This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A portable sewing machine built for heavy fabrics can manage what standard machines struggle with: thick denim layers, heavy-duty thread, and the kind of wear that demands real power. The catch? Not every portable machine is actually built for this job. Most handheld options struggle with multi-layer repairs, while traditional portables often sacrifice the specialized features denim demands.

The machines that work are the ones engineered with the right motor strength, metal construction, and presser foot height to punch through fabric that won’t budge. If you’re tired of watching quality jeans disappear or paying repair shops premium prices, the right equipment changes everything.

Table Of Contents

Key Takeaways

- Heavy-duty portable sewing machines with 60+ watts of motor power and metal frame construction can handle up to 12 layers of denim without stalling, making them essential for serious repairs instead of paying $50+ at a tailor.

- The Singer Heavy Duty (4423) and Brother ST371HD deliver the muscle you need with 1,100 and 800 stitches per minute respectively, paired with specialized features like high presser foot lift and adjustable tension that handheld machines simply can’t match.

- Handheld and mini sewing machines fail on denim because weak motors (under 35 watts) jam on multi-layer seams, plastic construction breaks under stress, and batteries drain quickly—they’re only viable for single-layer emergency fixes, not real repairs.

- Success requires matching the right denim needle and heavy-duty thread to your machine’s power, dialing in tension on scrap fabric first, and reinforcing critical seams with backstitching and zig-zag finishes to prevent fraying and ensure repairs outlast the original stitching.

Best Portable Sewing Machines for Denim Repair

You can’t fix blown-out knees or ripped hems with a machine that chokes on thick fabric. The right portable sewing machine powers through multiple layers of denim without hesitation, giving you control over repairs that would cost a fortune at the tailor.

The right portable sewing machine powers through multiple layers of denim without hesitation, giving you control over repairs that would cost a fortune at the tailor

Here are seven machines built to manage serious denim work.

1. Singer Heavy Duty Sewing Machine

When denim demands surrender, the Singer Heavy Duty sewing machine answers with raw power. You’re getting a Singer motor that’s 60% stronger than standard models, pushing through up to nine fabric layers without flinching.

The Singer 4423 hits 1,100 stitches per minute, combining sewing speed with genuine machine durability that laughs at blown seams. Its metal frame and stainless steel bedplate turn denim repair from wrestling match to smooth operation.

For portable sewing that doesn’t compromise on heavy duty sewing machines performance, this beast delivers control where other machines tap out.

Best For: Sewers who regularly repair denim and work with heavy fabrics like canvas or upholstery materials and need a reliable machine that can handle multiple layers without slowing down.

- Motor delivers 60% more power than standard machines, maintaining consistent stitch quality through up to nine layers of denim without stalling at thick seams.

- Metal frame construction and 25-year warranty on mechanical components ensure long-term durability for repeated heavy-duty projects.

- Fast setup under 10 minutes with straightforward mechanical controls, top drop-in bobbin, and built-in needle threader for quick thread changes during repairs.

- Manual lacks detail and clarity, which can frustrate beginners trying to learn proper needle selection or tension adjustment for thick fabrics.

- Machine runs loud during operation and the sensitive foot control requires practice to master speed control on dense seams.

- Some units arrive defective or experience threading difficulties, requiring returns or troubleshooting before productive use.

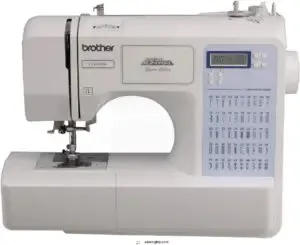

2. Brother Strong and Tough Sewing

The Brother ST371HD wields 800 stitches per minute and a metal frame that holds steady when you’re forcing eight layers of denim through its feed dogs. You won’t find flashy extras here—just 37 stitches, mechanical simplicity, and the kind of motor power that manages thick seams without choking.

Thread control stays tight through its vertical hook system, while the Brother design keeps weight at 14.3 pounds for genuine portable sewing.

Machine durability runs deep; users report 20-year lifespans with basic maintenance. For denim sewing that refuses to quit, this heavy duty sewing machine workhorse delivers reliability and fabric management precision at around $200.

