hand sewing.

Overlapping stitches provide unparalleled strength, making it ideal for joining felt, repairs, and outlines.

For machine sewing, the backstitch outshines the straight stitch in durability.

However, don’t dismiss the efficiency of straight stitches for quick, regular stitching.

Ultimately, your choice depends on the project’s demands and your skill level.

But let’s delve deeper to uncover the secrets of truly durable stitching.

Table Of Contents

Key Takeaways

- The backstitch is the strongest hand stitch, providing unparalleled strength through overlapping stitches.

- Machine-sewn backstitch is stronger than straight stitch, but hand-sewn backstitch is more durable and long-lasting.

- Properly maintained hand-stitched products can endure for generations.

- Select the optimal stitch based on desired resilience and aesthetic appeal.

Strongest Hand Stitch Vs Strongest Stitch on Sewing Machine

Harness the potential of manual stitching and sewing machines to generate robust and enduring stitches.

Manual stitching, with its amplified thread tension and thicker thread options, provides more robust seams that can endure greater wear and tear.

Saddle stitching, a specialized manual stitching approach, yields a secure and durable seam that withstands tearing.

Properly maintained hand-stitched products can endure for generations.

Nevertheless, machine stitching, while more efficient, may not provide the same degree of durability and longevity.

Select the optimal stitch for your undertaking based on your desired resilience and aesthetic appeal.

Hand Sewing: Backstitch Overview

The backstitch is considered the strongest hand stitch, renowned for its durability and ability to withstand wear and tear. You’ll learn the key steps to execute this versatile stitch, as well as its various applications, from joining felt pieces to creating decorative designs.

What is the Strongest Stitch?

The strongest hand stitch is the backstitch, which is a variation of a straight stitch. In the backstitch, the needle is placed behind the thread on the wrong side of the fabric, and the stitches on the wrong side overlap each other, providing strength. The backstitch is commonly used for joining felt pieces, hand repairs and mending, sewing outlines and designs, and as an alternative to knots at the start and end of sewing.

When working the backstitch by hand, it’s essential to keep the same distance from the fabric edge when sewing around corners and adjust the spacing of backstitches as needed. The front side of the fabric will resemble straight stitches, while the back side will have overlapping thread loops. The backstitch is a strong stitch that can secure the thread and add strength to the seam, making it an ideal choice for various sewing techniques.

The backstitch is also used as an alternative to knots at the start and end of sewing. To secure the thread and add strength to the seam, you can work 2-3 backstitches on top of each other at the start and end of a row of stitches. This technique avoids unsightly bumps from knots and ensures a clean finish for your sewing project.

Tips on Working the Backstitch by Hand

To work the backstitch by hand, start with a strong thread and pin your fabric pieces together.

Begin sewing near the edge, pushing the needle through the fabric from the back to the front.

Then, bring the needle up from the back and push it down near the previous stitch.

Use your finger as a guide along the fabric edge and keep the same distance from the edge when sewing around corners.

Adjust the spacing of backstitches as needed.

Remember that the front side of the fabric will resemble straight stitches, while the back side will have overlapping thread loops.

This stitch is commonly used for joining felt pieces, hand repairs, and mending, as well as sewing outlines and designs.

What is This Strong Back Stitch Used For?

The backstitch, renowned as the most resilient hand stitch, surpasses even the most robust stitch on a sewing machine in terms of strength and durability.

Its versatility extends from repairing tears to constructing enduring seams in areas subject to significant stress.

It’s your reliable choice for outlining shapes or as a solid starting point, providing an exceptional balance of strength and precision without excessive thickness.

Machine Sewing: Straight Stitch Vs Backstitch

You’ve mastered the backstitch, the most durable hand-stitching technique.

But now it’s time to explore the machine stitch equivalent.

Are you ready to compare the resilience and longevity of the backstitch against the formidable straight stitch from a sewing machine?

Selecting the appropriate stitch is imperative for your project’s triumph.

Assessing the advantages and disadvantages of hand versus machine stitching will empower you to make an enlightened choice.

Comparing Durability and Longevity

In contrasting the durability and longevity of hand stitching and machine stitching, the backstitch emerges as one of the most robust hand stitches.

This technique entails threading the needle behind the thread on the wrong side, producing overlapping stitches that impart strength.

Conversely, the straight stitch employed on a sewing machine is widely favored for its efficiency and consistency.

