This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ll want a multi-needle machine that can handle your production demands without breaking down mid-order.

You’ll want a multi-needle machine that can handle your production demands without breaking down mid-order.

The best embroidery machine for small business combines speed, reliability, and versatility—think Brother PR1050X for high-volume work or Janome MB-7 for precision projects.

Your choice depends on whether you’re stitching custom hats daily or handling occasional corporate orders.

Single-needle machines work for startups, but multi-needle systems separate weekend hobbyists from serious entrepreneurs.

Consider your workspace, budget, and growth plans—because nothing kills momentum like a machine that can’t keep up with your ambitions.

The right setup transforms your creative vision into profitable reality.

Table Of Contents

Key Takeaways

- You’ll need multi-needle machines for serious business growth – single-needle units work for startups, but multi-needle systems with 4-16 needles eliminate manual thread changes and dramatically increase production speed

- Don’t skimp on your budget planning – factor in $5,000-$20,000+ for quality multi-needle equipment, plus ongoing costs for thread, stabilizers, and maintenance to avoid the 78% failure rate plaguing undercapitalized embroidery businesses

- Focus on machines that handle your target market – if you’re doing corporate uniforms and bulk orders, prioritize speed (1,200+ stitches per minute) and large embroidery areas over compact portability

- You’ll maximize profits by choosing versatile machines with extensive design libraries, USB connectivity for custom patterns, and compatibility with professional digitizing software to handle diverse client requests without outsourcing

What to Look for in an Embroidery Machine

Choosing the right embroidery machine requires careful evaluation of several key features that’ll directly impact your business operations.

You’ll need to examine needle configuration, built-in design libraries, and the machine’s portability to verify it fits your specific workflow and workspace requirements.

The evaluation process involves considering how these features align with your business operations to ensure a smooth and efficient workflow.

Needles, Single or Multiple

Choosing between single-needle and multi-needle systems will shape your production workflow.

Single-needle units cost $300-$1,500 but require manual thread changes for each color, slowing production volume.

Multi-needle machines ($5,000-$20,000+) feature 4-16 needle heads for automatic color switching.

Multi-needle machines slash production time by eliminating manual thread changes between colors.

These machines often include multiple needle advantages, saving time by reducing thread changes.

Consider these needle efficiency factors:

- Thread changes – Single-needle requires stopping for each color switch

- Design complexity – Multi-needle handles intricate patterns without interruption

- Production volume – Higher output demands multi-needle capabilities

- Cost analysis – Balance upfront investment against time savings

- Needle size compatibility – Both systems accommodate various needle sizes for different fabrics

Embroidery Designs Included

Your embroidery machine’s design variety directly impacts your business potential.

Look for machines with extensive built-in design libraries – professional models offer 20,000+ patterns through membership programs.

These builtin designs range from basic motifs to complex decorative elements, giving you immediate production capability without additional software costs.

Built-in fonts matter substantially for monogramming and text work.

Quality machines include multiple font styles and automatic text-to-embroidery conversion.

The Brother PE535 offers 9 fonts, while the Janome MB4S provides 10 monogramming options.

Custom designs require compatible file formats and USB connectivity.

Advanced machines support various embroidery file formats, letting you import client artwork or purchase specialized patterns.

Design editing capabilities allow real-time modifications – resize, recolor, or combine patterns directly on the machine’s touchscreen.

Design storage capacity determines how many patterns you can save locally.

Professional embroidery software often comes bundled with higher-end machines, providing digitization tools and cloud-based pattern libraries.

Considering this, design versatility is a vital factor for expanding product offerings.

This combination of built-in variety and custom design capabilities helps you handle diverse client requests while maintaining efficient workflow.

Portability and Utility

When your small business embroidery machine becomes your mobile office, portability transforms from convenience to competitive advantage.

Compact machines with lightweight design enable mobile embroidery services, letting you bring on-site customization directly to customers’ locations.

For home embroidery business operations in a small workspace, look for machines under 30 pounds with sturdy carrying cases.

Modern portable units don’t sacrifice capability—many offer versatile projects ranging from caps to jackets while maintaining professional stitch quality.

Consider built-in design storage through USB ports or internal memory to eliminate laptop dependency during mobile work.

Smart small business embroidery owners choose machines that travel as hard as they do, turning any location into a profitable workspace for their embroidery machine business.

