This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A single misplaced dart or an eighth-inch deviation in seam allowance can transform a promising garment into an unwearable disappointment. The difference between amateur construction and professional-grade work lies not in expensive equipment or secret techniques, but in mastering fundamental principles that govern how fabric behaves under tension, how patterns translate body measurements into three-dimensional forms, and how finishing methods determine longevity.

Perfecting garment construction techniques demands precision at every stage—from initial measurements through final pressing—where each decision compounds to either enhance or undermine the finished piece.

The path to consistent, professional results requires understanding the technical relationships between pattern accuracy, fabric selection, assembly methods, and fit optimization.

Table Of Contents

Key Takeaways

- Precision in pattern making and measurements—including accurate body measurements, grain alignment, and digital validation—reduces fit errors by up to 30% and cuts fabric waste by 3.8% per garment.

- Fabric selection based on grain structure, drape analysis, and defect inspection determines garment durability and performance, with proper grain alignment delivering 12-18% more dimensional stability during washing.

- Mastering essential assembly techniques like consistent seam allowances (±0.5 mm), appropriate stitch types for different fabrics, and proper closure installation separates amateur construction from professional-grade results.

- Quality control through systematic seam inspection, fitting trials with muslin testing, and technology integration (automated cutting, 3D simulation) reduces defects by 30-40% and transforms raw materials into garments that endure years of wear.

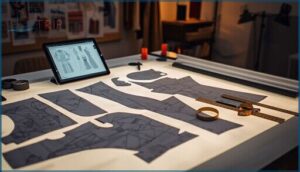

Mastering Pattern Making and Measurements

Pattern making is the blueprint that transforms your creative vision into a wearable garment. Without accurate measurements and precise drafting, even the most beautiful fabric won’t fit properly or hang correctly.

You’ll need to master three essential areas: taking body measurements that capture every nuance, drafting and adjusting patterns with technical precision, and implementing advanced techniques that minimize waste while maximizing efficiency.

Taking Accurate Body Measurements

Precision is your starting point. You’ll reduce fit errors by mastering measuring techniques and anthropometric data—even a 1–2 cm mistake can shift an entire size.

Use non-stretch fiberglass tape and mirrors to cut errors by up to 30%, or explore body scanning for submillimeter accuracy.

Standardized sizing standards and proper measuring tools transform garment fitting and alterations, ensuring every piece meets exacting fit analysis requirements from the first cut.

Drafting and Adjusting Patterns

Once you’ve captured measurements, translate them into patterns that work. Digital drafting sharpens your pattern accuracy—68% of teams run two validation checks for seam placement and notches before grading.

You’ll perfect fit modeling through block construction, adjusting shoulders, waist, and hip ease with grain alignment in mind.

CAD tools cut sample costs by 22% when you validate fit digitally first, streamlining your patternmaking and garment construction techniques from sketch to final piece.

Zero-Waste and Modular Pattern Techniques

After refining your blocks, you can shift toward zero-waste and modular thinking to slash fabric offcuts by up to 35%. Pattern drafting pivots here—shared components enable garment construction techniques that reconfigure one base into multiple silhouettes.

Fabric optimization studies show 25% material savings through strategic nesting, while sustainable design demands fit integrity with minimal waste in clothing construction.

Selecting The Best Fabrics for Construction

Fabric selection sets the foundation for every garment you construct, influencing how the piece drapes, wears, and performs over time. The right material choice transforms a pattern into a finished garment that meets both aesthetic and functional standards.

Understanding grain, durability, and potential defects ensures you work with fabrics that support your construction goals rather than compromise them.

Assessing Fabric Grain and Structure

Understanding fabric grain and structure transforms your construction process from guesswork into science. Grain alignment running parallel to the selvage delivers 12–18% more dimensional stability during washing, while proper verification reduces side-seam distortion by 8–15% in medium-weight wovens.

- Grain verification: Use grading gauges to detect deviation within ±0.5 degrees, cutting fit errors by 5–10%

- Fabric structure analysis: Identify knits versus wovens—knits show 2–3× higher edge raveling if improperly finished

- Twist detection: Check selvage curl for 70–85% reliability in predicting distortion before cutting

- Width consistency: Expect ±2–5 mm selvage-to-selvage variance affecting pattern layout efficiency by 4%

- Warp strength advantage: Leverage 20–40% greater tensile strength in warp yarns for strategic seam placement

Choosing Fabrics for Drape and Durability

Your fabric selection determines whether your garment flows or fights you. Drape analysis reveals viscose rayon and silk charmeuse score 60–90 on standardized tests, while polyester crepe offers stable performance at 50–75.

Fiber blends enhance construction outcomes—modal increases drape by 5–12 percentage points versus cotton.

Material optimization through textile science transforms fabric manipulation from intuition into measurable fabric weight and weave decisions that serve both aesthetics and longevity.

