This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

For lightweight cotton like voile, use a shorter stitch length of 1.8-2.5mm with reduced tension around 3-4.

Medium-weight cottons work well with 2.5mm stitch length and standard tension of 4-5.

Heavy cotton like denim needs longer stitches at 3-4mm and higher tension up to 6.

Always match your needle size to fabric weight—universal 80/12 for light cotton, 90/14 for medium, and 100/16 for heavy.

A straight stitch works for most seams, while zigzag prevents fraying on raw edges.

The secret lies in understanding how thread weight and fabric thickness create the perfect stitch harmony.

Table Of Contents

Key Takeaways

- Match your needle size to fabric weight – You’ll need 70/10 needles for lightweight cotton, 80/12 for medium-weight, and 90/14 to 100/16 for heavy fabrics like denim to prevent skipped stitches and fabric damage.

- Adjust tension based on cotton type – You should set tension between 3-4 for lightweight cottons to prevent puckering, 4-5 for medium-weight, and up to 5-6 for heavy cottons to ensure secure seams.

- Use proper stitch length for each project – You’ll get the best results with 1.8-2.5mm for delicate cottons, 2-2.5mm for standard quilting cotton, and 2.5-4mm for thick materials like canvas.

- Test settings on scraps first – You can’t predict how different cotton weights will behave, so always test your tension, stitch length, and needle combination on leftover fabric before starting your actual project.

Cotton Fabric Tension Settings

Getting your cotton fabric tension right means the difference between professional-looking seams and frustrating puckered messes.

Start with tension settings between 4 and 5 for most cotton fabrics, then adjust based on your specific fabric weight and project needs.

General Tension Guidelines

For cotton fabrics, set your sewing machine tension between 4 and 5 to achieve proper tension balance without fabric damage.

This range guarantees stitch security while preventing thread breakage.

Always perform scrap testing on leftover fabric before starting your project.

When in doubt, check your manual consultation guide for specific cotton stitch settings recommendations based on your machine model.

Fabric Weight and Thickness

Fabric weight and thickness are game-changers for your cotton stitch settings. Lightweight cotton needs gentler tension (2-3) to prevent puckering, while heavyweight cotton demands firmer tension (4-5) for secure seams.

Your fabric weight determines everything—match your tension settings or watch your seams fail.

Here’s your fabric weight roadmap:

- Lightweight fabrics: Use shorter stitch length (1.5-2mm) and reduce tension

- Medium-weight cotton: Set 2.0-2.5mm stitch length with tension around 4

- Heavyweight materials: Increase to 2.5-4mm stitch length with higher tension

Thread Type and Weight

Your thread choice affects tension balance just as much as fabric weight.

Cotton thread works best with cotton fabric, creating natural harmony in your stitches.

Match thread weight to your fabric’s thickness – lighter threads for delicate cottons, heavier threads for canvas.

Quality thread reduces lint buildup and maintains consistent tension throughout your project.

Choosing Right Needle Size

You’ll need the right needle size to get perfect stitches on cotton fabric without damaging the material.

The needle size directly affects how cleanly your thread penetrates the cotton fibers and prevents issues like skipped stitches or fabric puckering, which is why choosing the correct size is crucial for a perfect stitches.

Matching Needle to Fabric Weight

Matching needle size to cotton fabric weight prevents damage and guarantees smooth stitching.

Use 70/10 needles for lightweight cotton, 80/12 for medium-weight, and 90/14-100/16 for heavy fabrics.

Universal needles work for most cotton types, while specialty needles handle specific thread compatibility needs.

Proper needle selection optimizes sewing machine settings and stitch length performance.

Needle Size for Different Fabrics

Your sewing machine needle size directly impacts stitch quality across different fabric weights.

Use 70/10 needles for lightweight cotton like voile, preventing fabric damage. Standard 80/12 needles work perfectly for quilting cotton and medium-weight fabrics.

Heavy cotton requires 90/14 to 100/16 needles. This universal needle size is often recommended as 80/12 for standard cotton fabrics.

This Universal Needle Guide guarantees proper needle choice matches your cotton fabric weight for superior results.

Ballpoint Vs Sharp Needles

Choosing between ballpoint and sharp needles makes the difference between smooth stitching and fabric damage.

Sharp needles work best for tightly woven fabric like cotton poplin, piercing fibers cleanly.

Your needle selection depends on cotton type—woven cotton needs sharp points, while cotton blends with stretch require ballpoint tips for preventing damage to your project, and this choice is crucial for smooth stitching.