8 Best Options

You’ve narrowed down your search to these eight machines that balance cost, performance, and reliability for small business operations.

Each option brings unique strengths to help you launch or expand your embroidery business with confidence.

You can now proceed to evaluate these options to find the best fit for your business needs.

1. Janome MB4S Embroidery Machine

Four needles working in perfect harmony – that’s what sets the Janome MB4S apart from single-needle competitors.

This professional-grade machine delivers up to 1,200 stitches per minute while maintaining exceptional quality across various materials like patches, towels, and napkins.

You’ll appreciate the 5.7-inch color LCD touchscreen that makes accessing designs effortless, plus automatic thread cutting that keeps production flowing smoothly.

The multi-needle setup means fewer thread changes and faster turnaround times for your business orders.

However, consider the maintenance requirements carefully.

Regular oiling is essential, and you’ll want to verify local Janome service availability before purchasing.

Some users report reliability concerns after 1-3 years of heavy use, though others praise its consistent performance.

The machine excels at flat embroidery but requires specialized hoops for cap work.

At 25"D x 26"W x 17"H, it fits most workshops while delivering commercial-quality results that’ll impress your customers.

Best For: Apparel shops and small businesses seeking efficient multi-needle embroidery for flat garments and accessories.

- Requires regular maintenance and may be difficult to repair if local technicians are unavailable

- Mixed reliability, with some units developing issues after 1–3 years of heavy use

- Cannot embroider caps without additional specialized hoops

- Fast, professional-quality results with up to 1,200 stitches per minute and multi-needle operation

- Intuitive 5.7-inch color touchscreen with automatic thread cutting and easy design management

- Handles a wide range of materials and customizable designs for versatile business use

2. EverSewn Sparrow Sewing Embroidery Machine

Innovation meets practicality with the EverSewn Sparrow, a dual-purpose machine that bridges the gap between hobby and professional embroidery work.

You’ll appreciate its generous 4.75×7-inch embroidery area, which accommodates medium-sized designs that smaller machines can’t handle.

The 850 RPM stitching speed delivers efficiency without sacrificing precision, making it suitable for small business operations.

The machine includes over 100 built-in embroidery designs and accepts most standard file formats through its USB port.

You can expand your design library easily by importing patterns from various sources.

The automatic thread cutter eliminates manual trimming, while adjustable speed control lets you match the pace to your fabric type and design complexity.

Smart device connectivity through the EverSewn Pro app adds modern convenience, allowing you to monitor progress remotely and customize designs wirelessly.

The included straight stitch plate and multiple hoop sizes provide versatility for different project requirements.

However, some users report connectivity issues and tension adjustments that reset after power cycles, requiring manual recalibration for consistent results.

Best For: Home sewists and small business owners who want a versatile, tech-enabled sewing and embroidery machine for medium-sized projects.

- App connectivity issues and unreliable wireless integration

- Tension settings reset after each power cycle and require manual adjustment

- No dedicated tech support and frequent error codes with limited troubleshooting guidance

- Large 4.75×7-inch embroidery area and supports most design file formats

- Fast stitching speed up to 850 RPM with over 100 built-in designs and smart app control

- Includes multiple hoop sizes, automatic thread cutter, and adjustable speed for versatility

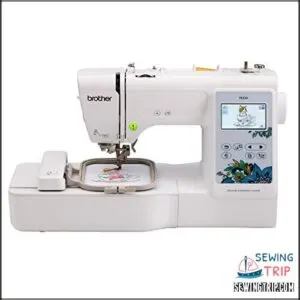

3. Brother PE535 Embroidery Machine

When you’re running tight deadlines, the Brother PE535 delivers professional results without breaking your budget.

This dedicated embroidery machine features a spacious 3.2" LCD touchscreen that lets you preview designs before stitching, plus a USB port for importing custom patterns.

With 80 built-in designs and 9 fonts at your fingertips, you’ll handle everything from basic monograms to intricate holiday motifs.

The 4" x 4" embroidery field suits most small business projects perfectly, while the intuitive interface keeps you productive even on your busiest days, ensuring you achieve high-quality outcomes with custom patterns.

Best For: Home crafters and small business owners who want affordable, high-quality machine embroidery for personal and custom projects.

- User-friendly touchscreen and intuitive controls make it ideal for beginners.

- USB port enables unlimited design possibilities with easy importing of new patterns.

- Produces clean, professional embroidery with strong resale value and free technical support.

