This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Most sewing machine operators never realize they’re fighting their foot pedal instead of controlling it. You press down expecting smooth acceleration, but the needle lurches forward or crawls at half the speed you need.

That’s because foot pedal speed settings aren’t just about how hard you push—they’re a carefully engineered system of sensors, resistors, and motor controllers that translate your pressure into precise stitch rates. When you understand how variable resistors map your foot position to voltage levels, or how pulse-width modulation regulates motor power, you gain the ability to match your machine’s response to any fabric or technique.

Modern digital controls let you cap maximum speeds, store custom profiles, and calibrate sensitivity in single-digit increments, turning an unpredictable pedal into a precision instrument that responds exactly how you want it to.

Table Of Contents

- Key Takeaways

- How Foot Pedal Speed Settings Work

- Factors Affecting Pedal Speed Performance

- Adjusting and Calibrating Foot Pedal Speed

- Optimizing Speed for Different Sewing Tasks

- Top Sewing Accessories for Speed Control

- 1. Simthread Embroidery Bobbins Thread

- 2. Amazon Basics Drafting Stool

- 3. New Brothread Prewound Bobbin Thread

- 4. Dreamstitch Blind Hem Presser Foot

- 5. HON Office Chair Mat

- 6. Outus Prewound Thread Bobbins for Sewing Machines

- 7. Janome Blind Hem Foot

- 8. Brother Blind Stitch Foot

- 9. ThreadNanny Sewing Machine Binder Foot

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Your foot pedal translates physical pressure into electronic signals through variable resistors or Hall-effect sensors that use pulse-width modulation to control motor speed with precision down to single-digit increments.

- Fabric density, needle size, and stitch length directly affect how much pedal pressure you need—heavyweight materials demand heavier thread and slower speeds while lightweight fabrics let you accelerate with finer needles.

- Modern digital speed controls let you cap maximum speeds, store custom profiles, and calibrate sensitivity to turn an unpredictable pedal into a precision instrument that responds exactly how you want.

- Matching pedal speed to your task makes the difference between clean seams and frustrating do-overs—straight seams need 300-800 stitches per minute while curves and thick materials require dropping to 20-50% of maximum speed.

How Foot Pedal Speed Settings Work

Your foot pedal isn’t just an on-off switch—it’s a precision control system that translates physical pressure into variable motor speed. Understanding how this mechanism works gives you the foundation to troubleshoot problems and enhance your sewing performance.

Let’s break down the three core components that determine how your pedal controls speed.

Mechanism of Foot Pedal Control

Your foot pedal controller transforms physical pressure into electronic signals that drive motor control. Inside the pedal, a variable resistor or Hall-effect sensor maps your foot’s position to voltage levels. The sewing machine speed control board reads these signals and uses pulse-width modulation to regulate motor RPM.

Here’s how pedal calibration guarantees accurate speed regulation:

- Sensor converts deflection into electrical output

- Control board processes voltage signals

- PWM adjusts motor drive power

- Nonlinear response curves improve low-speed precision

- Spring mechanisms prevent unintended acceleration

Proper foot pedal design balances sensitivity with safety, giving you command over every stitch. The audit process for scientific studies involves checking for methodological flaws to guarantee accuracy.

Relationship Between Pedal Pressure and Speed

Pressing down harder on your foot pedal pressure directly increases motor control output, ramping up sewing machine speed control from slow, deliberate stitches to maximum RPM. Pressure sensitivity translates your input through servo systems that map pedal calibration to precise speed response.

Light pressure gives you tight control for intricate work, while heavier pressure accelerates stitch quality through consistent feed rates—letting you command every seam. For ideal results, understanding language patterns is essential in adjusting and optimizing your control.

Speed Limit Dials and Digital Controls

Most modern machines give you a speed limit dial that caps your maximum stitch rate, even at full foot pedal pressure. Digital throttle systems take it further—offering 1–10% increments for precise speed calibration and storing custom profiles for different fabrics.

These control interfaces display real-time RPM and include motor overload protection, so your pedal sensitivity stays consistent without risking timing drift or unexpected throttle surges.

If you notice early warning signs like inconsistent response times or minor lag, checking your foot pedal control setup can help you catch wear patterns before they escalate into larger problems.

