This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ll pay more for features like higher needle counts, larger embroidery areas, faster stitching speeds, and advanced connectivity.

A 6-needle machine typically costs $12,000-$25,000, while 15-needle models range from $30,000-$80,000.

Multi-head commercial units for production work start at $50,000.

Your specific needs—whether you’re starting a small business or scaling up production—will determine which price range makes sense, and smart buyers know that understanding the key cost drivers can help you avoid overpaying for features you don’t need, which is a critical consideration for making an informed decision, and ultimately finding the right machine for your production work.

Table Of Contents

Key Takeaways

- You’ll pay $8,000-$25,000 for basic single to 6-needle machines, while 15-needle commercial models cost $30,000-$80,000, and multi-head production systems start at $50,000

- Your total investment includes hidden costs beyond the machine price – budget an extra $600-$4,000 annually for software, hoops, threads, stabilizers, and maintenance

- You’ll get better value by matching machine features to your actual production needs rather than buying the most expensive option – consider needle count, embroidery area size, and stitching speed based on your workflow

- You can reduce costs through smart shopping strategies like comparing local dealers vs. online platforms, exploring financing options, and considering used machines from reputable liquidators

Commercial Embroidery Costs

You’ll find commercial embroidery machine prices vary widely based on several key factors that directly impact your investment.

Understanding these cost drivers helps you make smart purchasing decisions that match your business needs and budget.

Factors Influencing Price

Your commercial embroidery machine’s price depends on several key factors that directly impact your investment.

Smart investment planning matches machine capabilities to your actual production needs, not wishful thinking.

Understanding these elements helps you make smarter purchasing decisions.

Here are the main factors that influence embroidery machine cost:

- Brand Reputation – Premium manufacturers command 25-40% higher prices than generic alternatives due to proven reliability and market positioning

- Advanced Features – Computerized systems, automated thread cutting, and color-changing capabilities can increase costs by 30-50% over manual models

- Built-in Tech – Digital displays, touchscreen controls, and smart connectivity features add $1000-4000 to the base price

- Machine Type – Single-head units range $5000-15000 while multi-head commercial embroidery machines start at $15000+ for high-volume production needs

Consider that the overall embroidery machine prices are also affected by market demand and technological advancements.

Features That Affect Embroidery Machine Pricing

Understanding machine features helps you decode embroidery machine prices effectively.

Feature Complexity drives costs substantially as advanced automation systems increase production capabilities.

Brand Influence affects pricing through reputation and reliability factors.

Machine Type determines base costs with single-needle models starting lower than multi-needle configurations.

Production Volume requirements influence feature selection and overall embroidery machine cost.

Included Packages with software, training, and support add value to commercial embroidery machine investments.

For hobbyists, single-needle machines are a good starting point.

Embroidery Area Size

A larger embroidery area size directly impacts commercial embroidery machine prices.

You’ll pay more for machines with bigger stitching fields because they handle complex designs and boost project versatility.

Standard hoop size ranges from 4×4" to 14×20", with actual embroiderable space slightly smaller.

Fabric thickness affects usable area, while production scale demands determine your ideal size requirements.

The relationship between embroidery area size and machine price is significant, as it influences the versatility of projects that can be undertaken.

Stitching Speed

Speed directly impacts commercial embroidery machine prices and your bottom line.

Machines operating at 600-1000 SPM cost more but deliver higher production volume. However, speed vs quality requires balance – excessive speeds cause needle deflection and thread breaks.

Material impact matters too; thick fabrics need slower speeds. Regular speed maintenance guarantees consistent performance.

Higher stitching speed means faster embroidery productivity, justifying premium commercial embroidery machine investments.

Built-in Designs and Fonts

Built-in designs and fonts substantially impact embroidery machine prices.

Premium commercial embroidery machines offer extensive creative options that justify higher costs.

Here’s what affects pricing:

- Design Libraries – Machines include 50-699 pre-installed designs for immediate use

- Font Collections – Premium models feature 28+ built-in fonts with multiple file format support

- Storage Capacity – Advanced machines store custom designs and expandable libraries

- Font Licensing – Commercial use requires proper licensing, adding operational costs

Design customization capabilities and design versatility directly influence embroidery machine prices.

