This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

That tiny number stamped on a needle’s shank—80/12, 90/14—looks like a serial code nobody explained to you. Most sewists grab whatever needle’s already in the machine and wonder later why their stitches look rough or their fabric puckers.

The truth is, sewing needle sizes follow a logical system, and once you crack it, you’ll never guess again. The metric number tells you the needle’s diameter in hundredths of a millimeter; the American number reflects its relative strength. Together, they tell you exactly what that needle can handle.

Knowing what sewing needle sizes mean puts you in control of every stitch, every seam, every project.

Table Of Contents

- Key Takeaways

- What Sewing Needle Sizes Mean

- How Sewing Machine Needles Are Sized

- Impact of Needle Size on Stitch Quality

- Choosing The Right Needle Size for Fabric

- Matching Needle Size to Thread Type

- Types of Sewing Machine Needles and Their Sizes

- Signs You Need to Change Needle Size

- Top Sewing Machine Needle Products

- Tips for Selecting and Maintaining Needle Sizes

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- The dual numbering on every needle pack (like 80/12) isn’t random — the first number is the shaft diameter in hundredths of a millimeter, and bigger always means thicker.

- Matching your needle size to your fabric weight is the single biggest factor in stitch quality — too small causes fraying and skipped stitches, too large leaves visible holes and puckering.

- Your needle and thread have to work as a team: the thread should fill roughly 40–45% of the needle’s eye, so heavier thread demands a larger needle, full stop.

- Replace your needle every 6–8 hours of sewing (or sooner if you hear popping, feel resistance, or notice skipped stitches) — a fresh needle fixes most mystery problems instantly.

What Sewing Needle Sizes Mean

Needle sizes aren’t just random numbers stamped on a package — they actually tell you a lot about what the needle can handle.

Once you understand the basics, hand and machine needle differences make the sizing system click into place pretty fast.

Once you understand the system, picking the right one becomes second nature. Here’s what those numbers really mean.

The Dual Numbering System (Metric and American)

Every needle package you’ll find shows two numbers — like 80/12 or 90/14. That’s the dual numbering system at work: metric system first, imperial system second.

These aren’t two different needles. It’s dual labeling for the same size, just using different measurement systems.

Master this, and needle calibration becomes second nature. No more guesswork at the notions wall.

For detailed guidance, you can review the recommended needle size selection guidelines.

How Needle Size Relates to Diameter

That metric number isn’t random — it’s the shaft diameter multiplied by 100. A size 80 needle is literally 0.80 mm thick. Size 100? That’s 1.00 mm.

This diameter calculation shapes everything: needle strength, fabric penetration, thread accommodation, and stitch quality. Bigger sewing needle sizes punch through heavy layers cleanly. Smaller needle sizes protect delicate fibers. That’s the logic behind every size range.

Needle diameter shapes everything: bigger sizes punch through heavy layers, smaller ones protect delicate fibers

Delivery estimates for sewing supplies can be found in the shipping and return policy.

Why Needle Size Matters in Sewing

So why does needle size actually matter? The short answer: everything downstream depends on it.

The right needle size protects your fabric, keeps your thread from fraying, and reduces strain on your sewing machine. Wrong size, and you’re fighting skipped stitches, broken thread, or torn fabric.

Matching your sewing machine needle to your project from the start is what separates frustrating guesswork from clean, confident results.

How Sewing Machine Needles Are Sized

Needle sizing has its own little language, and once you crack it, everything clicks into place.

There are two numbering systems at play — metric and American — and knowing how they work together tells you exactly what a needle can handle.

Here’s what you need to know about both systems and the size ranges you’ll actually use.

Understanding Metric Vs. American Numbers

Think of dual numbering like shoe sizes — same foot, different system. A pack labeled 80/12 means metric 80 (0.80 mm needle diameter) paired with American size 12.

Size charts use this dual numbering so you’re never guessing. Bigger numbers always mean thicker needles in both measurement standards, making needle selection straightforward once you understand how the two systems mirror each other.

Size Ranges for Common Sewing Needles

Sewing needle sizes fall into a clear spectrum, and knowing where each one lands makes needle selection almost automatic. Fine sewing needle sizes like 60/8 and 70/10 handle delicate fabrics, while middle-ground sizes — 80/12 and 90/14 — cover most everyday projects.

For heavy work, 100/16 to 110/18 muscle through dense layers. Good needle size charts map this range so choosing the right needle size is never guesswork.

Impact of Needle Size on Stitch Quality

Needle size does more than just fit your thread — it directly shapes how your stitches look and how your fabric holds up.