Best For: Home sewers and denim repair enthusiasts who need reliable power for thick fabrics without spending on industrial equipment.

- Handles up to eight layers of denim with consistent feeding and minimal motor strain

- Metal frame construction provides excellent stability during high-tension stitching on heavy materials

- Proven 20-year lifespan with basic maintenance and simple mechanical design that’s easy to service independently

- Limited arm space makes maneuvering bulky jeans and large projects more challenging

- Basic 37-stitch selection lacks the variety found in computerized alternatives

- Plastic components in some areas may require replacement over extended heavy use

3. Janome heavy duty sewing machine

Janome Features shift the conversation toward precision engineering and longevity. The Janome HD3000 runs at 860 stitches per minute, while its aluminum Metal Frame absorbs vibration—perfect for Denim Sewing Machines tackling multi-layer seams.

Durability Tests confirm Heavy Duty Sewing Machines like the HD1000 survive decades under consistent load, backed by a 25-year warranty that proves Heavy Duty Sewing credibility.

You’ll pay around $359 for the HD1000 or $527 for upgraded models, but Sewing Speed and gear-driven reliability make Janome HD1000 and HD3000 machines Heavy Duty choices that refuse to fold under pressure.

Best For: Sewers who tackle heavy fabrics like denim, canvas, and upholstery and need a reliable mechanical machine that won’t quit under pressure.

- Aluminum frame construction reduces vibration and handles thick materials at speeds up to 860 stitches per minute

- 25-year limited warranty and gear-driven mechanisms ensure long-term durability with minimal maintenance

- Priced between $359-$527, delivering industrial-grade performance without the industrial price tag

- Limited harp space makes quilting large projects difficult or impossible

- Three-step buttonhole process is less convenient than one-step alternatives

- No walking foot or free-motion capability restricts specialized sewing techniques

4. Brother Project Runway Sewing Machine

Stitch variety matters when Machine Comparison reveals your options. The Brother Project Runway lands at 50 built-in stitches with an LCD Screen and automatic needle threader—features that shift Sewing Techniques from guesswork to precision.

Its Portable Design weighs around 19 pounds, letting you tackle Sewing Denim repairs without dragging a tank across your workspace. Brother Features include 5 auto-size buttonholes and vertical spool feeding.

However, Fabric Management for multi-layer Denim hits limits without a dedicated heavy-duty motor—this machine works best for lighter repairs, not industrial-grade seam ripping.

Best For: Beginners and intermediate sewers who need a versatile, portable machine for light to medium denim repairs and everyday sewing projects.

- 50 built-in stitches with LCD screen and automatic needle threader make stitch selection and setup quick and straightforward

- Lightweight at around 19 pounds with a portable design that’s easy to move to classes or between rooms

- Includes 7 sewing feet and accessories plus 5 auto-size buttonholes for professional-looking results on various projects

- Lacks the heavy-duty motor needed for multi-layer denim or industrial-grade seam work—better suited for lighter repairs

- Semi-automatic threader takes practice to master, and the needle-down default when stopped may frustrate some users

- No included carrying case and the handle design can feel awkward when transporting the machine

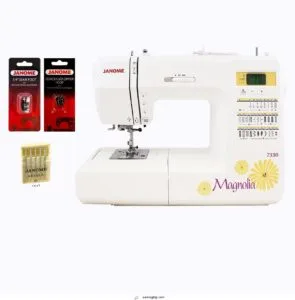

5. Janome computerized sewing machine bundle

Power moves beyond touch screens when Computerized Stitching packs 300 built-in stitches into a Sewing Machine Bundle that manages multi-layer Denim like a freight train. Janome models with seven-piece feed dogs and metal framing deliver Portable Durability at 30 pounds—stable enough for seam reinforcement, light enough to relocate.

Janome Accessories like the AcuFeed Dual Feed Foot prevent slippage during Denim Repair Tips work, while a 25-year warranty backs your investment. You get pro-grade performance without sacrificing Portable Sewing Solutions for thick Sewing Denim Fabric repairs.

