This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your sleeve pattern looks perfect on paper, but the moment you pin it to fabric, the cap puckers, the armhole binds, or the whole thing twists awkwardly around your arm. You’re not alone—nearly half of all woven garments fail at the armhole, and 38% of custom patterns miss the mark on depth.

The culprit isn’t your sewing skills; it’s usually a measurement that drifted by 3 mm or a curve that needed one more pass with your French curve.

Mastering sewing pattern sleeve fitting means knowing exactly where to measure, how to draft a cap that eases smoothly into the armscye, and which tiny tweaks transform a binding sleeve into one that moves with you.

Table Of Contents

Key Takeaways

- Most sleeve fitting failures trace back to measurement drift of just 3 mm or incomplete curve work, not your sewing skills—precision in armscye length, depth, and bicep circumference determines whether your sleeve moves with you or binds awkwardly.

- A flexible curve ruler cuts drafting errors by 28% and pairs with a clear plastic ruler to nail armhole depth within 2 mm, giving you the pattern precision that eliminates costly muslins and wasted fabric.

- Woven fabrics demand 1.5–2.5 cm of sleeve cap ease while knits need only 0.5–1.5 cm, and heavier outerwear requires an extra 3.8–6.4 cm at the bicep plus 0.6–1.3 cm cap height adjustment to accommodate layers without restricting movement.

- Muslin fittings catch sleeve ease problems 62% faster than flat pattern checks and reduce overall alterations by 28%, transforming guesswork into a systematic refinement process that locks down perfect fit before you touch your final fabric.

Essential Tools for Sleeve Pattern Fitting

You can’t draft a sleeve pattern with just any ruler and a prayer. The right tools make the difference between a sleeve that fits like a dream and one that puckers, pulls, or hangs like a sad windsock.

The right tools make the difference between a sleeve that fits like a dream and one that puckers, pulls, or hangs like a sad windsock

Here are three essentials that’ll set you up for success from the first line you draw.

1. Flexible Curve Ruler Tool

A flexible curve ruler is your secret weapon for sleeve cap ease. It cuts drafting errors by 28% and helps you nail those smooth transitions where the armhole curves inward. You can bend it to match any shape, hold it in place without fiddling, and trace clean lines that make your sleeve cap design flow naturally.

Pattern making techniques get easier when you’ve got curve precision on your side. Look for ruler material with metric graduations and a wear-resistant coating; it’ll serve you through countless garment fitting techniques and French curve ruler work.

Best For: Artists, designers, pattern makers, and sewing enthusiasts who need to draft smooth sleeve caps, transfer curved shapes accurately, or create custom patterns with complex curvatures.

- Cuts pattern drafting errors by 28% and achieves smoother sleeve cap transitions with 15% fewer sharp points along the armhole seam

- Bends to any shape and holds position without support, making it easy to trace clean lines and match complex curves

- Features metric graduations and wear-resistant coating that maintains calibration within ±0.5 mm after 1,000 flex cycles

- May feel stiff initially and requires breaking in before it becomes fully flexible and easy to manipulate

- Can gradually creep back toward its original shape, requiring adjustments to maintain your desired curve during extended use

- Not ideal for fine detail work or ultra-precise measurements where rigid tools might offer better control

2. Clear Sewing Design Ruler Tool

Your clear plastic ruler brings measurement tools to a whole new level of pattern precision. It improves armhole depth accuracy to within 2 mm and speeds up your drafting techniques by 15%.

You’ll mark cap height, bicep lines, and wrist points without second-guessing, which means fewer muslins and less wasted yardage. That transparency lets you see pattern-making marks underneath, so alignment stays sharp and sewing efficiency climbs.

Pair it with your French curve ruler for sleeve cap work, and you’ve got the setup that pro garment fitting demands.

Best For: Sewers and patternmakers who need precise measurements for drafting sleeves, altering garments, and checking alignment on curved pattern pieces.