Factors Affecting Pedal Speed Performance

Your foot pedal won’t perform the same way across every sewing scenario, and that’s not a flaw in your technique. Several physical and mechanical factors determine how responsive your speed control feels and how accurately you can execute different tasks.

Pairing proper foot pedal habits with essential beginner techniques like tension adjustments helps you handle any fabric confidently.

Understanding these variables gives you the insight to anticipate performance shifts and adjust your approach before problems surface.

Fabric Density and Thread Type

Dense fabrics hit the pedal hard—literally slowing your sewing speed and demanding the right thread type to match the challenge. Higher fabric density increases friction, forcing you to ease off the pedal and select threads with appropriate tensile strength to maintain stitch quality.

A variable speed sewing machine gives you precise pedal control to tackle dense materials without compromising stitch consistency or thread integrity.

- Heavyweight fabrics like denim and canvas need 40 wt or heavier thread for durability

- Polyester thread works best on tight weaves for strength and minimal stretch

- Cotton threads match natural fiber fabrics and improve compatibility with fabric finishing

- Lighter fabric weights (50–60 wt thread) allow faster sewing speed with smooth feeding

- Test swatches verify thread tension and material selection before committing to full seams

Needle Size and Stitch Length

Your needle selection and stitch length directly control how much foot pedal pressure you’ll need for smooth speed control. Larger needles (size 16–18) push through thick materials but slow your sewing speed, while smaller needles (size 9–11) glide faster on lightweight fabrics.

Longer stitch lengths reduce needle penetrations per inch, improving sewing accuracy and preventing thread breakage when you maintain consistent stitch tension.

Fine-tuning your industrial sewing machine speed control settings helps you balance faster output with the precision longer stitches naturally provide.

Machine Type and Maintenance

Your machine’s internal health shapes every aspect of speed control. Electronic controllers and brushless motors deliver smoother pedal response than older brushed systems, but only when you follow maintenance schedules—cleaning lint every 12–20 hours and inspecting gears for wear.

Belt replacement becomes critical when you notice slippage, as worn belts delay foot pedal pressure translation into consistent speed control.

Adjusting and Calibrating Foot Pedal Speed

Getting your foot pedal to respond exactly how you want it to isn’t guesswork—it’s a matter of proper calibration and adjustment. Whether you’re working with a vintage machine that needs manual tuning or a modern digital system with programmable settings, the right approach makes all the difference.

Here’s how to take control of your pedal’s performance and fix the most common speed-related issues.

Manual Calibration Techniques

If your foot pedal pressure doesn’t match your speed control expectations, manual calibration is your answer. Start by aligning spring tension to a neutral point, then verify with a tachometer across pedal travel.

Adjust the mechanical linkage or potentiometer in small increments while recording baseline speed mapping data.

Document each foot pedal controller adjustment in calibration logs, including exact screw settings and RPM readings for consistent pedal adjustment results.

Digital Speed Adjustment Features

Modern digital interfaces give you precision control that mechanical systems can’t match. You’ll find speed calibration tools that let you fine-tune motor settings in 1–5% increments, while firmware updates improve response curves over time. These features transform foot pedal pressure into exact sewing machine speed control through:

- Programmable memory presets for repeated tasks

- Real-time RPM displays via LCD screens

- Customizable speed limit dials with soft-start safety

- USB-enabled foot controller upgrades

- Micro-adjustment sliders for nuanced precision control

Troubleshooting Common Speed Issues

When your sewing machine troubleshooting reveals erratic speed control despite consistent foot pedal pressure, you’re likely dealing with worn linkage or faulty sensors. Response delay often stems from slipping belts, while intermittent power supply causes unpredictable surges.

| Issue | Root Cause |

|---|---|

| Speed fluctuations | Dirty encoder signals |

| Pedal lag | Outdated drivers |

| Calibration drift | Degraded springs |

Address error detection through pedal maintenance and firmware updates.

Optimizing Speed for Different Sewing Tasks

Matching your pedal speed to the task at hand makes the difference between clean, professional seams and frustrating do-overs. Each sewing scenario demands a different approach—what works for a long, straight construction seam won’t serve you well when maneuvering tight curves or wrestling with canvas.

Different sewing scenarios demand tailored pedal speeds—what works for straight seams fails on curves or heavy canvas

Here’s how to dial in the right speed for three common situations you’ll face at your machine.