Machines with artistic limitations cost less but restrict creative potential.

Needle Count

More needles mean fewer interruptions.

Single-needle machines require manual thread changes for each color, slowing your workflow considerably.

Multi-needle embroidery setups with 10-15 needles handle automatic color changes seamlessly.

This needle configuration dramatically improves productivity and thread management efficiency.

Commercial embroidery machine prices increase with higher needle counts, but the investment pays off through reduced labor time and enhanced production capabilities.

Connectivity Options

Wireless connectivity transforms how you manage your commercial embroidery machine.

WiFi Transfer and USB Ports let you send designs instantly from your computer or mobile device.

Network Integration connects multiple machines for streamlined production workflows.

Cloud Storage keeps your embroidery machine software and designs accessible anywhere.

Mobile Control apps let you monitor progress remotely.

These connectivity options add $200-800 to embroidery machine prices but boost productivity substantially.

Modern machines feature advanced touchscreen interfaces for simplified navigation, making it easier to use wireless connectivity and access cloud storage.

Top 5 Embroidery Machines

When you’re ready to invest in commercial embroidery equipment, these five machines represent the best value and performance in today’s market.

Each offers unique features that can transform your embroidery business from startup to established operation, which can be a key factor in taking your business to the next level with established operation.

1. Smartstitch 10 Needle Embroidery Machine

The Smartstitch 10 needle embroidery machine delivers professional results at an accessible price point.

You’ll get 1200 stitches per minute with a 14.2" x 9.5" embroidery area that handles everything from t-shirts to caps.

The 7-inch touchscreen makes operation straightforward while automatic threading saves time.

Built-in memory stores 500 designs or 32 million stitches, and at $149 monthly financing, it’s perfect for starting your embroidery business without breaking the bank, offering a great way to achieve starting your embroidery business.

Best For: Entrepreneurs and small business owners seeking a fast, user-friendly commercial embroidery machine with professional capabilities.

- High speed (1200 stitches/min) and large embroidery area for handling bulk orders.

- Beginner-friendly touchscreen interface and robust support network.

- Automatic threading and built-in design library for efficient workflow.

- Requires saving all packaging for returns, which may be inconvenient.

- Learning curve for advanced features may take a couple of months.

- Initial machine cost and required accessories can add up for new users.

2. Smartstitch 15 Needle Embroidery Machine

When you need serious embroidery power, this machine delivers.

The 15-needle system handles automatic color changes across a massive 14"x20" workspace, running at 1200 SPM, and tackles everything from leather jackets to baseball caps with precision laser positioning.

The 12" touchscreen and WiFi connectivity make design transfers seamless.

At around $6,000, you’re getting commercial-grade capabilities without breaking the bank completely.

Best For: Small business owners and ambitious home users looking for industrial-level embroidery capability, versatility, and solid support at a mid-range price.

- Handles a wide variety of materials, including hats, leather, denim, and more, with professional quality.

- Large 14"x20" embroidery area and automatic color change boost productivity for complex, multi-color projects.

- Excellent community support, ongoing training, and responsive technical service.

- Steep learning curve for new users, especially during initial setup and threading.

- Requires careful retention of original packaging for any future returns.

- Priced higher than basic machines, which may be a barrier for hobbyists or those on a tight budget.

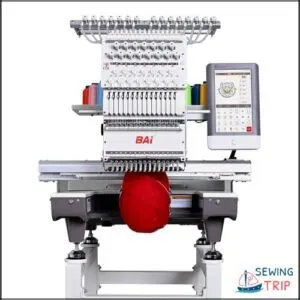

3. BAi 15 Needle Embroidery Machine

The BAi 15 Needle machine delivers commercial-grade performance at a competitive price point.

You’ll get 1,200 SPM speed with a massive 20×14 inch embroidery area for large designs.

The Institch I5 system provides step-by-step guidance that makes learning straightforward, and you can handle everything from structured caps to leather goods without skipping stitches.

The machine includes all necessary accessories and connects via WiFi or USB for easy design transfer.

Best For: Small business owners and embroidery entrepreneurs who want fast, professional results with easy operation and support.

