This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

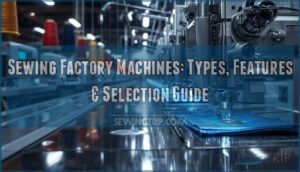

You’ve seen the shift happening across factory floors—apparel that used to take skilled hands hours to complete now rolls off automated lines in minutes. Automatic sewing systems have moved beyond simple electronic stitching into territory that would’ve seemed like science fiction a decade ago.

Machines now thread themselves, adjust tension on the fly, and use computer vision to track fabric as it moves. Some can sew entire garments with minimal human oversight.

The technology isn’t just faster—it’s reshaping who can compete in textile manufacturing, where production happens, and what skills matter in the industry. Whether you’re running a small tailoring shop or managing a production facility, understanding these systems means understanding where the sewing world is headed.

Table Of Contents

- What Are Automatic Sewing Systems?

- Types of Automatic Sewing Machines

- How Automatic Sewing Systems Work

- Key Features of Automatic Sewing Systems

- Benefits of Sewing Automation

- Use Cases for Automated Sewing

- Top 9 Automatic Sewing Machines Compared

- 1. Brother XM2701 Lightweight Sewing Machine

- 2. Mini Sewing Machine for Beginners

- 3. Singer Tradition Sewing Machine with Threader

- 4. Mini Portable Sewing Machine Beginner Friendly

- 5. Brother XR3774 Sewing and Quilting Machine

- 6. Janome MOD-19 Easy Sewing Machine

- 7. Brother Computerized Sewing and Quilting Machine

- 8. Brother GX37 Sewing Machine Value Bundle

- 9. Brother SE700 Sewing Embroidery Machine

- Choosing The Right Automatic Sewing System

- Integrating Automation Into Your Workflow

- Future Trends in Sewing Automation

- Frequently Asked Questions (FAQs)

- Conclusion

What Are Automatic Sewing Systems?

Automatic sewing systems use sophisticated technology to handle tasks that once required constant manual control, from threading needles to adjusting tension on the fly. These machines range from simple electronic models with pre-set stitches to full robotic systems that can sew entire garments with minimal human input.

To understand how they work and what sets them apart, you’ll need to look at their core components, how they differ from manual machines, and the various levels of automation available.

Definition and Core Components

You’ll find automatic sewing machines combine computer-controlled software, servo-driven mechanics, and automated fabric handling to perform stitching with minimal intervention. These systems integrate mechanical subsystems—needle bars, hooks, and feed dogs—with electronic controls that manage speed and position.

Sensing technologies like thread-break sensors and machine vision track fabric movement, while material handling modules use conveyors and clamps to stabilize your workpiece throughout the sewing automation process. These systems often use cyber-physical systems for smart automation.

Key Differences From Manual Machines

Manual sewing machines rely on foot control and hand-guided feeding, usually delivering 600–1,100 stitches per minute. In contrast, automatic sewing machines use programmable parameters and servo motors to exceed 5,000 stitches per minute in industrial settings.

You’ll notice automatic systems eliminate multi-step manual interventions—like four-step buttonholes—replacing them with one-step cycles that cut setup time and reduce operator-dependent variation across every run. These machines offer automated precision with a wide range of stitches.

Automation Levels in Sewing

Automation technology in sewing operates across three distinct levels. Manual machines demand high operator skill for positioning and speed control.

Semi-automation benefits include consistent feeding and reduced variability through servo-driven assists.

Full automation delivers up to 5,000 stitches per minute with robotic arms handling fabric and quality checks—a technological stage that’s driving industry adoption as automated sewing grows at 6.89% annually through 2030.

Types of Automatic Sewing Machines

Not all automatic sewing machines work the same way. Some rely on basic mechanical parts, while others use computerized systems or even robotic arms to handle fabrics.

Let’s look at the main types you’ll encounter and what sets them apart.

Mechanical Vs Electronic Vs Computerized

When you’re choosing among types of sewing machines, you’ll encounter three main categories. Mechanical sewing machines offer 10 to 30 stitches with manual dials—simple, durable, and budget-friendly. Electronic models add semi-automatic features and improved speed control mechanisms.