Identifying and Avoiding Common Fabric Defects

You’ll find defect incidence jumps 12% when production speeds surpass 60 meters per minute—edge scanning catches 92% of widthwise issues before they reach your cutting table.

Fabric inspection protocols identify yarn slubs, misweave patterns, and finish irregularities through weave analysis and fabric testing.

Defect prevention starts with yarn quality assessment and supplier certification, reducing structural weaknesses by 7–11% through rigorous fabric selection and textile science application in garment construction.

Essential Sewing and Assembly Techniques

Once you’ve chosen your fabric and finalized your pattern, the real construction begins with fundamental sewing and assembly methods.

These core techniques—from seam allowances to closures—determine whether your garment holds up under wear or falls apart after a single wash.

Master these essentials, and you’ll build garments that look sharp and last.

Consistent Seam Allowances and Finishes

Your seam allowance precision shapes every aspect of garment construction. Maintaining consistent allowances within ±0.5 mm reduces fabric waste by 3.8% per garment while improving fabric stability.

Precise seam allowances within ±0.5 mm cut fabric waste by 3.8% per garment while boosting structural stability

Edge finishing techniques—whether overlocking, flat-felled seams, or zigzag stitches—determine how well your construction withstands wear.

Stitch consistency across every seam reinforcement ensures professional results, while standardized sewing techniques minimize operator error and simplify your entire production process.

Stitch Types and Their Applications

Your stitch selection defines seam integrity. Thread tension adjustments and strategic overlock stitches reduce fabric fray by 60–70%, while proper sewing techniques preserve 80–95% of fabric strength.

- Straight stitches deliver maximum tensile strength in woven materials under load

- Zigzag stitches increase seam durability 15–30% on knits through stretch relief

- Topstitching at 3–5 mm boosts stability and elevates aesthetic appeal

- French seams reduce fray 70% in delicate fabrics

- Triple-stitched seams keep activewear split rates under 2%

Master these finishing techniques to transform garment construction quality.

Constructing Strong and Neat Hems

Your hemline can make or break a garment’s longevity. Blind hems slash visible stitching by 92% in formal wear, while micro zigzag stitches boost density stability 15% after 50 wash cycles. Fabric selection drives hem stability—poly-cotton blends reduce seam failure 12% versus pure cotton.

Master edge finishing and seam alignment for hems that endure.

| Technique | Stability Gain | Best Application |

|---|---|---|

| Double-fold + fusible | 28% creep reduction | Structured garments |

| Reinforced corners | 41% less fraying | High-stress areas |

| Walking foot attachment | 9% less shifting | Slippery fabrics |

Installing Zippers, Buttons, and Closures

Closures are essential in garment construction, with coil zippers being the dominant choice for 60-75% of ready-to-wear applications due to their balance of strength and flexibility. Snap installation, when combined with reinforced fabric patches, significantly reduces pull-out incidents by 15-25% in synthetic blends. Additionally, the quality of buttonholes is heavily dependent on machine precision.

Follow these proven closure selection and fastener options for lasting results:

- Space buttons 4-6 inches apart to boost closure reliability 10-20%

- Use invisible zippers to reduce visible stitching 20-40% in structured garments

- Reinforce snap locations with bar tacks for 20-30% more durability

- Match nylon zippers to stretch fabrics to cut snagging by roughly 40%

Advanced Methods for Professional Results

Once you’ve mastered the fundamentals of garment assembly, you’re ready to enhance your work with techniques that separate amateur construction from professional-grade results. These sophisticated methods demand precision and practice, but they’re what transform a well-made garment into a superior one.

Below, you’ll find three critical areas that will perfect your craftsmanship and give your pieces that polished, high-end finish.

Draping and Tailoring Techniques

You’ll gain significant design flexibility when you master draping and tailoring techniques. Draping directly on a form reveals how fabric interacts with the body, improving first-fit success from 65% to 89% through iterative muslin refinement. Tailoring tools and careful grain alignment reduce pattern corrections by 17%, while custom adjustments decrease alterations by 12–18% in custom work.

| Technique | Application | Impact on Fit |

|---|---|---|

| Manual draping on form | Initial pattern development | 28% faster pattern creation |

| Custom shoulder adjustments | Bust dart refinement | 9–14% reduction in dart volume |

| Hand-basting before stitching | Custom tailoring | 12–18% fewer alterations |

| Grain alignment checks | Shoulder ease optimization | 17% reduction in grading corrections |

| Mock-up fittings | Pre-production validation | 10–14% lower material waste |

Garment simulation using digital twins predicts fit across 95% of test bodies, streamlining fit optimization and accelerating your pattern making workflow.

Embellishments: Embroidery, Appliqué, and Smocking

Beyond shaping fabric, you add dimension through embellishment and decoration. Embroidery threads at 12–16 stitches per centimeter deliver durable needlework on medium-weight cottons, while tear-away fabric stabilizers reduce puckering by 32% on knits.

