This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

These machines bridge the gap between household models that choke on upholstery vinyl and industrial behemoths that require dedicated floor space and 220-volt outlets.

Whether you’re stitching dodgers for a sailboat, recovering restaurant booth seating, or crafting leather bags that’ll outlast their owners, choosing the right Sailrite model determines whether you’ll finish your project or fight your equipment every step of the way.

Table Of Contents

Key Takeaways

- Sailrite machines fill the niche between household models that fail on heavy materials and industrial machines requiring dedicated space, handling canvas up to 10 layers and leather up to 16-20 ounces with walking foot mechanisms that prevent skipped stitches.

- The Ultrafeed LS delivers portable straight-stitch capability at 55 pounds, the LSZ adds zigzag versatility for marine canvas work, the Leatherwork specializes in precision leather control up to 16 ounces, and the Fabricator provides stationary industrial power for continuous commercial operations.

- All-metal construction and U.S.

-based support distinguish Sailrite from competitors, with machines maintaining 60-80% resale value and achieving ROI within 18-24 months for heavy-duty users, though speed maxes out at 500-1,100 stitches per minute versus 3,000+ for true industrial models. - Match your machine choice to actual project demands—portability matters for mobile repair work, zigzag capability is essential for stretchy fabrics, and motor power must align with your thickest regular material rather than impressive specifications you won’t use.

Sailrite Sewing Machines Overview

Sailrite has built its reputation on machines that don’t quit when the fabric gets tough. Whether you’re working with sailcloth, marine canvas, or thick leather, these machines handle materials that would jam most household models.

Let’s break down what makes Sailrite different, what features you’ll find across their lineup, and who actually benefits from investing in one of these workhorses.

Brand Reputation and Quality

Reputation sets Sailrite apart in the heavy-duty sewing world. Since 1969, this Indiana-based manufacturer has built machines that consistently earn customer satisfaction scores above 4.7 out of 5, with over 92% of verified purchases rated 4–5 stars. You’re looking at all-metal construction engineered for 10+ years of service, A+ BBB accreditation, and direct U.S. support that resolves issues within three business days. The machine is also known for its compact and portable design.

Key quality indicators you’ll notice:

- Machined steel internals and aluminum housings outlast imported alternatives

- Walking-foot mechanism works with 10–16 oz materials without skipped stitches

- Factory testing ensures consistent tolerances across every unit

- Warranty support backed by 300+ repair tutorials and same-day parts shipping

- Market position between home machines and $2,000+ industrial models delivers professional capability at accessible prices

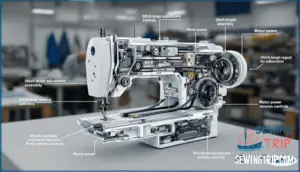

Common Features Across Models

Beyond that reputation, every Sailrite sewing machine shares engineering DNA that separates them from consumer-grade equipment. Across the lineup, from the portable Ultrafeed to the industrial Fabricator, you’ll find all-metal internal components and aluminum body frames. Walking foot mechanisms synchronize fabric feeding for uniform stitches, while proprietary motor systems—like the 550-watt WorkerB Power Pack—deliver variable speed control from less than 1 stitch per second to 550+ stitches per minute. Patented Posi-Pin safety systems protect internals during jams, and UL-certified electrical components meet domestic use standards. The Ultrafeed LSZ can perform both straight and zigzag stitches.

| Feature | Portable Models | Industrial Models |

|---|---|---|

| Construction | All-metal internals, aluminum frame | Reinforced steel gears, aluminum housing |

| Motor Systems | WorkerB Power Pack (550W) | Workhorse Servo Motor (3/4 HP) |

| Stitch Control | Walking foot, adjustable 1–6mm length | Compound walking foot, up to 8mm length |

| Safety Systems | Posi-Pin overload protection | Heavy-duty overload protection, motor thermal guards |

| Portability | Reinforced carrying case, 55 lbs | Fixed installation, 100+ lbs |

These shared capabilities mean you’re working with professional-grade tools whether you choose portability or stationary power.

Ideal Users and Applications

With these shared mechanical foundations in place, you can match Sailrite sewing machines to specific work environments. DIY enthusiasts tackle boat canvas and upholstery projects using portable Ultrafeed models, while marine professionals rely on industrial machines for high-volume marine fabric projects. Leather applications and industrial sewing operations demand the precision of stationary units designed for continuous production.

- Marine canvas fabricators handle Sunbrella assemblies, dodgers, and bimini tops with compound walking foot systems

- Custom upholstery shops complete automotive interiors and furniture restoration using zigzag capabilities for decorative stitching

- Leather craftspeople process 16-ounce hides for saddles, holsters, and bag construction with specialized presser feet

- DIY canvas projects range from sailboat covers to RV awnings, benefiting from variable speed control and portability

Comparing Top Sailrite Models

Sailrite’s lineup includes four distinct machines, each built for different sewing demands. The Ultrafeed models offer portability, while the Leatherwork and Fabricator cater to specialized heavy-duty work.

