This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You wouldn’t use a bread knife to carve wood, yet most people grab whatever scissors are nearby when they need to cut fabric—and then wonder why the edges fray, the cuts drift off course, or the fabric seems to fight back with every snip. Understanding what makes fabric scissors different from regular scissors transforms that frustrating experience into smooth, professional-looking results every time.

The distinction runs far deeper than just sharper blades; it’s built into the steel composition, blade geometry, edge angles, and even the offset handle design that lets you glide along a cutting surface without lifting delicate textiles.

Once you see how these specialized tools preserve fiber integrity and deliver drift-free cutting lines, you’ll never reach for household scissors again.

Table Of Contents

- Key Takeaways

- Key Differences Between Fabric and Regular Scissors

- Why Fabric Scissors Matter in Sewing

- Types of Fabric Scissors and Their Uses

- How Fabric Scissors Differ From Paper Scissors

- Top Fabric Scissors for Precise Cutting

- Caring for and Maintaining Fabric Scissors

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Fabric scissors differ from regular scissors through specialized steel composition, steeper blade angles (60-70 degrees), offset handle design, and 7-9 inch blade lengths that deliver clean cuts without crushing fibers or causing fraying within a 1mm tolerance.

- Using fabric scissors on paper, cardboard, or adhesives rapidly dulls the precision-ground edge through abrasion and residue buildup, compromising cutting accuracy and requiring costly resharpening or replacement every 6-12 months with heavy use.

- Different fabric scissors serve distinct purposes: dressmaker shears (8-12 inches) for long straight cuts, embroidery scissors (3-4 inches) for detail work, pinking shears for zigzag fray-prevention, and tailor scissors for cutting multiple layers without drift.

- Proper maintenance extends blade life significantly through immediate lint removal after each use, isopropyl alcohol for residue cleaning, sharpening with 600-1000 grit stones at the correct bevel angle, and storing scissors flat in dry sheaths away from moisture and metal contact.

Key Differences Between Fabric and Regular Scissors

When you grab a pair of fabric scissors instead of regular household scissors, you’re working with a tool engineered for a completely different purpose. The distinctions aren’t just cosmetic—they’re built into every element, from the blade geometry to the handle balance, and each feature directly affects your cutting precision and comfort.

Whether you need straight cuts, curved seams, or detailed trimming, choosing the right fabric scissors for home use makes all the difference in your finished projects.

Let’s break down the four critical differences that separate fabric scissors from their general-purpose counterparts.

Understanding these differences helps you choose the right pair from the essential sewing scissors for quilting that every fabric artist needs.

Blade Angle and Sharpness

Blade geometry is where fabric scissors break free from ordinary tools. You’ll notice the finer edge sharpness and steeper bevel angle that minimize fabric fraying, giving you cutting efficiency that household scissors can’t match.

When your blades lose that precision, sharpening fabric scissors at home restores the clean edge that prevents fiber crushing and keeps cuts within that critical 1mm tolerance.

This blade design maintains precision cutting through multiple passes, reducing drag and keeping your edge sharp longer. Master proper sharpening and scissor maintenance, and you’ll transform every cutting technique into clean, professional results.

Understanding how self-healing mats work helps you maximize their lifespan and keep your blades performing at their best.

Blade Length and Edge Precision

When you’re aiming for precision cutting, length matters—fabric scissors usually span 7 to 9 inches, balancing reach with control for your fabric cutting techniques.

This blade geometry delivers cutting accuracy because:

- Longer blades minimize fabric tearing on woven textiles with straighter passes

- Tapered edges reduce snagging, protecting delicate fibers

- Enhanced edge retention keeps scissor sharpness consistent across multiple cuts

- Strategic blade design maintains your cutting technique without drift

Handle Design and Ergonomics

You’ll notice that Ergonomic Grips on fabric scissors aren’t just about Grip Comfort—they’re engineered for sustained control during hours of cutting. Scissor Balance shifts weight toward the pivot, reducing pinch force, while Grip Materials like cushioned rubber follow natural Finger Contours to minimize strain.

A Bent Grip design aligns blade axis with your wrist posture, unlike Straight Grip styles on regular scissors, giving you precision without fatigue that’s essential for serious Scissor Care and long-term Ergonomics.