Pick the wrong size and you’ll deal with skipped stitches, torn fibers, or thread that keeps snapping mid-seam. Here’s what you need to know about getting it right.

Effects of Using Too Small or Large a Needle

Getting the wrong size is like wearing shoes two sizes off — everything feels wrong. A needle size that’s too small causes thread fraying, skipped stitches, and that annoying sewing noise when it struggles through heavy fabric.

Go too large, and you’ll deal with fabric puckering, stitch distortion, and visible holes. Smart sewing machine needle selection keeps your thread, fabric, and stitches working in harmony.

Preventing Fabric Damage and Thread Breakage

Prevention starts with matching needle size and needle type to your fabric and thread before you sew a single stitch. Wrong needle sharpness tears fibers and cranks up thread tension.

Slow your sewing speed on thick layers, and check machine calibration so stitches form evenly. Fabric and thread compatibility — keeping needle size proportional to both — is your best defense against broken threads and damaged fabric.

Matching Needle Size to Desired Stitch Outcome

Your needle size is basically a dial for stitch control. A size 70/10 keeps stitches nearly invisible on lightweight fabric, preserving natural fabric drape.

A 90/14 or 100/16 lets thick thread sit proudly for bold topstitching. Proper needle calibration keeps thread tension balanced, protecting seam integrity. Match needle size to your thread and fabric, and stitch quality takes care of itself.

Choosing The Right Needle Size for Fabric

Picking the right needle size comes down to one thing: knowing your fabric. A mismatch here leads to broken thread, skipped stitches, or fabric that looks like it lost a fight.

Here’s how needle sizes break down across lightweight, medium-weight, and heavyweight fabrics.

Needle Sizes for Lightweight Fabrics

Delicate fabrics are unforgiving — and the wrong needle size can ruin them fast. For lightweight materials like chiffon, voile, and fine silk, fabric selection should always guide your needle size choice first. Stick with sizes 60/8 or 70/10.

- Chiffon and georgette — size 60/8 keeps stitch formation clean with no visible holes

- Light cotton and lawn — size 70/10 manages fabric thickness without thread tension issues

- Lightweight knits — a 70/10 ballpoint respects fabric stretch and prevents runs

- Fine silk — pair a 60/8 Microtex with matching thread weight for invisible seams

Needle Sizes for Medium-Weight Fabrics

Medium-weight fabrics are the sweet spot of sewing — sturdy enough to hold structure, forgiving enough to stay manageable.

For most medium-weight fabrics like quilting cotton, linen, and poplin, needle sizes 75/11 to 90/14 cover your range. Needle selection here hinges on fabric weight and thread compatibility. Size 80/12 is your reliable default, delivering clean sewing performance without punching oversized holes through your fabric.

Needle Sizes for Heavyweight Fabrics

Once you hit heavyweight fabrics — denim over 12 ounces, canvas, upholstery, or vinyl — fabric weight demands a serious upgrade in large needle selection.

Start with a 100/16 for heavy fabric sewing and step up to 110/18 for dense material like thick layers or bulky seams. Heavyweight stitch quality depends on matching fabric thickness to the right needle size, so don’t shortchange yourself here.

Matching Needle Size to Thread Type

Your thread and needle need to work as a team — get them out of sync and your stitches will show it fast. The size of your needle’s eye has to match the weight of your thread, or you’ll be fighting breakage and tension problems the whole way through.

Here’s what you need to know about pairing them right.

Fine Threads and Smaller Needles

Fine thread is picky — pair it wrong and your stitches turn into a mess fast. For delicate fabric handling and thread tension control, stick to sizes 60/8 to 70/10. Fine thread selection matters because the thread should fill about 40–45% of the needle eye size.

- Use Microtex needle types for precise small needle techniques on silk or chiffon

- Match your sewing machine needle to your thread weight, not just fabric

- Smaller needle size keeps holes tight, protecting delicate weaving fibers

Thick Threads and Larger Needles

Thick thread needs room to breathe. If you’re working with heavy duty sewing projects — think upholstery, canvas bags, or denim — you’ll need a larger needle size to support the thread weight.

A Tex 45–50 thread pairs well with a 90/14 to 100/16. Forcing thick thread through a small needle wrecks stitch formation, causes fabric damage, and speeds up needle wear fast.

Balancing Thread, Fabric, and Needle Size

Getting thread tension right comes down to three things working together: needle size, thread weight, and fabric thickness. When they’re balanced, stitches lie flat and tension sits near your machine’s normal range.

A size 80/12 needle with 50-weight cotton on quilting fabric is a classic match. Test on a scrap first — that one step saves your actual project every time.