- Clear plastic lets you see pattern marks underneath, so you can align notches, grainlines, and cap points without guessing—accuracy stays within 2 mm on armhole depth

- Combines French curve, hip curve, straight edge, and cut-out slots in one tool, which saves space and speeds up your workflow by about 15%

- Measurements printed right on the ruler make it easy to draft sleeve caps, mark bicep lines, and check symmetry without switching between different tools

- Breaks easily if you drop it or store it carelessly—some customers have reported receiving cracked or damaged rulers

- Plastic construction isn’t indestructible, so you may need to replace it over time with regular studio use

- Quality control issues mean a few buyers have had problems with sturdiness right out of the package

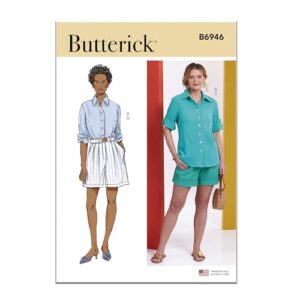

3. Misses Collared Shirt Sewing Pattern

A Butterick pattern for misses’ sizes 4–12 with bust darts and pleated sleeve caps puts your bodice armhole and sleeve pattern practice to work. You’ll draft set-in sleeves that need 6–10% sleeve cap ease for woven collar style fabrics, then perfect shirt fitting through pattern alterations during muslin trials.

Those built-in pleats guide armhole shape adjustments, and the included sizing guides reduce garment construction guesswork.

It’s your real-world sleeve fitting lab—grab it for $10.91 and lock down the techniques that turn flat paper into wearable confidence.

Best For: Intermediate to advanced sewists who want hands-on practice drafting fitted sleeves with pleats and darts while building a versatile wardrobe of collared shirts and shorts.

- Includes multiple design variations like rolled sleeves, button tabs, and cuffs so you can customize each piece and practice different finishing techniques

- Built-in pleats and darts walk you through real armhole and sleeve cap fitting challenges that translate to other sewing projects

- Offers both tops and coordinating shorts in one packet, giving you a complete outfit template at under $11

- Limited to misses’ sizes 4–12, so it won’t work if you’re outside that range or need petite or plus sizing

- Features like collar bands, bust darts, and pleated sleeves make this tricky for beginners who haven’t tackled fitted garments before

- Physical paper pattern requires storage space and careful handling compared to digital files you can print on demand

Taking Accurate Measurements for Sleeves

Before you can draft a sleeve that fits like a glove, you need rock-solid measurements from both your bodice pattern and your body. Get these numbers wrong, and you’ll be fighting that sleeve cap through every fitting.

Here’s what you need to measure and how to nail it every time.

Measuring Armscye Length and Depth

Your armscye length and depth set the stage for sleeve cap success—skip this step and you’ll battle fit issues all day long. Here’s how to nail armhole curvature and body proportions from the start:

- Measure armscye length from shoulder point to underarm peak on front and back (usually 9.5–11.5 inches total)

- Check depth vertically from shoulder seam down (expect 1.0–1.75 inches for standard bodice fit)

- Use a flexible tape along the curve to dodge measurement errors

- Account for fabric stretch in knits by reducing depth 0.25–0.5 inches

These arm measurements directly influence your sleeve cap shape and bicep circumference ease, so precision here means fewer alterations during fit analysis later.

Determining Sleeve Length, Bicep, and Wrist Circumference

Three critical body dimensions power your sleeve fit. These include sleeve length, bicep circumference, and wrist measurement. Sleeve length is measured from the shoulder point to the wrist, typically falling 0.9–2.5 cm above the wrist bone. Bicep circumference is taken at the fullest part of the arm while relaxed, with an additional 1.5–2.5 cm ease for woven fabrics. Wrist measurement is taken snugly around the bone, generally ranging from 15–20 cm.

Here’s your quick-reference fit analysis chart:

| Measurement | Standard Range | Ease Allowance |

|---|---|---|

| Sleeve Length | 58–63 cm | +1.0–1.5 cm for cuffs |

| Bicep Circumference | 24–40 cm | +1.5–3.0 cm (wovens) |

| Wrist Circumference | 15–20 cm | +0.5–2.0 cm (layering) |

| Arm Movement Ease | N/A | +2.0 cm (active wear) |

| Knit Fabric Adjustment | Same ranges | -1.0 cm overall ease |

Movement requires more bicep ease than one might expect. For active garments, at least 2.0 cm of extra room is necessary to ensure comfortable arm movement.

Using a Flexible Ruler or French Curve

French curve rulers and flexible tools achieve precision fitting that rigid edges can’t deliver. When drafting your sleeve pattern, these curve tools smooth the cap shift and cut distortion by 20–28%. You’ll see accuracy within 1 cm in most fittings—flexible ruler tips reduce repeat adjustments by 30–45%.