Material and Construction

Material Compatibility starts with Blade Materials—high-carbon Carbon Steel or Stainless Steel forged to exact bevel angles that slice fabric without snagging. Steel Forging produces thin, lightweight Blade Design optimized for textile fibers, while Joint Engineering reinforces pivots against lateral stress.

If you’re working with hand fatigue or joint discomfort, specialized seam rippers designed for arthritis pair those same ergonomic principles with precision blades for tear-free unpicking.

Edge Retention depends on heat-treated blades and precise Handle Design that balances weight distribution, unlike regular scissors built for paper’s different grain and density.

Why Fabric Scissors Matter in Sewing

You might wonder whether investing in proper fabric scissors really has an impact on your sewing projects, or if any sharp pair will do the job. The truth is, fabric scissors aren’t just a luxury for professional seamstresses—they’re fundamental tools that directly affect the quality of every cut you make, the longevity of your materials, and how much you’ll actually enjoy the process.

Fabric scissors aren’t a luxury—they’re fundamental tools that directly affect cut quality, material longevity, and your enjoyment of every sewing project

Let’s look at three critical ways fabric scissors transform your sewing work, from the precision of your cuts to the final appearance of your finished pieces.

Importance of Clean, Accurate Cuts

When you’re wielding fabric scissors with proper cutting precision, you’re not just snipping textiles—you’re building the foundation for professional-grade sewing. Accurate edges transform your work by:

- Reducing fabric fray at seam allowances, which prevents unraveling during garment construction and extends the lifespan of your finished pieces.

- Minimizing material waste through aligned pattern placement, eliminating costly mistakes that require resewing entire sections.

- Enhancing seam quality with flawless intersections that eliminate visible puckering along hems and maintain consistent drape throughout your textile cutting projects.

Impact on Fabric Quality and Project Outcome

Cutting accuracy with fabric scissors directly shapes seam integrity and fabric durability throughout your project. Sharp, precision-ground blades preserve fiber integrity by eliminating multiple passes that weaken textile handling zones, while proper edge engagement prevents snagging on delicate weaves.

This precision in fabric cutting and sewing translates to exceptional material compatibility, reducing alteration rates and boosting project efficiency with consistent fabric quality across every seam.

Efficiency and Comfort for Sewists

When you’re working through long sewing sessions, ergonomic grips and scissor balance directly reduce hand fatigue by up to 15% compared to standard models, boosting both cutting precision and sewing productivity.

Contoured grip design delivers three critical advantages for precision cutting and sewing:

- Soft-touch grips improve hold security during extended fabric manipulation

- Cushioned pivot points minimize wrist strain across repetitive cuts

- Light-weight construction lowers effort while maintaining accuracy

These ergonomics transform your sewing tools into extensions of your craft, supporting weaving and other sewing and crafting tasks with sustained comfort.

Types of Fabric Scissors and Their Uses

You can’t conquer precision sewing with just one pair of scissors. Different fabrics, cutting angles, and project requirements demand specialized tools designed for specific tasks.

Let’s break down the four main types of fabric scissors you’ll encounter and what makes each one essential for particular cutting challenges.

Dressmaker Shears

When you’re slicing through long garment panels, dressmaker shears give you the precision and reach regular scissors can’t match. These specialized tools feature blade lengths from 8 to 12 inches with beveled, offset edges that glide along flat surfaces without lifting your fabric. The ergonomic handle design and balanced shear construction reduce hand fatigue, while their razor-sharp edge delivers clean cuts through cotton, linen, and silk without snagging delicate weaves.

| Feature | Design Purpose |

|---|---|

| Blade Geometry | Curved lower blade, beveled upper edge for flat-surface cutting |

| Handle Ergonomics | Oversized loops with weight distribution for extended sessions |

| Shear Balance | 8-12 inch length optimized for straight cuts and garment seams |

| Fabric Compatibility | Ground edge for woven textiles—cotton, linen, silk—not heavy denim |

| Cutting Technique | Offset tang provides leverage for long, distortion-free grain cuts |

Embroidery Scissors

When precision matters more than power, embroidery scissors deliver the stitch control you need for intricate fabric handling. These compact tools feature short, pointed scissor blades—usually 3 to 4 inches—designed for delicate thread management in sewing and embroidery projects.