Best Speeds for Straight Seams

You’ll get the best seam quality on straight runs when you stay between 300 and 800 stitches per minute—that sweet spot where stitch control meets speed.

For general garment work, aim for moderate foot pedal pressure to hold fabric tension steady and prevent drift.

Beginners should start at your machine’s lowest speed limits, then gradually increase as your pedal technique sharpens and you maintain consistent sewing speed without chasing the needle.

Adjusting Speed for Curves and Corners

Curves and corners demand a lighter touch—drop your sewing speed to roughly 20–30% of maximum before you enter a turn. That level of speed calibration keeps stitch bite consistent and prevents skipped stitches as you navigate tight arcs.

Here’s your corner navigation checklist for better fabric handling:

- Reduce foot pedal pressure before the curve begins

- Coordinate hand guidance with gentle pedal inputs

- Pause briefly at the peak to realign

- Accelerate gradually as you exit the turn

Speed Recommendations for Thick Materials

When you tackle thick fabric sewing, dial your speed down to 40–50% of maximum—that prevents needle deflection and thread snapping on dense materials. Run a fabric density test on scrap first, then bump speed in 10–20% increments while checking stitch quality.

Heavy duty threads and a size 90/14 needle give you room to accelerate slightly, but slow stitch techniques always win on multi-layer seams.

Top Sewing Accessories for Speed Control

You can’t master speed control without the right tools backing you up. The accessories you choose directly affect how smoothly your machine reacts to pedal pressure and how comfortable you remain during extended sessions.

Here are nine proven accessories that give you better control over your sewing speed and overall workflow.

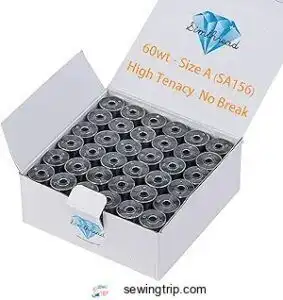

1. Simthread Embroidery Bobbins Thread

Consistency matters when you’re chasing smooth embroidery at higher speeds. Simthread’s 60-weight polyester bobbins deliver that reliability—128 inches of thread wound to steady tension, cutting friction and static that can derail needle control.

Thread quality directly impacts your sewing speed: uniform thickness prevents skipped stitches, while the high-tenacity filament holds up under stress.

You’ll find bobbin compatibility with Brother, Janome, and Juki machines, though double-check your model first. Choose the right material durability for your embroidery techniques, and you’re set for precision work without constant rethreading interruptions.

| Best For | Embroiderers and sewers who need reliable, pre-wound bobbins that work with common machines like Brother, Janome, and Juki for high-speed projects without constant rewinding. |

|---|---|

| Brand | Simthread |

| Material | Polyester |

| Primary Use | Machine Embroidery |

| Compatibility | Multiple Machines |

| Color | Black |

| Weight | 1.08 ounces |

| Additional Features |

|

- High-tenacity polyester keeps tension steady and reduces friction, so you get fewer skipped stitches and smoother runs at higher speeds.

- Pre-wound design saves time—no need to wind your own bobbins, just load and go.

- Compatible with a wide range of popular embroidery and sewing machines, making it a versatile choice for most setups.

- Limited to 60-weight black thread, so you’ll need to look elsewhere if your project calls for different colors or weights.

- Not universal—some machines like the Ricoma EM-1010 reportedly don’t fit these bobbins, so check compatibility before buying.

- At 144 bobbins per pack, it might be overkill if you only do occasional embroidery work.

2. Amazon Basics Drafting Stool

Your posture shapes how well you control that foot pedal through long sewing sessions. The Amazon Basics Drafting Stool brings ergonomic design to your workspace with an adjustable height range that places your leg at the ideal angle for steady speed control—no cramped knees or overextended ankles throwing off your rhythm.