Here’s how they stack up against each other.

Ultrafeed LS (Straight Stitch)

If you want a workhorse that doesn’t quit when the fabric gets thick, the Ultrafeed LS delivers exactly that. This portable heavy-duty sewing machine tackles straight stitch work through up to 10 layers of canvas or 8 layers of sailcloth without hesitation.

The walking foot feed system paired with the Posi-Pin System ensures 100% power transfer for consistent stitching on denim projects, upholstery applications, and vinyl. Its all-metal construction and portable design make it perfect for canvas sewing on the go.

Ultrafeed LSZ (Straight & Zigzag)

The Ultrafeed LSZ-1 adds zigzag capability to the proven LS platform, opening up marine canvas and sail repair applications that demand both straight stitch and zigzag stitch versatility. You get the same portable sewing machine durability with expanded stitch control through a simple mechanical lever.

This machine is suitable for:

- Sail Repair Projects – Zigzag applications secure sail seams and prevent edge fraying on Dacron and vinyl-laminated sailcloth

- Marine Canvas Fabrication – Switch between stitch types for decorative finishes and reinforced seams on boat covers and bimini tops

- Heavy Material Penetration – Sews through 10 layers of canvas or 8 layers of sailcloth with the walking foot feed system

- Enhanced Torque Control – Optional Monster II Balance Wheel provides smoother manual operation on thick material assemblies

The Sailrite Ultrafeed LSZ delivers portable versatility without sacrificing the heavy-duty performance you need for professional-grade marine work.

Leatherwork (Leather Sewing)

When precision leather sewing demands specialized control, the Sailrite Leatherwork machine delivers servo motor accuracy and knurled presser feet designed to prevent surface marking on thick hides. You can tackle leather thickness up to 16 ounces with speed control ranging from 0.5 to 412 stitches per minute.

| Feature | Specification |

|---|---|

| Leather Types | Upholstery, suede, veg-tan, bridle, saddlery, saddle |

| Motor Power | Workhorse Servo Motor: 550W, 3/4 HP |

| Speed Range | 0.5–412 stitches/minute |

| Torque System | Power Plus Balance Wheel with speed reducer |

The walking foot mechanism ensures consistent feed through dense materials while maintaining stitch quality across canvas and denim applications beyond traditional leatherwork.

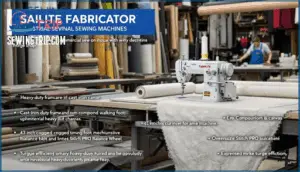

Fabricator (Industrial Use)

Full-size industrial sewing machines like the Sailrite Fabricator transform commercial canvas shops with compound walking foot mechanisms and cast-iron durability built for continuous performance. You gain precise power control down to 3/4 stitch per second through the Workhorse Servo Motor system, handling leather up to 20 ounces across professional projects.

- Torque efficiency: 43-inch cogged timing belt with oversized Stitch PRO Balance Wheel minimizes motor wear during extended operation cycles

- Industrial applications: Built for canvas, upholstery, and awning shops requiring uninterrupted heavy-duty materials processing

- Vibration reduction: Cast-iron structure with machined components ensures stability through thick denim, vinyl, and drapery fabric assemblies

- Varied capacity: Processes heavy canvas and industrial-grade leather while maintaining consistent stitch quality on varied materials

- Professional-grade construction: Hand-assembled at Sailrite’s Indiana facility, exceeding 100 pounds for stationary workstation integration

Key Features and Technical Specs

Once you know which Sailrite machine fits your work, you’ll want to understand what it can actually do. The specs matter because they determine how thick your materials can be, how fast you can sew, and what thread you’ll need.

Let’s break down the key technical features that separate one machine from another.

Stitch Options and Capabilities

Your machine’s stitch versatility can make or break thick-layer work. The Ultrafeed LS accommodates straight stitches up to 6mm, ideal for long runs on canvas and sailcloth. Need zigzag stitch options? The LSZ offers adjustable zigzag stitch width to 5mm plus straight stitch capability.

All current Ultrafeeds include the EZ Set Plate for stitch length control—thumbscrews lock in perfect forward-reverse matching. Material compatibility spans leather to upholstery fabric, with zigzag stitches flexing seams under load.

Motor Power and Speed Control

Consistent torque is the backbone of multi-layer penetration, especially when punching through 10 layers of canvas or heavy leather.

The WorkerB Power Pack Motor System delivers 2.5 times the power of standard portable motors, giving you speed variability from 1 to 550 stitches per minute.