- Limited to a 4" x 4" embroidery area, restricting larger projects.

- Does not function as a traditional sewing machine.

- Additional software for creating custom designs is expensive and not included.

4. CAMFive Embroidery Machine

Delivering professional embroidery results requires precision that CAMFive’s double-head machine provides.

You’ll appreciate the expansive 19.6" x 16.5" working area that accommodates large designs, while the 1200 spm speed keeps production moving efficiently.

The 8" HD touchscreen simplifies operation with instant design editing and preview capabilities.

With 15 needles and Japanese rotary hooks, you can execute complex multicolor patterns on various materials from t-shirts to leather goods.

The included Wilcom digitizing software, Madeira thread starter kit, and two-day training guarantee you’re ready for continuous 24-hour operation.

Best For: Small businesses and production studios seeking efficient, high-quality embroidery on diverse materials for custom and bulk orders.

- Large 19.6" x 16.5" working area and high 1200 spm speed for efficient large-scale production.

- User-friendly 8" HD touchscreen with instant design editing and preview features.

- Includes Wilcom digitizing software, Madeira thread kit, and comprehensive two-day on-site training.

- Semi-compact size may still require significant workspace.

- Professional-grade features may be overwhelming for absolute beginners.

- Continuous operation may require regular maintenance to ensure durability.

5. Singer Legacy SE300 Embroidery Machine

With both sewing and embroidery capabilities, the Singer Legacy SE300 delivers versatility for small businesses seeking dual functionality.

You’ll access 250 built-in stitches and 200 embroidery designs with six font options, while the LCD touchscreen simplifies pattern selection and customization.

The machine includes two embroidery hoops and automatic features like needle threading and tension adjustment.

However, users report motor overload issues and the black-and-white screen makes color identification challenging during embroidery projects.

Best For: Small business owners and home crafters needing a machine that handles both sewing and embroidery with a range of built-in patterns.

- 250 built-in stitches and 200 embroidery designs, plus 6 fonts for personalization

- LCD touchscreen for easy pattern selection and customization

- Automatic needle threader and tension adjustment simplify setup and use

- Motor overload issues and frequent needle breakage reported by users

- Black-and-white screen makes it hard to identify colors during embroidery

- Large, bulky design may be inconvenient for small workspaces

6. Juki HZL F600 Sewing Quilting Machine

With 255 built-in stitches and industrial-grade aluminum construction, the Juki HZL F600 transforms your small business embroidery projects into professional-quality work.

You’ll appreciate the maximum 900 stitches per minute speed that keeps production moving without sacrificing precision.

The box feed technology guarantees consistent stitch quality across different fabric weights, from delicate silk to heavy denim.

The LCD screen simplifies pattern selection while the automatic needle threader saves time during busy production runs.

You can handle larger projects thanks to the generous work area and wider underarm space.

The top-loading bobbin system makes thread changes quick and efficient.

At $2,099, this machine bridges the gap between home and commercial equipment.

The extensive accessory package includes quilting feet and specialized attachments.

While it’s primarily a sewing machine, the robust construction and professional features make it suitable for embroidery businesses requiring reliable, high-volume production capabilities.

Best For: Small business owners and advanced sewists who need industrial-level performance and versatility for sewing, quilting, and light embroidery projects.

- High price point may be out of reach for hobbyists or occasional users.

- Some users report issues with durability, timing, and the automatic needle threader.

- Instruction manual can be difficult to follow, especially for beginners.

- Fast 900 stitches per minute and box feed technology deliver exceptional stitch quality on all fabrics.

- Wide work area with comprehensive quilting accessories supports large, complex projects.

- Durable industrial-grade construction and feature set rival commercial machines at a home-friendly price.

7. Bohin Super Automatic Needle Threader

Whether you’re tackling delicate applique work or heavy-duty embroidery projects, the Bohin Super Automatic Needle Threader eliminates threading frustrations with remarkable precision.

This compact French-made tool measures 3 x 2 x 1.25 inches and handles needles from size 1 to 11 effortlessly, with a 99% success rate on first attempts.

You’ll appreciate its magnetic needle picker for organization, and built-in thread cutter for workflow efficiency, making it invaluable for users with vision challenges or arthritis.

The single-button operation pushes thread completely through the needle eye, making it a game-changing addition to any embroidery toolkit.

Best For: Anyone who struggles with threading needles due to poor eyesight, arthritis, or frequent sewing and quilting projects.