Best Stitch Settings for Cotton

When sewing with cotton, you’ll want to choose the right stitch settings for clean seams and a professional look.

Use a straight stitch for most seams, a zigzag for stretch, and decorative stitches when you want to add some flair.

Straight Stitch for Simple Seams

Now that you’ve matched your needle to your fabric weight, it’s time to master the straight stitch for perfect seams.

The straight stitch serves as your foundation for most cotton projects, delivering reliable results with proper sewing machine settings.

Follow these steps for flawless straight stitching:

- Set stitch length for cotton between 2-2.5mm for ideal seam strength

- Adjust thread selection to match your fabric weight and color

- Maintain consistent seam allowances using your machine’s seam guides

- Apply gentle pressing techniques after stitching to set your seams

Your sewing machine tension should remain at 4-5 for most cotton fabric stitches.

This best stitch for cotton creates strong, even seams without puckering.

Practice stitch reinforcement at stress points like pocket corners for professional results.

Zigzag Stitch for Stretchy Fabrics

When straight stitches crack under stress, zigzag becomes your fabric’s best friend. This flexible stitch moves with stretchy cotton, preventing broken seams in knits and activewear.

Set your tension balance around 3-4, use a ballpoint needle type, and adjust fabric feed pressure for smooth results. Understanding the importance of a ballpoint needle type is essential for preventing fabric damage when sewing stretchy fabrics.

| Setting | Lightweight Cotton | Medium-Weight Cotton |

|---|---|---|

| Stitch width | 1.5-2mm | 2-2.5mm |

| Stitch length | 1.5-2mm | 2-2.5mm |

| Tension | 3 | 3.5-4 |

Your sewing machine settings should accommodate cotton fabric’s stretch while maintaining clean edges. Test these stitch settings on scraps first—zigzag works perfectly for stretchy fabrics when properly calibrated.

Decorative Stitches for Embellishment

Decorative stitches transform plain cotton fabric into stunning masterpieces using embroidery designs and applique techniques.

Your sewing machine settings should match the decorative thread weight you’re using. Most cotton stitch guide recommendations suggest tension between 3-4 for intricate stitch patterns.

Heavier decorative thread requires slightly higher tension, while delicate fabric painting details need lower settings for smooth results.

Many crafters find that basic stitches add elegance to their projects, which can enhance the overall visual appeal of the work, and create a sense of elegance and masterpieces.

Adjusting Tension for Balanced Stitches

You’ll achieve balanced stitches by setting your tension between 4 and 5 for most cotton fabrics.

Then testing on scraps before starting your project ensures that you have the right settings for your specific fabric, which is crucial for a professional finish.

Proper tension prevents puckering on lightweight cottons and loose stitches on heavier materials, ensuring your seams look professional every time.

Preventing Puckering and Skipped Stitches

Why do puckering and skipped stitches plague your cotton projects? Poor tension balance creates these frustrating issues that ruin otherwise perfect seams.

Follow these troubleshooting steps:

- Needle Quality – Replace dull needles immediately as they pierce fabric poorly

- Thread Matching – Use identical thread weights in bobbin and upper positions

- Machine Maintenance – Clean lint from tension disks and oil moving parts regularly

Fabric stabilization prevents stretching during sewing. Adjust your sewing machine settings gradually, testing cotton scraps first. Thread tension problems often stem from improper threading or worn components requiring immediate attention.

Achieving Smooth and Even Stitches

Smooth cotton stitching requires proper tension balance between your upper and bobbin threads.

Set your machine to tension 4-5 for most cotton weights, adjusting based on fabric thickness.

Quality thread and consistent fabric handling create professional results every time.

| Cotton Weight | Tension Setting | Thread Quality Tips |

|---|---|---|

| Lightweight | 3-4 | Use fine polyester thread |

| Medium-weight | 4-5 | Match top and bobbin threads |

| Heavy-weight | 4.5-5.5 | Choose strong cotton thread |

| Stretchy cotton | 2-3 | Consider elastic thread |

| Quilting cotton | 4-4.5 | Pre-wash fabric first |

Balanced stitching happens when your sewing machine settings work together.

Consistent seams depend on steady fabric feeding and proper stitch length (2-2.5mm for cotton).

Avoiding imperfections means testing settings on scraps before starting your project to achieve high-quality seams and ensure smooth operation.

Troubleshooting Tension Issues

When sewing machine tension goes wrong, you’ll spot telltale signs fast. Skipped stitches and thread breakage signal loose tension, while puckering fabric means it’s too tight.