The Workhorse Servo Motor pushes 550 watts with adjustable control between 400 and 3,600 stitches per minute. Its brushless design maintains torque consistency even at crawling speeds.

Power consumption drops roughly 20% compared to clutch systems, and you’ll gain servo motor benefits like quieter operation and precise low-speed control for detailed work.

Thread and Needle Compatibility

Pairing the right needle with your thread size determines whether you’re penetrating thick canvas cleanly or shredding fibers mid-seam. Ultrafeed models handle Tex 30 through Tex 92 thread with needles ranging from size 10 to 22 under 135×16 or 135×17 systems, while the Fabricator pushes up to Tex 138 with size 24 needles.

Match lightweight fabrics with Tex 30–40 thread, marine canvas with Tex 90–92, and heavy leather with Tex 135 for consistent stitch formation and minimal thread fray.

Accessories and Add-Ons

Beyond needle-thread pairing, the right accessories transform your machine into a specialized tool. Sailrite’s accessory packages offer package compatibility across LS and LSZ models, delivering material optimization for canvas, leather, or upholstery work.

Consider these functional benefits:

- Speed Reduction Kit – drops stitching to 640 SPM for precision control

- Binder Attachments – 3/4" and 1" widths for professional edge finishing

- Monster II Balance Wheel – adds 7 pounds of inertia for smoother hand-cranking

- Leather Craft Tool Kit – includes smooth feet, swing gauge, and specialized needles

These sewing machine accessories provide economic value through bundled pricing while extending your machine’s capabilities without replacing components.

Pros and Cons of Sailrite Machines

Every sewing machine has its strengths and trade-offs, and Sailrite’s lineup is no exception. Understanding what these machines do well and where they might fall short will help you make a confident decision.

Let’s break down the advantages, limitations, and support you can expect from Sailrite.

Advantages for Heavy-Duty Projects

When you’re tackling thick canvas or multi-layer assemblies, Sailrite’s walking foot mechanism and reinforced structural design deliver the material handling power you need. The Ultrafeed models handle up to 3/8-inch fabric stacks without slippage, while motor efficiency at slow speeds prevents needle breakage on dense weaves.

Economic advantages emerge through reduced downtime and stitch adaptability across heavy-duty applications, making these machines reliable workhorses for marine canvas and upholstery projects.

Limitations and Drawbacks

While Sailrite machines excel at heavy-duty work, speed limitations become apparent—the Ultrafeed LSZ maxes out around 500–700 stitches per minute, far below industrial standards exceeding 3,000. Vibration issues from the aluminum chassis can shift your table during extended runs, and portability tradeoffs mean that 55–62 pound weight complicates transport.

Maintenance needs include manual lubrication at multiple points, and material constraints limit thickness beyond 3/8 inch. These sewing machine drawbacks don’t diminish overall machine quality and reliability, but understanding them helps you evaluate cost versus application.

Customer Support and Warranty

On the support side, you get access to technical support for life. Phone reps average under two minutes on weekdays, backed by over 300 video tutorials that’ve racked up 20 million views.

Warranty coverage spans 90 days standard, though the Fabricator extends to two years. The return policy requires authorization within 30 days, and you’ll cover shipping both ways.

User satisfaction sits at 3.4 out of 5 stars, with praise for responsiveness but scattered complaints about email delays.

Choosing The Best Sailrite Machine

Picking the right Sailrite machine comes down to understanding what you’ll actually sew, where you’ll use it, and how much you’re willing to invest.

Your project requirements, workspace setup, and budget all play a role in finding the best fit.

Let’s break down the key factors that’ll help you make a smart decision.

Assessing Sewing Needs

Before you even think about which Sailrite sewing machine to buy, you need to match your project reality to machine capability. Start by mapping what you’ll actually be sewing—not what you might do someday—against these critical factors:

- Project Material: The Ultrafeed LS and LSZ handle canvas and upholstery fabrics up to 10 mm thick, while the Leatherwork specializes in leather up to 3/8 inch, and the Fabricator addresses both leather and multi-layered fabrics at 16 oz per yard weights.

- Sewing Frequency: Hobbyist models like the LSZ work well for up to 15 hours weekly, but the Fabricator accommodates continuous daily operation exceeding 8 hours without motor strain.

- Skill Level: Entry-level users benefit from the simplified straight-stitch LS, intermediate DIYers prefer the LSZ’s zigzag versatility, and professionals handling heavy vinyl or leather projects need the Leatherwork’s precision control.

Your budget constraints matter, but choosing a sewing machine that can’t handle your project size or material thickness costs more in frustration than money saved upfront.

Portability Vs. Industrial Use

When you’re deciding between portable and industrial sewing machines, location flexibility drives the choice. The Ultrafeed LS and LSZ—at 55 pounds each—support mobile applications like boat repair or outdoor upholstery work, operating on standard 110V power requirements.