- 99% first-attempt success rate for threading needle sizes 1 to 11

- Magnetic needle picker and built-in thread cutter for added convenience

- Saves time and reduces frustration, especially for users with vision or dexterity issues

- Not as effective for needles with round or elongated eyes

- Some users may need multiple attempts and practice for certain needle types

- Does not include detailed instructions, which may increase learning curve

8. Simplicity Bobbin Winder Machine

While many embroidery machines require you to wind bobbins manually, the Simplicity Bobbin Winder Machine handles this tedious task automatically.

This compact device operates on 120V power or AA batteries, making it perfect for your workspace or travel needs.

You’ll appreciate its automatic shut-off feature that prevents overwinding, though you might need to manually adjust for completely full bobbins.

The machine works with most standard bobbins but won’t accommodate Singer Centaur II, Husqvarna Viking, or certain Brother models.

Its portable design means you can wind bobbins anywhere, saving your embroidery machine’s motor for actual stitching work.

Best For: Crafters and sewing enthusiasts who want a portable, time-saving solution for winding bobbins without relying on their sewing machine.

- Fast, even thread transfer with automatic shut-off to prevent overwinding

- Compact and portable with both AC and battery power options

- Reduces wear on sewing machine motors and saves time for larger projects

- Not compatible with all bobbin types, including Singer Centaur II, Husqvarna Viking, and some Brother machines

- Some users report uneven winding and difficult bobbin removal

- Build quality and price may not meet everyone’s expectations

Factors to Consider When Buying an Embroidery Machine

You’ll need to evaluate several key factors before investing in an embroidery machine for your small business.

Your decision should align with your specific business goals, budget constraints, and production requirements to guarantee long-term success.

Market Research

Savvy entrepreneurs know that market research forms the backbone of successful embroidery ventures. The embroidery industry profitable margins of 60% or higher make thorough market research essential before investing in equipment.

Understanding your target market and market demands helps you select machines that align with actual customer needs rather than wishful thinking.

Effective market research involves multiple strategic components:

- Target Audience: Identify specific demographics, businesses, and organizations requiring embroidery services

- Competitor Analysis: Study local competitors’ pricing strategies, service offerings, and market positioning

- Trend Identification: Monitor current market trends in customization, design preferences, and emerging opportunities

Smart niche selection emerges from understanding market trends and gaps in your area. Research reveals whether your market demands high-volume commercial work or specialized custom pieces.

This intelligence directly influences your pricing strategy and machine selection. Thorough competitor analysis shows you what’s working locally and identifies underserved segments.

The growing market for personalized products creates opportunities, but only market research reveals which segments offer the best returns on your investment. When considering used equipment, remember to check stitch count to gauge its usage.

Business Plan

Success creates opportunities, but a solid embroidery business plan transforms those opportunities into sustainable profits.

Your business plan serves as your roadmap, outlining how you’ll navigate the competitive landscape and achieve profitability.

The Executive Summary captures your vision, while Market Analysis identifies your target market and competitors.

Financial Projections forecast revenue streams and break-even points, typically showing 30-60% profit margins in embroidery businesses.

Your Operational Plan details daily workflows, and the Management Team section establishes credibility with potential investors or lenders.

| Business Plan Component | Key Focus Area |

|---|---|

| Executive Summary | Vision and profit goals |

| Market Analysis | Target market identification |

| Financial Projections | Revenue and cost forecasting |

| Operational Plan | Daily workflow optimization |

| Management Team | Leadership and expertise |

Market research within your business plan validates demand and pricing strategies, ensuring your embroidery business profit projections align with reality.

This alignment is crucial for the long-term success of your embroidery business, as it helps in making informed decisions about investments and expansions.

Equipment

Your commercial embroidery machine represents the backbone of your small business embroidery operation.

Quality equipment determines your production capacity and finished product standards. When selecting machinery, you’ll need to balance initial embroidery machine cost against long-term profitability potential.

Consider these critical equipment specifications:

- Multi-needle systems boost efficiency for high-volume embroidery business startup projects

- Large hoop size capacity accommodates diverse design requirements from logos to full-back graphics

- High SPM rate capabilities increase throughput while maintaining stitch precision

- Advanced needle system options handle various fabric types and thread weights effectively

- Built-in machine maintenance alerts prevent costly downtime and extend equipment lifespan

Thread quality directly impacts your machine’s performance and your reputation. Invest in commercial-grade thread that won’t break mid-design, causing production delays. Your embroidery machine business success depends on consistent output quality.