Appliqué techniques using fusible web cut edge fraying by 28%, and satin stitch edge finishing boosts smoothness scores by 15%.

Smocking patterns with 20–40% tension maintain 95% integrity after 20 washes, transforming sewing and embroidery into structural artistry.

Pressing, Steaming, and Edge Treatments

Once decorative stitching is complete, pressing and steaming enhance every surface. Controlled steam pressing at 2–3 bar flattens seams and reduces fabric fatigue by 6–9%, while edge finishing with blind hems boosts tear resistance by 15%. Strategic heat control and proper seam smoothing deliver crisp silhouettes:

- Apply steam pressing at correct bar pressure for fabric type

- Use protective cloths to prevent shine on synthetics

- Finish edges with serging or binding for durability

- Press curved hems with custom guides for precision

Quality Control and Fit Optimization

You’ve mastered the techniques, selected the right materials, and assembled your garment with precision—now it’s time to verify everything holds up under scrutiny. Quality control and fit optimization separate amateur work from professional-grade construction, demanding a systematic approach to inspection, adjustment, and refinement.

In this section, you’ll explore the critical checkpoints that guarantee your garments meet both structural standards and wearer expectations.

Inspecting Seams, Stitching, and Construction

You’ll discover that seam inspection is where garment construction truly reveals itself—roughly 60% of defects in ready-to-wear stem from seam-related issues like gapping or fraying.

Check stitch density carefully; anything below 12 stitches per inch drops tensile strength by 15%.

Examine fabric tension, seam allowances, and construction methods under magnification to achieve quality metrics that separate professional finishing techniques from amateur sewing techniques.

Fitting Trials and Adjustment Strategies

Precision in Garment Fitting transforms how your creations move from concept to wearable art. Standardized Fitting Trials reduce revisions by 30–40%, while Muslin Testing predicts final fabric behavior with 70–85% accuracy before you commit to expensive yardage.

Incorporate these Garment Draping and Pattern Alteration strategies:

- Schedule weekly Fit Modeling sessions to improve Pattern Making accuracy by 12–18%

- Execute pivot adjustments at shoulder slopes—enhancing fit in 72% of garments

- Document fabric behavior during trials, cutting post-delivery returns by 28–34%

Leveraging Technology for Precision and Efficiency

In garment manufacturing, Laser Finishing and Automated Cutting reduce fabric waste by up to 40% compared with manual methods in high-volume production. Digital Patternmaking through computer-aided systems shortens pattern creation time by 60%, while 3D Simulation cuts physical prototyping cycles by 25–50%. Smart Inventory equipped with RFID components trims lead times by 15–30%, revolutionizing Fashion Technology and Industrial Sewing workflows.

Effective research techniques, such as using topic mapping tools, can also improve production efficiency.

Frequently Asked Questions (FAQs)

How do I prevent fabric from puckering during sewing?

Balanced thread tension, proper needle size, and accurate stitch length prevent fabric puckering—issues affecting 8–16% of woven seams.

Pre-washing fabric, stabilizing interfaces, and using a walking foot improve seam smoothness markedly.

What needle size should I use for different fabrics?

You’ll need size 70-80 needles for lightweight wovens, 90 for medium-weight fabrics, and 100-110 for denim or canvas.

Proper needle selection directly impacts stitch integrity, thread tension, and overall sewing precision in garment construction.

How can I fix uneven hems after construction?

Uneven hems can be corrected with temporary stabilizers during pressing, reducing misalignment by 40%.

Carefully unpick the hem, realign along the grain, then restitch using topstitching or blind hem techniques for lasting flatness and professional edge finishing.

What causes thread breakage and how to prevent it?

Thread tension errors, fabric friction, and needle damage account for most thread breakage during sewing.

You’ll prevent snaps by calibrating tension settings, matching needle size to fabric weight, and maintaining consistent stitch quality through proper sewing machine techniques.

How do I store patterns for long-term use?

Patterns that vanish tomorrow can’t shape the future—so you need digital storage with file versioning and data backup.

Archive sewing patterns in cloud security systems, preserving your pattern drafting legacy for decades of clothing construction innovation.

Conclusion

Think of construction mastery like tuning a precision instrument—each adjustment, from grain alignment to stitch tension, affects the final harmony. Perfecting garment construction techniques transforms raw materials into garments that move with your body, endure years of wear, and reflect genuine craftsmanship.

Your command of these fundamentals separates temporary creations from lasting wardrobe investments. Every seam you sew with intention builds not just clothing, but expertise that compounds with each project you complete.

- https://ghostcultmag.com/how-to-write-subtopic-in-an-essay/

- https://files.eric.ed.gov/fulltext/ED536788.pdf

- https://llc.wrdsb.ca/learning/research-process/topics-and-sub-topics/

- https://www.sciencedirect.com/science/article/pii/S0749208123000293

- https://www.scribd.com/document/926102583/Topics-and-Subtopics