This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ve probably spotted “viscose” and “rayon” on clothing labels and assumed they were different fabrics. Here’s the twist: viscose is actually a type of rayon, not a separate material. The confusion stems from regional naming preferences—Europeans usually say “viscose” while Americans prefer “rayon”—but both terms describe the same regenerated cellulose fiber.

Despite this overlap, the distinction matters when you’re choosing between garments labeled with these names, particularly since production methods can vary slightly and affect the fabric’s final properties. Understanding what sets these semi-synthetic textiles apart from natural and fully synthetic options helps you make smarter decisions about comfort, durability, and environmental impact when you’re standing in front of that clothing rack.

Table Of Contents

- Key Takeaways

- What is Rayon?

- What is Viscose?

- How Are Rayon and Viscose Made?

- Key Differences: Viscose Vs Rayon

- Comparing Fabric Properties

- Viscose Vs Rayon in Clothing

- Environmental Impact of Each Fabric

- Viscose Vs Rayon: Cost and Availability

- Choosing The Right Fabric for You

- Future Trends in Rayon and Viscose

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Viscose is actually a type of rayon, not a separate fabric—the terms describe the same regenerated cellulose fiber, with “viscose” preferred in Europe and “rayon” in North America.

- Both fabrics offer silk-like drape and breathability at affordable prices ($2.50–$5.00 per yard), but traditional production relies on harsh chemicals like carbon disulfide that can pollute waterways without proper closed-loop systems.

- Sustainable alternatives like lyocell and modal use gentler, closed-loop processes that recover 99% of solvents while delivering superior softness and reduced environmental impact compared to conventional viscose.

- When shopping, focus on environmental certifications (FSC, OEKO-TEX) and production methods rather than the viscose versus rayon label, since both fabrics require gentle care and are prone to 2–6% shrinkage after washing.

What is Rayon?

Rayon is a semi-synthetic fabric that sits between natural and synthetic materials, created by regenerating cellulose from wood pulp or plant fibers. It’s been around since the late 1800s and earned the nickname “artificial silk” for its luxurious drape and soft feel.

To understand what makes rayon unique, you’ll want to look at where it came from, the different types available today, and how it’s used in everyday clothing.

Definition and Origins

Rayon is a regenerated cellulose fiber created by dissolving cellulose and extruding it through spinnerets. This semisynthetic fabric traces its fiber history to the late 19th century, when French scientist Hilaire de Chardonnet pioneered early rayon evolution.

The textile legacy began as a silk alternative, though modern viscose origins refined the process. Today, you’ll find cellulose sources like wood pulp transformed into the adaptable cellulose fibers we recognize as rayon.

The production of rayon involves careful analysis of methodological rigor to guarantee quality and consistency.

Types of Rayon

You’ll find several distinct rayon families, each with unique production methods.

Viscose rayon dominates the market through its cost-effective viscose spinning process. The cuprammonium process creates finer fibers for lightweight textiles. Modal fabric, made from beech-tree cellulose sources, offers enhanced properties. Bamboo rayon uses standard viscose chemistry on bamboo pulp.

Lyocell production stands apart with its closed-loop system, making it the most sustainable regenerated cellulose fiber option available today.

Common Uses of Rayon

With such versatility, you’ll see rayon woven into fashion textiles like blouses and dresses, home upholstery for sofas and drapes, and nonwoven products including disposable wipes.

The regenerated cellulose fiber works in outdoor fabrics where breathability matters, plus industrial filtration systems.

These clothing materials adapt across weaving processes, making rayon and viscose fabric characteristics valuable from everyday wear to specialized technical applications.

What is Viscose?

Viscose is the most widely produced type of rayon, accounting for the majority of regenerated cellulose fibers you’ll find in clothing stores. It’s made through a specific chemical process that transforms wood pulp into a multipurpose fabric with properties similar to silk and cotton.

To understand what sets viscose apart, you need to know how it’s made, where it fits in the rayon family, and what makes it such a popular choice in fashion.

Definition and Production

When you understand how viscose comes to life, the entire rayon family starts making more sense. Manufacturing begins with wood pulp from trees like eucalyptus or beech, which contains 87-97% cellulose. This raw material gets dissolved in sodium hydroxide and carbon disulfide through the viscose process, transforming solid plant matter into a viscous solution that’s extruded and regenerated into soft, wearable fibers.