Supplies

Beyond equipment selection, your supply choices directly impact production quality and efficiency.

Thread Quality determines stitch durability and appearance, while Needles must match fabric weight and thread type.

Stabilizers prevent fabric puckering during embroidery, and proper Hoops Selection guarantees consistent tension.

Stock various thread weights, universal needles, tear-away stabilizers, and multiple hoop sizes.

| Supply Category | Essential Items | Professional Upgrade |

|---|---|---|

| Thread | Polyester 40wt, Basic colors | Rayon thread, 200+ colors |

| Stabilizers | Tear-away, Cut-away | Water-soluble, Heat-away |

| Hardware | Universal needles, Standard hoops | Specialty needles, Magnetic hoops |

Keep your Bobbin Winder maintained and stock pre-wound bobbins for uninterrupted production.

Marketing

Effective marketing transforms your embroidery business from a hidden gem into a thriving enterprise.

You’ll need strategic approaches that connect with customers while building sustainable profit margins.

Market research helps identify your target market and understand their specific needs, whether they’re local sports teams or corporate clients seeking branded merchandise.

Your marketing channels should include multiple touchpoints:

- Social Media – Showcase finished products on Instagram and Facebook to attract visual-oriented customers

- Local Partnerships – Connect with sports teams, schools, and businesses needing custom work

- Online Marketplace – List services on Etsy or specialized embroidery platforms for broader reach

- Customer Retention – Implement loyalty programs and follow-up communications for repeat business

Brand Building requires consistent messaging across all platforms.

Focus on your unique value proposition and quality craftsmanship.

Remember, embroidery business marketing isn’t just about selling machines—it’s about positioning yourself as the go-to expert for custom embroidery solutions that deliver measurable embroidery business profit.

Financial Mistakes When Starting an Embroidery Business

Starting an embroidery business without proper financial planning can quickly drain your startup capital and derail your entrepreneurial dreams.

You’ll need to avoid common money mistakes that plague new embroidery entrepreneurs, from inadequate budgeting to poor pricing strategies that can sink your business before it gains traction, including issues like inadequate budgeting.

Not Having a Budget

Starting an embroidery business without Financial Planning creates Costly Mistakes that drain resources quickly.

Overspending Risks emerge when you don’t track commercial embroidery machine costs, thread expenses, and operational overhead.

Smart Investment Strategy requires understanding embroidery machine price ranges and projected embroidery business profit margins.

| Budget Category | Monthly Cost | Annual Investment |

|---|---|---|

| Equipment/Maintenance | $200-500 | $2,400-6,000 |

| Materials/Thread | $150-300 | $1,800-3,600 |

| Marketing/Operations | $100-250 | $1,200-3,000 |

| Emergency Fund | $200-400 | $2,400-4,800 |

Budgeting Importance becomes clear when considering high revenue earnings potential—many businesses achieve 60% profit margins with proper investment planning and cost control.

Not Diversifying

Many small business embroidery owners focus solely on one service type, creating market saturation risks and limited revenue streams.

Don’t put all your eggs in one basket—diversifying your embroidery business protects against competitive disadvantage and missed opportunities.

Offer custom patches, promotional items, and specialty garments alongside standard logo work.

This approach prevents stagnant growth while maximizing your commercial embroidery machine investment across multiple profitable niches.

Not Tracking Expenses

Your embroidery business’s financial foundation crumbles without proper expense tracking. You can’t make informed decisions when you’re flying blind through costs, material purchases, and equipment investments.

Expense Tracking Importance becomes crystal clear when you realize that small business embroidery operations typically maintain 60% profit margins, but only with accurate cost control.

Software Solutions like QuickBooks or FreshBooks help track every thread spool, stabilizer roll, and embroidery machine maintenance cost. These tools provide real-time Budgeting Impact analysis, showing exactly where your money flows.

Without this visibility, you’ll struggle with Profitability Analysis and Financial Forecasting for future growth. Smart embroidery business owners track machine hours, thread consumption per project, and customer acquisition costs.

This data drives pricing decisions and reveals which services generate the highest returns. When you know your true costs, you can price competitively while protecting your margins in this profitable industry.

Not Marketing

Marketing remains your business’s heartbeat, yet many entrepreneurs overlook this vital element when launching their embroidery ventures.