Computerized sewing machines deliver 50 to 500+ built-in stitches, programmable memory, LCD user interfaces, and automatic tension—boosting consistency and productivity but raising upfront cost comparison considerations.

Overlocking and Serger Machines

Overlock machines specialize in finishing seams, preventing fraying, and joining fabric edges in one pass—making them essential for knit garments and high-speed production. Industrial four-thread sergers reach 7,000 stitches per minute, while five-thread models offer chainstitch strength plus overedge coverage. When evaluating serger machine speed and performance characteristics, also review safety guarding practices around belts and needle areas.

- Overlock stitch types include three-thread (504), four-thread mock safety (512), and five-thread full safety (516) per ISO 4915.

- Market size for serger machines hit $2.1 billion in 2024, forecast to reach $3.4 billion by 2033.

- Differential feed (0.7–2.0 ratio) controls stretch and pucker on knits.

- Stitch length adjusts from 0.6 mm to 3.8 mm for varied fabric weights.

Robotic and Sewbot Systems

Full robotic sewing systems combine mechanical arms with computer vision to handle limp fabrics and complete garments in seconds—Sewbot lines finish T‑shirts in 22 seconds versus three minutes manually.

Robotic precision with AI integration facilitates automated reshoring by cutting labor costs up to 60 percent.

Fabric manipulation techniques like water‑soluble stiffeners let sewing robots grip textiles as easily as rigid parts.

How Automatic Sewing Systems Work

Automatic sewing systems rely on a combination of smart sensors, control software, and mechanical precision to handle fabric and stitching with minimal human input. These machines use sophisticated vision systems to detect fabric edges and guide stitches, while their control units translate digital patterns into precise needle movements.

Understanding how these components work together helps you see why automated systems deliver consistent results at speeds manual machines can’t match.

Sensors and Machine Vision

Think of vision systems as your machine’s eyes—they guide every stitch with precision you can’t achieve manually. Modern camera setups capture fabric seams at 68-micrometer resolution, feeding data to motion control stages accurate within 10 micrometers.

Deep learning models inspect each stitch in 0.062 seconds, catching defects instantly. Sensor feedback and machine vision systems turn raw images into ideal seam detection, transforming how you handle quality control.

Control Systems and Pattern Recognition

Your control system runs on a hierarchical structure—a supervisory layer coordinates tasks while lower loops execute real-time stitching. Pattern trajectory generation translates digital seam drawings into motion commands.

AI recognition models inspect defects at 84.6% precision, enabling quality monitoring mid-production. Feedback strategies like model predictive control adjust tension and speed dynamically, outperforming basic PID.

Vision systems and CNC-like precision make today’s AI sewing machine adaptable across fabrics.

Integration With Fabric Handling

You won’t hit seam targets if fabric arrives misaligned. Conveyorized feeding delivers pieces to the needle plate with sub-1 mm repeatability, while vacuum hold-down grips plies without slip. Edge alignment sensors correct drift before stitching begins, and robotic placement lifts the presser foot to position seams precisely.

Fabric handling systems and material handling integration cut cycle time 72%, driving quality outcomes across automated production systems.

Key Features of Automatic Sewing Systems

When you’re shopping for an automatic sewing system, you’ll notice a handful of features that show up again and again across different models. These aren’t just bells and whistles—they’re the tools that actually make your work faster and more consistent.

Let’s walk through the four key features you should keep an eye on.

Automatic Threading and Tension Control

You’ll find that automatic needle threading saves valuable setup time on modern automatic sewing machines. These self-threading sewing machine features use lever-actuated hooks to pass thread through the needle eye in one motion.

Automatic tension adjustment monitors fabric thickness and stitch patterns to maintain balanced stitches without manual retuning.

Together, these threading mechanisms and tension principles boost stitch quality, reliability impacts, and productivity impacts across your projects.

Built-in Stitch Patterns and Fonts

Your automatic sewing machine stores dozens to hundreds of built-in stitches—entry-level models offer 50 to 100 stitch options, while premium units pack 600 or more. Stitch pattern variety ranges from straight and zigzag to decorative stitches like scallops and florals.