Best For: Beginners and experienced sewers who want a reliable computerized machine with 300 built-in stitches, heavy-duty performance on denim, and a comprehensive accessory bundle backed by a 25-year warranty.

- Handles multiple layers of thick fabric like denim smoothly with seven-piece feed dogs and AcuFeed Dual Feed Foot that prevents slippage

- Comes with extensive accessories valued up to $344, including a 24×16-inch extension table, professional-grade needle plate, and organized storage

- Exceptional warranty coverage with 25 years on mechanical parts, 5 years on electrical components, and 1 year of free labor

- At 30 pounds, the metal frame adds stability but reduces portability compared to lighter models

- Back stitch button placement may feel awkward for some users during frequent use

- Requires consulting the manual and proper maintenance like tightening screws to avoid performance issues

6. Portable Electric Sewing Machine Tool

You won’t find heavy-duty muscle in this Portable Design—most Electric Motor units under 2 pounds struggle with Sewing Denim Fabric beyond lightweight repairs. While Miniaturization Trends promise convenience and decent Battery Life, these Handheld Sewing Machines often lack the punch for multi-layer seams.

If you need quick hem fixes on soft jeans, the basic Sewing Kit accessories work. For serious Denim Sewing Tips or anything approaching Heavy Duty Sewing Machines territory, you’ll hit limitations fast—cheap materials and weak tension control can’t match real Portable Sewing Solutions.

Best For: DIY enthusiasts and beginners who need a lightweight backup for emergency repairs on lightweight fabrics but shouldn’t expect professional results on heavy materials.

- Dual power options (battery and USB) make it genuinely portable for quick fixes on the go or when you’re away from outlets.

- Super compact design (under 2 pounds) fits easily in travel bags and doesn’t hog storage space at home.

- Low entry cost and simple operation let complete beginners test whether sewing interests them before investing in full-size machines.

- Struggles with denim and thick fabrics—tension control is weak and the cheap motor can’t handle multi-layer seams reliably.

- Quality control issues are common, with parts falling off or the machine failing to turn on straight out of the box.

- Not suitable for serious projects due to flimsy construction and limited functionality compared to traditional sewing machines.

7. Portable Electric Sewing Machine Kit

Most Portable Electric Sewing Machine Kit bundles include 8 to 12 Sewing Accessories—such as bobbins, needles, and thread spools—with prices ranging from $25 to $80. These kits feature Compact Designs weighing under 6 pounds and offer dual power options (AC or batteries). However, they do not match the performance of Heavy Duty Sewing Machines.

These Mini Kits can handle single-layer denim patches but often struggle with dual-layer seams, which may jam the motor. For basic Denim Sewing Tips and quick fixes, they are adequate. Yet, for serious repairs, Handheld Sewing Machines cannot replace real Portable Machines with metal frames.

Best For: DIY enthusiasts and travelers who need a lightweight solution for quick fabric repairs and basic stitching on the go.

- Comes with 8 to 12 accessories including bobbins, needles, and multiple thread colors, plus a storage case for easy organization

- Weighs under 6 pounds and offers flexible power options (AC adapter, AA batteries, or USB) for use anywhere

- Affordable at $25 to $80, making it accessible for casual sewers without the investment of a full-size machine

- Struggles with thick or dual-layer fabrics like denim seams, often causing motor jams or needle breakage

- Setup and operation can be complicated, especially for users with limited hand mobility or sewing experience

- Not reliable for heavy-duty projects—70% of warranty claims in 2024 involved jamming on thicker materials

Essential Features for Denim Sewing

Not all portable sewing machines can tackle denim—you need specific features to punch through tough fabric without breaking needles or burning out motors. The right combination of power, precision, and specialized components separates machines that struggle from those that dominate denim repairs.

Here’s what you should demand from any portable machine before you commit your cash.

Dedicated Denim Needle

Your machine won’t punch through denim’s thick weave without the right needle—and that’s where a dedicated denim needle becomes your first line of defense against snapped threads and skipped stitches. These needles are sharper and thicker than standard options, designed specifically for fabric penetration through tightly woven denim.