Without strategic outreach, even the finest commercial embroidery machine sits idle while potential customers remain unaware of your services.

You’re basically running a secret business that nobody knows exists.

Consider marketing as essential as your embroidery machine brands selection:

- Develop consistent social media presence showcasing your work and customer service excellence

- Network with local businesses requiring uniforms, promotional items, and custom apparel

- Create partnerships with event planners, sports teams, and corporate clients needing bulk orders

- Establish referral programs that leverage satisfied customers to generate new business opportunities

Small business success depends on visibility and reputation building through targeted marketing efforts, which is crucial for the growth and survival of your embroidery venture.

Not Pricing Correctly

Poor pricing strategies can devastate your embroidery business profits before you even realize what’s happening.

Cost calculation forms the foundation of sustainable pricing – factor in materials, labor, overhead, and desired profit margins.

Don’t fall into the trap of competing solely on price; instead, focus on value perception by highlighting your quality craftsmanship and service.

Competitive pricing research helps you understand market rates, but remember that pricing strategies should reflect your unique positioning.

Smart investment in quality equipment justifies premium pricing, while understanding your target market’s willingness to pay guarantees profitability in your small business venture.

Not Having a Website

A website isn’t just nice to have—it’s essential for your embroidery business survival. Without online visibility, you’re basically invisible to customers who search for embroidery services online.

Your small business loses credibility when potential clients can’t find professional information about your commercial embroidery capabilities. Missing out on digital marketing means stunted growth for your home embroidery business.

Consider these critical impacts:

- Missed customers: Most people research embroidery services online before making purchase decisions

- Limited marketing: Social media and search engines can’t drive traffic without a website foundation

- Brand credibility: Professional websites establish trust and showcase your embroidery machine capabilities

Your embroidery business competes against companies with strong online presence. When customers search for local embroidery services, businesses without websites become invisible.

A simple website displaying your work, pricing, and contact information transforms your operation from hobby-level to professional commercial embroidery service. Digital presence directly impacts revenue—don’t let competitors capture customers you could serve.

Not Setting Goals

Building a website is just the start—you also need clear direction. Without concrete business goals, your embroidery business becomes a ship without a compass. Define Success means establishing specific revenue targets, profit margin expectations, and customer acquisition numbers rather than vague hopes of "doing well."

Goal Setting requires measurable benchmarks. Set monthly revenue goals, track your profit margin percentage, and establish customer retention rates. Business Vision involves planning where you want your small business in one, three, and five years.

Strategic Planning breaks these long-term objectives into actionable quarterly milestones. Measuring Progress keeps you accountable. Review your embroidery business performance monthly, comparing actual revenue against projections.

Track which services generate the highest profits and adjust your offerings accordingly. Without these concrete business goals, you’ll struggle to make informed decisions about equipment purchases, pricing strategies, or market expansion. Smart goal-setting transforms wishful thinking into profitable reality.

How to Make Money With Embroidery Workshop

Once you’ve set up your embroidery workshop, you’ll need to focus on three key areas to turn your investment into steady income.

Streamlining your workflow, maximizing profit margins, and finding reliable customers will determine whether your embroidery business thrives or struggles to break even, which involves streamlining your operations to ensure efficiency.

Streamline Workflow

Smart workflow management transforms your embroidery machine into a profit powerhouse.

Implement Design Digitizing software to convert artwork quickly, while Automation Software handles repetitive tasks automatically.

Master Efficient Hooping techniques and organize Thread Management systems for seamless shifts.

Use Optimized Layouts to maximize fabric usage, reducing waste and boosting production efficiency in your small business operations.

Increase Profits

Your embroidery business profit potential depends on smart pricing strategies and niche targeting.

Meeting customization demand through efficient operations positions you ahead of market trends.

Here’s how to maximize your small business profit margin:

- Strategic Pricing – Price embroidery services at 60-70% markup to guarantee healthy revenue while remaining competitive in your local market.

- Niche Focus – Target specific industries like restaurants, medical offices, or sports teams where your embroidery business can become the go-to provider.

- Operational Efficiency – Streamline production workflows and batch similar orders together to reduce setup time and increase profitable output per hour.

Find Customers

Finding your target audience requires strategic planning beyond basic machine operation.

Social media platforms generate 67% of new customer acquisition for embroidery businesses, making online presence essential.