Many machines include font customization options for monogramming, with 6 to 10 embroidery fonts built in. Speed-stitch coordination ensures decorative stitch applications stay precise even at high throughput.

LCD Displays and User Interfaces

Modern automatic sewing machines feature LCD screens or color touchscreens that make managing hundreds of stitches simple. You’ll see larger displays—often 3 inches or more—on mid-range and premium models, with backlighting for display readability under any workshop light.

Touchscreen navigation lets you scale embroidery designs, adjust tension, and receive clear error messaging on-screen. These straightforward interfaces lower the learning curve, boosting ease of use and interface usability while supporting AI integration for smart pattern suggestions.

Presser Feet and Attachments

As you navigate LCD screens, your choice of presser feet and attachments can make or break efficiency. Foot Functionality shapes every seam, from zippers to quilting. Pressure Control adjusts to fabric thickness, boosting stitch quality. Smart Integration means sensor-driven adjustments. Commercial Trends show bundled kits are popular, reflecting strong Market Adoption for adaptable accessories in automatic sewing machines.

- Zipper and buttonhole feet

- Walking and quilting feet

- Overcast and embroidery attachments

- Bundled multifunction kits

Benefits of Sewing Automation

Switching to automated sewing brings clear advantages for your workflow and results. You’ll notice improvements that go beyond just saving time.

Here’s what you can expect from sewing automation.

Increased Productivity and Speed

Ever wondered how much faster your production line could run? With Automated Sewing, Cycle Time drops from minutes to seconds—think 117 to 8 seconds per piece. Labor Savings soar, Uptime Impact rises, and Feature Speeds mean more units per shift. Scalability Gains let you handle rush orders with ease. Here’s how it feels:

| Cycle Time | Labor Savings | Uptime Impact |

|---|---|---|

| 8 sec/piece | 93% reduced | 71% higher |

| 33 sec | 1 handler:17 | Fewer stops |

| 72% faster | Less fatigue | Steady flow |

| 20% boost | More output | Quick change |

| Fluid | Efficient | Reliable |

Consistency and Stitch Quality

Precision is the backbone of reliable stitching. With stitch parameter control, you get consistent seam lines—no more guessing. Vision defect detection spots skipped or broken stitches before they become problems. Robotic stitch precision and real-time monitoring keep stitch accuracy high.

That’s why Automatic Sewing Machines, with these features, consistently outperform manual setups in defect rate impact and quality.

Labor Cost Reduction

When you switch to Automatic Sewing Machines, labor costs drop sharply—sometimes by 60%. You’re investing in Automation ROI, not just speed. Operator Training gets easier, and workforce restructuring means fewer specialized skills needed. That’s a game changer for production efficiency improvements.

- Less time spent on manual tasks

- Skill shift toward machine oversight

- Error reduction boosts quality and savings

Versatility for Different Projects

Whether you’re making quilts, denim jeans, or embroidered home décor, automatic sewing machines adapt fast. Modular machine design lets you swap out presser feet and tables for each project. Material feed systems handle thick layers or delicate knits. Digital design import means you can shift from garment construction to embroidery with ease—true versatility for any sewing project.

| Feature | Versatility Example |

|---|---|

| Project stitch count | Garment to quilt shift |

| Material feed systems | Leather, denim, jersey |

| Robotic seam types | Pleats, hems, piping |

| Modular machine design | Presser feet/table swap |

| Digital design import | Embroidery, monogramming |

Use Cases for Automated Sewing

Automated sewing systems fit into many areas, from clothing factories to custom shops. You’ll find their strengths show up in different industries and workflows.

Here’s how these machines are making a difference across a few key use cases.

Apparel and Fashion Manufacturing

Did you know Sewbot integration is helping fashion labels hit daily targets of 800,000 T-shirts? Apparel manufacturing is shifting, with automation ROI driving reshoring impacts and boosting skilled labor demand. Customization trends are easier to tackle, thanks to automated sewing machines. If you’re scanning automatic sewing machine reviews, consider these advantages:

- Faster production cycles

- Consistent stitch quality

- Lower labor costs

- Flexible design changes

- Enhanced scalability

Upholstery and Industrial Textiles

Ever wondered how automatic sewing machines transform upholstery and industrial textiles? In Automotive Upholstery and Furniture Automation, sophisticated features drive defect reduction and cut costs.