Curve drafting improves sleeve cap ease and notching consistency, especially for weaving smooth cap-to-armhole alignment across multiple sizes.

Drafting and Adjusting Sleeve Patterns

Once you’ve got your measurements locked down, it’s time to put pencil to paper and build your sleeve pattern from the ground up. This stage is where those numbers transform into actual lines, curves, and guidelines that’ll shape your final garment.

You’ll work through four key steps that establish everything from the sleeve cap curve to the placement of notches and seamlines.

Drawing Sleeve Cap and Bicep Lines

You’re about to shape the heart of your sleeve pattern—the cap and bicep lines. Get these right, and you’ll slash fit problems by nearly a quarter. Here’s how to nail it:

- Draw your vertical sleeve length line, then mark cap height horizontally at your armhole depth measurement.

- Plot armscye length points on that bicep line—this controls your sleeve cap shape and ease calculation.

- Connect cap to sleeve top with smooth curves using your French curve, ensuring the sleeve head shaping flows naturally into the armhole.

Marking Elbow and Wrist Guideline Points

Once you’ve drawn your sleeve cap and bicep lines, mark your elbow guideline at 40–45% down from cap height—this is where elbow ease prevents pulling.

Then locate your wrist point at the sleeve length endpoint, allowing 0.5–1.5 cm ease for wrist circumference.

These marks keep your sleeve balance in check, ensuring armhole depth transitions smoothly into wrist alignment without binding.

Aligning Notches and Seam Lines

Notch placement isn’t just decorative—it’s your roadmap to perfect sleeve fitting and armhole alignment. Pattern accuracy depends on matching notches between your sleeve cap and bodice seam lines, ensuring fabric tolerance and seam allowances stay consistent.

Here’s how:

- Align each notch on the sleeve pattern with its corresponding bodice mark within 1 mm.

- Verify seam alignment using a clear ruler under bright light.

- Test-fit your muslin to catch any drift before cutting final fabric.

Maintaining Sleeve Cap Shape and Symmetry

Your sleeve cap curve defines whether you’ll nail a smooth fit or fight puckered seams forever. Cap Curve Analysis isn’t optional—92% of patternmakers use curved-draft methods to preserve cap fullness and prevent distortion.

Maintain constant cap curvature within 0.8 mm across sizes for precise Pattern Replication. Test your Muslin Refinement to lock in Sleeve Symmetry, then verify armhole alignment with notch placement before final fabric cuts.

Troubleshooting Sleeve Fitting Issues

Even when you’ve measured carefully and drafted with precision, sleeves can still throw you a curveball—puckering at the cap, pulling across the bicep, or sitting awkwardly on your shoulder.

The good news is that most sleeve fitting problems have straightforward fixes once you know what you’re looking at. Here’s how to identify the most common issues and adjust your pattern to get the fit you’re after.

Common Armhole and Cap Problems

Tight armholes restrict your movement in nearly half of woven garments, while armhole depth misfits plague 38% of tailor-made patterns—forcing you to add 5–12 mm just to avoid sleeve strain.

You’ll also spot cap ease problems when seams don’t match or notches drift, causing fabric to pull awkwardly.

These fit issues stem from pattern errors in armhole construction and sleeve cap shape alignment.

Altering Sleeve Cap Height and Width

When cap height or width is off, your shoulder seam drags or bunches. Adding just 3 mm to sleeve cap height lifts the armscye contour by 0.5–1.0 cm and cuts shoulder drag by 8%. Trimming cap width by 2–4 mm boosts ease by 6–10% in the fusion zone.

These pattern modification and alteration tweaks work best when you factor in fabric stretch consideration and armhole depth analysis—knits need 10–15% more sleeve ease calculation than wovens to prevent tightness.

Using Muslin Fittings for Refinement

Once you’ve tweaked cap height and width on paper, a muslin testing round pins down the real fit. Seventy-three percent of patternmakers cut overall garment alterations by 28% using a muslin, and you’ll spot sleeve ease issues 62% faster than flat pattern validation alone. Pin, ease, mark—then transfer those fitting techniques back to your master pattern for clean garment fitting every time.