The production of viscose involves a complex cellulose regeneration process that requires careful control of temperature and pressure.

Viscose as a Rayon Variant

In the textile industry’s fabric classification system, you’ll find viscose consistently marketed as a type of rayon—specifically, viscose rayon. This designation stems from its chemical regeneration process using cellulose sources and carbon disulfide, which distinguishes it from modal and lyocell within the regenerated cellulose family.

Standards bodies group these cellulosic fibers together, shaping how you’ll see viscose vs rayon comparison labels worldwide.

Common Uses of Viscose

You’ll see viscose woven into dresses, blouses, and scarves in fashion apparel because it drapes beautifully and feels soft against your skin.

Clothing production relies on viscose for linings and lightweight summer pieces, while home textiles use it in bedding and upholstery.

Viscose blends combine this rayon variant with cotton or polyester to balance cost with performance in the textile industry.

How Are Rayon and Viscose Made?

Understanding how these fabrics come to life helps explain why they behave the way they do. Both rayon and viscose start with natural cellulose, but the journey from wood pulp to wearable fabric involves some serious chemistry.

Let’s walk through the raw materials, the production steps, and what all those chemicals mean for the environment.

Raw Materials and Cellulose Sources

Both viscose and rayon start their journey from cellulose—the structural building block you’ll find in plants. Most of this regenerated cellulose comes from wood pulp, particularly eucalyptus blends with pine or beech. You’ll also encounter bamboo fibers as an alternative source.

Sustainable forestry certifications guarantee responsible sourcing, while recycled textiles are emerging as lower-impact feedstock options in modern production.

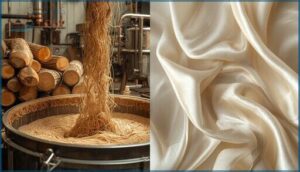

The Viscose Process Explained

The viscose process transforms cellulose into regenerated fiber through a multi-step chemical reaction. First, you steep wood pulp in caustic soda to create alkali cellulose. Then carbon disulfide converts it into cellulose xanthate—a thick, honey-colored viscose solution.

When you extrude this liquid through spinnerets into an acid bath, it solidifies into continuous rayon filaments ready for weaving.

Chemical Inputs and Environmental Impact

Making viscose rayon isn’t gentle on the planet. The process relies on toxic chemicals that demand careful waste management and strict emission controls. Here’s what you should know:

- Sodium hydroxide (caustic soda) runs 25–40 kg per ton of fiber, creating harsh alkaline wastewater

- Carbon disulfide emissions historically polluted air near facilities until modern solvent recovery systems reclaimed up to 95%

- Sulfuric acid and bleaching agents generate waste streams requiring treatment before discharge

Fortunately, sustainable production methods and eco-friendly alternatives like lyocell offer cleaner paths forward. When you’re weighing viscose versus other sustainable fabric options, understanding these environmental concerns helps you make informed choices about the textiles touching your skin.

Key Differences: Viscose Vs Rayon

Here’s where things get a bit tricky—rayon and viscose aren’t exactly different fabrics, but the terms don’t mean the same thing either. The confusion comes down to how the industry classifies these materials, how they’re produced, and what people call them depending on where you live.

Let’s break down the three main distinctions that actually matter when you’re comparing labels or shopping for clothes.

Terminology and Classification

Understanding the language around these materials clears up a lot of confusion. Rayon acts as the umbrella term for all regenerated cellulose fibers—think of it as the broad fiber class in material science. Viscose sits underneath that umbrella as one specific type, produced through a particular chemical process. Other fabric types like lyocell and modal also fall under rayon, though they use different industry standards for production.

Here’s how the textile terms break down:

| Term | Classification |

|---|---|

| Rayon | Generic name for all cellulosic fibers made from regenerated cellulose |

| Viscose | Specific rayon variant produced via the viscose process |

| Lyocell | Rayon subtype using closed-loop solvent spinning |

| Modal | Rayon subtype made from beech tree pulp |

| Cupro | Rayon subtype using copper-ammonia process |

In North America, you’ll often see “rayon” on clothing labels, while European markets frequently use “viscose” for the same material—it’s regional preference rather than a technical difference.