Their fine embroidery tips access tight spaces without snagging silk or organza, while hardened steel edges maintain sharpness through countless detail cuts, giving you mastery over every snip in your sewing and crafting work.

Pinking Shears

You’ll recognize pinking shears by their distinctive serrated edge, which creates a zigzag cut that reduces fabric fray on woven materials like cotton and linen. The pinking blade features reinforced teeth that maintain consistent spacing through repetitive cutting fabric sessions, giving you decorative seam finishes while minimizing bulk at allowances.

These specialized fabric scissors excel in sewing and crafting projects where raw edges need visual control without traditional finishing.

Tailor Scissors

Tailor scissors give you powerful leverage with their 8 to 12-inch scissor blade, letting you slice continuous, drift-free lines through multiple fabric layers without repositioning.

The precision edges stay sharp through extended fabric cutting sessions, thanks to high-carbon steel construction and convex bevels that reduce friction.

You’ll appreciate the oversized finger loops and balanced pivot point, which transform marathon sewing sessions into controlled, fatigue-free work.

How Fabric Scissors Differ From Paper Scissors

You might think scissors are scissors, but fabric scissors and paper scissors are built for completely different battles. The blade construction, edge geometry, and material tolerances vary markedly between these two tools, which means using the wrong one will cost you in performance and longevity.

Let’s break down the specific differences that make each tool suited to its intended material.

Edge Durability and Sharpness

You’ll notice fabric scissors hold their sharp edge longer because of premium steel composition and specialized edge geometry designed for textile fibers. Regular scissors dull quickly on fabric since their blades lack the micro-serration and edge honing that grip delicate threads without slippage.

Proper blade sharpening and maintenance extend this advantage, making scissor selection vital for precision cutting that delivers clean, professional results every time.

Blade Thickness and Flexibility

Fabric scissors feature thinner, more flexible blades than household scissors, which lets you track smoothly along curves and intricate patterns without snagging threads. This blade geometry concentrates cutting force along the edge, boosting fabric uptake and cutting efficiency while reducing fraying risk. Regular scissors’ stiffness transfers lateral force that distorts delicate textiles, so flexibility matters when precision cutting demands clean results.

- Enhanced blade design facilitates smooth tracking through woven fabrics

- Steep bevel geometry improves fabric uptake and reduces fraying

- Thinner construction prevents snagging during intricate pattern work

Effects of Using Scissors on The Wrong Material

Using your fabric scissors on cardboard, tape, or heavy plastics dulls the blades surprisingly fast, because adhesives and grit embed into the cutting edge and compromise sharpness. That damage shows up as uneven cuts and fabric fraying when you return to textiles, forcing you to rework seams and waste material—so material compatibility directly impacts cutting accuracy and scissor maintenance costs over time.

| Wrong Material | Blade Impact | Fabric Consequence |

|---|---|---|

| Cardboard/paper | Edge dulling from cellulose fibers | Uneven cuts, increased fraying |

| Adhesive tape | Residue buildup on blade | Sticky drag, snagged threads |

| Heavy denim layers | Blade warping, misalignment | Reduced cutting accuracy |

| Plastic packaging | Edge chipping, micro-damage | Jagged fabric edges |

| Wire/metal | Severe nicks, permanent damage | Unusable for precise work |

Top Fabric Scissors for Precise Cutting

Now that you understand what sets fabric scissors apart from their paper-cutting counterparts, you’ll want to choose the right pair for your projects.

The market offers dozens of options, each designed with specific cutting tasks in mind, from dressmaker shears to pinking blades.

Below, you’ll find six top-performing fabric scissors that deliver the precision, durability, and edge retention you need for professional-quality results.

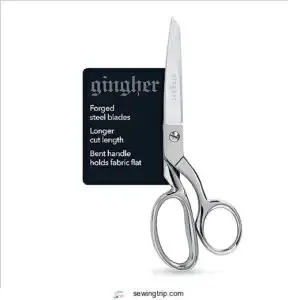

1. Gingher Stainless Steel Fabric Scissors

When you’re cutting through multiple layers of dense fabric, you’ll appreciate how Gingher Stainless Steel Fabric Scissors combine sharpness retention with cutting precision. These sewing scissors feature high-carbon stainless steel blades with ergonomic grips that reduce fatigue during extended sessions, allowing you to maintain blade alignment through a tension screw for consistent performance.

