This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your grandmother knew something modern sewers are rediscovering: a needle, thread, and practiced hands can repair a torn seam faster than dragging out the machine. Hand sewing isn’t just a backup plan when technology fails—it’s often the better choice for delicate fabrics, invisible hems, and precise alterations.

While machines excel at speed, essential hand sewing methods give you unrivaled control, portability, and the ability to work anywhere without plugging in. The techniques haven’t changed much in centuries because they work, from the humble running stitch that tacks fabric together to the nearly invisible slip stitch that makes professional-looking hems.

Once you’ve mastered the core stitches and understand which needle pairs with which fabric, you’ll handle everything from quick repairs to detailed embellishments with confidence.

Table Of Contents

- Key Takeaways

- Essential Hand Sewing Tools

- Selecting The Right Needle and Thread

- Preparing Fabric for Hand Sewing

- How to Thread a Needle Easily

- Tying Secure Knots for Sewing

- Running Stitch: The Foundation Stitch

- Backstitch for Strong Seams

- Decorative and Edge Finishing Stitches

- Invisible and Hemming Stitches

- Hand Sewing Tips for Best Results

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Hand sewing gives you unmatched control and portability for delicate fabrics, invisible hems, and precise alterations that machines can’t replicate—your grandmother’s needle-and-thread approach often beats dragging out equipment for quick repairs.

- Matching your needle size to fabric weight and pairing it with quality thread prevents puckering, breakage, and visible holes, while proper fabric prep through prewashing and accurate cutting sets the foundation for professional-looking seams.

- The backstitch creates machine-strong seams for high-stress areas, while invisible techniques like slip stitch and ladder stitch let you finish hems and mend tears without leaving any trace on the right side of your fabric.

- Smart habits like maintaining consistent stitch tension, using ergonomic posture to prevent hand fatigue, and troubleshooting common issues (thread breakage, fabric distortion) separate amateur work from polished, durable results.

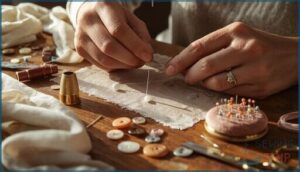

Essential Hand Sewing Tools

Before you stitch a single seam, you’ll need the right tools in your hands. Think of these essentials as your sewing toolkit—the foundation that makes every project easier, cleaner, and more enjoyable.

A well-chosen sewing kit for beginners bundles these must-haves together, giving you a ready-to-go setup without the guesswork.

Let’s walk through the must-haves that’ll set you up for success from your very first stitch.

A solid embroidery starter kit bundles everything together so you’re not scrambling for supplies mid-project.

Needle Types and Uses

Different sewing needles tackle specific tasks, so you’ll want to match the right one to your fabric.

If your machine’s thread cutter isn’t working smoothly, troubleshooting common sewing machine issues can help you get back to seamless stitching.

Sharps work beautifully for woven materials and general mending, while ball point needles glide through knits without snagging fibers.

For a complete rundown of hand-stitching techniques for different fabrics, there are dozens of tips that match the right needle type to each project.

For embroidery and decorative stitches, choose needles with larger eyes to accommodate thicker thread. Each needle type ensures your needlework stays smooth and professional-looking.

To better understand these options, consult this overview of needle types and their purposes.

Choosing Quality Thread

Once you’ve picked your needle, thread quality makes or breaks your project. Here’s what matters:

Before you even start threading, cutting your thread at a 45-degree angle creates a sharp point that slides through the needle’s eye without fraying.

- Thread Materials: Polyester blends balance strength with flexibility, while cotton suits natural fabrics but may shrink.

- Fiber Strength: Core spun threads resist breakage under stress and repeated washing.

- Color Fastness: Quality dyes won’t fade or bleed onto your fabric.

- Thread Finish: Smooth coatings reduce friction and prevent annoying tangles.

It’s vital to think about how when starting any hand sewing project.

Store spools in cool, dry spots away from sunlight—proper thread management keeps colors vibrant and fibers strong for years.

Scissors, Thimbles, and Accessories

Sharp scissors are non-negotiable—dressmaker shears with 7-to-10-inch blades keep fabric flat, while small snips trim curves and clip threads without dulling on paper.

A well-fitted thimble protects your pushing finger; metal suits heavy fabrics, leather molds to your shape, and rubber feels gentle on lightweight materials.