Build local partnerships with schools, sports teams, and corporations needing uniforms. Personalized offerings through custom designs strengthen customer loyalty while retaining existing clients.

Focus on niche markets where your small business can excel, creating lasting relationships through exceptional service and quality work. The embroidery market is projected to grow substantially by 2028.

Tools and Crafting Techniques Needed

Beyond your embroidery machine, you’ll need essential tools and supplies to deliver professional results.

The right combination of sharp scissors, quality thread, stabilizers, and proper hooping techniques makes the difference between amateur and commercial-grade embroidery work.

Sharp Scissors

Quality scissors serve as your precision instruments for clean cuts around embroidered designs.

When running an embroidery business, invest in appliqué scissors with curved blades for detailed cutting around fabric edges.

Thread snips provide quick, accurate trimming without disturbing your embroidery machine’s workspace.

Ergonomic scissors reduce hand fatigue during long commercial embroidery sessions, protecting your profit margin by maintaining consistent productivity.

Consider specialized embroidery scissor options for more intricate work.

Proper scissor maintenance keeps blades sharp, ensuring clean cuts that won’t fray threads or damage delicate fabrics in your small business operations, which is crucial for clean cuts and maintaining delicate fabrics.

Stitching Thread

Professional machine embroidery thread serves as the foundation for exceptional results in your business operations. Thread quality directly impacts production efficiency and final product appearance.

Superior threads reduce thread breakage incidents that halt production and create costly delays. Material composition affects how threads perform under machine tension control systems.

Thread weight typically ranges from 40 to 50 weight for ideal balance between durability and compatibility with most embroidery machines. Heavier weights provide thread durability for items requiring frequent washing, while lighter weights offer finer detail work.

Polyester threads deliver consistent performance across various fabric types, maintaining color integrity through multiple wash cycles. To explore options, consider a reliable thread supplier.

Color variety enables creative flexibility for custom orders and branding projects. Professional thread lines offer hundreds of shade options, allowing you to match corporate colors precisely.

Quality machine embroidery thread prevents frustrating production interruptions that damage client relationships and reduce profitability. Investing in premium thread pays dividends through reduced maintenance costs and superior finished products.

Sturdy Cloth

Your choice of base fabric sets the foundation for professional-quality results with your embroidery machine.

Canvas, denim, and heavy cotton provide excellent fabric durability that withstands repeated washing and wearing, making them perfect for commercial embroidery projects like corporate uniforms and promotional items.

When working with sturdy materials, you’ll need to adjust thread tension settings on your heavyduty embroidery machine.

Dense fabrics require lower tension to prevent thread breaks, while your needle choice becomes critical—size 90/14 needles handle thick materials without creating unsightly holes.

Consider stabilizer use carefully with robust fabrics.

Cut-away stabilizers work best under heavy materials, providing lasting support that prevents puckering.

Stitch density also matters—reduce density on thick fabrics to avoid thread buildup that creates stiff, uncomfortable garments.

For small business owners focusing on embroidery machine for shirts, cotton blends offer the sweet spot between durability and workability.

They’re forgiving for beginners yet professional enough for client work, maintaining their appearance through countless washes while showcasing your embroidery skills beautifully.

Design Object

Your design object serves as the foundation for successful embroidery projects.

Design complexity determines thread choice and stitch density requirements for your embroidery machine designs.

Simple geometric patterns work well for beginners, while intricate florals demand advanced design editing software skills.

Object material influences color palette decisions – darker fabrics showcase lighter threads beautifully.

Consider design creation workflows when selecting patterns.

Complex designs require careful embroidery digitizing to maintain quality.

USB design transfer capabilities let you import custom artwork easily, expanding creative possibilities beyond built-in options.

Accurate pattern making relies on essential pattern tools.

Machine Inputs

Before starting your embroidery machine, you’ll configure essential machine inputs that determine your project’s success.

Thread Quality affects stitch consistency, while Fabric Stabilizers prevent puckering during stitching.

Hoop Selection must match your design size and fabric weight.

Different Needle Types work better with specific materials and thread weights.

Design Software lets you import, edit, and customize embroidery machine designs before transferring them to your machine.

Modern embroidery machine software simplifies this process through USB connections or wireless transfers.

Small business owners should invest in quality embroidery machine supplies to guarantee professional results and minimize production delays, using the best Design Software.