Manufacturing Process Variations

While rayon acts as the broader category, the real story lies in how different types get made. Traditional viscose relies on caustic soda and carbon disulfide to break down cellulose into a spinning solution, then uses sulfuric acid coagulation methods to regenerate the fibers. Lyocell takes a cleaner route—it dissolves cellulose directly in NMMO solvent systems, achieving fiber regeneration without toxic chemical inputs.

| Process Type | Key Chemical Inputs |

|---|---|

| Viscose | Carbon disulfide, caustic soda, sulfuric acid |

| Lyocell | NMMO (closed-loop solvent) |

| Modal | Similar to viscose with modified beech pulp |

| Cupro | Copper-ammonia solution |

These textile innovations matter because they directly affect environmental impact and worker safety. You’ll find that lyocell’s closed-loop approach recycles over 99% of its solvents, while traditional viscose releases more chemical waste during production.

Regional Naming Conventions

When you pick up a garment tag, geographic location shapes what you’ll read. Europe defaults to “viscose” on most manufacturer labels, while North America leans toward “rayon”—sometimes listing “viscose rayon” on technical specs. Canadian regulations mirror U.S. labeling standards, though supplier choices vary.

Brands often switch terminology between collections: European lines say viscose, American versions say rayon, reflecting consumer perception and regional preferences.

| Region | Primary Term | Secondary Usage |

|---|---|---|

| Europe | Viscose | Rayon (technical) |

| United States | Rayon | Viscose rayon |

| Canada | Rayon/Both | Supplier-dependent |

| Technical Docs | Viscose rayon | Process-specific (Lyocell, Modal, Tencel) |

| Fashion Marketing | Regional preference | Brand positioning |

Comparing Fabric Properties

When you’re deciding between viscose and rayon, the feel of the fabric matters just as much as the technical names. Both fabrics share similar qualities, but subtle differences in texture, breathability, and durability can influence how they perform in your wardrobe.

Let’s break down the key properties so you know what to expect from each fabric.

Texture and Feel

When you run your fingers across these fabrics, rayon feels smooth and silky with a cool, fluid drape—thanks to its low elasticity and lustrous finish. Viscose offers a softer, cotton-like hand with subtle sheen, though it can feel slightly heavier.

Both showcase excellent drape dynamics, and surface finishing techniques can improve fabric softness or adjust texture through fiber blending in common weaves.

Breathability and Moisture Absorption

Beyond how they feel, fabric properties like breathability and moisture absorption matter when you’re deciding comfort. Both rayon and viscose pull moisture in readily—viscose fibers usually reach 11–15% moisture regain at room temperature, while rayon shows similar values. Air permeability and wicking performance depend on weave density and finishing, but both fabrics let your skin breathe and stay cool in humid conditions.

- Viscose absorbs moisture quickly, keeping you comfortable during warm, humid days

- Rayon’s high moisture regain helps manage sweat through rapid wicking and evaporation

- Fabric breathability improves when weave structure allows good air permeability between fibers

- Fiber finishes can boost moisture transport, improving overall wicking performance in garments

- Evaporation rates stay strong in both fabrics, contributing to that fresh, cool feeling

Durability and Shrinkage

Fabric longevity depends on how well material stability holds up through washing and wear. Both rayon and viscose exhibit moderate durability, but shrinkage—typically 2% to 6%—is noticeable, especially after the first wash. Care methods such as using cold water and air drying can help control shrinkage.

Here’s a quick textile performance comparison:

| Factor | Rayon | Viscose |

|---|---|---|

| Typical shrinkage | 2–6% first wash | Often higher initial shrinkage |

| Wet strength | Lower than dry | Reduced when wet |

| Abrasion resistance | Moderate, improved with finishing | Similar, needs careful laundering |

| Best care approach | Cold wash, air dry | Gentle cycle, avoid high heat |

Blends with synthetics reduce shrinkage and enhance overall fabric properties for everyday wear.

Viscose Vs Rayon in Clothing

When you’re shopping for clothes or checking labels, understanding how viscose and rayon perform in real garments helps you make smarter choices. Each fabric brings specific strengths to different types of clothing, from how they hang on your body to how much effort they’ll demand at laundry time.

Let’s break down what you need to know about wearing and caring for these fabrics.