Types of Sewing Machine Needles and Their Sizes

Not all sewing machine needles are built the same — and that’s actually a good thing. Each type is designed with a specific fabric or thread in mind, so knowing which one to reach for makes a real difference.

Here are the main needle types and the sizes that work best with each.

Universal Needle Sizes

Universal needles are the Swiss Army knife of sewing machine needle types — adaptable enough for most everyday projects. Their slightly rounded tip works across woven and many common fabrics without constant switching.

Sewing needle sizes like 80/12 and 90/14 cover medium-weight fabrics well, while needle size 60/8 suits delicate weaves. Needle material and fabric density both influence your choice, so keep a range on hand.

Ballpoint and Stretch Needle Sizes

Knit fabrics need a different game plan. Ballpoint needles come in sizes 70/10, 80/12, and 90/14 — lighter for T-shirts, heavier for sweatshirt knits.

Stretch needles, sized 75/11 and 90/14, use modified needle geometry to handle high-spandex fabrics without skipped stitches. Smart sewing needle selection means matching needle types and thread compatibility to your fabric tension, not just grabbing whatever’s nearby.

Denim, Leather, and Specialty Needle Sizes

Heavy fabric sewing calls for a whole different toolkit. Here’s what you need to know about denim needle, leather needle, and specialty threads options:

- Denim needle sizes run 90/14 to 110/18

- Leather needle sizes span 80/12 to 110/18

- Leather stitching uses wedge-shaped cutting points

- Specialty threads need metallic or topstitch needle types

- Industrial needles reach sizes like 120/19

Smart sewing machine needle selection makes all the difference.

Embroidery and Quilting Needle Sizes

Both embroidery and quilting demand precision needles — and size is everything here.

| Needle Type | Size Range | Best For |

|---|---|---|

| Embroidery | 65/9 – 70/10 | Fine 60-weight embroidery threads, delicate fabrics |

| Embroidery | 75/11 – 80/12 | Standard 40-weight thread, medium fabric density |

| Embroidery | 90/14 | Heavy 30-weight threads, dense stitch formation |

| Quilting | 70/10 – 80/12 | Light quilting layers, fine cotton |

| Quilting | 80/12 – 90/14 | Thick batting, multiple quilting layers |

The oversized eye on an embroidery needle protects specialty threads from shredding, while quilting needle materials handle repeated passes through bulky seams without deflecting.

Signs You Need to Change Needle Size

Your needle talks to you — you just have to know what to listen for. When something’s off, the signs show up fast and they’re hard to ignore.

Here’s what to watch (and listen) for.

Skipped Stitches and Thread Breakage

Skipped stitches are your sewing machine’s way of waving a red flag. When your needle size doesn’t match your thread or fabric, stitch formation breaks down fast.

A dull sewing machine needle can’t form a clean loop, so the hook misses it entirely. Poor thread tension makes it worse. Don’t ignore it — swap the needle now.

Visible Fabric Holes or Snags

Visible holes along your seam mean your needle size is too large for the fabric. On fine fabrics like chiffon, a 90/14 sewing machine needle leaves gaps the thread can’t fill — stitch visibility becomes a real problem.

For hole prevention and snag reduction, match needle size to fabric weight. Needle sharpness matters too — a dull needle drags fibers, causing fabric damage across all fabric types.

Audible Popping or Resistance

Your machine’s telling you something when it starts making that rhythmic pop-pop sound. That noise isn’t random — it’s your sewing machine needle struggling.

Here’s what audible popping and needle resistance actually signal:

- Fabric drag means your needle size is too small for dense material

- Popping sounds indicate a dull needle tearing fibers instead of piercing cleanly

- Thread tension problems follow when needle types don’t match your thread weight

- Machine vibration increases as resistance builds with every stroke

Swap that needle first.

Top Sewing Machine Needle Products

Picking the right needle brand can make a real difference in how your projects turn out.

Some needles just perform better, last longer, and work more reliably across different fabrics and threads.

Here are four solid options worth keeping in your sewing kit.

1. Singer Universal Sewing Machine Needles

Singer’s Model 4790 pack is a solid starting kit for most home sewists. You get 20 needles across three sizes — 80/12, 90/14, and 100/16 — color-coded so you’re not squinting at tiny numbers mid-project.

They use the standard 130/705 H system, meaning they’ll fit Singer, Brother, Kenmore, and most other home machines without fuss. The slightly rounded universal point accommodates both wovens and stable knits.