Fabric in Hoop

Proper hoop preparation determines whether your embroidery machine delivers professional results or disappointing mishaps. Getting fabric positioning right prevents costly mistakes and wasted materials in your small business operations.

Key Hoop Setup Considerations:

- Hoop Size – Match your embroidery designs to appropriate hoop dimensions for ideal coverage

- Fabric Stabilizers – Use backing materials to prevent puckering and maintain design integrity

- Tension Control – Adjust fabric tautness based on material weight and weave structure

- Fabric Choice – Select appropriate materials that work well with your embroidery machine’s capabilities

- Hoop Burn – Avoid over-tightening that damages delicate fabrics or leaves permanent marks

Different materials require specific handling techniques. Stretch fabrics need gentle tension, while woven materials can handle firmer securing. Position your fabric evenly within the hoop boundaries, ensuring no wrinkles or loose areas that could shift during stitching.

Experienced embroiderers develop muscle memory for proper hoop preparation, reducing setup time and improving consistency. Your embroidery business success depends on mastering these fundamentals before tackling complex commercial projects.

Frequently Asked Questions (FAQs)

What type of materials are best for embroidery?

Cotton, linen, and denim work best for embroidery. They’re stable, hold stitches well, and won’t stretch. Avoid stretchy fabrics like jersey—they’ll distort your designs and cause thread breaks.

How long will an embroidery machine last?

Like a trusted workhorse that serves faithfully for decades, quality embroidery machines typically last 10-15 years with proper maintenance.

You’ll maximize longevity through regular cleaning, oiling, and professional servicing when needed.

What software is compatible with an embroidery machine?

Most embroidery machines work with proprietary software from their manufacturers, like Brother’s PE-Design or Janome’s Digitizer MBX.

You’ll also find compatible third-party options including Wilcom, Embird, and Hatch Embroidery for expanded design capabilities.

Are there any special maintenance requirements for embroidery machines?

You’ll need regular oiling, lint removal, and tension adjustments to keep your machine running smoothly. Clean the bobbin area weekly and replace needles after every project for peak performance.

What is the best way to learn embroidery?

Practice makes perfect when mastering any craft.

Start with simple beginner kits containing pre-drawn patterns, basic threads, and hoops.

The best way to learn is by doing, so practice fundamental stitches consistently.

What maintenance schedule prevents embroidery machine breakdowns?

Clean your machine weekly, oil monthly, and replace needles every 8-12 hours of use. Check tension settings regularly and keep the workspace dust-free to prevent costly breakdowns.

How much thread inventory should businesses maintain?

Popular wisdom claims you’ll never run out if you stock two weeks’ worth, but that’s dangerously low.

You should maintain 3-4 weeks of thread inventory based on your average monthly usage, plus safety stock for popular colors and rush orders.

Which stabilizers work best for different fabrics?

Cutaway stabilizers work best for lightweight woven fabrics, while tearaway stabilizers suit heavier fabrics.

You’ll want washaway stabilizers for delicate materials like silk, and topping prevents stitches from sinking into textured fabrics.

What software creates custom embroidery designs effectively?

Sarah’s boutique hired a designer who couldn’t deliver digitized files that matched her vision.

Wilcom’s EmbroideryStudio and Hatch lead the market, while Ink/Stitch offers free, open-source digitizing.

You’ll create precise designs with professional software.

How long do commercial embroidery machines last?

You’ll get 15-20 years from well-maintained commercial embroidery machines. Regular maintenance, quality thread, and proper usage extend their lifespan substantially, making them solid long-term investments for your business.

Conclusion

Statistics show that 78% of embroidery businesses fail within their first year due to equipment limitations.

Choosing the best embroidery machine for small business isn’t just about features—it’s about matching your equipment to your growth trajectory.

You’ll need reliability for consistent orders, speed for profitability, and versatility for diverse projects.

Whether you’re starting with single-needle simplicity or scaling with multi-needle efficiency, your machine becomes your business partner.

Research thoroughly, budget realistically, and invest in quality that supports your entrepreneurial vision.

- https://sewinginsight.com/best/best-embroidery-machine-for-small-business/

- https://thekeyfact.com/8-best-embroidery-machines-for-small-businesses/

- https://maghubworld.com/top-embroidery-machines-for-small-businesses-2025/

- https://embroiderymachineworld.com/best-embroidery-machines-for-small-business/

- https://sewingcrafter.com/embroidery-home-business/