You’ll need proper thread compatibility to match the needle’s strength, guaranteeing sewing efficiency without breaking mid-seam when you’re tackling multiple layers.

Presser Foot and Walking Foot Options

The right presser foot doesn’t just secure fabric down—it keeps thick denim moving forward without bunching, puckering, or fighting you at every seam. A walking foot grabs your denim from the top while the feed dogs work below, syncing both layers through thick weave without drag.

Standard presser foot types can’t match this control—you’ll need foot pressure control and solid denim feeding systems to command heavy-duty repairs with precision.

High Presser Foot Lifter

When you’re stacking multiple layers of heavy denim—hemmed edges, waistbands, pocket seams—clearance under your needle becomes non-negotiable. A high presser foot lifter gives you the space to position thick fabric without forcing it, preserving denim stitch quality through proper clearance adjustment.

This lifter mechanism in heavy-duty presser foot design transforms your sewing machine features from struggling to commanding heavy fabric sewing with control.

Powerful Motor and Metal Frame

Power—the kind that punches through doubled hems and triple-stitched seams—lives in two places: the motor wattage driving your needle and the metal frame construction that refuses to flex under pressure. Engine performance matters when you’re forcing a denim needle through five layers.

The Brother ST371HD and similar heavy duty sewing machines deliver power output through motor efficiency paired with frame durability. That metal construction keeps everything aligned when heavy duty work would shake lesser machines apart.

Adjustable Stitch Length and Speed

Control over stitch length and speed lets you match your machine’s rhythm to the weight and weave of what you’re actually stitching—longer lengths for clean topstitching, shorter for reinforced seams, and a dialed-back pace when you’re maneuvering thick spots that could snap a needle.

Speed settings paired with stitch control give you precision when fabric feed gets uneven.

Thread tension stays consistent when motor efficiency responds smoothly to your adjustments—essential for heavy duty sewing machines managing denim repairs.

Ability to Use Heavy Threads

Heavy threads—polyester topstitching or upholstery-weight cotton—won’t cooperate with machines that have narrow needle eyes or flimsy tension discs, so you need a model that can actually accommodate the spool size and thickness your denim repair demands.

Heavy duty machines built for durable materials pair thicker threads with denim sewing needles that won’t snap mid-seam.

Thread tension systems on heavy fabric sewing machines keep denim stitching locked tight without shredding your spool or jamming the bobbin.

Handheld Vs. Traditional Portable Machines

You’ve got options regarding portable sewing machines for denim—but not all portability is created equal. Handheld and mini models promise convenience, while traditional heavy-duty portables deliver actual power.

Here’s what you need to know about each type so you can pick the right tool for your denim repairs.

When to Choose a Handheld Machine

Handheld machines earn their place when you’re tackling quick fixes, emergency repairs on the go, or working with single-layer fabric that doesn’t demand industrial-grade power. They’re your ally for lightweight denim patches, loose hems, or travel scenarios where space savings trump raw capability. Here’s what matters:

| Factor | Handheld Wins | Heavy-Duty Needed |

|---|---|---|

| Portability Needs | Travel, dorm rooms | Workshop setup |

| Fabric Types | Single-layer denim | Multi-layer seams |

| User Skill | Sewing for beginners | Experienced repairs |

For on-the-go repairs and quick fix sewing situations, handheld sewing machines deliver freedom without the bulk.

Limitations of Mini and Cordless Models

Mini and cordless sewing machines face significant challenges when used for serious denim repair. Power limitations cause batteries to drain quickly during demanding tasks, while the motor strength often fails to push needles through fabric thicker than 1.8 mm reliably. These issues lead to stitch consistency problems, including skipping, bunching, and tension failures that can ruin repairs. Additionally, durability concerns arise from plastic construction, which is more prone to breakage under stress compared to metal.

