This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Use a ballpoint needle that slides between fibers rather than piercing them.

Set your machine to a zigzag or stretch stitch—these move with the fabric rather than fighting against it.

You can also try a twin needle for a professional finish that maintains elasticity.

Always test your settings on a scrap piece first.

While sewing, gently stretch the fabric slightly to create a hem that won’t snap when worn.

Stabilizing tape can be your secret weapon for particularly stubborn knits.

The difference between a wavy hem and a sleek finish often lies in these small but vital details.

Table Of Contents

Key Takeaways

- You’ll need specialized equipment for stretchy fabrics, including a ballpoint needle that slides between the fibers and either a zigzag stitch or a twin needle that maintains elasticity.

- Before sewing, properly prepare your fabric by pressing it with a warm iron and stabilizing it with hem tape or lightweight interfacing to prevent puckering and waviness.

- When pinning your hem, position the pins perpendicular to the fabric edge and gently stretch the material while folding it to maintain elasticity and ensure even results.

- To prevent common issues like uneven hemlines or loose stitches, use a walking foot for smooth feeding, apply gentle tension while sewing, and finish with proper pressing.

Preparing Stretchy Fabric

You’ll need to prepare your stretchy fabric properly before hemming to prevent frustrating puckering and waviness.

Pressing the fabric with a warm iron and stabilizing it with the right tools, such as hem tape or lightweight interfacing, creates the foundation for a professional-looking, elastic hem that won’t distort.

The process of creating a professional-looking, elastic hem involves using the right tools and techniques, including stabilizing the fabric, which is crucial for preventing distortion, and results in a professional-looking finish.

Pressing Fabric Before Hemming

Why is pressing fabric before hemming so essential? It’s the foundation of your entire hemming process.

Before you fold a single inch of your stretchy fabric, set your iron to a low setting and thoroughly remove all wrinkles. This fabric relaxation step guarantees your measurements stay accurate and your hem lies flat.

Position your material properly on the ironing board, applying gentle pressure to prepare the fabric without stretching it out of shape, ensuring a smooth process.

Stabilizing Fabric for Sewing

One essential step before stitching stretchy fabrics is properly stabilizing them to prevent unwanted stretching during sewing.

Apply hem tape or fusible interfacing along the edge where you’ll fold your hem. Knit stay tape works wonderfully for maintaining shape without sacrificing flexibility.

Knit stay tape: your stretchy fabric’s silent partner for flawless hems that move with you!

For lightweight fabrics, try tissue paper underneath while sewing or use stabilizer sprays. A light application of starch can also provide temporary stability without affecting the fabric’s natural stretch.

Washing and Drying Fabric

Fabric shrinkage can derail even the most perfect hemline.

Always pre-wash your stretchy fabric before cutting or sewing to prevent unwelcome surprises later. Use cold water and gentle detergent to preserve color fastness and fiber integrity.

Avoid fabric softening agents as they can interfere with stitch adhesion. When drying, opt for air-drying methods over high heat to maintain the fabric’s natural stretch properties.

Understanding the right stretch sewing techniques is essential for a professional finish and to achieve the desired outcome with stretchy fabric.

Selecting Appropriate Thread and Needles

With your fabric prepped and dry, it’s time to choose your thread and needle arsenal.

For stretchy fabrics, ballpoint or stretch needles are non-negotiable—they slip between fibers rather than piercing them, preventing snags.

Pair them with polyester thread (it has built-in give) or wooly nylon thread for seams that flex with your fabric.

Skip cotton thread—it’ll snap when your fabric stretches.

Using the right ballpoint needles is essential for a successful sewing experience.

Folding and Pinning Hem

You’ll need to properly fold and secure your stretchy fabric before sewing to prevent wavy, unprofessional hems.

Position your pins perpendicular to the fabric edge while gently stretching the material to maintain its elasticity and guarantee an even, professional-looking finished hem, which will help achieve a professional-looking result.

Folding Fabric Edge to Desired Length

When folding the fabric edge to desired length, precision matters for professional results.

When folding your fabric edge, precision isn’t just helpful—it’s the cornerstone of truly professional results.

Measure from the bottom edge, then fold evenly using a ruler as your guide.

For proper hem alignment, gently stretch the fabric while folding to maintain elasticity and prevent waviness.

Different fold techniques work better for various stretch fabrics—single folds work well for thin materials, while double folds add structure to medium-weight knits.

Securing Folded Hem With Sharp Pins

After creating your perfect fold, secure it with sharp pins to maintain hem security while you work. Proper pin placement prevents slipping during the pivotal sewing stage.

Using the right sharp sewing pins is essential for a successful hem.

Here’s how to pin effectively when hemming stretch fabric:

- Space pins evenly every 2-3 inches

- Insert completely through both layers

- Keep fabric tension consistent between pins

- Use ball-head pins for knit hems

- Remove pins just before your presser foot reaches them to ensure a smooth and successful sewing experience.

By following these steps, you can achieve a professional-looking hem with minimal effort.