The offset grip design aids proper fabric cutting and management techniques, while the sharp tip handles thread-trimming tasks. Though finger holes can feel slippery with dry hands, these fabric scissors deliver the durability and control serious sewists demand for dressmaking, tailoring, and quilting projects.

| Best For | Sewers, quilters, and fabric crafters who need durable, precise scissors for cutting multiple layers of fabric and handling extended projects. |

|---|---|

| Material | Stainless Steel |

| Blade Material | Stainless Steel |

| Color | Silver |

| Primary Use | Fabric cutting |

| Handle Type | Bent handle |

| Length | 8 inches |

| Additional Features |

|

- Precision-ground blades cut cleanly through multiple fabric layers without fraying edges

- Bent handle design keeps your hand comfortable and positioned above the cutting surface for better control

- Premium forged stainless steel with chrome finish ensures long-lasting sharpness and durability

- Finger holes can feel slippery if you have very dry hands

- At 7.2 ounces, they’re heavier than some users prefer for all-day cutting

- Handle size may feel cramped for people with larger hands

2. Westcott Titanium Fabric Scissors

You’ll find the 5-inch Westcott Titanium Fabric Scissors deliver impressive blade sharpness for intricate fabric cutting and handling tasks, thanks to a titanium coating that resists corrosion while maintaining edge retention longer than standard sewing scissors.

The ergonomic design features soft grips that reduce hand fatigue during extended sessions, though you’ll want to handle them carefully since some users report the construction feels lighter than expected.

For scissor selection and maintenance considerations, these micro-tip fabric scissors excel at detail work like embroidery and thread-trimming, making them ideal for crafters who prioritize precision over heavy-duty applications.

| Best For | Crafters, sewers, and DIY enthusiasts who need precise cutting for detailed work like embroidery, thread trimming, and intricate fabric projects rather than heavy-duty applications. |

|---|---|

| Material | Stainless Steel |

| Blade Material | Stainless Steel |

| Color | Gold |

| Primary Use | Multipurpose cutting |

| Handle Type | Ergonomic |

| Length | 5 inches |

| Additional Features |

|

- Titanium-coated blades stay sharp longer and resist corrosion from fabric fibers and sewing chemicals

- Micro-tip design excels at detail work and precise cuts on various materials including fabric, paper, and ribbon

- Soft-grip handles provide comfort during extended use and work for both right and left-handed users

- Handle construction feels flimsy and lighter than some users expected

- Scissors are smaller than anticipated at 5 inches, which may not suit everyone’s needs

- Blades can become dull over time with heavy use and require careful handling to maintain sharpness

3. Singer Pinking Shears For Fabric

You’ll discover the 9-inch Singer Pinking Shears deliver sturdy zigzag cutting techniques that transform raw fabric edges into finished, fray-resistant seams, thanks to sawtooth blades engineered for textile fraying prevention on woven materials like cotton and silk.

The stainless steel construction maintains sharpness through repeated cutting fabric sessions, while soft grip grips reduce fatigue during extended sewing projects.

For sewing tool maintenance and fabric edge finishing, these pinking shears excel at decorative hems and seam allowances, though you’ll need to avoid delicate fabrics where the zigzag pattern might distort fiber structure.

| Best For | Home sewers and crafters who regularly work with woven fabrics like cotton and silk and need reliable fray prevention on seams and decorative edges. |

|---|---|

| Material | Titanium |

| Blade Material | Titanium |

| Color | White/Grey |

| Primary Use | Crafting and sewing |

| Handle Type | Soft handles |

| Length | 6.5 inches |

| Additional Features |

|

- Heavy-duty stainless steel blades stay sharp through repeated use and handle both lightweight and thicker fabrics

- Soft grip handles reduce hand fatigue during long sewing sessions, making extended projects more comfortable

- Zigzag pattern effectively minimizes fraying on woven fabric edges while creating clean, finished seams

- Not suitable for delicate fabrics like silk where the zigzag cut may snag or distort fibers

- Blades will eventually dull with heavy use and may be difficult to resharpen depending on the design

- Less precise than regular fabric scissors for straight pattern cutting and detailed sewing work

4. Hisuper Embroidery Scissors

When precision embroidery techniques demand compact sewing tools, you’ll appreciate how the 3.6-inch Hisuper Embroidery Scissors combine stainless steel durability with hand-polished craftsmanship for clean thread cutting in detailed fabric handling tasks. The short blade length enhances control during intricate stitching, while the included polka-dot leather cover protects against rust and blade damage during storage, a vital element of scissor maintenance.