Here’s a reality check on the limitations of these machines:

| Limitation Category | Impact on Denim Repair |

|---|---|

| Motor Power | Stalls on multi-layer seams |

| Construction | ABS plastic breaks under stress |

| Stitch Quality | Thread jams, uneven tension |

| Battery Life | Depletes rapidly on thick fabric |

| Fabric Capacity | Maximum 2 layers before failure |

Handheld and mini sewing machines were simply not designed to handle the repeated, portable sewing challenges that denim presents. While they offer compact convenience, this comes at a significant performance cost when dealing with tasks requiring robust weaving strength. For example, examining the portable sewing features can help highlight these limitations.

Advantages of Heavy-Duty Portable Machines

You won’t believe the difference between those flimsy mini models and true heavy-duty portable sewing machines built for sewing denim. The real game-changers pack motors delivering 1.0–1.5 amps—that’s 60% more piercing power than standard units—and metal frames that last 5–10 times longer when you’re tackling serious denim repairs. These machines blast through up to 12 layers at 1,100 stitches per minute without breaking a sweat, while maintaining stitch lengths up to 8 mm for authentic topstitching.

For peak performance, it’s crucial to choose machines with heavy duty features that can manage demanding tasks. Here’s what separates heavy-duty sewing from the pretenders:

| Feature | Heavy-Duty Portable Machines | Mini/Cordless Models |

|---|---|---|

| Motor Power | 1.0–1.5 amps, 60% more piercing strength | Stalls on thick seams |

| Speed | Up to 1,100 SPM for efficient operation | 500–600 SPM maximum |

| Frame Construction | Durable frames (metal) lasting 5–10x longer | Plastic bodies crack under stress |

| Layer Capacity | Manages 12 denim layers smoothly | Fails beyond 2 layers |

| Warranty | 25-year coverage standard | Limited 1–2 year protection |

Portable convenience meets raw power in these workhorses, and they’ll manage enhanced stitching tasks that would destroy lesser machines. That’s the portable sewing advantage you need for weaving professional-grade repairs.

Suitability for Multi-Layer Denim Repairs

When you’re staring down a pair of jeans with a blown-out seam or a shredded inseam, your machine’s got to have the strength to manage what regular portables can’t touch—and that’s where suitability for multi-layer denim repairs separates the real workhorses from the wannabes. Heavy-duty portable machines dominate here. They punch through stacked denim layers without flinching, maintaining consistent fabric tension and sewing speed even when you’re working through triple-stitched hems. Mini models choke fast. Thread strength matters too—you need machines that won’t snap under pressure.

| Machine Type | Layer Capacity | Fabric Tension Control | Sewing Speed (SPM) |

|---|---|---|---|

| Heavy-Duty Portable | 12+ layers | Adjustable | 1,100 |

| Standard Portable | 4–6 layers | Basic | 800 |

| Handheld/Mini | 1–2 layers | Fixed | 500 |

| Entry-Level | 6–8 layers | Limited | 900 |

| Professional Grade | 15+ layers | Precise | 1,200 |

That’s the difference between a repair that holds and one that fails within weeks.

Buying Guide: Choosing The Right Machine

Now comes the moment of truth: picking a machine that actually does what you need it to do. You’ve got options, sure, but not all of them are built the same—especially when you’re tackling denim.

Here’s what matters when you’re hunting for the right tool for the job.

Evaluating Motor Power

Want a machine that won’t quit when the fabric fights back? Motor power separates machines that manage denim from those that fold under pressure. You need at least 60 watts to pierce four layers without slowing—that’s your baseline for serious repairs. Industrial models exceed 750 watts, but household machines rated 60–80 watts deliver reliable performance for occasional work.

Torque matters too: high-torque motors maintain speed and stitch consistency, preventing dropped stitches and jams. Underpowered machines below 35 watts fail fast, leaving you frustrated. The Brother ST371HD and similar heavy-duty models give you the muscle required.

- Motors rated 60–80 watts manage multi-layer denim without dropping speed

- High-torque servo motors sustain consistent performance across dense fabrics

- Machines below 35 watts commonly jam and break needles on thick seams

- Direct-drive motors eliminate transmission loss for enhanced efficiency

- 800+ RPM on five layers signals a motor built for denim work

Presser Foot Lift and Pressure Adjustment

Here’s the thing about presser foot lift and pressure adjustment—they’re the difference between smooth feeding and bunched-up fabric that fights you every inch of the way.