A few users mentioned durability hiccups, but for everyday cotton, flannel, and denim blends, these deliver reliable, smooth stitching.

| Best For | Home sewists of all skill levels who work with everyday fabrics like cotton, denim, and flannel and need a reliable, versatile needle pack that fits most standard machines. |

|---|---|

| Brand | SINGER |

| Machine Compatibility | Most home machines |

| Pack Size | 20 needles |

| Fabric Suitability | Woven fabrics |

| Point Type | Universal |

| Needle Size | 80/12, 90/14, 100/16 |

| Additional Features |

|

- Color-coded sizing makes it easy to grab the right needle without hunting for tiny numbers

- Fits Singer, Brother, Kenmore, and most other home machines right out of the box

- Three size options (80/12, 90/14, 100/16) cover a wide range of everyday sewing projects

- Some users reported needles bending or breaking sooner than expected

- Quality control has been inconsistent — at least one buyer received an empty package

- Not a great fit for heavy-duty work like leather or thick upholstery fabrics

2. SCHMETZ Microtex Sewing Machine Needles

When you need precision sewing on delicate fabrics, SCHMETZ Microtex needles are the upgrade worth making. The 80/12 size hits a sweet spot — sharp enough to pierce tightly woven microfibers, silk, and coated materials cleanly, without dragging or puckering.

That slim, acute point isn’t just marketing language; it genuinely produces straighter topstitching and crisper seams. Each five-needle card fits most home machines using the standard 130/705 H-M system. If clean finishes matter to you, these deliver.

| Best For | Sewers who work with delicate or tightly woven fabrics like silk, microfiber, and polyester and want clean, precise results on detailed projects. |

|---|---|

| Brand | SCHMETZ |

| Machine Compatibility | All home machines |

| Pack Size | 5 needles |

| Fabric Suitability | Light to medium fabrics |

| Point Type | Microtex sharp |

| Needle Size | 80/12 |

| Additional Features |

|

- Ultra-sharp point cuts through fine fabrics cleanly, reducing puckering and distortion

- Works with most home sewing machines, so no compatibility headaches

- Great for topstitching and quilting where neat, accurate seams really matter

- Not ideal for thick or heavy fabrics — the fine point isn’t built for that kind of work

- Needles may need replacing more often on big or complex projects

- Only comes in size 80/12, so it won’t cover every sewing task you throw at it

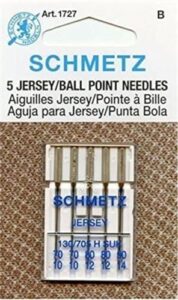

3. Schmetz Jersey Sewing Machine Needles

If Microtex needles are built for precision on wovens, Jersey needles solve a completely different problem — keeping knit loops intact.

The medium ball point slides between the fibers instead of piercing them, which means no runs, no snags, and no puckered seams on your T-shirts or sweatshirt fleece. The mixed five-pack covers sizes 70/10 through 90/14, so you’re set from lightweight cotton jersey to heavier bouclé. The Orange color band makes them impossible to mix up in your needle case.

| Best For | Anyone who sews with knit fabrics — jersey, sweatshirt fleece, bouclé, or tulle — and wants smooth, snag-free stitches every time. |

|---|---|

| Brand | SCHMETZ |

| Machine Compatibility | All home machines |

| Pack Size | 5 needles |

| Fabric Suitability | Knit fabrics |

| Point Type | Ball point |

| Needle Size | Varies |

| Additional Features |

|

- The medium ball point slides between fabric fibers instead of piercing them, so no more runs or puckered seams on your knits.

- Works with lightweight and heavy knit projects alike, giving you solid coverage across a range of fabrics.

- Compatible with all home sewing machine brands, so no guessing if they’ll fit your machine.

- Heavy use can cause the needles to break or wear out faster than expected.

- Results can vary depending on your specific machine and fabric combo, so some trial and error may be needed.

- Only works with domestic machines — not an option if you’re sewing on industrial or commercial equipment.

4. Titanium Coated Topstitch Sewing Needles

If you do a lot of quilting or decorative topstitching, the High-Quality Threads Titanium Coated Topstitch Needle is worth the upgrade. The size 90/14 fits heavier threads — think 40-weight cotton or bold decorative polyester — and the oversized eye keeps them from shredding mid-project.

That titanium-nitride coating isn’t just a pretty gold finish. It lasts 5 to 8 times longer than a standard needle and stays cooler at speed. Five needles per pack, compatible with any home machine.

| Best For | Quilters and sewists who work with heavier or decorative threads and need a needle that can handle multiple layers without shredding or dulling fast. |

|---|---|

| Brand | Superior Threads |

| Machine Compatibility | Any home machine |

| Pack Size | 5 needles |

| Fabric Suitability | Medium to heavy fabrics |

| Point Type | Universal sharp |

| Needle Size | 90/14 |

| Additional Features |

|

- The titanium-nitride coating lasts way longer than a standard needle — you won’t be swapping these out every other project.