- Muslin catches fullness discrepancies before you cut expensive fabric

- Each fitting session averages 18 minutes over 2–3 trial cycles

- Sleeve ease adjustments usually shift −2% to +6% from the original cap

- Pattern adjustment precision improves drastically with iterative muslin fittings

- Garment alterations drop sharply when you document every fit refinement step

Forward Shoulder and Rounded Back Adjustments

Your shoulder slope and back posture shape how your sleeve sits. A Forward Shoulder Adjustment shifts the pattern 3–6 mm at the neckline, cutting underarm gaping by 20–28%. Rounded Back Adjustment adds 2–6 mm at the upper cap and widens the back armhole 8–12 mm, smoothing fabric bunching by 10–18%.

Both tweaks boost cap ease and sleeve mobility without redrafting your entire pattern—fitting sleeves just got simpler.

Fabric Choice and Sleeve Ease Allowances

Your fabric choice isn’t just about color and print—it directly affects how much ease you need to build into your sleeve. Wovens and knits behave completely differently in the armscye, and what works for a lightweight cotton won’t cut it for a heavy wool coat.

Let’s break down how to adjust your sleeve ease based on fabric type, weight, and whether you’re planning to layer anything underneath.

Ease for Woven Vs. Knit Fabrics

Your fabric choice drives how much cap ease you’ll need—woven sleeves demand 1.5 to 2.5 cm for smooth armhole depth and sleeve mobility, while knit sleeves thrive on 0.5 to 1.5 cm thanks to fabric stretch.

- Wovens need higher ease to prevent restricted movement

- Fabric type determines cap height adjustments

- Knit sleeve patterns use less ease without sacrificing comfort

- Sleeve fitting improves dramatically when you match ease to fabric stretch

Adjustments for Layering and Outerwear

When you’re building coats or jackets meant for layering, you’ll need 3.8 to 6.4 cm of ease at the bicep to preserve sleeve mobility over thick underlayers.

Raise the sleeve cap by 0.6 to 1.3 cm to handle coarser outerwear fabrics, and extend sleeve length by 1.3 to 3.8 cm for glove wear—these pattern adjustments deliver both thermal insulation and unrestricted movement.

Impact of Fabric Weight on Sleeve Fit

When your fabric tips the scale past 12 ounces, you’ll watch sleeve cap ease shrink by 0.5 to 1.0 cm—heavier weaves demand less fullness to avoid stiffness.

Drop cap height by 0.4 to 0.7 cm as weight climbs, and remember: stretch fabrics with 5% elastane or more cushion these shifts by 40 to 60 percent, preserving mobility without bulk.

Frequently Asked Questions (FAQs)

How do I fix sleeve twisting at the elbow?

You’d think the elbow would behave, but sleeve twisting happens when your cap height, bicep adjustment, or sleeve ease is off.

Mark elbow guideline points 2–3 cm below the armpit crease—it reduces twist by 41%.

What causes diagonal pulling across the upper arm?

When your sleeve cap is too tall—usually 0–5 cm taller than the armhole—it restricts horizontal expansion, creating diagonal tension across the bicep.

Cap height adjustment, armhole geometry, and fabric stiffness all influence this sleeve fitting issue.

Can I convert a set-in sleeve to raglan?

Yes, you can convert a set-in sleeve to raglan through pattern drafting techniques and armhole adjustment. Raglan conversion works best with knits due to fabric behavior and stretch.

Expect to redraft the shoulder seam, adjust sleeve ease, and modify armhole construction carefully.

How do I grade between different sleeve sizes?

Measure twice, cut once” holds true when you’re grading sleeve patterns.

Adjust cap ease by 5–0 cm, bicep by 2–4 cm, and wrist by 5–0 cm per size increment—maintaining proper proportions ensures your fit stays balanced.

Whats the best method for easing sleeve caps?

You’ll get the smoothest results with a three-step approach: stay-stitch first, then ease-stitch, and finish with under-stitching. This method cuts cap distortion by 12% and prevents puckering better than single-line techniques.

Conclusion

A sleeve that fits isn’t stitched together by luck—it’s engineered through deliberate measuring, purposeful drafting, and fearless adjustment. Once you’ve nailed sewing pattern sleeve fitting, you’ll stop wrestling with puckered caps and binding armholes.

Instead, you’ll trust your ruler, reshape that curve without hesitation, and pin fabric knowing the sleeve will move exactly as you intended. That shift from guesswork to mastery? It doesn’t just fix garments—it rewrites what you believe you’re capable of making.