Technical Textiles benefit from precise pattern control and rapid cycle times.

If you’re scanning automatic sewing machine reviews, you’ll notice consistent stitch quality and efficiency—key advantages when tackling complex upholstery and industrial textiles projects at scale.

Custom Tailoring and Prototyping

Picture cutting lead times in half—automatic sewing machines make it possible in custom tailoring and prototyping. Virtual prototyping and fit personalization let you preview designs before fabric touches a needle. Here’s how automation transforms your workflow:

- Rapid pattern recognition

- Efficient fabric handling

- Precise stitch accuracy

- Adjustable runs from sample to batch

- Simplified technology stack for resource efficiency

Top 9 Automatic Sewing Machines Compared

Choosing the right automatic sewing machine can feel overwhelming with so many options out there.

To help you narrow things down, here are nine models that stand out for different needs and skill levels. Take a look and see which one fits your projects best.

1. Brother XM2701 Lightweight Sewing Machine

Efficiency is a key feature of the Brother XM2701 automatic sewing machine. You get 27 built-in stitch capabilities, an automatic needle threader, and six included accessories—ideal for daily sewing tasks.

Automation features like the drop-in bobbin and one-step buttonholer simplify setup, boosting ease of use. This lightweight model fits tight spaces and travels easily, making it a strong market position choice for beginners or hobbyists.

For basic repairs, quilting, or home projects, its versatility and consistent results set it apart.

Best For: Beginners and casual sewists who want an easy-to-use, portable machine for everyday sewing and craft projects.

- 27 built-in stitches and automatic needle threader make setup and sewing simple

- Lightweight design is easy to store and carry to classes or sewing groups

- Includes six presser feet and useful accessories right out of the box

- May struggle with thick fabrics or heavy-duty sewing tasks

- Foot pedal can be sticky and require extra pressure

- Bobbin cover is sometimes missing and may need to be purchased separately

2. Mini Sewing Machine for Beginners

If portability tops your list, a mini sewing machine for beginners is worth your attention. These automatic sewing machines weigh just 1.7 pounds, making them easy to move or store.

The kit contents often include bobbins, needles, and a built-in thread cutter—practical for quick repairs or learning the basics.

You’ll notice stitching limitations, as these beginner-friendly sewing machines handle only light fabrics. Still, safety features and a gentle learning curve make them ideal for new users, especially those seeking ease of use.

Best For: Beginners, kids, and casual crafters who want a simple, portable sewing machine for light projects and quick repairs.

- Lightweight and easy to carry or store

- Comes with starter accessories and safety features

- Simple controls and setup for new users

- Only suitable for basic sewing and light fabrics

- Some users report durability and reliability issues

- Lacks advanced features found in full-size machines

3. Singer Tradition Sewing Machine with Threader

If you’re ready to step up from basic models, the Singer Tradition automatic sewing machine stands out for its reliable Needle Threader and straightforward sewing machine features. With 23 stitch options and solid stitch performance, you get flexibility for garments or home décor.

The automatic needle threader and clear threading guides save you time, especially if you’re new to sewing machines.

Included accessories, a sturdy metal frame, and detailed warranty details mean you’re covered for most household projects, from fabric handling to repairs.

Best For: Beginners and casual sewists who want an easy-to-use machine with helpful features for everyday sewing projects.

- Automatic needle threader makes setup quick and simple

- 23 built-in stitches offer versatility for clothes, crafts, and repairs

- Lightweight and portable with a sturdy metal frame for home use

- Bobbin tension and zigzag stitch can be finicky for some users

- Machine may move around during use due to its light weight

- Not designed for heavy-duty or professional sewing tasks

4. Mini Portable Sewing Machine Beginner Friendly

If you’re after an easy-to-use automatic sewing machine that fits small spaces and busy schedules, a Mini Portable Sewing Machine is hard to beat.