Round out your sewing kit essentials with straight pins, a magnetic pin cushion, and a tape measure for precision.

| Tool | Material Options | Best For |

|---|---|---|

| Scissors | Steel, carbon blades | Cutting fabric, trimming seams |

| Thimble | Metal, leather, rubber | Pushing needles through layers |

| Pin Cushion | Magnetic, wrist-strap | Holding pins within reach |

Needle Threaders and Marking Tools

Wire-loop threaders slip fine thread through tiny needle eyes in one pass, while spring-loaded models punch it through with a quick press—both beat squinting under a lamp.

Water-soluble fabric pens and disappearing-ink markers transfer pattern lines that vanish after washing or within 72 hours, so you’ll mark seam allowances without permanent traces cluttering your finished work.

Selecting The Right Needle and Thread

Pairing the right needle with the right thread is like choosing the perfect dance partner—get it wrong, and everything feels awkward and frustrating. The fabric you’re working with, the type of project you’re tackling, and how you store your materials all play a role in getting clean, professional results.

Matching needle to thread is like finding a dance partner—the wrong pairing makes every stitch feel awkward and frustrating

Here’s what you need to know to make smart choices every time.

Matching Needle Size to Fabric

Choosing the right needle size keeps your fabric damage-free and your stitch quality smooth. Lightweight fabrics like silk need fine needles, sizes 9 to 12, while heavy denim demands thick sizes 1 to 4.

Match needle diameter to fabric thickness so thread selection flows naturally, too—you’ll avoid puckering, broken threads, and those annoying holes that won’t press out.

Thread Types for Different Projects

Cotton threads work beautifully on woven fabrics like linen and quilting cotton because they have low stretch and handle high heat. Synthetic fibers—polyester and nylon—bring strength and flexibility, making them perfect for knits and heavy wear items.

Thread weights matter, too: lighter 50 weight suits garment seams, while bold 12 weight stands out in visible mending.

Decorative threads add shine to embroidery, but save structural work for project threads built for durability.

Tips for Thread Storage and Management

Beyond choosing the right thread types for your sewing kit, smart thread organization prevents headaches down the line. Store spools away from sunlight—UV rays weaken fibers and fade colors.

Use bobbin storage boxes or spool management racks with pegs to keep colors separated, and try spool huggers for tangle prevention.

Color coding by shade family speeds up your next project, while proper thread management tips save time and preserve quality.

Preparing Fabric for Hand Sewing

Before you make your first stitch, you need to get your fabric ready—this step makes the difference between a finished project that looks polished and one that puckers or shifts. Proper preparation prevents surprises like shrinkage, crooked seams, or frayed edges down the line.

Let’s walk through the three key steps that set you up for sewing success.

Pre-washing and Ironing Techniques

Proper fabric prep is like building on solid ground—it sets the stage for everything that follows. Prewashing removes surface finishes and stabilizes shrinkage, especially on natural fibers like cotton and linen, which can shrink 3 to 5 percent. Then, steam pressing while fabrics are still damp relaxes fibers and smooths wrinkles beautifully.

- Use cool or warm water to minimize color fade during prewash

- Iron fabrics slightly damp for smooth, crisp results with less effort

- Choose the correct heat setting to prevent scorching or unwanted shine

- Place a press cloth between iron and delicate textiles for protection

- Clean your iron soleplate regularly to avoid sticky marks and transfers

Marking Seam Lines and Patterns

Accurate pattern transfer turns printed symbols into real seam lines you can actually sew. Tailors chalk, water soluble pens, and tracing wheels are your go-to marking tools for capturing darts, pockets, and grainline alignment from sewing patterns.

Test every marker on a scrap first—some fade fast, others set with heat. Precision here means seams that match perfectly, so measuring tape and careful sewing pattern interpretation make all the difference.

Cutting Fabric Accurately

Clean cuts set you up for seams that actually match. Sharp dressmaking scissors glide along fabric grain without pushing or chewing edges, while rotary cutting paired with a mat keeps long strips ruler-straight.

- Keep fabric flat on the table to prevent stretching

- Cut slippery satin in single layers using weights for edge control

- Use long, steady strokes that follow the weave direction

- Replace dull blades immediately—they create wavy, inaccurate cuts

Measuring tape confirms each piece before you trim.

How to Thread a Needle Easily

Threading a needle might seem tricky at first, but with the right techniques, you’ll sail through it every time. The secret isn’t just about your eyesight or steady hands—it’s about preparing your thread and using a few smart tricks.

Let’s walk through three simple methods that’ll make threading feel smooth, whether you’re working with fine silk or chunky embroidery floss.