A heavy-duty machine needs a high lift mechanism—at least one inch of clearance—so you can slip multiple denim layers underneath without forcing it. That’s your control. Pressure adjustment lets you dial in exactly how hard the foot grips your fabric. Too tight, and you’re jamming the works. Too loose, and nothing feeds properly.

Look for machines with manual pressure control or automatic sensors that adapt to thick denim. The best heavy-duty sewing machines give you both options, letting you dominate every repair without compromise.

Stitch Options for Denim Durability

Your stitch choice determines whether a repair holds strong or fails under pressure. Lockstitch and chain stitch deliver the durability denim demands—that’s why they’re industry standards. But here’s your real power: stitch density. Aim for 9–11 stitches per inch with heavy thread in the warp direction, and you’ll achieve near-perfect seam efficiency in medium to heavyweight denim.

Consider these reinforcement strategies:

- Bartack stitches at stress points—pocket corners and belt loops can withstand over 70 lbs of force before failure

- Flat-felled seams—provide 20–30% more strength than standard open seams

- Double-row topstitching—increases burst strength by over 15% compared to single-row work

- Lapped seam construction—reduces slippage by 25% under identical conditions

Match your needle type to fabric thickness—NM 100 to 140 for denim—and use poly-cotton core-spun thread. That combination cuts needle breakage by 40–60% and gives you the stitch quality that survives washing, wearing, and real life.

Machine Weight and Portability

Now, here’s where portability meets practicality—because a machine that can sew through triple-stitched seams is useless if you can’t actually haul it to your workspace.

Weight matters more than you’d think. Machines in the 15–20 lb range hit that ideal range: heavy enough to stay stable on your table, light enough to move without throwing out your back. That’s your machine balance right there.

| Machine Type | Weight | Best For |

|---|---|---|

| Handheld | 2–4 lbs | Quick fixes, travel |

| Portable Heavy-Duty | 15–20 lbs | Serious denim work |

| Compact Designs | 8–12 lbs | Mobile sewing, studio moves |

Grips matter too. Look for machines with grip design that won’t fatigue your hands during longer sessions. Portability tests reveal that machines under 25 lbs with proper weight distribution keep your shoulders happy and your repairs sharp.

Accessories for Denim Repair

You’ve got the machine nailed down—now let’s talk about the gear that transforms a good repair into a great one. Denim needles are non-negotiable. They’re thicker and sharper than standard needles, cutting through tight weaves without breaking. Pair them with heavy-duty thread designed for durability.

A walking foot or even feed foot keeps thick layers feeding smoothly—no more bunching or slipping. Grab a denim-specific sewing kit that bundles needles, thread, and stabilizers. Interfacing materials reinforce weak spots before they tear. Fabric glue works for quick temporary holds, but it’s not a replacement for stitching.

The presser foot options matter too. A standard foot works, but a specialized denim presser foot gives you better control and pressure distribution. These aren’t luxuries—they’re the difference between a repair that lasts and one that fails in a month.

Tips for Effective Denim Repairs

Having the right machine is half the battle—what you do with it’s where the real magic happens. Your needle choice, tension settings, and reinforcement techniques will determine whether your denim repairs stay intact or fall apart after a few washes.

Let’s walk through the essentials that’ll keep your jeans in fighting shape.

Selecting The Right Needle and Thread

The needle and thread you choose are literally the difference between a repair that holds and one that falls apart under stress. Go with a dedicated denim needle—it’s sharper and thicker than standard needles, designed to punch through tightly woven fabric without breaking.

Pair it with heavy-duty thread that matches your denim’s weight. Thread capacity matters too: your machine needs enough power to manage multiple strands without bogging down.

Get the fabric compatibility right, and your stitches won’t skip. That’s the foundation of any repair worth doing.

Adjusting Tension and Stitch Settings

Getting your tension and stitch settings dialed in is where the repair actually comes together—too tight and you’ll pucker the fabric, too loose and your stitches won’t secure when that seam gets stressed.