Compact designs like the Ruutcasy FSJ-SEW-M pack sewing basics into a lightweight frame, making them ideal for beginners or quick repairs. You get dual speed settings, a built-in lamp, and easy threading guides.

While Mini Machines won’t handle heavy fabrics, their portability and simple controls make them perfect for learning, DIY crafts, and everyday sewing tips.

Best For: Beginners, apartment dwellers, and casual sewers who need a portable option for simple repairs, hemming, and light craft projects without sacrificing desk or closet space.

- Weighs just over 1 pound and measures under 8 inches, making it easy to store in small spaces and carry for on-the-go sewing or classes.

- Includes helpful beginner features like threading guides, a built-in LED lamp, and two speed settings that let you control your pace as you learn.

- Dual power modes (AC adapter or batteries) give you flexibility to sew anywhere without needing an outlet nearby.

- Not suitable for heavy fabrics like thick denim or multiple layers, as the motor can stall and stitches may skip on tougher materials.

- Limited to basic stitches with fewer built-in options compared to full-size machines, so you’ll outgrow it quickly if you move beyond simple projects.

- Some users report durability issues and difficulties with threading or setup, which can be frustrating when you’re just starting out.

5. Brother XR3774 Sewing and Quilting Machine

With 37 stitches and a full quilting features set, the Brother XR3774 offers serious versatility at a mid-$100 price point. You’ll get eight presser feet, a wide table, and an automatic needle threader—usability that suits beginners and seasoned sewists alike.

Stitch selection happens via a front dial, while a 25-year warranty backs the brand’s reliability. This automatic sewing machine doesn’t have computerized controls, but its free arm and walking foot position it as a practical choice for home quilting and everyday sewing projects.

Best For: Beginners and intermediate sewists who want a versatile machine for garment sewing and home quilting without spending on computerized features they don’t need.

- 37 built-in stitches plus 8 presser feet give you plenty of options for different projects right out of the box

- Wide table and free arm setup make quilting larger pieces much easier than compact machines

- 25-year limited warranty and lifetime phone support provide long-term peace of mind at a budget-friendly price

- Some users report occasional stitch skipping, which can interrupt workflow on longer projects

- No digital display or thread cutter means you’re doing more manual adjustments and snipping

- Limited throat space compared to mid-range quilting machines can make maneuvering big quilts tricky

6. Janome MOD-19 Easy Sewing Machine

If you’re shopping for an automatic sewing machine that won’t overwhelm a first-time user, Janome’s MOD-19 delivers 19 built-in stitches and automatic threading at around $140.

This lightweight mechanical model reaches 750–800 stitches per minute—a sewing speed that balances productivity with fabric compatibility across light to medium materials. You’ll appreciate the top-loading bobbin, five-piece feed dogs, and snap-on feet for easy stitching.

Janome backs it with a 25-year warranty, and sewing machine reviews consistently highlight its simplicity and automatic sewing machine features that reduce setup time without a steep learning curve.

Best For: Beginners and casual sewists who want a straightforward mechanical machine for basic garments, repairs, and light quilting without spending much or dealing with computerized controls.

- Automatic needle threader and snap-on feet cut down setup time, so you spend more time sewing and less time fumbling with tools.

- Five-piece feed dogs and adjustable stitch settings handle light to medium fabrics reliably, giving you consistent results across everyday projects.

- 25-year limited warranty and a sub-$200 price point offer solid long-term value for a portable machine that weighs under 12 pounds.

- Some users report tension issues and thread breaks on thicker materials like fleece, limiting the machine to lighter fabrics.

- Plastic components may not hold up as well as metal parts under heavy or daily use over several years.

- The 19-stitch selection and mechanical operation won’t satisfy advanced sewists who need complex decorative stitches or computerized features.

7. Brother Computerized Sewing and Quilting Machine

When you need a machine that handles quilting and garment work in one package, Brother’s computerized sewing machines deliver 70 to 130 built-in stitch options, automatic threading, and LCD displays that simplify setup.

The CS7000X and CP2410 models offer quilting features like drop feed, walking feet, and wide extension tables—automation level that speeds piecing while maintaining consistent seam allowances.