Cutting and Angling Thread Ends

A clean, angled cut is your ticket to stress-free threading. Trim your thread at a 45-degree angle with sharp sewing scissors—this creates a pointed tip that slips through the needle eye in one go, no frustration required.

The angled edge keeps fibers compact and prevents fraying, especially when you’re working with thicker threads or weaving delicate stitches by hand.

Using Needle Threaders

Even with a perfect angled cut, a needle threader can save you time and eye strain. The classic wire loop style is a staple in any sewing kit—you slip the thin loop through the needle eye, place your thread through it, then pull back to guide the thread straight through.

It’s a game changer for tiny-eyed needles or when you’re working with slippery threads that refuse to cooperate.

Waxing Thread to Prevent Tangles

Now that your thread is loaded, waxing becomes your secret weapon for tangle prevention. Run the strand over a beeswax or paraffin block with a smooth stroke—this thread coating cuts friction and helps stitches glide through fabric without knotting.

It’s especially helpful in hand sewing when you’re pulling thread through multiple layers. Plus, the wax types you choose can slightly stiffen the strand, giving you better control over your needle and weaving techniques.

Tying Secure Knots for Sewing

A good knot is what keeps your stitches from unraveling, so it’s worth learning how to tie one that stays put. You’ll want a technique that’s quick, secure, and doesn’t create a bulky bump in your fabric.

Let’s cover the basics, plus a few clever alternatives and tips to prevent slipping.

Basic Knot Tying Techniques

Mastering knot security starts with choosing the right knot types for hand sewing. The square knot offers excellent thread tension when you tie left over right, then right over left—it’s your go-to for most stitches and fray prevention.

For decorative work like a French knot, you’ll wrap thread around the needle before weaving it back through. These tying methods keep your seams strong and your thread exactly where you want it.

Alternative Methods for Securing Thread

Beyond traditional knots, you can secure thread with adhesive bonds—fabric glue or fray-check liquid locks the tail after your final needle pass. Here are five alternatives that give you control:

- Safety wiring the thread tail through previous stitches creates mechanical resistance

- Thread locking by weaving back through your whip stitch

- Self locking backstitches that anchor themselves

- Wire sealing techniques borrowed from upholstery

- Using a thimble to push the needle through doubled thread layers

Preventing Knots From Slipping

A knot that won’t stay put can unravel your entire seam. You need thread friction to lock it down—wax or beeswax increases grip and prevents slipping.

Maintain equal tension control on both sides as you tighten slowly, then add knot reinforcement with a tiny backstitch or half hitch.

For slip prevention, trim tails to 2–3 millimeters and embed the knot under your seam allowance where stress won’t reach it.

Running Stitch: The Foundation Stitch

The running stitch is your starting point for hand sewing, a simple in-and-out motion that forms the basis for nearly everything else you’ll learn.

You’ll use it constantly for basting, gathering fabric, and creating quick seams that don’t need heavy-duty strength.

Let’s look at when it works best, how to stitch it properly, and what pitfalls to watch for.

When to Use Running Stitch

Running stitch is your go-to technique when you need speed and simplicity in hand sewing. This adaptable stitch works beautifully for:

- Temporary basting to hold fabric pieces before final stitching, with stitches spaced about 1/4 inch apart for easy removal

- Fabric gathering when you need controlled fullness along edges

- Quick repairs on seams that’ll be machine-sewn later

- Edge finishing on lightweight fabrics where invisibility isn’t critical

Step-by-Step Running Stitch Tutorial

Once you’ve threaded your needle and knotted the end, bring it up from the fabric’s wrong side at your starting point. Insert the needle back down a short distance ahead—about 1/8 inch works well—then repeat this in-and-out motion along your guideline. Speed up by weaving the needle through several times before pulling the thread through, keeping your fabric tension relaxed.

| Step | Action | Key Detail |

|---|---|---|

| Start | Bring needle up from back | Knot rests against wrong side |

| First stitch | Insert needle down along line | 1/8 inch stitch length typical |

| Continue | Weave needle in and out | Pull thread gently after several stitches |

| Finish | Take last stitch to back | Secure with small knot |

Common Mistakes and Fixes

Tension issues arise when you pull too hard—test thread tension on scrap fabric first to prevent puckering. Thread breakage often signals a needle-fabric mismatch; switch to finer thread on delicate materials.

Fabric distortion and uneven seam allowances usually stem from misaligned grain or sloppy measuring, so mark your lines with chalk and double-check measurements before cutting.