Best Uses for Each Fabric

You’ll find rayon works beautifully for lightweight blouses and summer wear because its soft hand keeps you comfortable in warm weather. Viscose shines in flowing linings and luxurious tops where you want that smooth, glossy finish.

When you’re shopping for casual clothing, rayon jersey delivers stretch and breathability, while viscose blends in scarves balance luster with airflow—perfect for fabric selection across fashion trends.

| Fabric Type | Best Applications | Key Advantage |

|---|---|---|

| Rayon | Blouses, summer dresses, t-shirts | Soft drape, breathable comfort |

| Viscose | Linings, formal tops, scarves | Glossy surface, elegant flow |

| Rayon Jersey | Casual wear, undergarments | Stretch, moisture absorption |

| Viscose Blends | Scarves, fashion accessories | Balance of luster and breathability |

| Rayon Crepe/Viscose Satin | Formal attire, evening wear | Refined appearance, enhanced drape |

Understanding these distinctions helps you choose textile blends that match your garment care expectations and clothing production needs.

Drape and Appearance

When light hits your garment, both viscose and rayon fabrics reveal a soft, subtle sheen that elevates visual appearance. Rayon usually offers more pronounced fluid movement in lighter weights, while viscose provides a smooth fall that conforms gently to your body’s lines—essential for drape analysis in textile selection.

| Fabric Feature | Rayon | Viscose |

|---|---|---|

| Surface Texture | Slightly lustrous, swishy flow | Smooth, gentle hang |

| Light Reflection | Enhanced sheen in satin weaves | Moderate luster, matte finish options |

| Flow Dynamics | Pronounced fluid drape | Soft, breathable silhouette |

You’ll notice fabric texture differences most clearly when comparing lighter rayon with heavier viscose—the silk finish quality changes with weave density and moisture levels.

Maintenance and Care Tips

Treating your rayon or viscose like fine fabric—because it’s—keeps textiles looking fresh longer. You’ll extend garment life by hand washing in cold water with mild detergent, air drying flat to prevent shrinkage, and using low-heat ironing with a pressing cloth. When dry cleaning alternatives make sense, test breathability first—gentle washing often works better than you’d expect.

| Care Method | Action | Benefit |

|---|---|---|

| Fabric Storage | Store clean, avoid heavy hanging | Prevents distortion, maintains shape |

| Gentle Washing | Cold water, delicate cycle | Minimizes shrinkage prevention needs |

| Ironing Tips | Low heat, use pressing cloth | Protects fiber integrity, reduces marks |

Environmental Impact of Each Fabric

The environmental footprint of rayon and viscose often gets overlooked when you’re shopping for soft, breathable fabrics. Traditional production methods rely on harsh chemicals that can pollute waterways and harm workers if not managed properly.

Understanding these impacts—and knowing which alternatives and certifications to look for—helps you make choices that align with your values.

Chemical Usage and Pollution

When you’re looking at viscose and rayon production, carbon disulfide and caustic soda drive the manufacturing process—but they come with real environmental concerns. These toxic chemicals can pollute water and air if mills don’t invest in pollution control systems.

Modern sustainable production relies on closed-loop processes that recover chemicals and treat wastewater, though adoption varies widely. The environmental impact depends heavily on whether manufacturers prioritize eco-friendly practices over cost-cutting shortcuts.

Sustainable Alternatives (Lyocell, Modal)

If you want Eco Friendly Fabrics that skip viscose’s pollution problems, lyocell and modal are your sustainable alternatives worth serious consideration. Lyocell uses N,N-dimethylacetamide in Closed Loop Systems with 99% solvent recovery, while modal comes from beechwood processed with gentler chemicals. Both leverage Renewable Resources and deliver softer, more breathable Sustainable Materials than conventional rayon—perfect for Sustainable fashion without compromising comfort.

Lyocell and modal offer cleaner, closed-loop alternatives to viscose, recovering 99% of solvents while delivering superior softness and breathability

- Lyocell (marketed as TENCEL) recovers solvents through Green Production with minimal emissions

- Modal offers enhanced drape and reduced wrinkling compared to standard viscose

- Both fibers source wood pulp from certified forests, improving lifecycle sustainability

- Industrial composting and fiber-to-fiber recycling expand end-of-life options for these materials

Certifications and Responsible Sourcing

Beyond production methods, you can verify responsible textiles through Eco Labels and Green Certifications. FSC marks responsibly sourced wood pulp, while OEKO TEX confirms chemical safety.