User feedback highlights ease-of-use but also notes reliability issues including thread tangling and service costs around $250. These automatic sewing machine features suit everyday quilting, though heavy users may encounter maintenance needs.

Best For: Sewers and quilters who want automated features like one-step buttonholes and automatic threading without the complexity of industrial machines.

- 70–130 built-in stitches with LCD selection make it easy to switch between garment sewing and quilting projects

- Comes with 10–13 presser feet including walking foot, 1/4-inch piecing foot, and wide extension table for quilt work

- Automatic needle threader and drop-in bobbin system reduce setup time compared to manual machines

- User reports mention thread tangling issues and bobbin winding problems even on new units

- Service costs can run around $250 when reliability issues like safety shutoffs occur

- Not built for heavy-duty fabrics or industrial-level continuous use

8. Brother GX37 Sewing Machine Value Bundle

The GX37 value bundle pairs 37 built-in stitches with a premium six-color thread set, automatic needle threader, and clear-view top-drop bobbin system—all for under $150 when discounted. At 10 pounds, portability benefits make it easy to move between workspaces.

Stitch customization through adjustable length and width settings, plus six included presser feet, suits garment construction and mending tasks. This mechanical model offers beginner friendliness without computerized complexity, though it lacks features like auto thread cutters found in higher-tier automatic sewing machines.

Bundle value delivers immediate project starts.

Best For: Beginners and casual sewers who want an affordable, portable machine with enough built-in stitches for everyday garment construction, mending, and basic quilting projects.

- Bundle includes six premium thread colors and six presser feet, so you can start sewing right away without buying extras.

- Automatic needle threader and clear-view bobbin system make setup fast and reduce frustration for new users.

- Lightweight at just over 10 pounds with a compact design, making it easy to store or move between rooms.

- Some users report issues with the reverse function sticking and thread knotting during operation.

- Not built for heavy-duty fabrics or intensive quilting—durability concerns include fragile parts that may not hold up over time.

- The LED light is dim and the built-in storage compartment is awkwardly positioned, making it hard to access accessories quickly.

9. Brother SE700 Sewing Embroidery Machine

The SE700 combines 710 stitches per minute in sewing mode with dedicated embroidery capabilities—135 built-in designs, 10 fonts, and a 4×4-inch field. Its 3.7-inch color LCD touchscreen lets you edit, rotate, and preview patterns directly, while integrated Wi-Fi links to Brother’s Artspira app for custom designs.

Automatic needle threading and thread cutting reduce manual steps, and the 25-year chassis warranty signals durability. At roughly $700, this automatic sewing machine bridges basic construction and decorative work in a compact footprint.

Best For: Hobbyists and home sewers who want both practical garment construction and custom embroidery without needing two separate machines.

- High-speed sewing at 710 stitches per minute with automatic needle threading and thread cutting saves time on repetitive tasks

- Built-in Wi-Fi and touchscreen let you import, edit, and preview embroidery designs without connecting cables or switching devices

- 25-year chassis warranty and long electronic coverage (6 years) suggest the machine’s built to last beyond entry-level alternatives

- 4×4-inch embroidery field limits you to smaller designs—larger projects require re-hooping or won’t fit at all

- Throat space may feel cramped for quilting or bulky fabric layers compared to dedicated sewing-only machines

- Full design library access often requires a Brother iBroidery subscription, adding ongoing costs beyond the initial purchase

Choosing The Right Automatic Sewing System

Picking the right automatic sewing system can feel like choosing the right tool for a job—you need to match the machine to what you’re actually making.

Your decision depends on how much you plan to sew, which features matter most for your projects, and what you can realistically spend.

Let’s walk through the key factors that’ll help you find a system that fits your needs.

Assessing Project Needs and Volume

Before you invest in automation, ask yourself: will my volume justify the cost? Automatic sewing machines shine when production efficiency matters. For basics like T-shirts, you’ll need 3,000–4,000 pieces daily to keep a robotic line humming above 90% utilization. Mix complexity—switching between styles—cuts throughput, so plan project scope around similar SMVs.