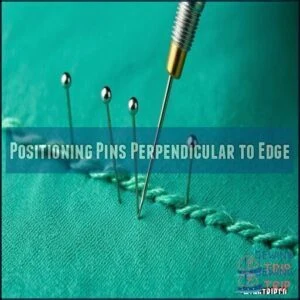

Positioning Pins Perpendicular to Edge

The correct pin placement makes all the difference when hemming stretch fabric.

Position pins perpendicular to the fabric edge, like tiny soldiers standing at attention.

This technique provides maximum hem security while preventing fabric from shifting during sewing.

For ideal edge alignment and sewing accuracy, space pins evenly about 2-3 inches apart.

This approach maintains consistent fabric tension throughout your hemming process, ensuring professional results when sewing knit hems.

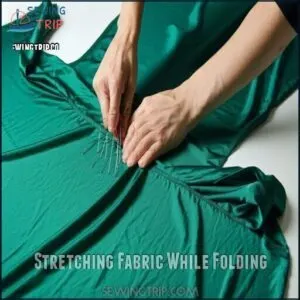

Stretching Fabric While Folding

While pinning, gently stretch the fabric as you fold the hem. This keeps the edge smooth and maintains elasticity, preventing puckering.

Proper stretch fabric sewing techniques are essential for achieving professional results. Think of it as balancing fabric tension for perfect hem alignment.

Stretch methods like this guarantee stretch fabric hems move naturally. Pair these fold techniques with sharp pins for edge control, and you’re mastering sewing stretchy fabric effortlessly, using the right stretch fabric sewing techniques.

Sewing Hem on Stretchy Fabric

You’ll need to sew with a gentle, steady hand to create professional-looking hems on stretchy fabric.

Thread your needle with matching thread and use small, even stitches while slightly stretching the fabric to maintain its elasticity during the hemming process, which requires a gentle approach.

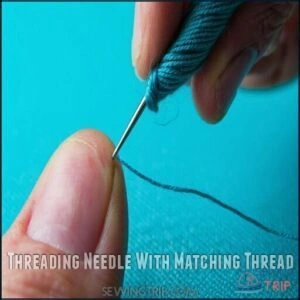

Threading Needle With Matching Thread

Now that your pins are in place, let’s talk about threading your needle.

Choose a polyester or nylon thread that matches your fabric exactly—these thread types maintain elasticity when stretched. Thread quality matters; opt for a strong, smooth thread to prevent breakage during sewing.

When threading, cut at a 45-degree angle for easier insertion, and keep your thread length manageable—about 18 inches works well for most stretch hem techniques.

Sewing Straight Stitch Along Folded Edge

With your thread secured, position your fabric under the presser foot exactly at the folded edge.

Set your stitch length to 2.5-3.0 mm for ideal seam security when working with stretch fabrics.

Apply light fabric tension as you guide the material through the machine, ensuring the straight stitch runs parallel to your fold, creating a clean edge finishing.

Unlike woven materials, stretch fabric sewing requires you to gently feed the fabric without pulling, which is crucial for a successful outcome with clean edge finishing.

Making Small Even Stitches

Consistent stitch size is key to successful stretch fabric sewing.

You’ll want to maintain small, even stitches of about 1/4 inch apart for superior stitch control and durability.

Proper thread tension prevents puckering, while the right needle selection guarantees smooth penetration.

Set your machine to a shorter stitch length (2-2.5mm) when creating a stretch stitch hem, which provides enough flexibility without compromising the twin needle hem’s structural integrity, and ensures superior stitch control.

Gently Stretching Knit Fabric While Sewing

The secret to perfect elastic seams lies in how you handle fabric tension while sewing.

When hemming knit fabric, apply these stretch control techniques:

- Pull the fabric slightly in front of and behind the needle

- Maintain even pressure throughout the seam

- Avoid overstretching, which causes waviness

- Release tension gradually as you finish each section

This careful manipulation prevents puckering while ensuring your stretch stitch hem remains flexible.

Understanding stretch fabric properties is essential for achieving professional-looking results, and it helps in handling fabric tension.

Troubleshooting Common Issues

You’ll encounter some frustrating moments when hemming stretchy fabrics, but don’t worry—they’re all fixable with the right techniques.

When your hem puckers, waves, or comes loose, these straightforward solutions will help you achieve that professional finish you’re looking for.

Fixing Uneven Hemlines With Catch Stitch

Rescuing an uneven hemline doesn’t have to mean starting over. The catch stitch is your secret weapon for fixing wobbly hems on stretchy fabrics.

This hand-sewing technique allows the fabric to maintain its natural stretch while creating a smooth finish.

| Catch Stitch Steps | Hem Repair Tips |

|---|---|

| Work from left to right | Keep stitches loose |

| Create small diagonal stitches | Maintain even spacing |

| Catch 1/8" of folded edge | Use matching thread |

| Space stitches 1/4" apart | Stretch fabric slightly while working |

Preventing Puckering With Ballpoint Needle

Struggling with puckered hems on your stretchy fabrics?

Using a ballpoint needle is essential for preventing this common issue. Unlike regular needles that pierce through fabric threads, a stretch or ballpoint needle gently pushes between the fibers of knit fabric.