Nonetheless, for items that necessitate exceptional durability and longevity, hand stitching with a backstitch may be a superior option.

Contemplate the intended purpose and utilization of the item, desired durability, accessibility of skilled hand stitchers, and personal preferences when selecting the optimal stitch for your project.

Choosing the Right Stitch for Your Project

When considering the appropriate stitch for your endeavor, the selection between a backstitch and a straight stitch can be pivotal in terms of resilience and longevity.

Backstitch variations provide enhanced control over the placement and firmness of the stitches, rendering them indispensable for intricate designs and mending.

The caliber of the needle and the thickness of the fabric ought to be taken into account, along with adjustments to the thread’s tension.

Ornamental backstitching can bestow a distinct aesthetic upon your creation, positioning it as a robust alternative to knots at the commencement and conclusion of sewing sequences.

Understanding the attributes of the most robust hand stitch and the most robust stitch on a sewing machine will empower you to make well-informed decisions for your project.

Hand Vs Machine Stitching: Pros and Cons

Concerning hand versus machine stitching, there are advantages and disadvantages to evaluate.

Machine stitching is typically quicker and more regular.

However, it might not offer the same level of sturdiness and lifespan as hand stitching.

Hand stitching, on the other hand, demands a higher skill level and is more time-consuming.

But it can create a distinctive appearance and is often favored for smaller projects or items with intricate designs.

The decision between hand and machine stitching ultimately hinges on your skill level, time constraints, cost considerations, aesthetic preferences, and project scale.

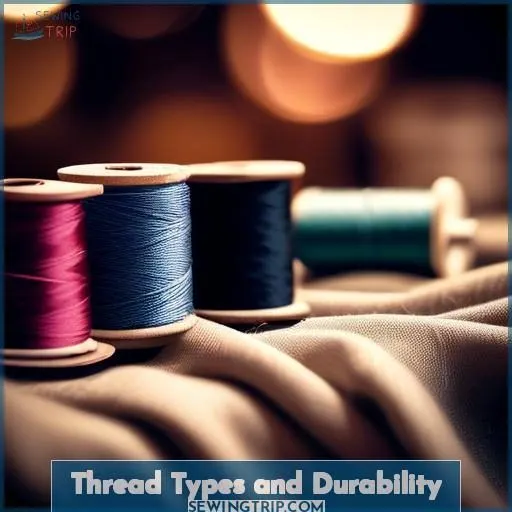

Thread Types and Durability

You have various thread options for durable stitching, each with its distinctive features. Artificial sinew, linen, nylon, dacron, and waxed thread are renowned options, known for their resilience, resistance to wear and tear, and appropriateness for various sewing methods.

Artificial Sinew

Artificial sinew, a durable thread option, is perfect for those seeking strong and comfortable stitching.

To prepare it for use, coat with beeswax and twist before stitching.

Artificial sinew is suitable for various applications, including joining felt pieces, hand repairs, and mending.

It’s also a popular choice for sewing outlines and designs.

When choosing thread, consider factors like durability and supplier availability.

Tandy Leather Factory and Brettuns Village are among the top suppliers for artificial sinew.

Linen

Linen thread is a popular choice for hand stitching due to its durability and long-lasting properties.

To prepare linen for stitching, it can be coated with beeswax and twisted before use.

Linen is strong and smooth, creating even stitching.

It’s also water-resistant, making it ideal for outdoor projects.

Linen thread is available from various suppliers, including Tandy Leather Factory and Brettuns Village.

Nylon

Nylon thread is a sought-after option for heavy-duty applications due to its fortitude and endurance. It originates from nylon polymers, rendering it more resilient to abrasion and less susceptible to fragility compared to conventional sewing threads. Nylon thread is recognized for its substantial tensile strength and immunity to chemicals, abrasion, and sunlight, making it appropriate for a diverse array of applications, encompassing work uniforms, outdoor apparel, upholstery, and industrial conveyer belts.

When it pertains to durability and longevity, nylon thread emerges as a formidable contender. It possesses a breaking strength of approximately 11 lbs, which is befitting for heavy-duty applications. Nylon thread is also resistant to moisture, acidic and alkaline environments, and aging, establishing it as a dependable choice for enduring seams.