The Higg MSI scores rate Supply Chain transparency, and REACH compliance protects both workers and ecosystems.

These frameworks strengthen Sustainable Supply Chain Management, giving you confidence that your Ecofriendly textiles meet global standards from forest to finished fabric.

Viscose Vs Rayon: Cost and Availability

When you’re shopping for fabric or clothing, price usually plays a big role in your decision. Both rayon and viscose fall into the affordable category compared to natural silks or premium fabrics, but their costs can vary based on quality, production methods, and where you buy them.

Let’s break down how these fabrics compare regarding price, how easy they’re to find, and what that means for your wardrobe budget.

Price Comparison

You’ll find rayon and viscose fabrics priced quite similarly—usually $2.50 to $5.00 per yard at retail. The fabric costs depend more on finish, weight, and blend than on whether it’s labeled rayon or viscose. Budget options exist in both categories, while premium treatments push prices above $6.00.

Here’s how textile production factors shape what you pay:

| Cost Factor | Impact on Price | Typical Range |

|---|---|---|

| Base fabric (plain weave) | Standard pricing | $2.50–$4.50/yard |

| Special finishes (satin, twill) | Small premium | $4.00–$5.50/yard |

| Certified sustainable | Higher due to compliance | $5.00–$7.00/yard |

| Blends with elastane/polyester | Mid-range pricing | $3.50–$5.00/yard |

Fabric comparison shopping reveals that weaving method, print complexity, and certifications drive price trends more than the rayon versus viscose distinction. Market analysis shows both fabrics occupy the same price bracket, so you’re really choosing based on drape and finish rather than cost.

Market Presence and Popularity

Both fabrics dominate global sales, with viscose production exceeding 1.9 million metric tons in 2023. You’ll encounter viscose mainly in Asian and European mid-priced fashion, while rayon appears across retail strategies worldwide. Consumer demand shifts toward certified sustainable options affect textile industry offerings. Regional naming conventions influence how brands market these materials, shaping fashion industry trends and availability patterns you see today.

| Region | Primary Label | Market Share Focus |

|---|---|---|

| Asia | Viscose | Mid-tier apparel |

| Europe | Viscose/Rayon | Eco-certified lines |

| North America | Rayon | Budget to premium |

Affordability in Fashion

Beyond widespread market presence, you’ll find viscose and rayon in nearly every price bracket. Fast fashion retailers stock $10–40 viscose-rich pieces that drive budget shopping, while mid-range brands price rayon blends at $40–120. Premium labels justify $150+ tags through specialized finishes, creating affordable luxury tiers. The textile industry’s production scale keeps both fabrics accessible across discount retail and fashion industry trends.

| Price Tier | Viscose/Rayon Range | Target Segment |

|---|---|---|

| Fast Fashion | $10–$40 | High-volume basics |

| Mid-Range | $40–$120 | Quality-conscious shoppers |

| Premium | $150+ | Designer-finished pieces |

Choosing The Right Fabric for You

Now that you understand the technical differences between viscose and rayon, it’s time to figure out which one actually works for your wardrobe and lifestyle.

The right fabric depends on how you’ll wear it, where you live, and what matters most to you—whether that’s comfort, climate performance, or keeping up with current trends.

Let’s break down the practical considerations that’ll help you make a choice you won’t regret.

Comfort and Allergen Considerations

If you have sensitive skin, rayon and viscose deserve a closer look before you commit. Trace chemicals from the viscose process can trigger skin irritation in some people, especially if production controls weren’t tight. Here’s what affects your comfort:

- Allergen testing and certifications offer the most reliable hypoallergenic guidance for your wardrobe choices.

- Fabric breathability and moisture management vary with blends, influencing how moisture feels against your skin.

- Softness and drape depend on finishing treatments, which also impact allergen potential and overall wearability.

Performance in Different Climates

Where you live shapes how well rayon and viscose perform. Hot, humid climates often suit their breathability and moisture absorption, though you’ll notice more wrinkling and slower drying times. Cold, dry conditions reduce their natural softness and drape while increasing static.