- Commercial-grade speed (1,200 SPM) and large embroidery area for high-volume production

- Intuitive step-by-step Institch I5 system makes it easy to learn and operate

- Includes all accessories with WiFi and USB design transfer for flexible workflow

- Upfront investment may be high for hobbyists or casual users

- Large physical footprint may not suit very small workspaces

- Learning curve still exists despite guidance, especially for total beginners

4. Smartstitch 12 Needle Embroidery Machine

With twelve needles working in perfect harmony, this machine delivers professional results at 1200 SPM.

You’ll appreciate its compact 29"×23"×19" footprint that won’t overwhelm your workspace.

The 7-inch touchscreen makes operation straightforward, while the 9.5"×12.6" embroidery area handles most commercial projects.

It’s important for maximum production to review stitch speed requirements to achieve the best outcomes.

At 39kg, it’s portable enough for mobile businesses yet sturdy enough for daily production work.

Best For: Small business owners and home-based professionals who need fast, commercial-quality embroidery in a compact, user-friendly machine.

- Large embroidery area and 12-needle system allow complex, multi-color designs.

- Compact size and pre-threaded needles make it easy to set up and fit into small workspaces.

- Comprehensive training, community support, and regular follow-ups ensure a smooth learning curve.

- Learning digitizing and file quality may require time and practice.

- Time zone differences can delay customer support response.

- Stand assembly is required and may take extra setup time.

5. TOYOT 15 Needle Embroidery Machine

Many commercial users rave about the TOYOT 15 Needle Embroidery Machine for its reliability and professional output.

This machine features a 14.2" x 7.9" embroidery area and reaches 1,200 stitches per minute.

You’ll appreciate its robust metal construction that reduces vibration and noise during operation.

The 10-inch touch screen makes navigation simple, while WiFi connectivity streamlines design transfers, and it includes features like laser positioning and automatic color changes, making it perfect for custom apparel businesses, priced around $7,500.

Best For: Small businesses and embroidery professionals who need a fast, reliable, multi-needle machine for high-quality custom apparel.

- Lacks detailed manual instructions, requiring extra time to learn setup.

- No included software package, increasing total startup costs.

- Support mainly via Facebook; dedicated customer service is limited.

- Large 14.2" x 7.9" embroidery area supports diverse project sizes.

- Fast stitching speed of up to 1,200 stitches per minute enhances productivity.

- Sturdy metal build minimizes vibration and noise for quieter operation.

Machine Price Factors

When you’re shopping for commercial embroidery machines, the machine price is just the beginning.

You’ll also need to budget for essential software, accessories, supplies, and ongoing maintenance that can add thousands to your total investment.

Software and Designs

Beyond buying your embroidery machine, you’ll need embroidery digitizing software and embroidery designs to bring projects to life.

Design digitizing converts artwork into embroidery machine formats, and software compatibility matters since each machine requires specific file types.

Font libraries and custom designs add licensing costs, and quality embroidery machine software with extensive embroidery patterns typically runs $200-2,000 depending on features. The cost includes the need for embroidery digitizing software and embroidery designs.

Hoops and Accessories

Accessories transform your embroidery machine into a powerhouse.

Smart investment in the right tools saves time and boosts quality.

Here’s what drives costs:

- Hoop Sizes – Larger hoops handle bigger designs but cost more

- Magnetic Hoops – Premium pricing for faster setup and precision

- Specialty Hoops – Cap frames and tubular hoops add versatility

- Accessory Storage – Organization systems keep supplies accessible

- Thread Management – Stands and guides prevent tangles and breaks

Different machines require different embroidery hoop styles.

Threads and Stabilizers

Your embroidery threads and stabilizers form the foundation of quality work. Different thread types serve specific purposes while stabilizers provide essential backing support.

Material compatibility matters when selecting supplies for cotton versus leather projects. Color matching guarantees professional results across fabric variations.

Knowing the embroidery thread price helps in budgeting for projects. Smart storage solutions keep your embroidery supplies organized and readily accessible for consistent production workflows, ensuring consistent production.

Maintenance and Repairs

Regular embroidery machine maintenance prevents costly breakdowns and extends equipment life. Smart operators follow preventative maintenance schedules to avoid expensive repair costs down the road.