Backstitch for Strong Seams

When you need a seam that won’t give up on you, backstitch is your go-to stitch. It creates a strong, continuous line that rivals machine sewing, making it perfect for repairs, garment construction, and anything that needs to hold up under stress.

Let’s walk through when to use it, how to sew it properly, and the secrets to keeping your backstitches clean and consistent.

Applications of Backstitch

You’ll reach for backstitch when you need serious seam reinforcement, especially on shoulder lines and high-stress areas where fabric repair demands durability. It’s your go-to for starting and finishing hand sewing projects without bulky knots.

Backstitch also creates precise, continuous lines in embroidery designs. Its variations adapt beautifully to curves and corners, blending decorative appeal with rock-solid strength in both sewing techniques and embroidery techniques alike.

How to Sew a Backstitch

Once you’ve chosen your backstitch project, start by bringing your needle up through the fabric at your seam line. Make a small stitch forward, then bring the needle back up one stitch length ahead. Insert it down at the end of your previous stitch, weaving backward underneath.

Repeat this rhythm—forward on top, backward below—maintaining consistent stitch length and tension control for sewing precision.

Achieving Even and Neat Backstitches

Keep your backstitch technique consistent by targeting 1.5 to 2 millimeters per stitch—that’s your sweet spot for a tight, professional seam.

Thread tension management makes the difference between smooth backstitches and puckered messes, so maintain just-taut tension without pulling.

Needle angle precision matters too; push straight through at uniform depth. Fabric grain alignment keeps your line true, preventing that frustrating zigzag drift.

Decorative and Edge Finishing Stitches

Once you’ve mastered the basics, it’s time to add polish and personality to your work. Decorative stitches aren’t just pretty—they also serve practical purposes like preventing fraying and reinforcing edges.

Here are three essential finishing stitches every hand sewer should know.

Blanket Stitch for Edges

Blanket stitch gives your fabric edges both edge protection and decorative edging in one move. You’ll work the needle along the raw edge, creating evenly spaced vertical legs that lock down fraying fibers—especially helpful on wool and felt.

Adjust your tension control and spacing based on the fabric selection, keeping stitches about 3 to 6 mm apart. Try stitch variations like long-and-short or triple blanket for bolder borders on hand sewing projects.

Whip Stitch for Binding Seams

Whip stitch wraps thread over raw edges in a continuous spiral, binding seams or joining felt pieces with visible diagonal loops. You’ll insert the needle from back to front through both layers, spacing stitches 3 to 5 mm apart for solid edge finishing without stiffness.

Keep stitch tension even—too tight creates ridges, too loose lets batting peek through. Start with a hidden knot inside the layers, then work uniform angled stitches. End by weaving your thread tail through previous stitches on the wrong side. Choose strong cotton or polyester thread for durability, and align fabric edges carefully during fabric preparation so your hand sewing stays flat and professional-looking.

- Quilt binding: Secure folded binding to quilt backing with nearly invisible seam binding.

- Felt projects: Join toy or ornament edges while decorating the seam.

- Knitted pieces: Connect cast-off edges at shoulders or sides.

- Textile art: Trap batting and threads in mini quilts or postcards.

French Knots and Embellishments

French knots form tiny raised dots when you wrap embroidery thread around your needle one to three times, then pull it through fabric close to—but not exactly at—the exit point. These knot variations are perfect for flower centers, polka-dot embroidery designs, or textured sheep’s wool.

They rely on even tension and short thread lengths. Cotton floss or pearl cotton gives you the best stitch texture and prevents tangles during weaving.

Invisible and Hemming Stitches

Sometimes you need stitches that disappear into the fabric, leaving no visible trace. Invisible stitches are your secret weapon for hems, linings, and closures that look professionally finished.

Let’s walk through the techniques that’ll make your hand-sewn edges clean, strong, and virtually undetectable.

Slip Stitch (Blind Hem) Techniques

The slip stitch is your go-to Silent Hem Method when you want invisible hand sewing. You’ll hide stitches inside the hem fold—grab only a few fabric fibers with your needle so nothing shows on the right side. Thread Tension Control matters here: pull gently to avoid puckering.

This Hidden Stitch Tips technique works beautifully on woven, medium-weight fabrics, and Fabric Compatibility ensures Blind Hem Finishing looks flawless every time.

Hem Stitch for Neat Edges

Edge Finishing with hem stitch gives you a crisp, nearly invisible hemline, especially on woven fabrics. You’ll catch the fabric fold with tiny, evenly spaced stitches—keep your thread tension gentle and your needle at a shallow angle.