- The oversized eye handles thick, decorative, or 40-weight threads without shredding them mid-stitch.

- Works with any home sewing machine, so no compatibility headaches.

- They cost more than basic needles, so the price might sting if you’re used to grabbing a cheap pack.

- Not the right choice for knit fabrics — you’ll want a ballpoint needle for those.

- Very thick or dense materials (like heavy denim) can snap the needle if you don’t prep the fabric first.

Tips for Selecting and Maintaining Needle Sizes

Getting the right needle is only half the battle — keeping it in good shape is what actually keeps your projects running smoothly.

A few simple habits can save you from frustrating mid-project mishaps.

Here’s what you need to know about replacing needles, inspecting, and storing your needles the right way.

How Often to Replace Sewing Needles

Most sewists replace their sewing machine needle every 6 to 8 hours of active stitching — and that’s solid sewing needle maintenance. Needle wear factors like fabric density effects and sewing speed impact matter too.

Heavy denim dulls a needle fast. Replacement schedules should also reflect needle coating benefits: titanium-coated needles can stretch to 30-plus hours. Smart needle selection means knowing when to swap.

Checking for Needle Damage or Wear

Wear detection starts with your fingernail. Drag the needle tip lightly across it — if it catches or scratches, that’s a damage sign you can’t ignore.

A good needle glides smooth. Watch for thread breakage, skipped stitches, or that telltale popping sound during needle inspection. These are your machine’s way of asking for better needle care and smarter sewing needle selection.

Best Practices for Needle Storage and Organization

Think of your needle collection like a tiny toolbox — chaos in there costs you time and projects. Smart needle storage and organization tips protect your investment and keep you sewing without interruption.

- Use rigid containers like tins or tubes for needle safety and to prevent bent tips

- Label compartments by needle types and size for faster sewing needle selection

- Track in-use needles on a felt pad grid for easy needle tracking

- Keep your go-to sizes within arm’s reach for real workspace optimization

Frequently Asked Questions (FAQs)

Is a 29 or 30 gauge needle bigger?

The 29 gauge needle is bigger. In the gauge system, a higher number means a thinner needle. So 29 gauge has a wider diameter — about 337 mm — versus 30 gauge at 312 mm.

Is a 23 or 18 gauge needle bigger?

The 18 gauge needle is bigger. It measures about 27mm in diameter — nearly twice the 64mm of a 23 gauge. In needle sizing, lower numbers always mean larger needle diameter.

Can I use the same needle for all fabrics?

Technically, you can — but you shouldn’t. One needle won’t handle every fabric well.

Poor fabric and needle compatibility leads to skipped stitches, damaged threads, and ruined seams. Match your needle to your material every time.

Do needle sizes vary between sewing machine brands?

Good news: needle sizes don’t vary between brands. Domestic needle sizes follow a standardized system — so a size 80/12 from Singer fits your Brother or Janome just the same.

How does needle size affect tension settings?

Needle size directly affects thread tension. A larger needle creates a bigger hole, reducing fabric resistance and loosening stitch balance.

A smaller needle tightens that grip, increasing drag — often requiring tension adjustment to keep stitches even.

Are hand sewing and machine needle sizes the same?

No, they’re not. Hand needle sizes run in reverse — higher numbers mean finer needles.

A size 10 hand needle and a size 10 machine needle are completely different, as machine needle sizes do the opposite.

Can needle size impact seam allowance accuracy?

Yes, absolutely. The wrong needle size causes fabric distortion, needle deflection, and uneven stitch formation — all of which throw off your seam allowance accuracy.

Matching needle size to fabric keeps every stitch quality consistent and measurements true.

Conclusion

It’s almost funny — that tiny stamped number people ignore is the one detail that controls everything.

Now you know what sewing needle sizes mean, and that knowledge quietly changes how every project feels under your hands.

Match your needle to your fabric weight, pair it with the right thread, and replace it before it fights you. The machine stays the same. The thread stays the same. But the right needle? That’s what actually does the work.

- https://www.sewessential.co.uk/blog/how-to-choose-the-right-sewing-machine-needle/

- https://blog.treasurie.com/sewing-machine-needle-sizes/

- https://konsew.com/blog/what-do-the-size-numbers-mean-on-sewing-machine-needles

- https://blog.wawak.com/post/sewing-machine-needle-and-thread-size-chart

- https://www.schmetzneedles.com/pages/sewing-machine-needle-chart