Adjust your tension and stitch length according to fabric type, and confirm your thread choice complements the fabric’s elasticity.

This needle selection substantially reduces puckering while maintaining the garment’s stretchability.

Re-stitching Loose Hems

Loose hems on stretchy fabric can be frustrating, but they’re easy to fix.

First, remove any loose threads completely.

Then, reapply hem tape for stability before sewing with elastic thread. Use a zigzag stitch for flexibility, ensuring your fabric stretch is accommodated.

Stitch reinforcement is essential—sew slowly with even tension to prevent puckered fabric. Double-check your hem stability by gently stretching the fabric after stitching.

Using Fusible Webbing or Tape

When loose hems won’t stay put, fusible webbing or tape offers a quick solution.

These adhesive products create strong bonds between fabric layers without stitching.

For knit fabric hems, choose lightweight fusible hem tape specifically designed for stretchy fabric.

Simply insert the tape between folded layers, press with a warm iron, and the webbing melts to form a flexible bond that moves with your garment. The quality of fusible hem tape is essential for a successful and durable hem.

Finishing Touches and Alternative Methods

You’ll need to apply these final techniques to achieve a professional-looking hem that maintains its elasticity.

A walking foot, proper pressing, and clean edge trimming will transform your stretchy fabric project from homemade to polished.

Trimming Excess Fabric for Clean Edge

With your common hem issues under control, it’s time to focus on creating clean edges for your finished garment.

Trimming excess fabric is a precision step that can make or break your hem’s professional appearance.

Use sharp scissors or a rotary cutter to trim excess fabric from your stretchy knit fabric, maintaining a consistent 1/4 to 1/2 inch allowance. This precision cutting prevents bulkiness and guarantees your hem lies flat when worn.

Pressing Hem in Place With Iron

After completing your stretchy fabric hem, pressing it with an iron seals the deal for a professional finish.

Set your iron to the appropriate temperature for your fabric type to avoid shrinking.

Apply gentle steam pressing along the hemline, keeping the iron moving to prevent scorching.

This vital step locks your stitches in place when hemming knit fabrics and makes certain your garment looks store-bought rather than homemade, ensuring a professional look.

Using Walking Foot for Smooth Sewing

When dealing with stretchy fabrics that love to misbehave, a walking foot becomes your secret weapon for smooth sewing.

This specialized presser foot maintains tension control while guiding both fabric layers evenly through your machine. It prevents knit fabric from stretching or puckering, ensuring stitch regulation and sewing accuracy.

For even feeding of multiple layers, consider using a walking foot. For professional-looking hems, adjust your walking foot properly and pair it with a stretch needle.

Frequently Asked Questions (FAQs)

What is the best stitch to hem stretchy fabric?

The zigzag stitch is your best choice for hemming stretchy fabric. It flexes with the material while maintaining stability. For a more professional finish, try using a twin needle instead.

Can stretchy material be hemmed?

You can tame those elastic fabrics with the right approach. Stretchy materials can be hemmed using specialized stitches like zigzag or twin needle, proper stabilization techniques, and the right equipment.

How do you hem stretchy fabric without puckering?

You’ll need to use a ballpoint needle and stretch the fabric slightly while sewing.

Apply stabilizers like hem tape, use a walking foot, and select the zigzag stitch to prevent unwanted puckering on your hem.

What is the best sewing machine setting for stretchy fabric?

Want to tame your stretchy fabric?

Use a zigzag stitch with 5-5 width and 5-0 length.

Set medium pressure, use a ballpoint needle, and slightly loosen your tension for smooth, pucker-free results.

How to hem without a sewing machine?

Use a hand-sewing technique with a stretch stitch or blind hem stitch.

Pin your folded edge.

Then work with a ballpoint needle and stretchy thread, gently pulling the fabric as you stitch.

When to use coverstitch versus serger?

Sergers trim and finish seams in one step, making them perfect for construction.

You’ll want a coverstitch machine specifically for creating professional, stretchy hems with that double line of stitching on top.

Best hemming technique for swimwear fabric?

Like a well-executed dive, your swimwear hems require precision.

For best results, use a twin needle or zigzag stitch on folded edges with stretch needles. Pressing lightly before sewing to maintain elasticity.

How to maintain stretch in workout leggings?

You’ll maintain stretch in workout leggings by using a zigzag stitch, ballpoint needle, and stretchy polyester thread.

Fold gently while pinning, sew with minimal tension, and iron with low heat after finishing.

Can I use wonder tape on activewear?

Yes, wonder tape works well on activewear.

It’ll temporarily hold your hem in place without damaging the fabric’s stretch properties.

Remember to remove it after sewing to maintain the garment’s full elasticity, and note that wonder tape is the key to achieving this without causing damage.

Conclusion

Just as a sailor masters the unpredictable sea, you’ll conquer the challenge of sewing hems on stretchy fabric with these techniques.

Whether you choose zigzag stitches, twin needles, or stabilizing tape, your persistence will pay off.

Remember to test your settings, gently stretch while sewing, and press carefully for professional results.

With practice, those once-frustrating knits will become your favorite materials to work with. Your perfectly hemmed stretchy garments will soon be turning heads.