The 360-degree swivel and chrome base with dual-wheel casters let you shift quickly between your sewing machine and cutting table without breaking focus, while the 250-pound weight capacity and faux leather seat deliver comfort features that hold up during marathon projects.

| Best For | Sewers who need comfortable height adjustment and easy movement between workstations during long crafting sessions. |

|---|---|

| Brand | Amazon Basics |

| Material | Faux Leather |

| Primary Use | Drafting/Office Seating |

| Compatibility | Universal |

| Color | Black |

| Weight | 12.56 pounds |

| Additional Features |

|

- Adjustable seat height lets you find the perfect leg angle for consistent foot pedal control without strain

- 360-degree swivel and dual-wheel casters make it easy to shift between your machine, cutting table, and ironing board

- Faux leather seat wipes clean quickly after dealing with fabric dust and thread debris

- Seat diameter runs larger than some expect, which might feel bulky in tighter sewing spaces

- Caster wheels require careful sitting since the stool can roll unexpectedly if you’re not centered

- Packaging sometimes arrives damaged during shipping, though the stool itself usually stays protected

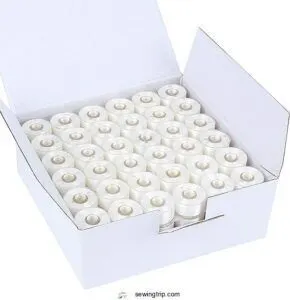

3. New Brothread Prewound Bobbin Thread

Maintaining steady sewing speed depends on consistent thread tension, and the New Brothread Prewound Bobbin Thread delivers that reliability across Brother-compatible machines. The plastic-sided design resists machine oil absorption, while the polyester filament maintains uniform tension—critical for speed control during embroidery and detailed work.

You’ll reduce downtime by skipping manual bobbin winding, letting you focus on foot controller precision instead of thread prep.

Store bobbins by thread type and weight in labeled containers so you can quickly match materials to your project without disrupting your rhythm.

| Best For | Sewers and embroiderers who want to speed up project turnaround by eliminating manual bobbin winding, especially those working with Brother, Babylock, or Janome machines on bulk orders or time-sensitive crafts. |

|---|---|

| Brand | Generic |

| Material | Plastic/Polyester |

| Primary Use | Machine Embroidery |

| Compatibility | Multiple Machines |

| Color | White |

| Weight | 1.01 pounds |

| Additional Features |

|

- Prewound design saves significant prep time and maintains consistent tension for smoother stitching across long embroidery runs

- Plastic-sided construction prevents oil absorption and distortion, extending bobbin lifespan and reducing maintenance interruptions

- Value pack of 144 bobbins offers cost-effective bulk purchasing for high-volume sewing or craft businesses

- Quality control inconsistencies reported by some users, including uneven winding that can trigger machine sensor issues

- Thread weight discrepancies noted in reviews, with some receiving 90wt instead of the expected 60wt

- Occasional fiber shedding and burrs on bobbin seams may cause thread breaks or require extra machine cleaning

4. Dreamstitch Blind Hem Presser Foot

Precision hemming demands steady foot controller input, and the Dreamstitch Blind Hem Presser Foot helps you maintain consistent sewing speed through its grooved fabric guide. This low-shank accessory holds lightweight to medium fabrics for blind hem techniques without constant manual correction, letting you focus on speed control instead of edge alignment.

Hem stitch quality improves when the foot feeds material evenly, reducing the jerky pedal adjustments that cause uneven stitching.

Check fabric compatibility before starting—cotton and linen work best, while heavy materials need alternate sewing machine accessories for reliable presser foot design performance.

| Best For | Sewers who want invisible hems on lightweight fabrics like cotton and linen without constantly adjusting fabric edges during stitching. |

|---|---|

| Brand | DREAMSTITCH |

| Material | Metal |

| Primary Use | Invisible Hemming |

| Compatibility | Low Shank Machines |

| Color | Metal |

| Weight | N/A |

| Additional Features |

|

- Grooved guide keeps fabric aligned so you can focus on steady pedal control instead of manual corrections

- Works with most low-shank machines from brands like Brother, Babylock, and Simplicity

- Creates professional-looking blind hems that are barely visible on the finished side

- Won’t fit high-shank machines and some users report compatibility issues even with listed models

- Limited to lightweight and medium fabrics—heavy materials need a different foot

- Small needle and proper setup required or you’ll get skipped stitches and fabric puckering

5. HON Office Chair Mat

Stable footing transforms foot controller responsiveness, and the HON Office Chair Mat delivers that foundation through its 36″ x 48″ polyurethane surface. This clear desk accessory keeps your workspace optimized by preventing chair drift during speed adjustment sequences, letting you hold precise sewing speed without repositioning between fabric passes.