Essential maintenance tasks include:

- Daily cleaning of bobbin areas and thread paths

- Monthly lubrication of moving parts and mechanisms

- Professional inspections every 6-12 months for commercial units

- Immediate troubleshooting when issues arise to prevent damage

DIY repairs work for basic problems, but complex embroidery machine service requires certified technicians. Machine longevity depends on consistent care and quality embroidery machine parts replacements.

Cost-Effective Upgrades

Smart upgrades don’t require breaking the bank. You can maximize your embroidery machine investment through strategic improvements that boost efficiency without major costs.

| Upgrade Type | Cost Range | Impact |

|---|---|---|

| Hoop Alternatives | $50-200 | Faster setup times |

| Software Optimization | $100-500 | Better design efficiency |

| DIY Repairs | $20-100 | Reduced downtime costs |

| Thread Savings | $30-150 | Lower operating expenses |

Focus on upgrades that directly impact your bottom line. Magnetic hoops reduce setup time substantially. Some users prefer hoopless embroidery options.

Updated software handles complex designs better. Learning basic Maintenance Tips saves service calls. These commercial embroidery machine upgrades deliver measurable embroidery machine cost savings without requiring a complete system overhaul.

Choosing Right Machine

Selecting the right commercial embroidery machine requires matching your specific needs with the right features and budget.

You’ll want to assess your production goals, evaluate your financial limits, and plan for future business growth to make the smartest investment, considering your financial limits.

Assessing Embroidery Goals

Before you invest your hard-earned money in an embroidery machine business, you need to know exactly what you’re getting into.

Your embroidery goals will determine your embroidery machine investment and shape your entire commercial embroidery strategy.

Consider these key factors when evaluating your embroidery business machine needs:

- Project Complexity – Simple logos or intricate multi-layered designs

- Production Volume – Daily output requirements and order frequency

- Material Variety – Fabrics you’ll embroider from cotton to leather

- Skill Level – Your current expertise and learning curve expectations

- Design Intricacy – Detail level and stitch count requirements.

Your embroidery machine cost directly correlates with these variables.

High Production Volume demands faster machines with multiple needles.

Complex Material Variety requires robust construction and versatile capabilities.

Understanding these requirements prevents costly mistakes and guarantees your commercial embroidery operation matches your business vision.

Evaluating Budget

Before setting your embroidery machine budget, map out all costs upfront. Financial planning prevents sticker shock later. Consider ROI analysis to justify your investment.

Don’t forget hidden costs like software, hoops, and maintenance. Explore leasing options and funding sources to spread expenses.

| Budget Category | Initial Cost | Ongoing Annual Cost |

|---|---|---|

| Machine Purchase | $5,000-$15,000 | $500-$1,200 |

| Software & Designs | $300-$2,000 | $200-$800 |

| Supplies & Maintenance | $200-$500 | $600-$1,500 |

| Training & Support | $100-$800 | $100-$400 |

Smart embroidery machine affordability means planning beyond the purchase price. Commercial embroidery machine pricing varies widely, so establish clear parameters before shopping. Your embroidery machine cost should align with projected revenue to guarantee profitability.

Considering Future Growth

Planning embroidery machine business expansion requires strategic thinking about scaling production and market diversification.

Your commercial embroidery machine investment should accommodate future growth rather than just current needs.

Consider technology adoption trends when analyzing embroidery machine cost analysis.

Multi-needle machines offer better investment returns through brand diversification opportunities.

Some machines offer handy features like an automatic thread cutter.

Embroidery machine financing options help support gradual expansion without overwhelming cash flow constraints.

Budgeting Embroidery

When planning your embroidery business budget, you’ll need to take into account machine costs based on your specific purpose and production needs.

Industrial embroidery machines vary substantially in price depending on the type and features you choose for your operation.

Embroidery Machine Cost on Purpose

Your purpose determines your embroidery machine cost more than any other factor.

Home hobby machines start around $500, while commercial embroidery operations need $5,000-$15,000 investments. Industrial embroidery machine prices jump to $15,000+ for multi-head systems.

Hidden costs include software, training, and maintenance. ROI justification becomes easier when you match machine capabilities to actual production needs rather than aspirational goals.