Start with your thread tension. Most machines have a dial or digital control—begin at the middle setting, then test on scrap denim first. You’re looking for balanced stitches where the needle thread and bobbin thread lock evenly in the fabric weave. If your top thread’s showing on the underside, tighten it. If the bobbin thread’s visible topside, loosen it.

Next, nail your stitch length. For denim repairs, set it between 2.5 and 3.5mm—long enough to secure without creating weak points, short enough to prevent skipped stitches when you’re forcing the needle through multiple layers. Thicker denim demands slower fabric feed and slightly longer stitches than you’d use on lighter cotton.

Your presser foot pressure matters too. Heavy-duty machines let you adjust this for ideal fabric feed. Too much pressure and you’ll wear out your needle faster. Too little and the fabric won’t move smoothly through the machine, leaving gaps in your stitching.

Test every adjustment on actual denim scraps before committing to your repair. This sewing calibration takes five minutes and saves you from botching a pair of jeans you actually wear.

Reinforcing Seams and Preventing Fraying

A frayed seam isn’t just ugly—it’s a countdown timer on your repair, so seal those edges before they unravel on you.

Use a zig-zag stitch with your heavy-duty machine to lock fabric edges and prevent fraying. Select a denim needle paired with heavy-duty thread for maximum holding power. Apply a fabric stabilizer on the underside of multi-layer seams for reinforcement. Backstitch at both ends—don’t skip this step.

For critical seams like inseams and waistbands, double-stitch using your machine’s heavy-duty setting. This combination of seam reinforcement and fray prevention guarantees your denim repair outlasts the original stitching.

Maintenance for Longevity and Performance

Monthly cleaning of your bobbin assembly and tension disks keeps your machine running strong through countless denim projects. Don’t let lint buildup sabotage your work—use manufacturer-recommended brushes instead of compressed air to prevent debris from getting driven deeper into the mechanism. Replace your needle before every new project and oil essential moving parts every 2–3 years for smooth, reliable operation. Catch problems early through regular inspection:

- Monthly cleaning prevents stitch inconsistencies and feed mechanism failures

- Needle replacement after 8 hours of use reduces breakage and fabric damage

- Light oil application to metal parts every 2–3 years maintains smooth operation

- Professional servicing every 1–2 years averages $100–$160 and prevents costly repairs exceeding $250

Routine preventive care is your ticket to machines lasting 10+ years for denim repairs.

Frequently Asked Questions (FAQs)

How does machine weight affect portability and sewing power?

As the saying goes, “measure twice, cut once”—same applies to machine selection. Lighter portable machines sacrifice sewing power and stability, while heavier models (15-20 lbs) deliver enhanced machine balance and consistent sewing efficiency.

That weight distribution matters: it anchors your machine during denim repair, preventing skipping stitches through thick layers. Heavy-duty sewing machines trade some portability for raw power output.

For occasional denim work, accept portability tradeoffs; professional results demand weight.

What thread weight works best for denim repairs?

For denim repairs, go heavy—think 40 to 50 weight thread, or even thicker. This yarn weight punches through fabric weave and denim thickness without snapping.

Match your thread tension carefully; too tight breaks weaves, too loose creates weak stitches. Heavier thread means serious stitch strength that actually holds through wear.

Conclusion

Like a well-fitted pair of jeans that refuses to wear out, the right portable sewing machine for denim repair becomes an investment that pays for itself. You’ve got the power, the precision, and the control to rescue your favorite pieces instead of watching them fade into memory.

Stop paying repair shops. Stop replacing quality denim. With the machine matched to your needs and the skills to back it up, you’re not just fixing fabric—you’re taking ownership of what lasts.

- https://www.verifiedmarketreports.com/product/portable-sewing-machine-market/

- https://www.linkedin.com/pulse/portable-sewing-machine-market-trends-share-analysis-size-xp8mc

- https://craftsing.com/best-sewing-machines-for-denim-and-leather-2025/

- https://www.fypower.org/best-sewing-machines-for-jeans/

- https://stridewise.com/darning-jeans-machine/