The Fabricator demands dedicated space considerations and two-person transport, but delivers industrial-grade stitch consistency at 1,100 stitches per minute for production environments requiring greater durability needs.

Budget and Long-Term Value

Your initial investment spans $995–$1,700 for the Ultrafeed LSZ, while the Fabricator runs $1,400–$1,600. Operating costs stay under $50 annually, and resale value holds at 60–80% of retail.

Sailrite’s warranty and customer support reduce long-term repair expenses, with heavy-duty users achieving ROI within 18–24 months through eliminated outsourcing costs and sustained durability.

Frequently Asked Questions (FAQs)

Is a Sailrite worth it?

Yes—if you’re tackling thick canvas, leather, or marine fabrics regularly. With resale values holding around $1,000–$1,700 and decades of service, the initial investment pays off through durability, solid customer support, and project suitability that hobby machines can’t match.

Sailrite machines justify their $1,000+ price tag if you regularly work thick canvas, leather, or marine fabrics—durability and resale value deliver long-term ROI

What is the most reliable brand of sewing machine?

Janome and Bernina lead in brand reliability, consistently ranking highest for durability and user satisfaction. Both offer strong warranty coverage, low repair costs, and lifespan estimates exceeding 20 years with proper maintenance, outperforming most competitors in technical support quality.

Which industrial straight sewing machine is the best?

The Sailrite Fabricator stands out among industrial straight stitch machines, delivering impressive industrial power and stitch quality through materials up to 1/2 inch thick.

Its servo motor provides enhanced speed control, reaching 1,108 stitches per minute, while the cast iron frame ensures durability that minimizes long-term costs for heavy-duty sewing projects.

Where are Sailrite sewing machines made?

Sailrite assembles machines at their Indiana headquarters, where they’ve maintained operations since Components come from international suppliers in China, Korea, Taiwan, and Mexico, then undergo quality control and final assembly in Columbia City to guarantee durability for heavy-duty canvas work.

How do I thread the Sailrite machine?

Threading your Sailrite machine isn’t rocket science, but treat it like defusing a bomb—one wrong move and nothing works.

Start with upper threading through tension discs and guides, wind your bobbin correctly, insert it clockwise, seat the needle flat-side-back, and match needle selection to your fabric.

Can Sailrite sew multiple layers at once?

Absolutely, your Sailrite manages multiple layers like a champ. The Ultrafeed models power through up to 10 layers of marine canvas, while the Fabricator conquers 16 layers of heavy fabric thanks to its walking foot mechanism and high-torque motor—perfect for thick materials and heavy-duty sewing machine projects requiring superb stitch quality.

What maintenance does a Sailrite require?

Most owners don’t realize lint buildup after just eight hours of heavy stitching can trigger performance issues. Your Sailrite needs routine cleaning of feed dogs and bobbin areas, regular lubrication with sewing machine oil every eight hours, timely needle management, and preventative measures like annual servicing to avoid neglected maintenance consequences.

How to troubleshoot skipped stitches on Sailrite?

Skipped stitches on your Sailrite sewing machine commonly arise from needle problems, thread tension issues, bobbin winding errors, timing misalignment, or fabric handling missteps.

Check your needle type first, adjust thread tension carefully, confirm proper bobbin insertion, and maintain consistent fabric feed while weaving through heavy materials.

Are Sailrite sewing machines portable?

Picture hauling your gear to a boat dock for canvas repairs—you’ll want a machine that moves with you. Yes, Sailrite machines are portable, especially the Ultrafeed LS-1 at 20 pounds with a carry case.

The LSZ-1 weighs 49 pounds, balancing portability with stability for mobile projects requiring zigzag stitches.

How long does shipping typically take for Sailrite?

Sailrite ships in-stock orders within 1-2 business days, with FedEx Ground delivery taking 1-5 days in the contiguous US.

Product availability and shipping method affect total timeframes, though customer support helps track orders efficiently.

Conclusion

Your machine won’t transform your skills—it’ll simply stop fighting you while you develop them. The best Sailrite sewing machine amplifies what you already know, letting you tackle projects that would send lesser equipment to the repair shop.

Match the motor power to your heaviest material, prioritize zigzag capability if you’re working with stretchy fabrics, and remember that portability matters when you’re stitching canvas on a boat deck. Choose based on what you’ll actually sew, not what sounds impressive.

- https://www.sailrite.com/Which-Sewing-Machine-is-Right-for-Me

- https://directus.sailrite.com/assets/eef323b3-d2b7-4093-a8c3-695a32a19208

- https://blog.sailrite.com/meet-our-customers

- https://www.reddit.com/r/Leatherworking/comments/16la0pe/does_anyone_have_any_experience_with_sailrites

- https://makerspaces.northeastern.edu/create/library/sailrite-sewing-machine-diy-training