Volume thresholds determine automation ROI: semi-automated cobots start at $15,000, while full robotic cells cost $100,000–$350,000. Labor costs in high-wage regions make high-volume output competitive, with payback in 18–24 months on automated manufacturing lines producing over one million units annually.

| System Type | Investment Range | Ideal Annual Volume |

|---|---|---|

| Semi-automated cobot | $15,000–$60,000 | Mid-volume (50K–500K) |

| Fully automated cell | $100,000–$350,000 | High-volume (1M+ units) |

| Robotic waistband unit | ~$20,000 | Moderate, focused ops |

Comparing Features and Specifications

Once you’ve locked in your volume, it’s time to compare specs head-to-head. Stitch variability matters—computerized models offer 100+ stitch options versus 10–20 on mechanical machines.

Speed comparison: industrial units run 3,000–5,000 stitches per minute; consumer automatic sewing machines top out around 850.

Check material compatibility for thick fabrics, noise levels under 70 dB for ergonomic design, and automatic sewing machine features like tension sensors that adjust mid-seam.

Evaluating Brand Reputation and Support

After comparing specs, dig into warranty coverage and dealer networks—brands like Singer offer 25 years on machine heads, while Janome’s authorized-dealer model gives you lifetime lessons and local service. Direct support matters; Brother’s customer service resolves multi-decade-old issues, boosting user satisfaction. Automatic sewing machine reviews highlight how training access and responsive help shape long-term confidence in automatic sewing machine brands, making support as critical as any feature.

- 25-year warranties protect your investment for decades

- Lifetime in-store lessons keep you mastering new techniques

- Toll-free hotlines answer questions fast when you’re stuck

- Authorized dealer networks provide hands-on demos before you buy

- Multi-decade lifespans mean one great choice lasts your career

Budget Considerations

Machine affordability spans a wide spectrum—basic computerized units run $100 to $250, while industrial models start around $1,600 and robotic cells reach $100,000 to $350,000. Don’t forget maintenance costs averaging $80 to $200 yearly.

Pre-owned options slash upfront expense, and ROI justification becomes straightforward in high-volume settings. Smart upgrade planning balances your budget with the features you’ll actually use daily.

Integrating Automation Into Your Workflow

Adding automation to your sewing operation isn’t just about buying new equipment. You’ll need to think through whether to upgrade your current machines or start fresh, how to train your team on new systems, and what kind of upkeep these machines require.

Let’s look at three key areas that’ll help you make the shift smooth and get the most from your investment.

Retrofitting Vs New Installations

When automating sewing processes, you’ll face a fork in the road: retrofit existing machines or install greenfield setups. Capital costs differ sharply—servo motor retrofits run $150–400 per unit versus $1,000–10,000 for new industrial automation solutions. Energy costs drop up to 70% with servo upgrades, often paying back within 12–24 months.

Consider these trade-offs:

- Labor impact: Retrofit gains are modest; integrated sewbot lines cut labor 50–70%.

- Downtime risk: Stage retrofits machine-by-machine to minimize disruption.

- Product mix: Retrofits suit varied SKUs; greenfield excels on high-volume repeatable runs.

- Payback horizon: Textile manufacturing technology retrofits approve faster at 24–36 months.

- Scalability: Automatic sewing machines in new cells consolidate operations and floor space.

Staff Training and Skill Development

Because automatic sewing machines demand new technical competencies, your upskilling initiatives are essential. Modern no-code interfaces cut the learning curve from weeks to days, making beginner-friendly sewing machines easier for staff to adopt.

Training investment pays off: operators mastering digital literacy and automation workflows open career pathways into higher-skilled roles. Focus on hands-on practice with these ease-of-use features to build confidence fast.

Maintenance and Predictive Upkeep

You’ll prevent most common issues with sewing machines through consistent cleaning schedules—daily lint removal and weekly lubrication keep your automatic system humming.

Predictive benefits are game-changing: AI monitoring cuts downtime reduction by 48% and slashes maintenance costs by 25%. Inspection frequencies matter, too.

Budget for robotic upkeep costs at 5%-12% annually, and prioritize quarterly calibrations. Build quality and durability improve when you’re proactive about troubleshooting before breakdowns hit.