The anti-skid backing grips carpet reliably, reducing the micro-movements that disrupt fine speed control on your sewing machine. Office ergonomics matter in sewing rooms—chair mat materials designed for floor protection eliminate distractions, keeping your focus on consistent pedal pressure instead of seat stability.

| Best For | Sewers who use foot pedals on carpeted floors and need a stable surface to prevent chair movement during precision speed control. |

|---|---|

| Brand | HON |

| Material | Polyurethane |

| Primary Use | Floor Protection |

| Compatibility | Carpeted Floors |

| Color | Clear |

| Weight | N/A |

| Additional Features |

|

- Anti-skid backing keeps the mat from shifting on carpet, which helps maintain consistent pedal pressure without chair drift

- Clear 36″ x 48″ surface blends into any sewing room while protecting carpet from chair wear

- Smooth polyurethane material allows your chair to glide easily when repositioning between projects

- Takes up to 72 hours to fully flatten after unboxing, delaying setup

- May not grip well on very dense carpeting and could require frequent repositioning

- Can develop cracks and indentations over time with heavy use

6. Outus Prewound Thread Bobbins for Sewing Machines

Thread quality affects sewing speed more than most sewers realize, and the Outus Prewound Thread Bobbins deliver consistent tension that keeps your foot pedal control smooth. You’ll get 50 class 15-compatible bobbins in organized bobbin storage, eliminating downtime from manual winding—prewound benefits that translate to uninterrupted sewing efficiency.

The 0.25kg thread type works across Brother and standard sewing machines, though you should verify compatibility before purchase. When your bobbin refills arrive ready to use, you maintain better speed control because thread tension stays uniform throughout each project.

| Best For | Sewers who want to skip the tedious bobbin-winding step and jump straight into projects with ready-to-use thread in multiple colors. |

|---|---|

| Brand | Brother |

| Material | Plastic |

| Primary Use | Sewing Projects |

| Compatibility | Brother Machines |

| Color | Assorted |

| Weight | 7.7 ounces |

| Additional Features |

|

- Saves tons of time since you don’t have to wind your own bobbins—just grab one and start sewing

- Comes with 50 bobbins in different colors, so you’ve got options for pretty much any fabric or project

- Works with Brother and most standard machines that use class 15 bobbins, making them versatile for everyday use

- Thread quality is hit-or-miss—some users say it’s just “OK” and not as smooth as premium brands

- Bobbins can break if you drop them, so you need to handle them carefully

- Finding where the thread starts can be tricky, which wastes time when you’re trying to load a new bobbin

7. Janome Blind Hem Foot

When you’re tackling blind hemming at higher sewing speed, the Janome Blind Hem Foot transforms your foot pedal control through its centered metal guide and three anti-slip grooves. Achieve sewing accuracy on curtains and garments by folding fabric precisely against the guide, which creates the slack needed for nearly invisible hem stitching.

The rectangular metal construction maintains stability during fabric folding, though you should verify compatibility with your specific Janome model before purchase. Practice speed control on scrap material to dial in your sewing techniques and foot calibration for professional results.

| Best For | Sewers who want professional-looking, nearly invisible hems on curtains and garments without the time investment of hand-stitching. |

|---|---|

| Brand | Janome |

| Material | Metal |

| Primary Use | Blind Hemming |

| Compatibility | Janome Machines |

| Color | Metal |

| Weight | N/A |

| Additional Features |

|

- Metal guide and anti-slip grooves keep fabric aligned for consistent, accurate blind hem stitches

- Creates the right amount of upper tension slack so your hem practically disappears on the finished side

- Works well on various projects from lightweight curtains to medium-weight garment hems

- Doesn’t fit all Janome models, so you’ll need to double-check compatibility before buying

- Takes some practice on scrap fabric to get your technique and machine settings dialed in

- Results can vary depending on your fabric type and the quality of your presser foot

8. Brother Blind Stitch Foot

You’ll gain exceptional stitch concealment with the Brother Blind Stitch Foot‘s adjustable sole plate, which locks fabric alignment during edge finishing at any sewing speed. This genuine Brother accessory accommodates all left-to-right needle locations on 7mm feed dog machines, giving you precise foot calibration through its built-in seam guide.