Fabric Preparation matters: iron a clean crease, then secure the fold with short bites.

This hand sewing technique delivers professional Hemline Control and subtle Seam Reinforcement every time.

Finishing Hems by Hand

Once you’ve worked through basic hand sewing stitches, it’s time to master Hem Finishing on real garments. Blind Stitching hides your needle work by anchoring thread into Folded Edges, while your thimble pushes through multiple layers without show.

Hand Hemming builds Seam Security with tiny catches—skip the whip stitch here and let each stitch vanish for a polished, professional edge.

Hand Sewing Tips for Best Results

Getting great results with hand sewing comes down to a few smart habits and techniques. If you want your stitches to look professional and your hands to stay comfortable, there are some tricks worth knowing.

Let’s go through the essentials to help you sew with confidence every time.

Maintaining Stitch Length and Tension

Stitch control is the difference between a seam that lasts and one that unravels after a single wash. Consistent tension keeps your stitches lying flat without puckering or gapping, and that means testing on scrap fabric first, every time.

- Use your finger pressure to guide the thread smoothly through the fabric

- Mark a sample line to monitor stitch length and spacing as you sew

- Adjust tension by changing needle size when thread snags or slips

Avoiding Fatigue and Hand Strain

Your hands aren’t built for hours of repetitive motion, so smart Ergonomic Posture is essential for Fatigue Prevention in hand sewing. Keep your forearms parallel to the floor, wrists neutral, and use a height-adjustable chair so elbows align with your workspace—this is Workspace Optimization in action.

Alternate Hand Relaxation techniques like gentle finger stretches every twenty minutes, choose sewing tools with cushioned grips for Tool Ergonomics, and let your thimble and needle do the work while you stay relaxed.

Troubleshooting Common Hand Sewing Issues

Even with the right posture, hand sewing can throw curveballs. Thread Breakage usually signals you’re using worn thread or pulling too hard, while Fabric Distortion often means your Tension Issues need adjusting. Watch for Needle Damage—bent tips cause Stitch Imperfections that’ll haunt your seams.

- Replace frayed thread before it snaps mid-stitch

- Check needle sharpness if fabric puckers or pulls

- Loosen your grip when stitches look uneven

- Rethread completely if bunching appears at seams

Frequently Asked Questions (FAQs)

What are the basics of hand sewing?

Before machines transformed garment construction, people relied entirely on hand sewing. Mastering Hand Sewing Basics starts with understanding your Sewing Kit Essentials: needle selection, thread quality, proper fabric preparation, and fundamental basic stitches.

What is the strongest hand stitch method?

When you need seam integrity that won’t quit, backstitch delivers the best fabric resistance. Its overlapping structure creates excellent thread tension and stitch strength, making it ideal for high-stress areas and lasting hand sewing techniques.

How do I fix a broken zipper by hand?

Start by inspecting your zipper’s slider and teeth alignment. Gently realign misaligned teeth with a needle, apply graphite lubricant along the track, then test slowly while guiding with your fingers for smooth operation.

Can I hand sew leather or thick materials?

You can hand sew leather and thick fabric with the right leather tools—pre-punch holes, use waxed thread, blunt needles, and a thimble.

Saddle stitching creates durable seams that won’t unravel even under stress.

How do I mend torn seams invisibly?

You’ll want to use a ladder stitch or slip stitch for invisible mending, threading your needle with matching thread and catching only the fabric edges.

Keep your stitches tiny and evenly spaced for perfect seam reinforcement and fabric repair.

Whats the best way to sew elastic waistbands?

You can sew elastic waistbands using two main techniques: create a fabric casing to thread elastic through, or attach elastic directly with a zigzag stitch.

Both methods require proper elastic sizing and finishing for a comfortable, durable fit.

How do I attach patches without puckering fabric?

Pin your patch flat with a lightweight stabilizer underneath to control fabric stretch. Use even running stitches close to the edge, adjusting stitch tension carefully, then finish with a gentle steam press for puckering prevention.

Conclusion

Think mastering essential hand sewing methods takes years of practice? You’ve just proven that wrong. With the right needle, a few core stitches, and steady hands, you can handle repairs and hems like a seasoned pro.

The beauty of hand sewing isn’t complexity—it’s precision you control stitch by stitch. Start with a running stitch today, fix that loose button tomorrow, and you’ll wonder why you ever doubted yourself.