For beginners, a budget embroidery machine offers essential features, making it a good starting point for those looking to understand the basics of embroidery machines.

Industrial Embroidery Machine Cost on Type

Different industrial embroidery machine types carry distinct price tags based on their design and capabilities.

Single-Head Cost ranges from $3,000 to $20,000 depending on features.

Multi-Head Pricing starts at $20,000 for basic systems, reaching $50,000 for large-scale operations.

Bridge-Type Cost and Cylinder-Bed Cost vary by manufacturer specifications.

Specialty Machine pricing exceeds $25,000 for unique applications like chenille work.

Buying Embroidery Machines

You have three main options when purchasing commercial embroidery machines: local stores, online platforms, and liquidators. Each option offers different advantages regarding pricing, support, and machine availability.

Local Store

Visiting an embroidery machine showroom provides unmatched Local Expertise and Hands-On Training opportunities.

You’ll experience In-Person Demos that reveal true machine capabilities and receive Immediate Support from knowledgeable staff.

This approach fosters Community Building while helping you understand embroidery machine cost factors.

Key benefits include:

- Test before buying – Compare multiple models side-by-side

- Expert guidance – Receive personalized recommendations from your embroidery machine dealer

- Instant gratification – Walk away with your embroidery machine for sale today

Online Platform

Online marketplaces dominate commercial embroidery machine sales with competitive pricing and extensive selection.

You’ll find embroidery machine prices 15-20% lower than local stores while comparing options across multiple vendors.

Virtual demos and digital support help evaluate machines remotely. Many platforms offer online financing and remote training programs for your embroidery machine online purchase, with competitive pricing and extensive selection being key benefits, and also providing virtual demos.

Liquidators

Liquidation sales offer substantial savings on used embroidery machines, but buyer beware.

Check liquidator reputation and inventory quality before purchasing.

Commercial embroidery equipment at these sales typically retains 40-60% original value.

Hidden costs like transportation can inflate your final embroidery machine cost.

Warranty options are limited, so inspect thoroughly, and use effective negotiation tactics to get the best deal, as these affordable embroidery machine deals reward prepared buyers who understand market values.

Frequently Asked Questions (FAQs)

What warranties come with commercial embroidery machines?

You’ll find warranty terms that’ll blow your mind!

Butterfly machines offer lifetime warranties on non-consumable parts.

Most commercial embroidery machines include warranties and support packages when you purchase them from dealers.

How much do embroidery machine repairs typically cost?

Embroidery machine repairs typically cost $140 for smaller machines and $170 for large machines, with basic servicing ranging $75 to $ You’ll pay more for complex repairs requiring specialized parts or extensive labor.

What financing options are available for machines?

Need flexible payment options for your embroidery equipment investment?

Most dealers offer financing through equipment loans, leasing programs, or manufacturer financing plans with competitive rates and terms customized to your business needs.

Do embroidery machines require special electrical requirements?

Most embroidery machines use standard household power outlets. You’ll need a stable 110-120V connection. Commercial machines may require dedicated circuits to prevent power fluctuations that affect stitching quality.

Whats the typical lifespan of commercial machines?

Well-maintained commercial embroidery machines typically last 15-20 years with proper care. You’ll get maximum lifespan through regular maintenance, quality parts, and professional servicing when needed.

Conclusion

Remember the old saying: "measure twice, cut once" – the same applies when investing in commercial embroidery machine prices.

You’ve learned that smart shopping means matching features to your actual needs rather than buying the most expensive option.

Whether you’re starting with a basic single-needle model or scaling up to multi-head production systems, understanding these price factors helps you make informed decisions.

Take time to evaluate your budget, assess your embroidery goals, and consider future growth before making this significant investment.

- https://dataintelo.com/report/global-commercial-embroidery-machine-market

- https://www.maximizemarketresearch.com/market-report/embroidery-equipment-market/148403/

- https://www.giiresearch.com/report/luci1597218-embroidery-equipment-market-report-trends-forecast.html

- https://datahorizzonresearch.com/computer-embroidery-machine-market-26462

- https://virtuemarketresearch.com/report/embroidery-market