Nylon thread is accessible in an assortment of diameters and vibrant colors, including clear-colored, and it won’t discolor or yellow over time. It can be procured in a variety of sizes, such as #69 and #207, which offer varying strengths and diameters to align with diverse sewing projects.

When seeking nylon thread, it’s crucial to contemplate the specifications of the thread, such as its breaking strength, heat resistance, and affinity with dyes. Nylon thread is also available in a bonded form, which incorporates a protective coating to impede fraying and heat due to friction during sewing.

Nylon thread finds widespread usage in various industries, including sewing, upholstery, and automotive interiors, owing to its strength, flexibility, and stretch. It’s also suitable for heavyweight materials like leather, canvas, vinyl, and webbing.

Dacron

Dacron thread is renowned for its strength and durability.

It is a popular selection for various applications, including outdoor use.

When compared to other thread types, Dacron demonstrates a superior strength-to-weight ratio.

It is impervious to abrasion, making it suitable for challenging environments.

Dacron is also nonconductive and nonmagnetic, which is advantageous in industries where such attributes are imperative.

Regarding cost-effectiveness, Dacron is frequently less expensive than other high-strength materials.

This makes it an attractive option for those seeking a balance between performance and affordability.

Waxed Thread

Waxed thread is a versatile and durable thread option that can markedly enhance the strength and longevity of your stitching projects. Here are four key points about waxed thread that you should consider:

- Strength and durability: Waxed thread is known for its increased strength and durability compared to unwaxed thread. This is because the wax coating makes the thread stiffer, which in turn makes it more resistant to wear and tear.

- Reduced tangling and fraying: Waxed thread is less prone to tangling and fraying, which can be particularly useful when working with abrasive materials like leather.

- Improved glide: The wax coating can also improve the ease of movement of the thread, making it easier to work with and sew, especially for hand-sewing projects.

- Versatility: Waxed thread is suitable for a wide range of applications, including leatherwork, bookbinding, and various craft projects.

To prepare waxed thread, you can apply wax directly to the thread before sewing. This can be done using beeswax or other types of wax, such as candle wax. Alternatively, you can purchase pre-waxed thread from suppliers like Tandy Leather Factory, Brettuns Village, or Old Navy.

When choosing waxed thread, consider factors such as the material you’ll be working with, the strength and durability required for your project, and your personal preference for the thread’s texture and appearance.

Hand Sewing: Backstitch as an Alternative to Knots

You can use the backstitch as an alternative to knots to secure your thread and add strength to your seams. By working 2-3 backstitches on top of each other at the start and end of a row of stitches, you’ll avoid unsightly bumps while ensuring a durable seam.

Securing Thread and Adding Strength

Excelling in the backstitch is essential for hand sewing enthusiasts pursuing sturdiness and longevity.

This technique entails guiding the needle behind the thread on the reverse side, generating overlapping stitches on the back.

The backstitch tension can be modified by varying the distance from the fabric’s edge.

Thread selection, needle size, and needle type contribute to achieving the desired strength.

Through practicing these techniques, you can create a secure and strong seam that will endure wear and tear.

Avoiding Unsightly Knots

Regarding hand sewing, the backstitch offers a transformative solution.

It serves as a superior alternative to knots, ensuring the resilience and longevity of your seams.

By employing 2-3 backstitches superimposed at the outset and conclusion of a row, you can effectively secure the thread, eliminating unsightly protrusions.

This technique excels in joining felt fabrics, facilitating repairs, delineating designs, and even as a substitute for knots at the commencement and termination of sewing.

Therefore, to abandon knots and enhance the durability of your hand-stitched creations, the backstitch emerges as the ideal choice.

Using Backstitch in Various Sewing Techniques

Explore the versatility of backstitch in various sewing techniques.

This strong hand stitch can be used as an alternative to knots, providing a seamless and durable finish.

For decorative purposes, try out different backstitch variations.

In leatherwork, use backstitch for repairs and reinforcement.

For quilting, backstitch can be used for outlines, designs, and binding.

Backstitch is a valuable tool for hand sewing, offering both strength and style.

Conclusion

Achieving over 90% of a stitch’s strength, the backstitch reigns supreme for hand and machine sewing projects demanding durability. You’ll obtain resilient stitching by mastering this technique, selecting the strongest thread types like linen or artificial sinew, and carefully considering when the strongest hand stitch vs sewing machine stitch best suits your needs. With practice, you can create long-lasting, professional results.