Though not the sharpest fabric scissors available, these crafting tools and supplies remain ideal for DIY embroidery, quilting, and portable sewing projects, offering reliable performance among specialized scissor types in your sewing tools and equipment collection.

| Best For | Crafters and sewers who need portable, precise scissors for embroidery, quilting, and detailed thread work on the go. |

|---|---|

| Material | Stainless Steel |

| Blade Material | Stainless Steel |

| Color | Colorful |

| Primary Use | Embroidery and sewing |

| Handle Type | Standard |

| Length | 3.6 inches |

| Additional Features |

|

- Hand-polished stainless steel blades deliver clean cuts through delicate threads and yarn without fraying

- Compact 3.6-inch size with included leather cover makes them easy to store and carry for travel projects

- Versatile enough for everyday cutting tasks, from embroidery to DIY crafts and hand sewing

- Blade sharpness falls short compared to premium embroidery scissors on the market

- Polka-dot leather cover may have minor fit or quality issues according to some users

- Requires consistent care and dry storage to prevent rust on the stainless steel blades

5. Bihrtc Embroidery Scissors Stainless Steel

If you’re drawn to the idea of scissors that handle multiple craft tasks without breaking the bank, the 4.5-inch BIHRTC Embroidery Scissors in gold-finished stainless steel deliver multipurpose cutting capability for embroidery, sewing, cross-stitch, and even office paper tasks. Though their sharpness and size may not suit every detailed application, they are particularly useful for general crafting.

The included leather cover protects your investment during storage, which is essential for basic scissor maintenance. The lightweight construction reduces hand fatigue across various fabric cutting operations.

However, some users report that these scissors aren’t curved at the ends, limiting their effectiveness for embroidery tips and thread work.

| Best For | Crafters who need affordable, multipurpose scissors for embroidery, sewing, cross-stitch, and light office tasks but don’t require precision detailing tools. |

|---|---|

| Material | Stainless Steel |

| Blade Material | Stainless Steel |

| Color | Gold |

| Primary Use | Embroidery and crafting |

| Handle Type | Comfortable design |

| Length | 4.5 inches |

| Additional Features |

|

- Comes with a protective leather cover to keep the blades safe during storage

- Lightweight stainless steel construction reduces hand fatigue during extended crafting sessions

- Multipurpose design handles fabrics, threads, and paper for various DIY projects

- Some users report the blades aren’t as sharp as expected for detailed work

- Lacks curved tips, which limits effectiveness for precise embroidery and thread cutting

- The 4.5-inch size may be too large for intricate tasks like de-threading

6. Jistl Green Pinking Shears Scissors

When fabric edge finishing demands a zigzag pattern that prevents fraying, the Jistl Green Pinking Shears offer 9.5-inch hardened stainless steel serrated blades designed for fabric scissors work, leather, and decorative ribbon applications.

The ABS ergonomic grips reduce hand fatigue during extended cutting fabric sessions, though some users note these pinking shears feel stiff and heavy compared to embroidery scissors.

For scissor selection and care, wipe the anti-rust coating before use, and follow standard cutting tool maintenance and serrated blade care practices to preserve edge geometry across woven textiles.

| Best For | Sewers and crafters who need a reliable zigzag edge finish on fabrics, leather, and decorative materials to prevent fraying. |

|---|---|

| Material | Stainless Steel |

| Blade Material | Stainless Steel |

| Color | Green |

| Primary Use | Decorative edging |

| Handle Type | ABS ergonomic |

| Length | 9.5 inches |

| Additional Features |

|

- Hardened stainless steel blades stay sharp through repeated use on thick materials like fabric and leather

- Ergonomic ABS handles reduce hand strain during long cutting sessions

- Versatile tool works on fabric, paper, ribbon, and leather for both functional and decorative projects

- Heavier and bulkier than typical scissors, which can feel awkward for some users

- Blades arrive stiff and require breaking in, plus decent hand strength to operate smoothly

- Anti-rust coating needs to be wiped off before first use, and the fixed screw can’t be adjusted for tension

Caring for and Maintaining Fabric Scissors

You’ve invested in quality fabric scissors, and now it’s time to keep them performing at their best. Without proper care, even the sharpest blades lose their edge, accumulate residue, and wear out faster than they should.