Uneven stitches often stem from bobbin problems or mismatched thread weights. Check your threading first, then test different cotton thread tension settings on scraps.

Most tension troubleshooting starts with simple fixes. Cleaning the machine’s tension device regularly can also help maintain consistent performance and is a key part of managing thread tension.

Sewing Machine Settings for Cotton

Your sewing machine’s upper thread dial should typically sit between 4 and 5 for most cotton fabrics, while your bobbin thread needs to match this tension for balanced stitches.

You’ll also want to adjust your presser foot pressure based on cotton weight—lighter pressure for delicate cottons and standard pressure for medium to heavy cotton fabrics, to ensure proper adjustment.

Upper Thread Dial Settings

Your sewing machine’s upper thread dial controls tension through carefully calibrated setting ranges, typically numbered 0-9.

Master your machine’s tension dial—precision between 4 and 5 unlocks perfect cotton stitches.

For cotton fabrics, start with dial settings between 4 and 5.

Thread guides and tension disks work together to regulate flow.

Understanding proper thread control is essential for quality stitches.

When troubleshooting dial issues, adjust incrementally and test on scraps.

Different thread types may require minor tweaks to these baseline sewing machine tension settings.

The key to successful sewing is proper thread control and understanding how to use the upper thread dial.

Bobbin Thread Settings

Once you’ve set your upper thread dial, turn your attention to bobbins tension basics.

Use a standard bobbin case type and match thread weight to your top thread for balanced stitches. Wind your bobbin smoothly—no lumps or gaps.

A consistent bobbin fill prevents hiccups in sewing machine tension. For the best results, consider using quality bobbin thread.

Adjust tension settings in quarter-turns, always testing on scrap cotton first.

Presser Foot Pressure Adjustment

Adjusting presser foot pressure prevents fabric feed issues that can plague cotton projects.

Most modern machines offer adjustable foot benefits through a simple dial or lever.

When pressure’s too heavy, lightweight cotton bunches and shifts.

Too light, and thick cotton won’t feed properly.

Testing foot pressure on scraps saves you from preventing fabric damage on your main project.

Incorrect pressure settings can lead to fabric puckering and uneven seams.

Start with medium pressure, then fine-tune based on how smoothly your cotton fabric moves through the machine, to achieve a better fabric feed and prevent fabric damage.

Cotton Fabric Types and Tension

Different cotton weights require specific tension adjustments to achieve professional-looking stitches.

You’ll need to match your machine’s settings to whether you’re working with delicate cotton voile or sturdy canvas to prevent puckering and guarantee strong seams.

Lightweight Cotton Fabrics

Delicate cotton whisper-weights like voile and lawn demand gentle handling.

Set your tension dial to 3-4 for Voile Stitching and Lawn Tension adjustments.

Use 70/10 Batiste Needles with fine thread for Chiffon Seams.

Your sewing machine settings should include 1.8-2.5mm stitch length for lightweight cotton. These Muslin Settings prevent puckering while maintaining thread tension balance.

Medium-Weight Cotton Fabrics

Medium-weight cotton fabrics like poplin and quilting cotton work best with sewing machine settings of tension 4 and stitch length 2.0-2.5mm.

These mediumweight materials require thread matching with your fabric weight, typically using 80/12 universal needle types.

Poplin stitching benefits from balanced thread tension, while quilting cotton handles standard stitch settings well.

Project examples include shirts and casual wear where consistent seam quality matters most.

Consider pre-washing cotton fabric to prevent shrinkage before starting your project.

Heavy-Weight Cotton Fabrics

Heavy cotton fabrics like denim and canvas demand higher sewing machine settings for cotton to handle their substantial fabric weight.

These thick cotton materials require specific adjustments that differ substantially from lighter alternatives.

Your heavyweight needles and upholstery tension settings need careful calibration:

- Set tension dial between 4-5 for secure denim sewing

- Use 90/14 or 100/16 needles for canvas stitching

- Increase stitch length to 2.5-4mm for thick layers

- Apply higher presser foot pressure for stability

- Choose quality seam finishes to prevent fraying

These adjustments prevent skipped stitches and guarantee professional results on sturdy fabrics.

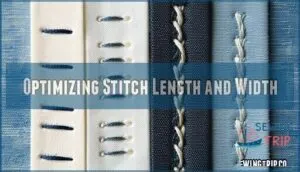

Optimizing Stitch Length and Width

Getting your stitch length and width just right can make the difference between a professional-looking seam and a messy disaster that has you reaching for the seam ripper.

The perfect stitch settings depend on your cotton’s weight, your project type, and what you want your finished seams to look like, which can be a crucial factor in achieving a perfect seam.