Control your foot pedal pressure while blind stitching hems on garments and home décor—the plastic construction manages lightweight to medium fabrics effectively.

Practice tension adjustments on scraps first, since the foot requires trial-and-error tuning before you’ll achieve consistently invisible seams.

| Best For | Sewers working on delicate fabrics like chiffon or satin who need invisible hems on garments and home décor projects without bulky topstitching. |

|---|---|

| Brand | Brother |

| Material | Plastic |

| Primary Use | Edge Stitching |

| Compatibility | Brother 7mm Machines |

| Color | Silverwhite |

| Weight | N/A |

| Additional Features |

|

- Adjustable sole plate locks fabric alignment and accommodates any needle position for precise, consistent seam widths across various projects

- Works effectively with 7mm feed dog Brother machines to create nearly invisible stitches on lightweight to medium fabrics

- Built-in seam guide allows custom width settings for versatile applications including blind hems, edge stitching, and fabric joining

- Instruction manual lacks clarity for beginners, requiring significant trial-and-error to dial in proper tension, length, and width settings

- Plastic construction may feel cheaply made compared to other presser foot options

- Demands practice and multiple test runs on scrap fabric before achieving consistently invisible results

9. ThreadNanny Sewing Machine Binder Foot

When edge finishing methods demand speed control precision, the ThreadNanny Sewing Machine Binder Foot transforms your fabric binding techniques. This 3.5 x 2.4 x 0.8-inch attachment fits low shank snap-on machines, guiding and folding bias tape through its funnel while you adjust your foot pedal pressure.

You’ll maintain consistent thread tension control on lightweight materials, though thick quilts exceed its capabilities.

Since sewing machine compatibility requires matching your presser foot shank system and no instructions come included, test your setup on scraps first—proper needle alignment prevents the wavy bindings that plague rushed installations.

| Best For | Sewers who regularly work with lightweight to medium-weight fabrics and want to speed up bias binding projects with cleaner, more professional-looking finishes. |

|---|---|

| Brand | ThreadNanny |

| Material | Plastic |

| Primary Use | Bias Binding |

| Compatibility | Low Shank Machines |

| Color | N/A |

| Weight | 0.64 ounces |

| Additional Features |

|

- Saves significant time by folding and feeding bias tape in one smooth motion instead of doing it manually

- Works across multiple low shank sewing machine brands, making it a versatile addition to your presser foot collection

- Creates consistent, professional results on decorative edges and rolled hems when properly set up

- Doesn’t include instructions, so beginners may struggle with initial setup and alignment

- Can’t handle thick quilts or bulky projects, limiting its use to thinner materials

- May require a separate low shank adaptor depending on your specific machine model

Frequently Asked Questions (FAQs)

Can foot pedals work with all machine brands?

Not always. Most sewing machines use standard electrical connectors, but brand compatibility varies. Computerized models often need specific pedal adapters for full speed control range.

Check your machine’s manual for supported universal connectors and foot pedal types.

How often should pedals be replaced or serviced?

You’ll need to inspect your foot pedal during your annual sewing machine maintenance. Replace it when you notice intermittent operation, visible damage, or loss of speed control—usually after five to ten years of regular use.

Are wireless foot pedals available for sewing machines?

Major sewing machine brands don’t offer wireless pedals as standard accessories. You can explore DIY Bluetooth adapters or cordless controls, but most machines rely on built-in start/stop buttons and ergonomic solutions instead.

What causes pedal lag or delayed speed response?

Pedal lag stems from motor response time, electronic interference, or calibration drift in your sewing machine.

Processing delays between foot pedal input and motor adjustment can reach several hundred milliseconds, affecting precision during speed adjustment tasks.

Do aftermarket pedals affect machine warranty coverage?

Using a third-party foot pedal can void your sewing machine warranty if the manufacturer’s terms prohibit unauthorized accessories.

Check warranty documentation carefully, confirm pedal compatibility, and retain purchase receipts to protect your consumer rights.

Conclusion

Think of a race car driver who can feel every shift in the track through the steering wheel—that’s the relationship you build with foot pedal speed settings once you’ve calibrated them to your touch.

You’ve turned a mechanical interface into an extension of your intention, where fabric weight, stitch complexity, and your own reflexes align without second-guessing.

The pedal no longer resists you; it responds, giving you complete authority over every seam you create.