Let’s walk through the essential maintenance practices that’ll protect your investment and guarantee clean, precise cuts for years to come.

Cleaning and Removing Fabric Residue

Residue removal keeps your fabric scissors sharp and your projects clean, because lint and fibers that build up on the blades will transfer to fresh fabric, ruining your next cut. Proper blade cleaning maintains cutting precision, prevents fabric fraying, and extends the life of your investment in quality tools.

- Wipe blades with a clean, dry cloth after each use to remove lint and fibers before lubrication

- Use isopropyl alcohol to dissolve sticky residues, avoiding harsh chemicals that corrode steel

- Dry blades thoroughly after solvent use to prevent rust and maintain edge sharpness

Proper Sharpening Techniques

You can’t cut like a pro with dull blades, so sharpening scissors becomes your non-negotiable maintenance ritual.

Use sharpening stones with 600–1000 grit to sharpen the edge without grinding away precious steel, keeping that 60–70 degree bevel angle intact for clean fabric cuts.

Blade honing through a dedicated scissor sharpener prevents uneven wear on curved edges, and sharpness testing on scrap material confirms your sewing tools are ready for precision work.

Storing Fabric Scissors Safely

Your sharpened blades deserve protection, so store scissors in a dedicated sheath or case that prevents accidents and preserves that razor edge you worked to restore.

Blade protection means keeping your fabric scissors flat in a dry drawer, away from moisture that breeds rust, and separated from other metal tools that’ll dull the edge through contact—smart storage solutions deliver safe handling every single time.

Tips for Prolonging Blade Life

Blade inspection after every major project catches nicks before they spread, while wiping down your cutting edges removes lint that quietly wears away sharpness—these edge maintenance habits keep fabric scissors performing like new.

You’ll extend tool life dramatically by reserving them strictly for textiles, never paper or cardboard, and following a sharpening schedule matched to your cutting volume, not random guesswork.

Frequently Asked Questions (FAQs)

Can fabric scissors cut other materials safely?

While it’s tempting to think sharp means all-purpose, your specialized shears aren’t built for harder materials like leather or metal.

These materials rapidly dull the blade design, which is optimized for cutting fabric, compromising both material safety and future performance.

How often should fabric scissors be replaced?

You’ll know it’s time when your fabric scissors snag or fray edges despite sharpening—usually every 6–12 months with regular use, though heavy-duty cutting demands earlier replacement for maximum cutting efficiency.

Are left-handed fabric scissors significantly different?

Yes, left-handed fabric scissors feature reversed blade orientation and counterclockwise handle ergonomics, improving cutting accuracy and handle comfort for left-dominant users.

Though you’ll find fewer specialized options compared to standard right-handed designs.

What causes fabric scissors to become dull?

Even premium fabric scissors fall victim to dulling factors like edge abrasion from dense weaves, cutting friction with synthetic fibers, and material fatigue from repeated flexing, all accelerated without proper maintenance and fabric preparation.

Do professional tailors use different scissors than hobbyists?

Professional tailors usually invest in dressmaker shears and tailoring shears with high-quality scissor material, sharper cutting techniques, and ergonomic tailoring equipment designed for garment construction.

Meanwhile, hobbyists often start with lighter, multipurpose professional tools for basic fabric handling.

Conclusion

Picture your fabric shears slicing through silk like light through water—no drag, no frayed edges, just a whisper-clean line that stays exactly where you intended. That’s what makes fabric scissors different from regular scissors: precision-engineered steel, offset grips that float above your cutting surface, and blade angles designed to preserve every fiber.

Once you’ve felt that seamless glide, you’ll guard those shears like the precision instruments they are, reserving them strictly for fabric and watching your projects transform.