Stitch Length for Different Fabrics

Fabric stitch length determines how your cotton fabric behaves under your sewing machine settings.

Lightweight cotton stitches work best at 1.5-2mm, preventing fabric bunching and maintaining delicate appearance.

Medium-weight cotton requires 2-2.5mm for balanced seams that won’t pucker.

Heavy fabric stitches need 2.5-4mm lengths to penetrate thick layers effectively.

Your project-specific lengths should match fabric thickness—shorter for delicate work, longer for sturdy construction projects. The choice of stitch length is crucial as it affects the overall appearance and durability of the fabric, making fabric stitch length and balanced seams essential considerations.

Stitch Width for Various Projects

When selecting stitch width for cotton projects, consider your specific task.

Use narrow decorative width (1-2mm) for topstitching and applique width. Medium buttonhole width (3-4mm) works for standard garments.

Wide edge finishing (5-6mm) prevents fraying on seam allowance. Your sewing machine settings should match the cotton fabric’s weight and project requirements for best results.

Adjusting Stitch Settings for Desired Outcome

Fine-tune your sewing machine settings to achieve professional results every time.

Adjust stitch length between 1.5-4mm based on cotton fabric weight and project requirements.

Shorter stitches create refined seam appearance on lightweight cottons, while longer stitches enhance stitch strength for heavy fabrics.

Balance stitch quality with fabric hand by testing settings first. Consider texture effects and project durability when selecting final parameters.

Frequently Asked Questions (FAQs)

What is the best sewing machine setting for cotton?

Set your machine to tension 4-5 for cotton. Use a 2-5mm stitch length with an 80/12 needle. Test on scraps first—lighter cottons need lower tension, heavier ones slightly higher.

What is the best stitch for cotton fabric?

Imagine this scenario: you’re sewing your daughter’s first school dress, and the stitches keep puckering.

For cotton fabric, use a straight stitch with 2-5mm length and tension between 4-5, adjusting slightly lower for lightweight cottons to prevent fabric damage.

What needle tension for cotton?

For cotton fabrics, you’ll want to set your needle tension between 4 and

Lightweight cotton needs slightly lower tension around 3-4, while heavier cotton requires the higher end at 4-5 for balanced stitches.

What should my sewing machine settings be on?

Like a finely tuned orchestra, your machine needs harmony between tension and stitch length.

Set tension to 4-5, stitch length to 2-5mm, and use an 80/12 needle for ideal cotton sewing results.

How often should I change needles when sewing cotton?

Change your needle after every 8-10 hours of sewing or when switching projects. Cotton’s natural fibers can dull needles quickly, causing snags and skipped stitches that’ll ruin your beautiful work.

Can I use cotton thread with polyester fabric?

Yes, you can use cotton thread with polyester fabric.

Cotton thread works well for most polyester projects, though it may shrink slightly during washing.

For best results, match thread weight to your fabric weight and test tension settings first.

What causes thread to break while sewing cotton?

Thread breaks during cotton sewing due to incorrect tension settings, old or bent needles, poor thread quality, improper threading, or sewing too fast.

Check your tension dial, replace needles regularly, and verify proper threading paths.

Should I backstitch when sewing cotton seams?

Building strong seams requires anchoring your work—absolutely backstitch at cotton seam beginnings and ends. This secures stitches, prevents unraveling, and guarantees your project won’t fall apart with wear.

How do I sew cotton knits without stretching?

Use a ballpoint needle, lower tension (2-3), and gentle handling. Stretch the fabric slightly while feeding it through the machine to prevent distortion and maintain the knit’s natural give.

Conclusion

Like a tailor adjusting each thread for the perfect fit, mastering the best stitch settings for cotton transforms your sewing from amateur to professional.

You’ve learned to match needle size to fabric weight, adjust tension for different cotton types, and select appropriate stitch lengths.

Remember that lightweight cottons need gentler settings while heavy fabrics require stronger adjustments.

Practice these techniques consistently, and you’ll create beautiful, durable seams every time. Your cotton projects will thank you for this attention to detail.

- https://mytextilefabric.com/blogs/news/10-must-know-tips-for-sewing-with-100-cotton-fabric

- https://nancysnotions.com/stitch-length-doesnt-have-to-be-confusing/

- https://www.youtube.com/watch?v=t6Jvq_q0N-o

- https://icefabrics.com/blogs/news/cutting-and-sewing-guides-for-cotton-fabrics

- https://wunderlabel.com/blog/p/choose-right-sewing-thread/