Here’s how climate adaptation affects each fabric’s thermal regulation, weather resistance, and fabric durability:

| Climate Type | Rayon Performance | Viscose Performance |

|---|---|---|

| Hot & Humid | Good breathability, wrinkling increases | Comfortable but requires frequent ironing |

| Cold & Dry | Limited warmth, needs layering | Reduced breathability, static buildup |

| Arid & Windy | Static issues, faster drying | Better moisture management with blends |

Style and Fashion Trends

Both rayon and viscose dominate runway looks because fast fashion relies on their affordable drape and versatility. Designer insights reveal that sustainability campaigns now shape trend analysis—you’ll see more eco-focused labels highlighting lyocell over conventional viscose.

The textile industry’s fashion forecast points toward blends that mimic natural fibers while keeping costs low, making style evolution inseparable from production transparency.

Future Trends in Rayon and Viscose

The textile industry is changing fast, and rayon and viscose production are right in the middle of it. You’ll see major shifts happening in how these fabrics are made, what shoppers are asking for, and where the market is headed.

Let’s look at three key trends shaping the upcoming era of these popular materials.

Innovations in Sustainable Production

The textile industry is shifting toward sustainable textiles that minimize harm. You’ll find several innovations reshaping how viscose and rayon are produced:

- Closed loop systems recover and reuse solvents, cutting waste and chemical release

- Eco friendly materials from renewable resources replace virgin pulp sources

- Green manufacturing integrates energy recovery to lower carbon footprints

- Non-toxic solvent options reduce worker exposure during regenerated cellulose processing

- Certification schemes verify responsible sourcing and ecofriendly practices throughout production

These advances make sustainable fashion more achievable.

Evolving Consumer Preferences

You’re joining a broader movement toward sustainable fashion as awareness of chemical-intensive processes climbs. Global sales of eco-friendly textiles rose 6–8% annually through 2023, and 54% of shoppers now pay premiums for certified green textiles.

Ethical sourcing, transparency, and eco-friendly fashion labels drive your choices—especially when brands publish supplier data for viscose and rayon. Consumer awareness reshapes the industry.

Textile Industry Outlook

You’ll see the textile industry shift toward tighter supply chain controls and eco-friendly practices as regenerated cellulose demand climbs 3–5% yearly through 2030. Asia-Pacific still dominates fabric production, yet fiber innovations and certifications reshape how viscose and rayon reach your closet:

- Global demand for breathable, affordable textiles fuels steady market trends

- Environmental rules push cleaner chemical processes in fiber mills

- Traceability programs win consumer trust in sustainable sourcing

- Raw-material price swings prompt suppliers to adjust quickly

Frequently Asked Questions (FAQs)

Can viscose or rayon be recycled after use?

Most viscose and rayon products end up in landfills rather than recycled into new fibers. Chemical recycling methods exist but aren’t widely scaled, making textile waste a persistent challenge in the circular economy.

How do viscose and rayon compare to silk?

Silk is a natural protein fiber with exceptional strength and thermoregulation.

Viscose and rayon are regenerated cellulose alternatives offering similar drape and moisture absorption at lower cost, though requiring gentler care.

Are rayon fabrics safe for sensitive skin types?

Absolutely—rayon fabrics can work wonders for sensitive skin care thanks to their breathability and regenerated cellulose softness, but you’ll want allergen testing or OEKO-TEX certification to sidestep chemical sensitivity and fabric hypoallergenicity concerns from residual dyes.

What causes viscose to pill over time?

Pilling factors include fiber breakage from mechanical abrasion during wear and washing. Yarn construction with low twist, short staple fibers, and loose fabric weaving allow fiber migration. Care practices like harsh detergents accelerate this textile production challenge.

Do viscose blends perform better than pure viscose?

Yes, blends often outperform pure viscose. Mixing viscose with cotton or polyester improves durability, reduces shrinkage, and enhances wrinkle resistance—giving you fabric that’s easier to care for while maintaining that signature drape.

Conclusion

The viscose vs rayon difference ultimately boils down to naming conventions rather than fabric fundamentals—they’re the same regenerated cellulose material wearing different regional labels.

Your focus should shift from terminology to production quality, environmental certifications, and how the garment performs against your skin. Check those care labels, consider the manufacturer’s sustainability practices, and trust what feels right when you wear it.

Smart fabric choices start with understanding what you’re actually buying, not just what it’s called.