Future Trends in Sewing Automation

The sewing industry is moving fast, and automation is leading the charge. New technologies like AI-powered robotics and smart systems are changing how garments get made, where they’re produced, and who’s needed to run the machines.

Here’s what you can expect in the coming years as these trends reshape the field.

AI and Smart Robotics in Sewing

Artificial intelligence is transforming how you approach sewing robot technology. AI-powered automation uses smart sensors and robot vision to guide robotic sewing machines through complex tasks with 95% precision in seam estimation.

These advances in sewing algorithms and fabric handling let automatic sewing machines adapt tension in real-time, correct deviations instantly, and reduce error rates to just 0.7%—making robotics in manufacturing smarter and more reliable than ever.

Reshoring and Global Production Shifts

Automation investment is helping you bring textile production closer to home. Rising labor costs in traditional hubs have pushed nearshoring strategies forward, with automated manufacturing cutting apparel production costs to USD 0.33 per shirt.

Supply chain resilience and sustainability goals now drive reshoring—automated plants can churn out 1.2 million garments annually while meeting environmental standards and reducing shipping footprints.

Automated reshoring plants now produce over a million garments yearly while cutting costs and meeting environmental goals

Evolving Roles and Career Opportunities

You’ll see automation impact reshape textile careers—not eliminate them. Cambodia and Vietnam face 86–88 percent sewing-role displacement, yet emerging roles in automation support, machine vision, and data analysis are rising fast.

Skill requirements now blend traditional fashion industry experience with robotics and nocode interfaces. Staff training programs help former operators pivot to technician roles.

Geographic shifts create career opportunities in automation hubs, while policy responses guarantee retraining keeps workers in the game.

Frequently Asked Questions (FAQs)

How do automatic sewing systems handle delicate fabrics?

You’ll find high-resolution vision sensors and soft grippers work together to hold silk and chiffon steady.

AI handling adjusts tension control in real-time, preventing snags while maintaining precision across delicate textiles.

What are common troubleshooting issues with automated machines?

Thread breakage, skipped stitches, needle breakage, tension errors, and feed failures plague sewing machines. You’ll face incorrect threading, bent needles, worn tension discs, and lint-clogged feed dogs—troubleshooting automatic sewing machines demands regular maintenance.

Can automatic systems work with unconventional materials?

Can your sewing machines handle silk or leather? Vision sensors and gripper technology in robotic systems tackle material slippage on unconventional textiles, preventing seam distortion through robotic piercing that adjusts to varying fabric weights automatically.

How long does it take to program custom patterns?

Programming a custom pattern depends on complexity—simple patterns often take 10–30 minutes, while complex designs can stretch to hours.

Automation impact, nocode interfaces, and AI-powered control systems help reduce changeover duration and flatten the learning curve.

What are energy consumption differences versus manual machines?

Manual machines use less power—basic models average 50 watts, while automatic sewing machines and electric sewing machines often reach 100 watts.

Servo vs clutch motors show major energy saving potential in industrial automation, cutting labor costs and boosting production efficiency.

Conclusion

Mastering efficiency, embracing innovation, and adapting your workflow—these are the pillars of progress as automatic sewing systems reshape the textile landscape. Whether you’re scaling up production or refining custom projects, the right system will help you deliver consistent results, reduce labor costs, and expand your creative possibilities.

With technology evolving rapidly, staying informed means staying competitive. Let your choice of equipment reflect your commitment to quality, speed, and adaptability, setting the pace for sewing innovation.

- https://infinitymarketresearch.com/report/automatic-sewing-system-market/18615

- https://www.futuremarketreport.com/industry-report/automatic-sewing-machine-market/

- https://www.linkedin.com/pulse/automatic-sewing-system-market-size-2026-drivers-pae8f

- https://www.gminsights.com/industry-analysis/industrial-sewing-machine-market

- https://www.prnewswire.com/news-releases/automation-market-in-textile-industry-to-grow-by-usd-775-92-million-2024-2028-as-ai-powers-market-evolution-facility-upgrades-boost-energy-efficiency---technavio-302311075.html